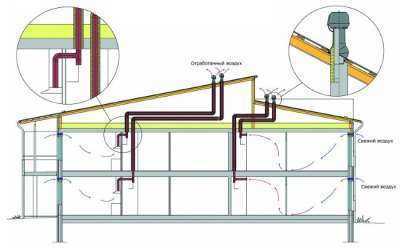

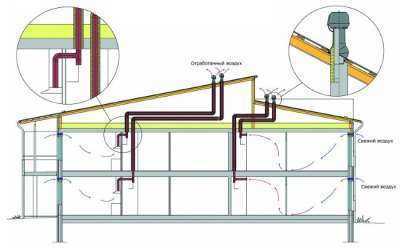

Examples of installing deflectors on ventilation ducts

Detailed description, application and advantages of Deflectors

| Model | Diameter | Description |

| TD-110 | Ø110 | It is most advisable to use for ventilation of rooms, lavatories, cellars, private garages. A wide range of standard sizes allows you to choose the Deflector for installation on an already laid air duct. |

| TD-120 | Ø120 | |

| TD-150 | Ø150 | |

| TD-160 | Ø160 | |

| TD-200 | Ø200 | A good solution for ventilation of living rooms with an area of up to 40m2 and with the number of people constantly staying there up to 4 people. At a wind speed of 3-4 m / s, it can draw from the room up to 200 m3 of air per hour. |

| TD-250 | Ø250 | |

| TD-300 | Ø300 | |

| TD-315 | Ø315 | |

| TD-350 | Ø350 | |

| TD-400 | Ø400 | They are used for ventilation of apartment buildings, large premises, livestock farms, hangars, warehouses, etc. The required air volume is achieved by installing several deflectors. The quantity is determined by calculation. |

| TD-500 | Ø500 | |

| TD-600 | Ø600 | |

| TD-680 | Ø680 | |

| TD-800 | Ø800 | |

| TD-1000 | Ø1000 |

Overall dimensions of TurboDeflectors

Material: Deflectors are made of stainless steel 0.5-1.0mm. Dimensions: Deflectors are available with two types of bases: BUT - nozzle for a round pipe WITH - flat base

| d | D | HA | hA | C | HC | hC | |

| TD-160 | 160 | 270 | 260 | 70 | 295 | 280 | 90 |

| TD-200 | 200 | 290 | 290 | 70 | 295 | 310 | 90 |

| TD-250 | 250 | 350 | 345 | 110 | 350 | 345 | 110 |

| TD-300 | 302 | 400 | 365 | 110 | 390 | 385 | 130 |

| TD-315 | 317 | 400 | 365 | 110 | 390 | 385 | 130 |

| TD-355 | 360 | 450 | 385 | 110 | 490 | 435 | 160 |

| TD-400 | 400 | 495 | 465 | 140 | 490 | 485 | 160 |

| TD-500 | 500 | 615 | 635 | 225 | 615 | 635 | 225 |

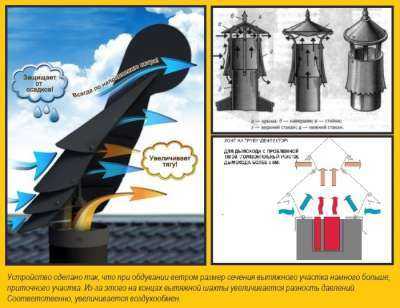

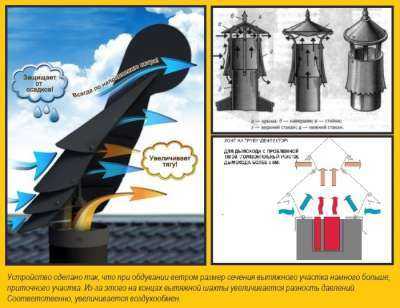

The principle of operation of the ventilation deflector

The ventilation deflector works according to a simple principle, regardless of the design and model of the device:

- directional wind streams hit the metal case;

- due to diffusers, the air forks, as a result of which the pressure level decreases;

- in the system pipe, the thrust increases.

The principle of operation of the device

The more resistance creates the base of the case, the more efficient is the air outflow in the channels of the systems. It is generally accepted that the device installed on the roof at a slight inclination to the horizontal plane works better. Experts state that the effectiveness of these devices is determined by 3 factors:

- the design and shape of the body;

- unit size;

- installation height.

