The issue of gas saving is especially acute during the heating season. Two factors are pushing towards its solution: the rise in the price of blue fuel and the sharp deterioration of the ecological situation in the global sense. Both owners of private houses and residents of urban high-rise buildings want to reduce costs. There are many techniques. We offer you five types of gas savings for heating a private house that can really help you.

House insulation

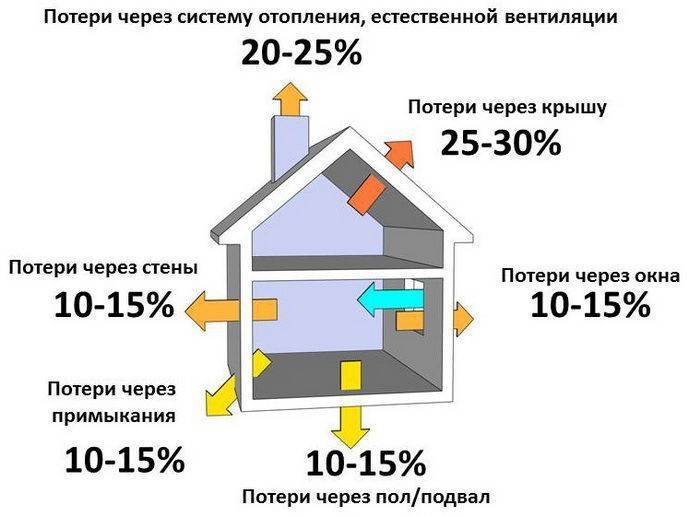

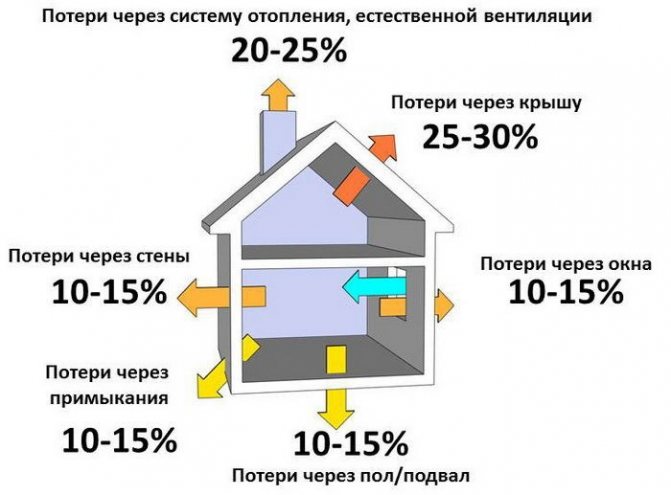

This is the first way that comes to mind. To effectively insulate, you need to analyze heat losses. Think about where the cold gets into your home and how the heat goes away. It is logical to assume that most of the heat is lost through windows and ventilation, through walls and roofs. In this regard, it is necessary to take such measures.

- Insulation of the roof and attic... For this, stone wool or foamed polymers are used. Covering with sandwich panels will be effective. When choosing a method of insulation, technical features and roof structure are taken into account.

- Reduction of heat losses through windows... There is no point in filling up the cracks in old windows. Better to replace them with modern energy-saving systems. On the market you will find double and triple glazed windows. Windows from a multi-contour profile have proven themselves well. Choose based on your own financial capabilities.

- Wall insulation... Front insulation is popular. After proper preparation of the wall, extruded polystyrene foam panels are glued to its outer side of the wall. Their thickness must be at least 20mm. Such a structure is reinforced with a reinforced mesh and plastered.

After completing the work, you will feel how much warmer it will become in your home. Natural gas consumption will immediately decrease by 20-30%. Such a good saving on heating is obtained.

Installing a wall-mounted boiler instead of a floor-standing boiler

For heating a residential building with an area of up to 400 sq. it is more correct to use a wall-mounted gas boiler. This will allow you to save more on gas. The wall installation can be considered a mini boiler room. It consists of structural elements:

- expansion tank;

- the safety team;

- circulation pump;

- electronic board.

Expensive models have additional elements:

- wireless weather-dependent programmer;

- indirect heating boiler;

- circulation pump with the possibility of frequency regulation.

Single-circuit hinged tanks are often equipped with a three-way valve. It is installed at the junction with the indirect heating boiler. The heat exchangers of the mounted boilers are made of copper or stainless steel.

The main savings on gas can be obtained due to the stable efficiency of the boiler. Unlike floor-standing models, wall-mounted ones most often offer forced draft solutions. The forced draft provides the combustion chamber with the right amount of oxygen. With natural thrust, this indicator is not always stable.

Connecting the thermostat to the boiler

A prerequisite for cost optimization is the automation of the heating process. If the gas supply will not be regulated depending on changes in external factors, it is difficult to talk about saving on heating. Indoor and outdoor temperatures are considered to be such factors. Temperature sensors are used to take readings. They are installed inside and outside the house.

The automation principle is very simple. When the outside temperature changes, a signal about this goes to the boiler control system.The gas flow increases or decreases depending on which parameters have been set. The system constantly tests the indoor air temperature. As soon as the temperature in the house drops below the one that you decided to adhere to, the gas supply increases, the boiler starts to work more intensively. The boiler will reduce operation or shut down when the temperature values set by you are reached. Saving does not harm the microclimate, but helps to maintain optimal temperature indicators.

There are boiler models that are equipped with thermostats with programmers. These are the smartest devices. With their help, you can program the temperature dependence. The device itself will calculate the operating mode.

By using the automatic adjustment method, you prevent unnecessary overheating of the media. This will save 5 to 10% of gas on heating a private house.

How to reduce the cost of electric heating

There are widespread cases when additional possibilities of such heating are not realized when using electricity to heat buildings. As a first approximation, electricity is one of the most expensive energy sources for civilian use.

