Many owners of country houses and apartments prefer to use autonomous heating and hot water supply systems, which require a water heater or a double-circuit boiler. The devices differ in many ways, the most important of which is the type of fuel used for operation. A water heating boiler has its own design features and operating principle.

What is a hot water boiler for?

If the housing does not provide for centralized heating and hot water supply, then the implementation of these functions is assigned to the boiler. As a rule, this situation occurs in suburban development. However, heating equipment can be successfully installed in the apartment as well.

With the right choice of technology, the system will effectively perform its task, creating warmth and comfort in the room, regardless of the weather outside the window. Hot water boilers are safe, easy-to-use devices, the heating efficiency of which depends on the specific model and a number of other factors.

Principle of operation and main characteristics

Wood-fired boilers with a water circuit are hot water equipment with a large power range, designed for heating homes and receiving hot water. Given the constant contact with open fire and the formation of water condensation, cast iron or special grades of steel are used for its manufacture, which are less susceptible to corrosion.

Like most hot water heating appliances, wood-fired boilers with a water circuit operate on the principle of a closed vessel. Wood, burning in the combustion chamber, releases energy to heat the liquid in the heat exchanger, which moves under pressure in the water circuit, heating the room.

The technical features of water-heating wood-burning appliances are determined by the following parameters.

- Power - depends on the volume of the furnace, the material of manufacture and the volume of the heat exchanger. The choice of the power of a wood-fired hot water boiler is determined by the size of the heated area and the level of thermal insulation of the building - on average 1 kW per 10 sq. M.

- The efficiency or efficiency of hot water equipment depends on the rate of circulation of the coolant, the parameters of the heat transfer of the fuel and the method of its combustion. Pyrolysis models and wood burning appliances for long burning can achieve efficiency up to 85–92%.

- The basic heating medium in the circuit is water; alternatively, non-freezing liquids can be used.

- According to the functions performed, it can be either single-circuit or have a second water heating circuit.

Design features

At the moment, several types of water heating equipment are produced, each of which has its own design. Setting the differences between them will allow you to correctly evaluate the technique and choose the appropriate model.

Fire-tube

These types of heaters are equipped with a pressurized gas-tight firebox. For their work, automated burners equipped with blowing fans are used. This feature allows the equipment to work without smoke exhausters, while all the necessary parameters are easily adjustable. As a result, the device is highly efficient and has an efficiency level of 92–95%.

Almost all fire tube boilers are equipped with a cylindrical furnace and smoke tubes inside. Depending on the layout, two- and three-way models are distinguished. This equipment was used in the 19th century and has undergone many changes since then. These boilers are in demand today because they are easy to use and do not require serious maintenance.

Considering the features of the equipment, first of all, it is worth noting that fire-tube boilers can be attributed to gas appliances. On their surface, special pipes are installed along which the coolant moves.

Fire tube boilers are of two types:

- Steam. The heating medium is heated by means of steam, therefore the inside of the boiler is equipped with a special container.

- Hot water. With the help of the liquid, the entire body is heated.

The principle of operation is as follows: gas or fuel is supplied to the burner located on the front of the body, which is burned. The role of the firebox is assigned to pipes located in the water, where all combustible material is burned.

Despite their relatively compact size, such devices are highly powerful and safe to operate. In addition, they can function in an autonomous mode, but this will require additional purchase of special equipment in the form of a pressure gauge, a water pressure sensor, and so on.

Water tube

In such models, water is heated by passing through metal pipes. The working pipes located outside are heated by the products of fuel combustion. Due to the design features, an increase in the heating surface is allowed, for which a larger number of water pipes are used.

Thanks to the convection flow in such systems, the movement of water is accelerated, which means that the heat transfer coefficient also increases. The upper limit of the outlet steam temperature reaches +550 ° C.

Water-tube models are more compact than flame-tube models. It is one piece equipment housed in a rugged case. The principle of operation of water tube technology is the natural circulation of water.

Number of contours

At the moment, the market offers a wide variety of heating equipment. First of all, you need to understand for what purpose the boiler is being bought: only for heating or even preparing hot water. To solve the first problem, a single-circuit model is sufficient - they are more affordable and not so intensive in fuel consumption.

To solve the second problem, a two-circuit device should be chosen. These models, in addition to being able to heat water in a flowing way, are additionally equipped with a built-in boiler, the volume of which varies from 150 to 180 liters. Instantaneous heating is optimal if you need to wash dishes or take a shower in the country.