No matter how reliable and high-quality the ventilation deflectors are, they have both advantages and disadvantages, which I would like to dwell on in more detail.

On the "pros" and cons of deflectors

As mentioned above, umbrella solutions can effectively prevent dirt and precipitation from entering the air ducts. With the correct selection and professional installation of the deflector, ventilation is improved. The efficiency of the system as a whole is increased by 20%.

The ventilation device helps to create or increase air draft in the exhaust ventilation ducts

Advice! For regions with light winds, it is recommended to equip the system with a device to enhance the inflow and outflow of air. It will exclude the effect of thrust "overturning"

The devices are not without drawbacks: with the vertical direction of the wind, the flow comes into contact with the upper section of the structure, while the air cannot be fully discharged outside. To eliminate this effect, designs with 2 cones were invented. In winter, ice appears on the base of the pipes, so it is necessary to regularly carry out preventive examinations.

Calculating the number of Turbo Deflectors

Calculation of the number of deflectors during installation Ventilated volume = room volume X air exchange per hour (note: air exchange per hour is different for different rooms)

For example: The room is 20m long, 12m wide and 4.4m high. The average wind force is 3.5 m / s. Air exchange for the room should be 3 times per hour. Thus, we get: Ventilated volume = (20 * 15 * 4.4) * 3 (air exchange) = 3168 m3 / h Thus, we must install 4 Deflectors TD-400

Ventilation deflector device

Each turbo deflector for ventilation consists of several functional elements:

- metal glasses (in the standard version there are 2);

- fixing brackets for secure attachment;

- supply and outlet pipe, which is put on the pipe and fixed with a clamp.

The shape of the outer glass differs in shape, expanding at the bottom. As for the bottom, it is absolutely flat. The cylinders are put on one another, and at the top, the cover is fixed on the racks.

Attention! The diameter of the cover must be larger than the outlet to prevent precipitation from falling into the system.

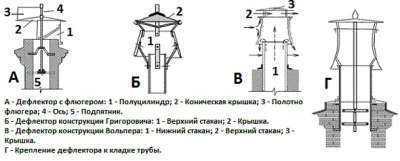

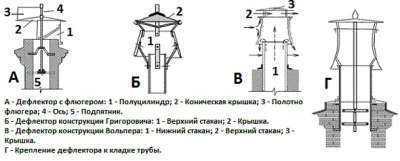

The figure below shows the components of different types of structures.

Note! The installation of rebounds is carried out in such a way that the street air creates an additional suction through the recesses between adjacent rings. This makes it possible to accelerate the removal of "heavy oxygen" from the ventilation system.

The deflector devices in the ventilation system of the house are implemented in such a way that when the air flows are directed from bottom to top, the device does not work well: it is reflected from the roof surface, after which oxygen rushes to the gases escaping in the upper part of the hole. This disadvantage is typical for all units. To eliminate it, 2-taper solutions are required, connections between themselves by a "bridge".

If the wind has a lateral direction, then the air masses are removed both from below and from above. The vertical orientation of the oxygen facilitates the outflow from the bottom.

We recommend watching a short video about the device

The principle of operation of the device

The operation of the turbo deflector is based on the following principles: using wind energy, the device creates a rarefaction of air in the ventilation shaft, increases traction and draws out polluted air from the room, ventilation duct, and under-roof space.

No matter how the direction and force of the wind change, the rotating head (impeller) always turns in one direction and creates a partial vacuum in the ventilation shaft.

Which increases the intensity of air movement in the pipe, eliminates the appearance of reverse thrust and improves the overall air exchange. In addition, the device prevents precipitation from entering the ventilation channel.

The turbo deflector is designed to improve the efficiency of ventilation ducts and chimneys. It improves the effect of natural ventilation, stabilizing it, prevents air from flowing from one ventilation channel to another and the manifestation of the reverse draft effect.

DIY ventilation deflector

Knowing about the device and the principle of operation of the device, many owners decide to make a ventilation deflector with their own hands. From the point of view of handwritten implementation, the version of Grigorovich's product is beyond competition, so we will consider the implementation of this particular option. The main advantage is that such ventilation works without electricity, all year round.

