Basic parameters of solid fuel boilers and stoves

Solid fuel heat supply is characterized by relatively low initial costs. There are affordable solid fuel home heating boilers on the market. However, the process of installing equipment and the entire system as a whole must be carried out according to certain rules.

Solid fuel boiler in the heating system

Almost all solid fuel stoves and boilers for hot water heating have the same characteristics. Their knowledge and ability to use information correctly will help you choose the right equipment for heating your home. When choosing, you should pay attention not only to technical aspects, but also to workmanship. Home heating boilers for solid fuels must be made of special grades of steel. The case is at least 2 mm thick. For the combustion chamber, heat-resistant steel with a thickness of 3 mm or more is used.

The advantage will be a guarantee from the manufacturer and seller of heating equipment. You also need to pay attention to the presence of a network of service centers for maintenance and repair. In order for reviews of solid fuel heating boilers to be only positive, when choosing equipment, you should study the following parameters:

- Rated power. It is determined by preliminary calculations of heat supply. To form a small stock, heating a private house with solid fuel must have a capacity of 15-20% more than the calculated one;

- Heat exchanger material... The most reliable are cast iron solid fuel heating boilers. Their disadvantage is a large indicator of inertness and possible destruction under strong mechanical stress. The alternative are lighter and cheaper models with a steel heat exchanger;

- Boiler type. In addition to classic direct combustion equipment, you can choose pyrolysis or long-burning boilers.

Do-it-yourself solid fuel heating boilers are often made. But to do this work, you need to choose the right manufacturing scheme and materials. The advantage of such designs is the ability to adapt according to the above parameters to a specific heating system.

All solid fuel air heating stoves are designed to use coal, wood, fuel briquettes or peat. Exceptions are pellet boilers, which differ in design and are intended only for pellets.

Choosing a boiler - purpose, features, pros and cons

Automatic boilers

The automatic boiler runs on granular solid fuel. The main feature and main advantage of its installation in a private house is the maximum automation of the operation of such a heating system.

Both the fuel is supplied and the ash is removed automatically. The disadvantage is the need for a special room.

Pyrolysis boilers

A pyrolysis solid fuel boiler generates heat by burning gas generated by decomposition under the influence of the high temperature of the solid fuel.

The main advantage is the efficiency reaching 90% and the durability of one load (up to 10 hours). But a solid fuel heating system with a pyrolysis boiler will also cost more to install.

Long burning boilers

The most famous long-burning boilers are the Buleryan type stove and the Stropuva solid fuel system. Their designs differ from each other, but in the main they are similar - one tab of fuel is enough for at least 30 hours of combustion.

The main disadvantage is the rapid cooling of the air if a country house is heated with uneven heat transfer from the premises.

Classic boilers

A classic boiler is similar in principle to a house stove. A stream of combustion air is supplied through the grate. The advantages include independence from other energy sources and the possibility of using different types of fuel. The downside is the need for regular fuel filling and the presence of a boiler room.

