The principle of operation of the stabilizer

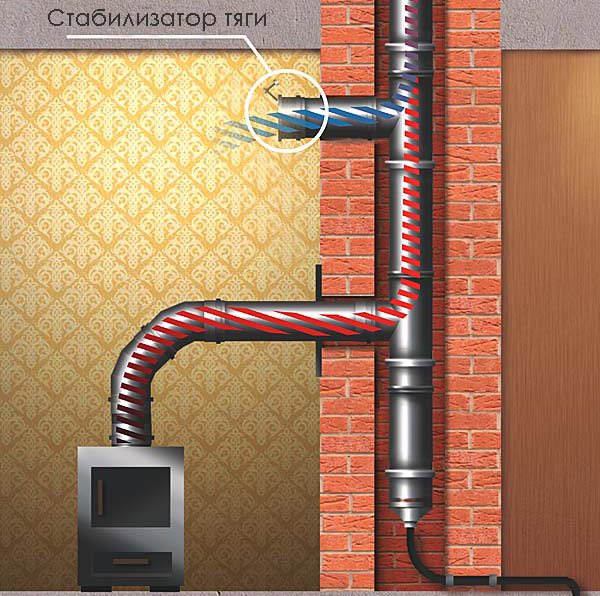

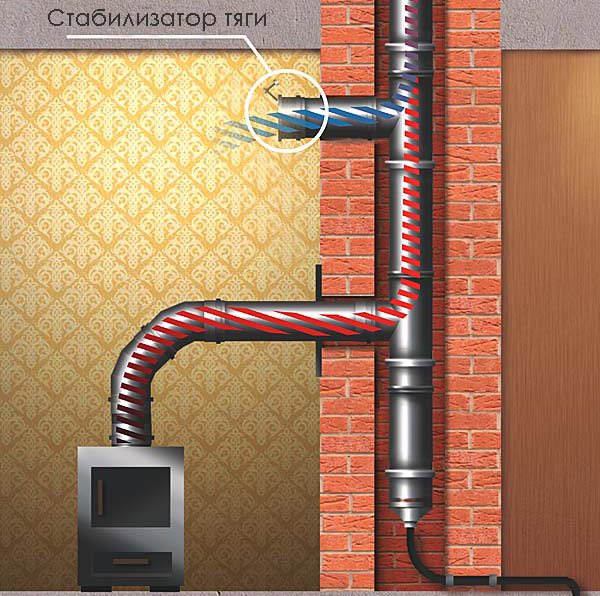

If the thrust force in the system begins to exceed its optimal values, then a valve opens in the regulator, which reduces the pressure and thermal lifting force due to the air coming from the room and mixing with the flue gases. The valve will remain open until the temperature drops and reaches the optimal level. Further, the valve will automatically close, the chimney system will continue to function properly.

This method of maintaining good traction is simple and effective. Fuel in a furnace or boiler will be burned evenly and consumed economically.

The installation of a chimney draft stabilizer provides the following advantages:

- improving the safety of the chimney system;

- reducing the amount of harmful substances emitted into the atmosphere;

- better circulation of air flows when the valve is kept ajar;

- the possibility of functioning both on forced and natural draft;

- uniform combustion of fuel in the boiler, which makes it impossible to overheat the chimney;

- protection against strong gusts of wind;

- no burning smell in the room;

- increase in the service life of the smoke exhaust duct;

- preventing heat loss;

- possibility of installation in modern low-temperature boilers;

- ensuring fuel economy by 15-20%.

Placement options: where to install the chimney draft stabilizer?

The compensator of the intensity of air flows in the chimney pipe is mounted in the same place where the heater is located, or in an adjacent room, where the exhaust from the heat generator to the chimney system passes.

The following methods of regulator placement are practiced:

- the device is introduced into the structure 500 mm above the connection point of the heat generator with the chimney;

- the device is installed at the level of joining the boiler with the flue duct, maintaining a distance of at least 400 mm from the floor surface.

A separate category of stabilizers is a piece of pipe with an expansion in the shape of a fungus, the model is installed on the exhaust of the exhaust duct. The design provides an open area under the "hat" for the flow of outside air. When the temperature of the outgoing flows changes, the sensor, which is installed under the bell, is triggered, as a result of which the heating device is automatically turned off. How it works:

- with a deterioration in traction or the opposite effect in the exhaust system, there is an accumulation of generated gases under the fungus;

- the sensor heats up under the influence of thermal loads;

- a change in the temperature of the sensor causes the fuel supply to the burner to be cut off and the heat generator is switched off.