However, upon closer examination, it turns out that in this way you can significantly save on heating. To understand how this is possible, you should familiarize yourself with the operating mode of the central power system.

It is quite difficult to predict the change in load during the day, at the same time, the operational regulation of the generated power seems to be an even more difficult task. In this regard, a tendency is born to stimulate electricity consumption during those hours when the total load on the network decreases. A kilowatt of electricity in the night tariff zone is 2.5–3 times cheaper than during peak and semi-peak loads, which creates an excellent opportunity to reduce heating costs.

The idea of multi-tariff daily consumption implies the accumulation of heat generated in eight hours of the night zone, with its subsequent use during the downtime of the heating equipment.

In buildings constructed of dense building materials with external thermal insulation, the function of heat accumulation is assumed by the building structures and interior items themselves.

This is not always convenient, because during sleep the optimal air temperature for a person is 3-5 ° C lower than during wakefulness, besides, not every house is able to keep warm for such a long time.

An alternative to this method of heat storage is the installation of a liquid heat accumulator. At night, an insulated container with water with a volume of 2-3 m3 is heated to the maximum possible temperature, while heat is supplied to the living quarters in sufficient volume.

After the end of the night tariff, the coolant takes heat from the accumulator through a secondary heat exchanger and distributes it throughout the building. The operation of the system is simplified by the fact that during the period from 8 am to 4 pm most residential buildings are uninhabited and do not necessarily need to maintain the optimum temperature.

Room adjustment

Not all rooms need to be heated equally. It is not necessary to maintain the same temperature in rooms for different purposes. Those requiring increased gas costs include:

- bedrooms and nurseries;

- showers and bathrooms, toilets;

- living rooms and offices.

Non-residential rooms will require less heating:

- storerooms and warehouses;

- sports or gymnasiums;

- garage premises;

- working workshops.

Regulators are installed separately for each radiator. These are small devices. Their task is to decrease or increase the flow of the coolant volume in the battery. Or a complete overlap of the feed. There are several types of thermostats.Each of them works according to a special principle, has advantages and disadvantages.

- Mechanical... They imply manual adjustment of the coolant volume. The main advantage of mechanical regulators is the low price and simplicity of the device. The degree of heat transfer from the radiator is manually adjustable. You can independently determine the amount of coolant entering the battery.

- Electronic... Readings are taken from remote sensors. The device is based on a programmable microprocessor. There are control buttons on the regulator. With their help, the desired temperature is set. Some models of electronic regulators can control both a pump and a mixer. There are two types of electronic thermal sensors:

- Mechanical thermal heads. This is a valve that at a certain moment squeezes a special fluid. It expands when heated and decreases when it cools. The adjustment error remains.

The installation of thermostats allows you to optimize the gas consumption by choosing the mode of heating the water in the boiler. You can create comfortable conditions in each room. This will save from 5 to 10% of the funds that you pay for gas.

Saving gas on a gas stove

Pay special attention to saving gas when using a gas stove. Adjust the burner power of the stove, after boiling, reduce the burner to a minimum. Use less water when cooking vegetables. They will cook even if they are not completely covered with water. By the way, recommendations for saving gas when cooking on the stove will also help save electricity when using an electric stove.

When cooking, be sure to close the lid tightly, then the gas consumption will decrease several times. Do not leave the cover open or half open. In both cases, the gas consumption is equally high. Do not use a gas oven for small meals. Cooking on a hotplate is much more economical.

Choose pots and pans with a thick, flat bottom that will heat up evenly and quickly. In addition, the bottom of the items must match the diameter of the hotplate. Do not use enameled and aluminum cookware, Teflon coated products in your cooking, as they are not economical. Stainless materials are a suitable solution. How to choose a stainless steel pot, see here.

Installing a condensing boiler

There is another way to achieve savings in comparison with a conventional boiler in 10-15% of the consumption of gas consumed. Install a condensing boiler. The boilers get their name because the system uses the kinetics of water released along with steam.

The technology is based on the laws of physics. After the combustion of the gas, carbon dioxide and water molecules are released. The liquid evaporates and generates heat. Condensation of the resulting steam allows the return of thermal energy, transferring it to the coolant. A special compartment is provided for steam in the condensing unit. It acts as a heat exchanger.

Economical technology is the reason that condensing boilers are used by 70% of the population in Europe. In addition to high efficiency indicators, they have other advantages:

- compact size and light weight;

- the ability to accurately modulate the required temperatures;

- low temperature of exhaust gases;

- low noise level during boiler operation;

- small amount of harmful emissions.

The efficiency of condensing equipment is more than 100%. The main disadvantage of such installations is their very high price. It is on average 50-80% higher than the price of a conventional boiler. The cost depends on the capacity of the installation, the number of circuits with which it is equipped. The material of the heat exchanger, the number of operating modes are also taken into account. It may be that high-tech equipment will not pay off in the first year of its use.

Important! Ideally, such boilers work only in low-temperature heating systems, such as hot water floors. In other systems, the efficiency practically does not differ from traditional wall-mounted boilers.

Magnetic Gas Saver

Gas Saver is a magnetic device in the form of a bracelet with neodymium magnets, the use of which reduces gas consumption by 28-45%. The essence of its work lies in the fact that the device creates a magnetic field, when passing through which the order of the arrangement of molecules changes, they line up in a certain order. As a result, gas enters the combustion chamber, the combustion of which occurs without additional expenditure of energy required to break molecular bonds.

The efficiency from the combustion of gas is significantly increased. The amount of harmful substances released during combustion is reduced. Manufacturers claim a 30 percent reduction in fuel costs. The device can be used for instantaneous water heaters, heating boilers, kitchen stoves.