You should first prepare:

- sheet-type stainless steel, can be replaced with galvanized steel;

- electric drill;

- fixing clamps, bolts, rivets and nuts;

- drawing tool for metal surfaces;

- compass;

- sheet cardboard;

- ruler;

- scissors for metal and paper.

Calculation of device parameters (Grigorovich)

We give you the simplest calculation option, without any formulas:

- the height of the deflector is 1.6 times the diameter of the chimney.

- the width of the diffuser is 1.2 times the diameter of the chimney.

- the width of the cover is equal to two diameters of the chimney.

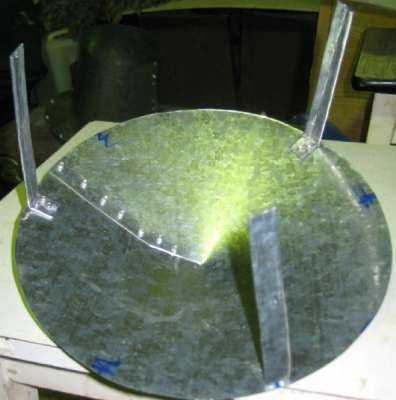

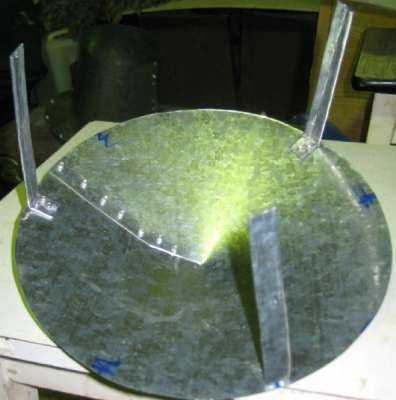

On the basis of the available dimensions and drawings, the individual elements of the deflector are cut out of the cardboard.Certain skills are required to create a rotating device, so it is better to practice on mock-ups and only then proceed to a metal analogue.

Manufacturing of a structure

The patterns must be attached to the metal sheets, and then drawn around with a scribe. Further, the algorithm is simple - we cut out the elements and details of the future structure with metal scissors. The individual parts are connected with rivets and bolts. If the mechanism is active, then it is better to fix the parts by welding.

Layouts of deflectors for ventilation systems made of cardboard

In order to securely fasten the rotary hood, several curved metal strips must be prepared to act as brackets.

We fix the brackets with rivets or bolts

As for the reverse cone, it makes sense to fix it at the umbrella.

Assembled devices

We recommend watching a video on making a TsAGI deflector with your own hands

Installation work

The lower of 2 glasses is installed on the outlet chimney. The top glass is attached to it. For greater stability structure, 2 parts are clamped with a clamp, and they do the same with exhaust holes. The hood is pressed against the prepared brackets. If we are talking about a region where the wind direction often changes, it makes sense to equip the installation with a reverse cone, which will allow the unit to work fully in all wind directions.

So, in this article we examined what a ventilation deflector is. Summing up, we can say - this is a simple and effective device that improves ventilation of objects of any complexity, be it public buildings or residential buildings. A small element increases the performance of the ventilation system by 15-20%, reliably protecting the interior from precipitation, small particles, debris and dust.

Finally, we recommend watching a video comparison of two types of deflectors

Find out how to protect yourself from theft by management companies

How to cover the roof of a house with roofing felt with your own hands

Deflector types

After analyzing or taking a quick glance at the types of deflectors on the market, you can get into a state of slight confusion over the number of solutions available.

From the point of view of the design of the device, it is customary to divide into several types:

- TsAGI - thrust is enhanced due to air and thermal pressure, high-altitude pressure drop. Installed directly into the ventilation duct, which complicates routine inspections and cleaning;

- spherical or round (Volper type);

- Khanzhenkov's solutions in the form of an open plate - the main structural difference lies in an additional wall located around the duct. The hood is in the shape of a plate;

- rotary products (hood, net) - a wind chute that rotates on a special rod. Due to turbulence, the thrust in the channel is enhanced;

- units operating according to the principle described by Grigorovich;

- in the form of a star.

From the point of view of simplicity of design and the possibility of implementation, the unconditional leadership is held by the Grigorovich ventilation device. It consists of several pairs of umbrellas, arranged in one "plate", which is mounted above the channel wall.

Grigorovich's device

In the last 2-3 years, there are a variety of products on sale that do not have a clear belonging to any type: a rotating deflector with spiral blades, an umbrella, bearing units.