Mounting of the mushroom regulator is carried out by means of self-tapping screws and nuts. For this, holes are pre-drilled in a dedicated section of the top of the chimney pipe.

DIY chimney draft stabilizer

Advantages and disadvantages

Equipping a heat generating unit with a draft regulator is considered the most effective way to ensure uniform fuel combustion. This is the key to energy conservation and significant savings in combustible resources. Also, among the advantages of installing a pressure stabilizer in the chimney, the following points are noted:

- the efficiency and safety of the system as a whole is ensured, since uniform combustion of the fuel occurs and overheating of the chimney is excluded, which leads to an increase in its service life;

- the efficiency of heating equipment increases, the level of heat loss is leveled, energy savings are up to 15%;

- the possibility of smoke and burning into the room is excluded;

- the level of emission of harmful compounds into the atmosphere is qualitatively reduced.

The equally impressive capabilities of the chimney stabilizer are also impressed with both natural and forced draft.

It is noteworthy that the automatic traction force regulator makes it possible to connect new models of boilers of low-temperature categories to the old chimney system.

This is interesting: Butterflies on the wall in the interior of the apartment - we explain in detail

The device and purpose of the stabilizer

The draft stabilizer is an additional insert on the chimney with a damper, with which it is possible to regulate the intensity of fuel combustion and the force of draft in the pipe. The draft stabilizer is installed only on low-temperature heating equipment, where the maximum heating of the exhaust gases does not exceed 500 degrees.

Purpose of the traction stabilizer:

- reduce the rate of removal of combustion products from the furnace;

- prevent the formation of back draft in the pipe and the throwing of smoke into the room;

- extend the life of the chimney by reducing the emission temperature;

- to increase the fire safety of heating equipment by preventing the emission of sparks and flames from the pipe;

- reduce fuel consumption;

- increase the efficiency of the furnace.