Solid fuel heating schemes

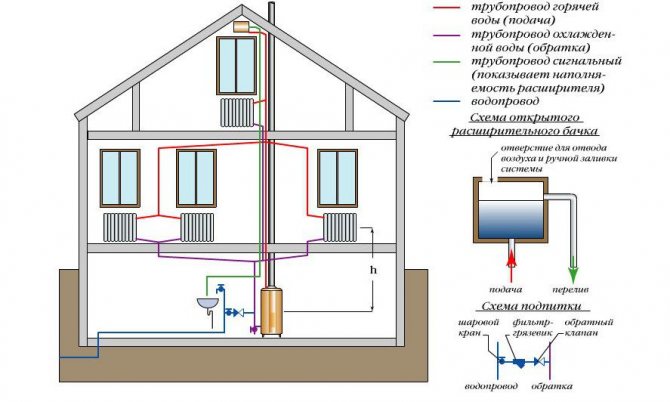

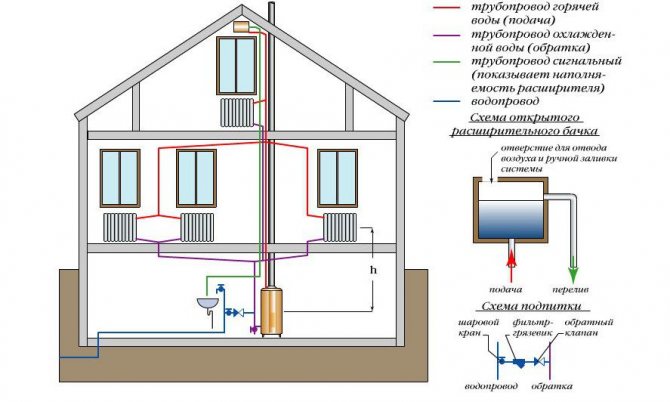

The installation of heating equipment is preceded by the choice of a scheme. The complete set of heat supply, the parameters of the system's operation, as well as the type of coolant depend on it. In some cases, a solid fuel steam heating scheme is advisable. But most often they choose water heating at home.

House water heating scheme

The choice is determined by the characteristics of the house - its area, heat losses and the required temperature mode of heating. For uniform heat distribution, a scheme for installing a solid fuel heating boiler in a water circuit is recommended. If the area of the house is small, air heating can be used. In rare cases, home-made steam boilers for solid fuel heating are used.

At the first stage of choosing a scheme for installing a solid fuel heating boiler, it is difficult to determine the type of heat supply. Currently, the most common types are the following:

- Water with natural circulation... Applicable for small private houses and summer cottages. This is due to the maximum possible length of the line up to 30 m. Even with a powerful heating boiler for a house on solid fuel, the water circulation rate will be small;

- Forced circulation water... For this type of heat supply, you can consider making a solid fuel heating boiler with a built-in pump. Thanks to this design, the heating area is significantly increased;

- Air... It can be implemented using special do-it-yourself solid fuel heating boilers, which have channels for the circulation of warm air in the design. An alternative is to install an air heat exchanger and a duct system to distribute heated air to the rooms of the house;

- Steam... It is used extremely rarely in autonomous heating due to the high cost of equipment and the need for constant monitoring of the state of the coolant. Most solid fuel steam heating schemes are designed to heat large buildings.

The best option for installing a home solid fuel heating boiler is water heat supply with forced circulation. It has good performance and is inexpensive to maintain. You can also note a large number of schemes, according to which you can independently calculate a solid fuel heating boiler.

In any heating system, regardless of the chosen scheme, safety elements must be present. For solid fuel boilers for hot water heating, these are air vents, drain and check valves.

Video

Choosing boiler equipment. The video will focus on the choice of boiler equipment. You will learn: what to look for, what elements are required in the boiler room, what should be the chimney for a gas boiler and, using a cheap device, to protect yourself from the loss of two hundred thousand rubles.

Alteration of engineering systems and installation of a modular boiler room. How to modernize a boiler room if it no longer meets the needs of the house? Engineering systems specialist Vladimir Sukhorukov will tell you how to completely remodel the heating system and why you need a second modular boiler room.

Heating without gas: engineering communications with your own hands. How to heat a house without gas, and even with interruptions in electricity? Vladimir Sukhorukov, using the example of his home, will tell you how you can organize a heating system with a homemade boiler and automation, which will allow you not to be left without heat in any situation.

House made of straw. Engineering Communication. Heating and ventilation. To heat a house insulated with straw, its owner did not spend money on the main gas. Instead, he made his own heating system based on coal and electric boilers.

Communications in a frame house. With your own hands. The owner of this small frame house built it as a "training" house before erecting a full-size cottage. In the video, he shares his experience in engineering communications and an inexpensive way to heat a home with a pellet fireplace.

Direct fired boilers

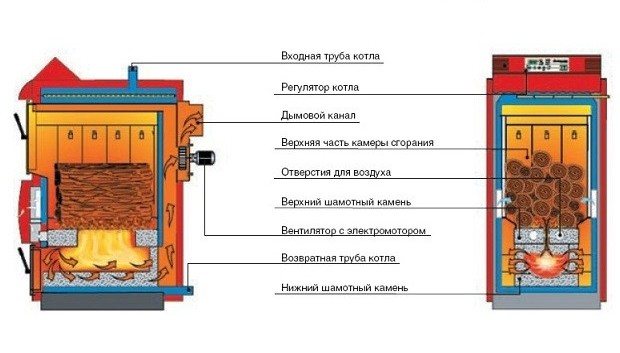

The simplest solid fuel heating boiler device has classic models. They consist of a combustion chamber, ash pan, heat exchanger and chimney. The transfer of thermal energy to water occurs due to the combustion of fuel in the furnace.