Schemes and connection features

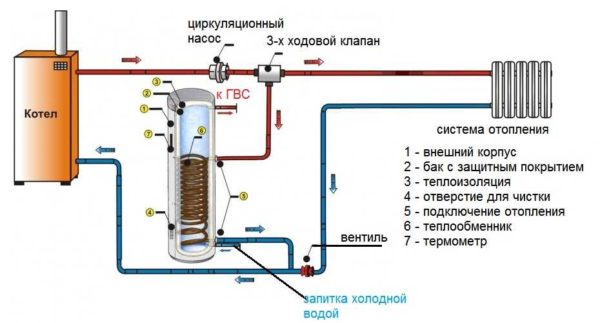

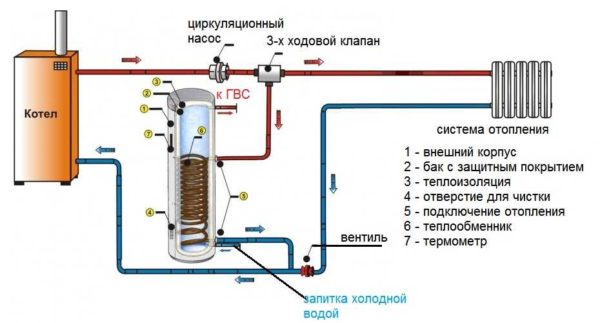

There are two principles for connecting an indirect heating boiler: with and without hot water heating priority. With priority heating, if necessary, the entire heating medium is pumped through the boiler heat exchanger. Heating takes a little time. As soon as the temperature reaches the set one (controlled by a sensor, thermostatic valve or thermostat), all the flow is directed back to the radiators.

In schemes without water heating priority, only a certain part of the coolant flow is directed to indirect water heating. This leads to the fact that the water is heated for a long time.

Scheme without priority

When connecting an indirect heating boiler, it is better to choose a scheme with a priority - it provides hot water in the required amount. At the same time, heating does not suffer much - 20-40 minutes are usually enough to heat the entire volume of water, and 3-8 minutes to maintain the temperature at a flow rate in general. During such a time, no house can cool down enough to feel it. But this is provided that the capacity of the boiler is comparable to the capacity of the boiler. Ideally, the boiler is more efficient, with a margin of 25-30%.

General rules

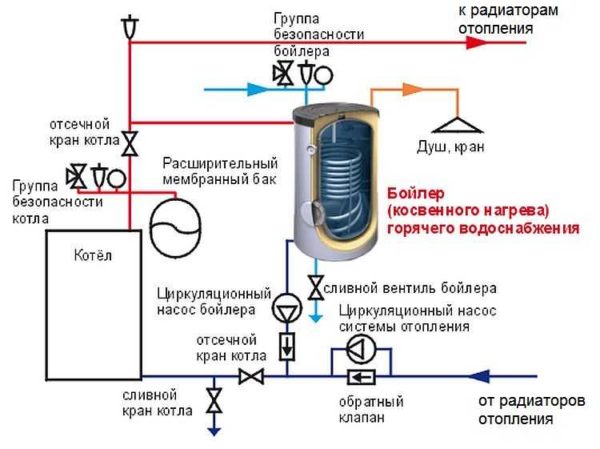

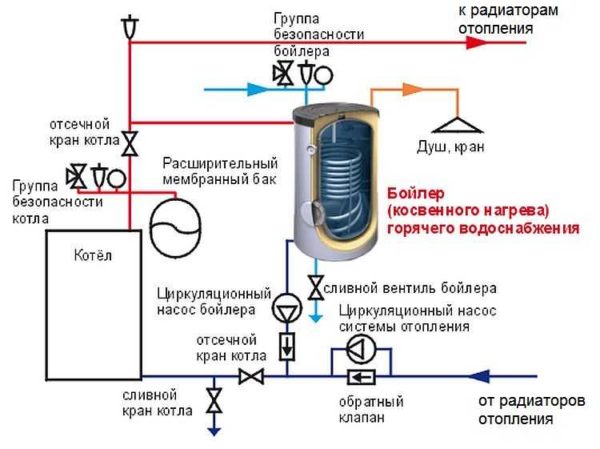

To ensure the normal operation of all appliances connected to the hot water rail, an expansion tank for hot water is installed at the outlet of the boiler (not for heating). Its volume is 10% of the volume of the tank. It is required to neutralize thermal expansion.