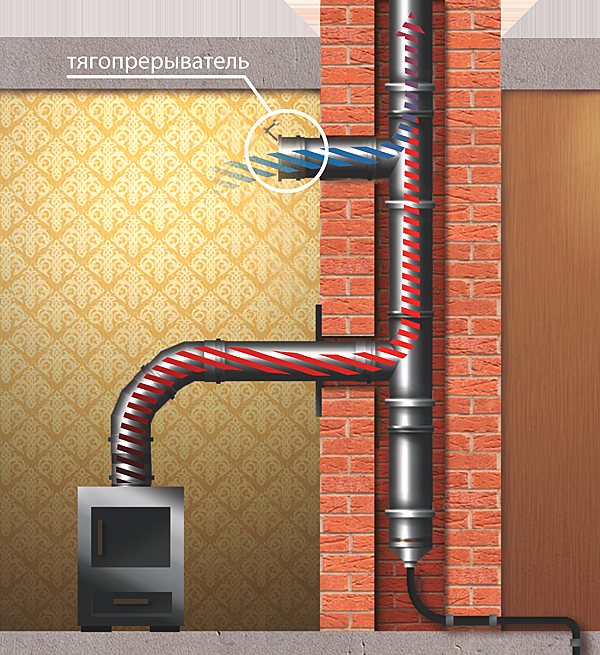

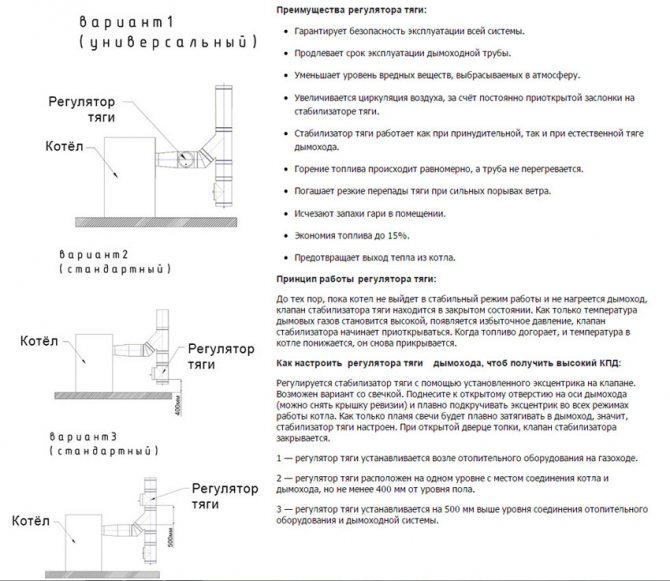

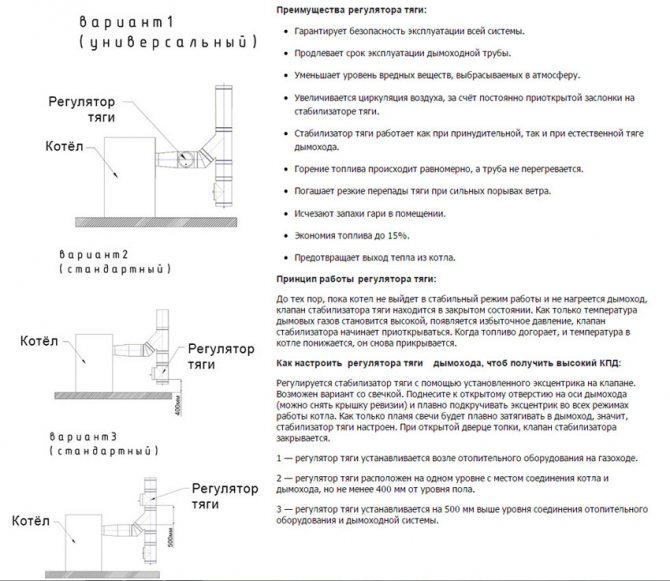

The draft stabilizer is installed in three locations and only in the boiler room:

- The first option is above the furnace outlet on the first vertical pipe segment. The distance from the stabilizer to the horizontal section is 40-60 cm.

- The second option is at the level of the chimney outlet from the stove, but not lower than 40 cm from the floor level.

- The third option is shown in the diagram.

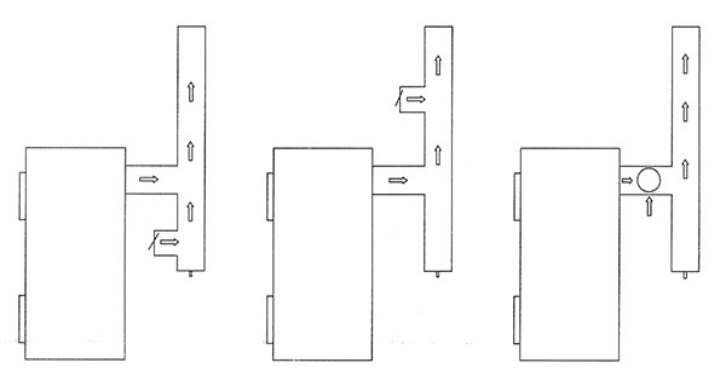

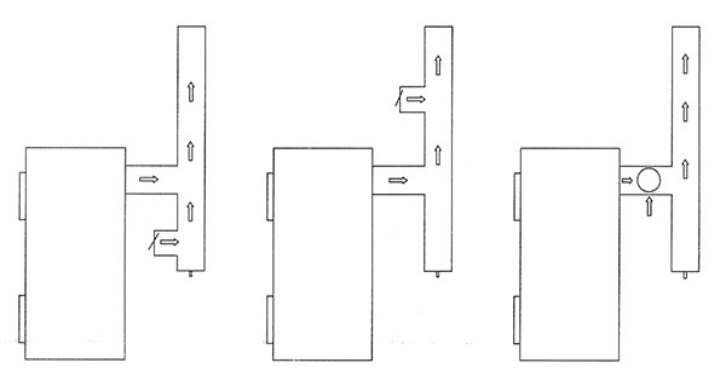

The smoke regulator is an additional entrance to the chimney for air intake. The device is a horizontally oriented branch pipe, one end of which is closed by a vertical movable flap, and the other is built into the chimney. The damper must exactly match the inner diameter of the nozzle so that air does not leak in the closed position.