Direct combustion boiler design

The advantage of such models is reliability and simplicity of design. For the independent manufacture of a solid fuel heating boiler of this type, you will need a minimum of tools and materials.

But along with the positive qualities, these boilers have a number of disadvantages. The main one is high fuel consumption. In reviews of direct combustion solid fuel heating boilers, they indicate the need for the constant addition of firewood or coal. If this is not done, the temperature of the water in the pipes will inevitably decrease.

It should also be noted such features of heating a private house with solid fuel using boilers of this type:

- Large indicator of inertia... The time for heating water in pipes to the required temperature can be from 10 to 30 minutes, depending on the type of system and its characteristics;

- Power regulation problems... As in solid fuel air heating stoves, this can only be done by limiting the air flow through the ash pan. Therefore, when designing a heating system, it is necessary to provide for the installation of safety devices;

- Low efficiency rate... Usually it is around 60-65%. This is due to the fact that some of the thermal energy leaves along with carbon monoxide through the chimney;

- Equipment... The composition of steel and cast iron solid fuel heating boilers does not include a circulation pump, a safety group.

It is also worth noting the absence of a second circuit for hot water supply. Alternatively, you can consider the possibility of connecting a tank of direct or indirect heating, if this is provided for by the design. In this case, when calculating a solid fuel heating boiler, the installation of additional equipment should be taken into account.

In most cases, in the device of a solid fuel heating boiler, the operating time on one batch of firewood or coal is from 4 to 6 hours. The higher the combustion intensity, the shorter the time for one cycle.

Solid fuel pyrolysis boilers

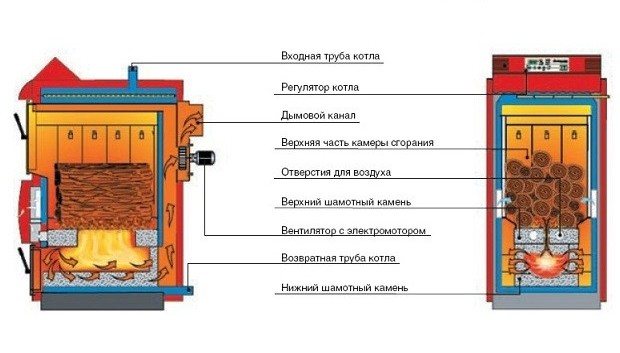

To optimize fuel consumption and increase efficiency, pyrolysis home heating boilers for solid fuel have been developed. Despite the similarity of the processes taking place inside the structure, their principle of operation differs from the described models of direct combustion.

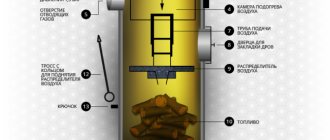

Pyrolysis boiler design

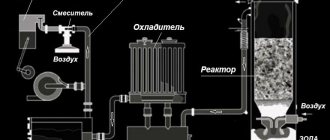

Similar solid fuel boilers for hot water supply are also called gas-fired boilers. Their principle of operation is not based on direct combustion of firewood, but on the formation of a volatile mixture. With a relatively small temperature effect on the wood and with a minimal flow of oxygen, the process of their smoldering occurs. As a result, the so-called wood gas is formed.Rising through special channels, it enters the combustion chamber, where it mixes with the air flow and ignites.

The advantage of operating gas-fired heating boilers for a house on solid fuels is economical fuel consumption. On average, one batch of firewood is enough for 12-18 hours of work. In addition, pyrolysis cast iron boilers for solid fuel heat supply are characterized by the following qualities:

- Electrical connection... For efficient operation, the boiler must be equipped with a fan or turbine (rare);

- Fuel quality... Before loading, the wood must go through a drying stage. The optimum humidity for heating a private cottage with solid fuel should be 8-10%;

- Minimum volume of carbon monoxide... Most of them are burned in the secondary chamber. Due to this, when calculating a solid fuel boiler, it is possible to provide for a chimney with a smaller diameter. But it must be insulated, since there is a high probability of condensation on its surface;

- Fuel types... The device of a solid fuel pyrolysis boiler is made in such a way that logs, sawdust and wood waste can be used. It is important that they have the right level of humidity and do not contain foreign impurities.