Detailed piping diagram for an indirect heating water heater

Also, shut-off valves (ball valves) are installed in each branch of the connection. They are needed so that every device can be used - a three-way valve, a circulation pump, etc. - if necessary, disconnect and service.

Check valves are usually also installed on the supply pipelines. They are necessary to exclude the possibility of counterflow. In this case, the connection of an indirect heating boiler will be safe and easy to maintain.

Installation next to the boiler in a forced circulation system (with 3-way valve)

If there is already a circulation pump in the system, and it is installed on the supply, and the forced heating boiler can be placed next to the boiler, it is better to organize a separate circuit that goes from the heating boiler. This connection of an indirect heating boiler is realized with most wall-mounted gas or other boilers, in which a circulation pump is installed on the supply pipe. With this connection scheme, it turns out that the water heater and the heating system are connected in parallel.

If there is a pump in the flow line and a water heater located next to the boiler

With this method of piping, after the circulation pump, a three-way valve is installed, controlled by a temperature sensor (installed on the boiler). One of the outputs of the three-way valve is connected to the boiler branch pipe for connecting the heating. A tee is cut into the return pipe before entering the boiler, a branch pipe is connected into it to drain water from the heat exchanger. Actually, the tie-in to the heating system is complete.

The procedure for this scheme is as follows:

- When the sensor receives information that the water temperature is lower than the set one, the three-way valve switches the coolant to the boiler. The heating system is turned off.

- The entire flow of the coolant goes through the heat exchanger, the water in the tank heats up.

- The water heats up enough, the three-way valve redirects the coolant to the heating system.

As you can see, the scheme is simple, its operation is also clear.

Scheme with two circulation pumps

When installing a water heater into the system in a circulation pump, but not next to it, but at a certain distance, it is better to install a circulation pump in the circuit on the water heater. The connection of an indirect heating boiler for this case is shown in the diagram below.

Wiring diagram for a boiler with automatic control

The circulation pump can be installed either on the supply pipe, or on the opposite. In this scheme, there is no three-way valve, the circuit is connected through ordinary tees. The switching of the coolant flow is carried out by turning the pumps on / off, and it is controlled by a temperature sensor, which has two pairs of contacts.

If the water in the tank is colder than the one set on the sensor, the power circuit of the circulation pump in the boiler circuit is turned on. When the specified degree of heating is reached, the contacts of the pump are closed, which drives the coolant into the heating system.

Types of water heaters for heating systems

Boilers, i.e. water heaters, are available in a wide range. Some models are capable of preparing hot water for a bath for 20 minutes, while others immediately heat the liquid during its use. Flow devices are preferred by those who don't like to wait.

Gas

As the name implies, such a system runs on gas. These boilers are also called columns, before they were installed in almost every "Khrushchev". This was explained by the low cost of gas during the Soviet era, which was the key advantage of the units.

However, for the full operation of the gas column, it is necessary to equip a chimney through which combustion products are removed from the room. It is because of this that gas models are increasingly being replaced by a modern alternative.However, with proper operation, their efficiency will be higher compared to an electric boiler, due to their high power. For full-fledged operation, the equipment is connected to a central gas system or a cylinder.

There are flow-through and storage models. The former are capable of instantly heating the running water. As a rule, such a device is called a column and is most often found in Russian homes. The storage tank is not provided, since the system is able to prepare any amount of water, which is heated by a gas burner.

Accumulative models are practically not used, because they are not relevant if the gas supply is established in the city. As a rule, they are found in places with weak highways or in areas where there is no wiring.

Advantages:

- after turning on the device, the water immediately begins to heat up;

- unlimited hot liquid.

There is only one drawback - to install such equipment, you must obtain a special permit from the gas service. In addition, you will have to contact a specialized company that will install the system.

Solid fuel

A solid fuel boiler is the best solution for a summer cottage or a free-standing autonomous room (bath, sauna). Such systems are installed most often in cases where there are difficulties with the supply of electricity.

Suitable as fuel for boilers:

- coal;

- logs;

- briquettes.

Solid fuel equipment must be connected to the water supply system. Often, columns of this type are equipped with a mixer through which already heated water is supplied. Of course, the scope of their application is quite narrow, but due to its simplicity and efficiency, the equipment is still in demand. Such columns have existed on the heating technology market for about 50 years, and during this period their properties and capabilities have improved significantly.

