Nuances of work

Electric heat generators have high efficiency, which means they are suitable for large areas. The most economical of all are electrode boilers.

All electric boilers are equipped with a regulation system for temperature control and a stabilizer that protects against voltage surges - the devices are almost always sensitive to them. By the way, the main problem of calculating an electric boiler is most often the load on the network, which, as a rule, is more than the norm.

Components

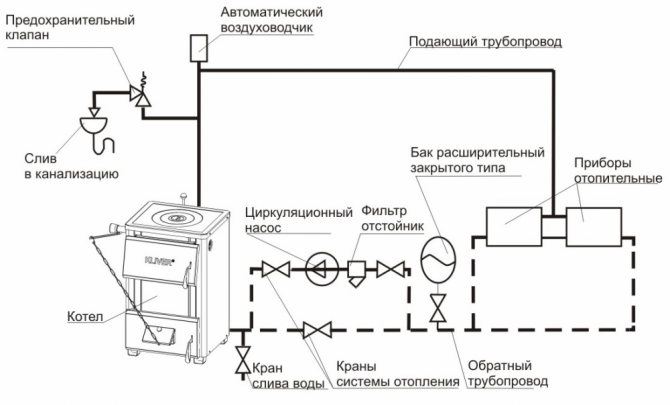

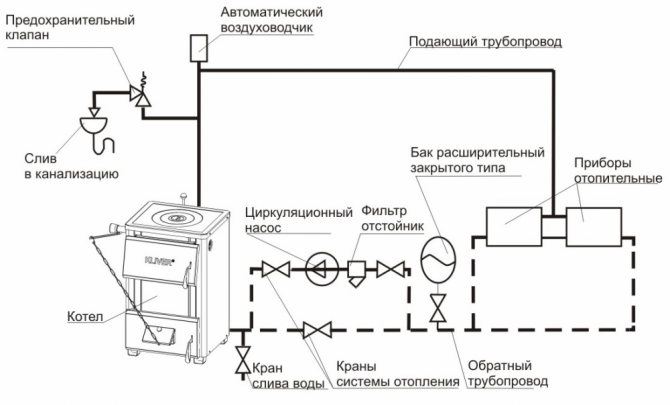

Correct connection of the electric boiler to the heating system ensures further trouble-free operation and efficiency. The electric boiler installation system consists of the following components:

- apparatus;

- temperature sensors;

- radiators;

- drain and shut-off valves;

- expansion tank;

- circulation pump and filter.

Site selection and rules

Installation of an electric boiler is possible only on a wall trimmed with non-combustible material and is better in a non-residential area, although a kitchen is also a good fit. It is also necessary to provide for the possibility of water leakage: if such a place is near the boiler, then this creates a risk of short circuit and fire.

Know for safety

According to the established standards, there must be a distance of at least 5 cm from the electric boiler to the walls, the free space in front of it is 70 cm, at the top - at least 80 cm, at the bottom - at least 50 cm.

If the boiler consumes no more than 3.5 kW, then it can be connected to a regular electrical outlet. Boilers with a capacity of 3.5-7 kW are connected directly to the panel with a dedicated cable. They can be powered from 220 V.

A separate cable is not a whim of the manufacturer: the safety instructions limit the maximum current at the outlet to 16 A. But boilers with an electric power of 7 kW or more are powered only from 380 V.

What is an electric boiler

An electric boiler is a special high-tech equipment designed for heating various kinds of premises. A distinctive feature of such a unit is the use of a special type of fuel - electrical energy. In many respects, the boiler is superior to equipment operating on other types of fuel: liquid, solid, gas.

Electrical equipment is considered the safest to use. But in order for it to function well, it is necessary to strictly observe the rules of its operation and provide timely technological maintenance.

Watch a video describing the principle of operation and the device of the Protherm Skat electric boiler.

Device

Despite the large variety of boilers with different operating principles, the device of all models is approximately the same. The main place in the structure is given to the heating element. Depending on the type of heater used and the principle of its operation, there are several types of boilers.

All heating elements are located in heat exchangers, which are considered the main structural elements of the boiler. In case of their malfunction, heating of the coolant is impossible.

Depending on the design and manufacturer, the equipment may have a different configuration.

List of elements:

- Electronic control unit. Regulates the temperature, turning the equipment on and off at the right time.

- Circulation pump (heat pump). It is an indispensable component of the system, maintains a stable speed of movement of the coolant in the circuit.Produces forced circulation of liquid and creates the necessary pressure in the system, while ensuring the most efficient heat exchange and warming up the room.

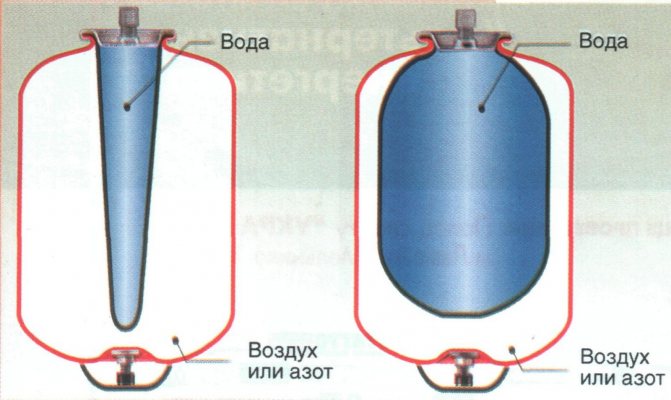

- Expansion tank. Not all types of electric boilers with a pump are equipped with an expansion vessel. Therefore, if equipment is purchased without a tank, it will be necessary to purchase this part separately and install it by cutting it into the heating pipe circuit.