To regulate the power of do-it-yourself solid fuel heating boilers, you can connect a fan to the control unit. It will adjust the power of the device depending on the indoor and outdoor temperature. In this way, you can reduce fuel consumption and optimize heating performance.

It is possible to improve the characteristics of a home-made gas-generating solid fuel heating boiler by lining its outer surface. This will reduce the heat loss of the structure.

Solid fuel boiler for long burning

One of the alternatives to a pyrolysis heating boiler are long-burning models. This is a relatively new heating structure, which is characterized by low fuel consumption and a long combustion period.

Long burning boiler

The classic scheme for installing a solid fuel heat supply boiler provides for significant heating of water in a heat exchanger. Currently, low-temperature systems are gaining great popularity. It is for such schemes that a long-burning boiler will be optimal. It differs from classical models in the absence of an ash pan and in the way of air supply to maintain the fuel combustion process. Reviews of long-burning boilers for solid fuel heating indicate their high efficiency and reliability of operation.

Structurally, it consists of a large combustion chamber that occupies about 90% of the total boiler volume. The air is supplied through the top pipe, which is lowered by gravity as the fuel burns. In fact, a smoldering process takes place, due to which the temperature of the coolant does not exceed + 70 ° C.

It will be useful for the consumer to know the following properties of a long-burning boiler:

- The presence of an automatic draft regulator... This is a mechanical device that has a thermocouple in its design. When it heats up, the air flow decreases. The reverse process provokes a decrease in the temperature of exposure to the thermoelement;

- No need to connect to the mains;

- Ash removal is carried out once every 3-4 days of work... However, with a large amount of combustion products, a sharp deterioration in the operation of the boiler occurs;

- Burning occurs only at the top... This results in a significant reduction in fuel consumption.

One of the disadvantages of long-burning boilers is their high cost. However, with the correct design of the heating system, compensation for primary costs will occur after 4-5 heating seasons.It is also necessary to protect the structure from moisture.

It is necessary to control the circulation rate of the coolant. Its intense cooling can provoke moisture loss on the surface of the heat exchanger..

How does such a unit work?

Solid fuel devices use various types of solid fuels for their work. These are firewood, coal, oil shale, peat, etc. The boiler operation cycle can be conditionally divided into three phases. Let's consider each of them in more detail.

Stage # 1 - firing up the boiler

The cycle begins with ignition, which is characterized by a sharp increase in temperature on average from 40 ° C to 600 ° C in 5-10 minutes. The temperature values of the combustion heat exchanger begin to rise, which depend on the parameters of the system and can vary from 40 ° C to 70 ° C. At a minimum, a heat stroke is possible on the heating system as a whole and on the heat exchanger itself. The latter, especially made of cast iron, will not be able to withstand such conditions for a long time and bursts. If the circulation rate of the coolant is low, and the heating takes place quickly, the liquid may boil, which will lead to a thermal and hydraulic shock to the heating system. The most vulnerable to it are plastic pipes. At this stage, the pipes begin to warm up, but the air in the room is still cold.

Coal, wood, pellets, peat, etc. can be used as fuel for solid fuel boilers.

Stage # 2 - heating the coolant

The temperature in the furnace continues to rise and reaches 1300 ° C for coal-fired boilers and about 1000C for wood-fired boilers. The coolant continues to warm up. At this stage, control is important, otherwise it can heat up to the maximum boiler temperature, which leaves 95 ° C, and this is already dangerous.

Regulation is carried out using a damper that controls the air supply. The optimum temperature must be maintained until complete combustion of the fuel. At this stage, the pipes in the room become hot, the air warms up.

Stage # 3 - fuel burnout

At the end of the boiler cycle, the fuel is completely burned out, and glowing coals are formed. The temperature drops to 600 ° C-400 ° C, which are considered the most comfortable for the system. The coolant slowly cools down, the air in the room also begins to cool down a little. After the embers have formed, the process of cooling the air and the coolant is immediately accelerated.

Having considered all the phases of the solid fuel boiler operation, you can clearly see its main feature - temperature cyclicity. It is due to the need to add a new portion of fuel from time to time in order to minimize fluctuations in the temperature of the coolant. To a greater extent, this problem is solved in automatic boilers, where there is an automated fuel supply and blowing of the burner fan. The rest need constant human monitoring and timely replenishment of the fuel supply.

Solid fuel boilers are slightly inferior in efficiency to units running on liquid fuel. Read more about this heating equipment in our material:.