Equipment advantages:

- Rapid heating of the liquid. For example, to prepare water for a shower, 15 to 20 minutes and several kilograms of solid fuel are enough. If the tank is large enough, then in 1 hour the boiler will prepare water for a family of 3-4 people.

- Autonomy. If you make the right choice, then you will not need to depend on electricity or gas.

- Availability. Compared to similar heating equipment, solid fuel models have a low price.

- Reliability. It is explained by the simple technology of the system, which is able to work reliably for many years.

Along with the advantages, solid fuel devices also have disadvantages.

There are such disadvantages:

- Fuel storage space required. For the most efficient combustion, certain requirements must be met.

- Inconvenience of cheap models. Such devices cause a lot of hassle during operation. They become more dirty, so they have to be cleaned more often so that their efficiency does not drop.

- Manual fuel loading. The amount of fuel loaded may vary depending on the model selected.

- Installation of assistive devices will be required. At a minimum, the unit will need a heat accumulator.

If we consider the principle of operation of a solid fuel boiler, it can be compared to a large wood-fired samovar. In the lower part there is a firebox, the waste from the combustion processes is discharged through the chimney. The coolant, in contact with the exhaust gases, heats up. The design of the models may vary, therefore, the rate of water preparation is also different.

Liquid fuel

Many homeowners use diesel as an energy source. Most often, this equipment is chosen if there is no gas pipeline in the area of residence, and the installation and use of electrical equipment will be very costly. With the help of liquid fuel units, it is possible to heat rooms with an area of 100 m2 or more.Often, devices are found in industrial facilities: factories, warehouses, and so on.

Advantages of diesel-powered models:

- high efficiency reaching 92%;

- convenient operation due to excellent automation;

- frequent maintenance is not required;

- for installation and start-up, you do not need a large number of permits and documents.

Many boilers operating on diesel fuel are able to take air directly from the street, for which they are equipped with a coaxial pipe. This means that you do not have to make a chimney, which can also be attributed to the advantages.

Such equipment cannot be called completely autonomous, since a diesel burner operates on electricity. And if difficulties arise with the supply of electricity, then you will need to install a generator. In addition, you will have to prepare a place for storing containers with fuel. For this purpose, fire-prevention measures are carried out, a high-quality ventilation system is equipped.

The principle of operation is as follows: a coolant moves through the pipes of the boiler, which can pass naturally or with the help of a circulation pump. Diesel fuel with air is supplied to the burner under pressure. This mixture is ignited in the combustion chamber.

Electric boilers

Based on the name, it becomes clear that such systems need electricity to heat water. These are the most common models that are often found in apartment buildings.

Advantages:

- in many regions, electricity is more affordable than gas;

- works from a 220 V network;

- no unnecessary pressure is created in the water supply;

- hot water can be supplied to several points at the same time;

- regulation of the temperature of the liquid allows you to set the extreme value, after which the fuse is activated;

- affordable cost.

In a word, if serious requirements are not imposed on the boiler, then the electrical model will be optimal. Such equipment has its drawbacks.

Among the disadvantages are:

- it takes time to heat the water;

- the electricity bill increases.

The key feature of the electric boiler is that it can be installed in any room where there is a network with a voltage of 220 V. This can be: an apartment, a country house, an office, a store, and so on. In addition, you do not need to obtain permits for their installation. In the course of work, carbon monoxide is not emitted, so you do not have to make a chimney.

Benefits of heating with wood-fired boilers

Ukrainian and foreign manufacturers, improving technologies and using modern materials, make a wood-fired hot water boiler a competitive equipment for the production of thermal energy.

Fig. 3 Long burning wood fired boiler

Reliability and cost-effectiveness!

The simplicity of the design of wood-fired boilers with a water circuit guarantees their reliability, and technologies for the complete combustion of wood fuel ensure economic efficiency and a long service life.

Energy independence!

Along with automated water heating devices, cheaper ones are also successfully used, including home-made designs designed for natural circulation of the coolant and arbitrary draft. This makes them independent from the power supply source.

Security!

The use of elementary devices for regulating temperature and pressure in the heating system makes wood-fired water heating boilers completely safe.

Easy to install and maintain!

The installation of a household wood-fired heating device does not require registration of permits in state supervisory authorities.

Affordable price!

One of the cheapest devices for autonomous heating systems. Even high-tech long-burning wood burning models outperform expensive gas equipment.