- Filters. Various impurities are purified and removed from water.

- Safety valves. Protect the system from unwanted operational deviations.

- Safety valve. Connected to the return pipe. Performs emergency water discharge when the pressure rises above the set rate.

- Pressure gauge. This device determines the pressure of liquids, gases inside the boiler and pipes of heating systems, it is necessary for monitoring.

- Thermal switch ... It turns off the equipment when it overheats. Connected to the thermal sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank and produces an emergency air release from the tank in case of overpressure.

Types of electric boilers

All electric boilers are divided into three types depending on the principle of operation of the heater.

Electric heating elements

The principle of operation is based on simple electrical heating of elements that give up their heat to the liquid. Heating element - heating element. Water or other permitted liquids are used as a heat carrier, in accordance with the instruction manual.

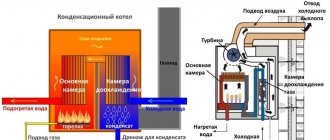

Induction

Their action is based on the principle of electromagnetic induction. The heating element is a coil, inside of which there is a pipeline filled with water. When an electric current passes through the coil under the influence of an electromagnetic field, the coolant is heated.

Ionic

The working element in such structures are electrodes placed in a special aqueous medium, where the process of heating the coolant occurs when an alternating current passes through it.

A feature of the use of this type of boilers is the mandatory control of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomena of electrolysis and breakdown must not be allowed. Failure to do so could result in equipment damage.

The liquid used must not be used for domestic purposes. The heat carrier that circulates through the pipes and enters the working tank of the boiler is in direct contact with the electric current. It is not recommended to carry out repair and commissioning work without the involvement of an experienced foreman.

Useful features and disadvantages

It is also worth considering installing a universal solid fuel boiler with built-in electric heating elements. Some models even have a hob, which does not require additional external finishing.

Electric boilers can easily tolerate power outages for up to 6 months. This makes them a good option in case of irregular use of the system or in case of interruptions in the supply of electricity needed to heat a private house.

The disadvantage of using an electric boiler is the need for powerful supply cables with a large cross section.

Power of electric heating boilers

A relative advantage of an electric heating boiler is a wide power range of various boilers and a stepwise power regulator for each boiler separately.

There are two power ranges for electric boilers.

- Range from 4 to 18 kilowatts;

- From 22 to 60 kilowatts.

The indicated boiler ranges assumes:

- For boilers 4-8 kW, two switching stages;

- Boilers 8-18 kW three switching stages;

- For boilers 22-60 kW, there are four or three switching stages.

Stepwise switching of power allows you to quickly integrate power with the temperature "overboard", this saves electricity consumption and reduces the cost of heating. Also, we forget that an electric boiler does not require operating costs (purchase and delivery of fuel, preparation of a special room) and practically does not require maintenance costs. The form of use is very simple: connect it correctly and use it.

Installation procedures

To suspend the device, you need a mounting plate, which is included in the delivery set: it is fixed to the wall with four dowels or anchor bolts with obligatory horizontal and vertical alignment. If this is a floor-standing boiler, then it is installed on a special support.

The device must be grounded, inspected and make sure that it is in the correct position, the water pressure in the system is normal, and all communications are connected.

Electric heating units must be connected with a wire, the cross-section of which is specified in the equipment documentation. The wires are run in special protective boxes.

Scheme options

There are various schemes: a diagram for connecting an electric boiler with heating radiators, schemes with the possibility of installing a cascade. The latter option is used if it is necessary to heat large areas. For the operation of devices in a cascade, the terminals of the control unit are connected to the terminals of the controlled one. If the plant system is controlled by a room regulator, then its control contacts are connected to the terminals of the master equipment.

Heating device piping

Strapping can be carried out in a straight and mixing pattern. The direct scheme assumes temperature control with a burner, mixing - with a mixer with a servo drive. The strapping is carried out as follows. A boiler collector is installed, a pipe of the required diameter is connected to the boiler.

A three-way mixing valve is installed at the inlet, which will regulate the temperature. A circulation pump is installed on the return line and a control unit is mounted. After piping, you can fill the system with a coolant and test the operation of the equipment for correctness.

Do not underestimate this stage: in reality, it is not as simple and insignificant as it might seem. Normal strapping allows the equipment to be used without an automation system, and this greatly reduces costs. Therefore, it must be performed at a professional level and taking into account the design features of the system and the boiler.

The piping of the electric boiler must be done by a specialist. If you still have to do it yourself, then you need already assembled distribution units. General scheme for the implementation of the heating system in the house.

Connection features

Installation of an electric boiler does not entail complicated work, however, it is worth considering the installation recommendations. If you perform the correct piping of the boiler, then it can be placed anywhere in the house and at the same time it will work effectively.

Electric boilers are suitable for use in different circulation systems. The equipment and the supply pipeline must be located at the lowest point of the heating system, which contributes to better heating of the radiators.

The boiler also needs to be grounded. The use of a zero phase is excluded, since the automation detects this as a short circuit.

In addition to the correct installation of the boiler and the selection of high-quality components, its professional arrangement is necessary. If the strapping is made according to the rules, then it will provide a minimum temperature difference between supply and return.