Classification of boilers by purpose

Not only residential buildings and apartments, but also industrial facilities need high-quality heating. Manufacturers provide for this fact and produce powerful installations, with the help of which large areas are easily heated. At the moment, there are 2 categories of boilers: domestic and industrial.

Household

This is the name of the heating equipment installed in apartments, cottages and summer cottages. For small heated areas, these devices are ideal, but for the conditions of the enterprise, their capacity will not be enough. There are no special requirements for them, the operation is simple and does not imply the presence of special skills.

Thus, domestic boilers are used for heating and hot water supply of individual houses. It can also be objects of public utility and household use.

Industrial

Nowadays, all enterprises producing heat energy have industrial equipment installed. We are talking about gas, steam and solid fuel boilers, which are fully automated, safe and functional at the same time.

An industrial boiler used for space heating and hot water supply has many advantages.

The following advantages of use are highlighted:

- ease of maintenance;

- the ability to work from several types of fuel;

- adjustment depending on weather conditions;

- upon request, the equipment can be built into a block-modular boiler room.

To regulate the operation of such systems, instrumentation and built-in automatic mechanisms are used, which makes the units safe and reliable. For the manufacture of the outer shell of the boilers, strong steel or cast iron is taken, and they are delivered to the enterprise in the most complete form, which facilitates the installation work.

The most demanded boilers in the industry are gas boilers. The fact is that this type of fuel is now the most accessible resource and, when burned, releases the most heat.

Boiler in a solid fuel boiler

Special attention should be paid to double-circuit solid fuel boilers, in which the boiler for the solid fuel boiler is located as an additional chamber with its own autonomous heating element.

Structurally, it can be either a fully built-in autonomous boiler, but heated from a common combustion chamber, or just a boiler with a special coil. Thanks to the large coil area, the water heats up quickly and evenly.

The second circuit in such heating devices can rightfully be called a solid fuel boiler. The main disadvantage is that it is almost impossible to accurately adjust the constant temperature for such boilers. You will not encounter such a problem, for example, in gas double-circuit boilers or in electric boilers. For this reason, it is still best to install an electric boiler if it is possible to supply electricity.

Devices of this type are very popular with owners of country houses, baths, private pools. A wood-fired boiler can be installed in a train or village, in other words, the equipment will be relevant in places with limited access to gas. The capacity of a power plant in remote settlements is not always sufficient to ensure comfortable living conditions. That is why the wood-burning water heater is so fond of the inhabitants of villages and small towns. It allows you to make living conditions much better by providing the entire living space with hot water. Despite the fact that the cost of the unit itself can be quite high, it quickly pays for itself due to fuel economy.

Types of boilers by heating and installation method

Modern boiler equipment can be classified according to many criteria. One of them is a method of heating the heat carrier.

There are 3 types of boilers:

- Heating elements. They are equipped with tubular electric heating elements.

- Electrode (ionic, electrolysis). If an alternating voltage passes through the coolant, it will begin to heat up. For this, fuel with certain characteristics is used.

- Induction. Their action is determined by the properties of ferromagnets, which are heated under the influence of an induction current.

Depending on the manufacturer and the specific model, each boiler has unique features, strengths and weaknesses. It is also customary to classify hot water boilers according to the method of installation.

Floor standing

Such units are installed in large rooms. Due to their significant weight, they are not allowed to be mounted on the wall. They often require their own foundation. The burners of such boilers are atmospheric and pressurized. The former are simpler, cheaper and quieter. The latter are more expensive, but their efficiency will also be higher. Any boiler is equipped with an atmospheric burner, but a supercharged one will have to be purchased.

Advantages:

- durable heat exchanger;

- if desired, heating systems with a large number of circuits are created;

- the possibility of increasing the power.

Along with the advantages, such equipment also has disadvantages.

Disadvantages:

- high price;

- large mass;

- the boiler must be installed in a separate room;

- restrictions on the use of coaxial chimneys.

Due to its high power, the unit effectively copes with the main task - heating a large industrial room.

Wall mounted

These models, in terms of their capacity, are ideal for heating rooms from 100 to 350 m2. They are compact units that are easy to install and attractive in design. Waste gases are discharged in two ways: through a chimney or a special coaxial pipe. The second method is forced due to the built-in fan and is therefore more efficient.

Advantages:

- compactness;

- installed in almost any room;

- availability;

- a coaxial chimney can be installed.

As for the shortcomings, there are only 2 of them: wall-mounted devices are not as powerful and reliable as compared to floor-standing ones.

Wall-mounted devices can have piezo ignition, for which a special button or an automatic electronic mechanism is provided. In a word, in the first case, the start is manual, and in the second - automatic, the main thing is that there are no problems with the supply of electricity.

Heating connection

We connect the prepared circuit directly to the heating system. From a safety point of view, it must be remembered that a solid fuel boiler at some moments can give an excessively high temperature. The storage barrel can contain water with a temperature of 90-100 degrees. This is too much for standard home heating radiators. You can get severely burned if accidentally touched. For this reason, it is necessary to add another mixing valve to the circuit. He will mix cooled water into the circuit.

If the house has underfloor heating, it is possible to connect them to the radiator circuit to supply return flow. You will need to install another pump. The connection will go to the mixing unit. Due to the high temperature, water from the heated heat exchanger is not taken directly, but through a safety mixing valve. This part is installed in order not to scald with hot steam when working with the system and checking it.

At the next stage, we connect the coolant recirculation line in the system through a special pump. We place check valves in the circuit in accordance with the diagram. This completes the complete set of functional elements, let's move on to the fittings.

Another filter is required in front of the boilers. Then, at the highest points of the system, we additionally mount automatic air vents. Next, we ensure the draining and filling of the system.To do this, we arrange the ball valves so that in the future we carry out technical inspection and repair of the equipment without draining the coolant from the circuit. Cranes are needed for:

Review of popular models

Any manufactured boiler meets all safety standards. However, more expensive models are equipped with a complex multistage diagnostic system and effective protective automation. The durability and reliability in general depend on how high-quality parts were used in the assembly of the unit. The most popular models according to consumer reviews and expert opinion are as follows.

Wolf CGG-1K-24

This is a dual circuit wall device. The boiler has a closed combustion chamber and is equipped with a forced smoke extraction function. The combustion products are discharged through concentric or separate air ducts. The chimney can be of different lengths, so the built-in fan automatically adjusts the speed.

This model has the following features:

- during installation, it does not require indentation from the side wall;

- works from both natural and liquefied (in cylinders) gas;

- starts quickly and smoothly;

- has a compact size and low weight (40–42 kg).

Let's also get acquainted with the technical characteristics.

The key parameters are:

- power - from 9.4 to 24 kW;

- the presence of two heat exchangers (copper and stainless steel);

- expansion tank volume - 8 l;

- productivity with regards to hot water - up to 11.5 liters per minute.

This model is made in Germany, and it is covered by a manufacturer's warranty for a period of 2 years.

Prices for boilers Wolf

boiler Wolf

Vaillant ecoTec plus VUW INT IV 246

This gas boiler is manufactured by a German company. Its thermal power is 20 kW, which is enough for efficient heating of a room with an area of up to 200 m2. This condensing equipment is used for both heating and hot water preparation. To heat the coolant, the latent heat of condensation is additionally used, which allows the boiler to reach a high efficiency factor with lower fuel consumption.

Features:

- the Aqua-Power-Plus function allows you to increase the power up to 24 kW in the DHW mode;

- the presence of a digital information and analytical DIA system and a built-in eBus module;

- can be used in a low-temperature heating system;

- the air required for combustion can be taken from both the inside and outside of the room.

This is a modern, electronically controlled model. The backlit display makes it easier for the user to monitor the operation.

Prices for boilers Vaillant

boiler Vaillant

Viessmann Vitogas 100-F GS1D870

This low-temperature model of a gas boiler is equipped with one circuit and an open combustion chamber. Thermal power indicator - 29 kW. The device is economical and efficient. Compact dimensions make installation work much easier; the water heater can be installed in a small utility room.

Features:

- for the manufacture of heat exchange surfaces, special gray cast iron with flake graphite is used;

- automation takes into account weather conditions, which allows the system to consume energy more efficiently;

- the possibility of combining with drives.

The only drawback of this model is its high cost.

"RusNIT 208M"

This is a wall mounted electric model produced by a domestic manufacturer. With the help of this compact device, you can heat residential buildings, summer cottages and various household premises with an area of up to 80 m2. For the manufacture of heating elements and a heat exchanger, stainless steel is used.

The unit is equipped with a three-stage power adjustment - 30, 60 and 100%. The range of temperatures maintained in the room is from +5 to +30 ° C. Water or antifreeze is used as a heat carrier. They are connected to 220 or 380 V.

There is a built-in thermal switch that prevents the liquid from heating above +90 ° C. If the system is not full, a special safety sensor is triggered.Thanks to the splash-proof design, the model can even be installed in the bathroom.

Features:

- availability;

- you can connect a circulation pump;

- 2-year warranty.

The only difficulty of this model is the problematic connection to the electrical network, so it is best to contact specialists.

Prices for boilers RusNIT

boiler RusNIT

ZOTA 24 Lux

Powerful electrical equipment that can heat both large cottages and industrial premises with an area of no more than 240 m2. This is a domestic unit, which is compact, easy to operate and affordable. The boiler allows maintaining the room temperature in the range from +5 to +35 ° C.

Heating of the coolant is infinitely adjustable, which makes it possible to combine the device with a "warm floor" system. Intelligent control circuitry is essential for efficient temperature maintenance and energy savings. The equipment is connected to a 380 V network.

Features:

- power - 24 kW;

- Efficiency - 99%;

- the device independently diagnoses malfunctions.

For reliable operation of ZOTA 24 Lux, it is additionally recommended to install a voltage stabilizer.

Protherm Skat 24 KR 13

This is a Czech model of a high-performance electronic boiler. Its power indicator reaches 24 kW. The unit has 1 circuit, it can be connected to a "warm floor" and a boiler for hot water. The sleek and compact design makes it easy to place the device.

The package includes: a 7-liter expansion tank, copper heating elements and a circulation pump. Availability of electronic control with indication and display. It is powered from a 380 V network. This is a safe model in operation, equipped with many protective systems.

Features:

- Efficiency - 99.5%;

- soft start;

- a boiler is being assembled in Slovakia;

- the warranty period is 2 years.

In any case, in order for the device to be as protected as possible, you will need to purchase a stabilizer. In operating mode, the boiler is quite noisy, so it is better if it is installed in a separate room.

Principle of operation

Wood-fired water heaters work according to a very simple principle. The lower titanium compartment is filled with fuel such as wood or coal. After a while, the heated air begins to rise up through a special hole. Water is heated in the upper compartment. On average, this takes from 20 to 30 minutes if the storage water heater is. In instantaneous water heaters, the water heats up in motion, passing through the heat exchanger to the tap.

The heated water moves up, where the outlet is located with a tee attached to it. The water is then redirected to the shower head or tap spout.

Firewood belongs to the group of solid fuels and can be used on the same level with coal for heating residential buildings not higher than 2 floors, and are also well applicable when organizing air heating in a house.

Installation features

First of all, you need to choose a frost-free room. The place of installation is coordinated with the controlling services. When buying a device, it is imperative to require a certificate from the seller, the presence of which will facilitate registration and obtaining permission for installation.

When choosing a place, you immediately need to think about how the combustion products will be discharged. You can install separate pipes or use a ready-made chimney. As a rule, heating equipment is already equipped with a discharge system. During installation, special care should be taken when connecting the device to the gas supply system.

The general requirements are as follows:

- It is allowed to install boilers only on load-bearing or solid walls.

- The hood and chimney are of the same dimensions.

- The system has free access, which is necessary for maintenance.

- If the boiler is installed in a cabinet, leave 5 cm free up to the top.It is also important to retain access to the installation nodes.

When self-installation, you need to make sure that the parameters of the equipment correspond to the capacity of the heating system. If the wall-mounted device is connected to the "old" wiring, cleaning and flushing of all pipes will be required, which will exclude further clogging.

The installation process itself consists of the following steps:

- During installation, a special cardboard template is used, which will help to make fasteners and holes for the chimney.

- Taking into account the free space for technological maintenance of the boiler, a template is attached to the wall. Previously, the places of fasteners and connections of wires are applied to it. These marks must be transferred to the wall using a marker or colored pencil. The template can then be removed.

- Next, the holes for the dowels are prepared using a drill of the appropriate diameter. Metal corners are inserted into them. It is important to choose the right dowels, taking into account the material and wall thickness.

- The top cover (front panel) is removed from the boiler. Thus, the device is easier to hang on the prepared mounts.

- Before installing the brackets, the correct dimensions of the chimney fittings are checked.

- Brackets are securely fastened.

Please note that each wall has its own way of installing the mounts. This is explained by the performance characteristics of the materials, meaning the load that the partition can withstand. Electric heating convectors with wall thermostat you will find the answer here.