The damper is the main working part of the draft stabilizer. It can be attached to the case on a movable axis in the upper part, which is typical for factory devices. Homemade dampers are usually attached to the axle through the diameter. To prevent it from tipping inward, clamps are placed at the bottom. The device is mounted on a vertical pipe, without inclination. On a finished sandwich pipe, it is convenient to do this through a conventional tee.

Principle of operation

There are two types of draft regulators - automatic and mechanical, manually controlled.

Reducing the draft in the pipe

The automatic draft stabilizer is a kind of membrane that reacts to changes in the density of smoke in the chimney. When the draft increases, the damper opens and admits an additional flow of cold air into the pipe. This helps to cool the combustion products, the gases become heavier and rise more slowly, the thrust decreases.

It is interesting! The smoke pressure is adjusted very quickly and the damper on the smoke regulator moves back and forth continuously. Since the part is metal, it emits a characteristic knock during operation. In the common people, the traction stabilizer was nicknamed the cracker.

The mechanical smoke regulator is manually adjusted. For this, there is a weight on the lower part of the regulator flap. When making a device with your own hands, it is convenient to use an ordinary bolt as a weight. The stabilizer is adjusted during the period of maximum fuel combustion. By tightening the bolt, the center of gravity of the damper is shifted in the desired direction so that it is kept closed at the required gas pressure in the chimney, and when it rises, it opens.

We recommend that you familiarize yourself with: How to properly install the corrugation on the toilet?

Backdraft prevention

The throw of smoke into the room (back draft) occurs when a sharp and significant decrease in the pressure of the smoke in the chimney. This happens when the weather is windy, when the furnace is opened, when the outside temperature changes. The traction stabilizer is sensitive to these changes and shuts off the cold air flow (the damper closes completely) as soon as this occurs. When the pressure rises above the desired value, the damper opens again.

When traction isn't enough

Methods for determining thrust

If you do not have an anemometer, use one of the popular methods for determining chimney draft:

- Smoke. The most obvious sign of a lack of draft is the presence of a small amount of smoke indoors, a large amount of smoke indicates a high risk of ignition and the risk of food poisoning.

- Flame color. By the color of the flame, you can understand the level of thrust. If the flame inside the stove is white and cracks when burning, then the thrust is very powerful. An orange-red color indicates a lack of traction. If the chimney is made correctly, the flame should have an even golden color that goes into yellow.

- With a match. It is necessary to bring a lighted match to the heater. If the flame deviates to the stove, then there is a draft. If it remains level, then you can be sure that there is a thrust, but of average magnitude. When the flame deviates in the opposite direction from the stove, back draft occurs in the chimney.

- With a mirror. Another way to check chimney draft is to attach a small mirror to the stove. Condensation on the surface of the mirror indicates that it is difficult to remove the smoke.

Attention!

The difference in pressure outside and indoors is the basis for creating a draft inside the chimney. The temperature in a heated room is higher than outside, and, consequently, the pressure it creates inside the room is higher. Hot air, supported from below by colder air, is squeezed out into a zone with a lower pressure, that is, into the atmosphere. When measured in summer, the temperature difference is the least striking, so the thrust will be worse and the measurement results may be low relative to the winter period.

Causes of malfunctions

After making sure that there is not enough draft inside the chimney, it is necessary to identify and correct the possible cause. Professionals say that the most common causes of chimney failure are.

Design error

To make the choice of a chimney pipe, it is necessary to focus on the volume of the firebox. If the size is less than the calculated parameter, then a weak chimney will not allow smoke to leave the room.

Short pipe length

A pipe length of less than 5 m does not have a significant difference between indoor and outdoor pressure, which creates a weak draft.

Incorrect position of the chimney pipe

The master stove-maker advises to lay the chimney vertically, as tight corners keep the smoke inside the chimney, reducing draft.

Long horizontal sections

If horizontal sections cannot be avoided when laying the chimney, make sure that their length does not exceed 100 cm, otherwise, an amplifier will be needed for this.

Getting into the wind support zone

If there is a tall building next to the house, it blocks the chimney from the wind, interfering with the normal functioning of the chimney system.

Weather conditions

Often, a decrease in draft occurs due to a decrease in atmospheric pressure, moisture ingress into the chimney due to rain, fog or snow. But this is not critical, because all these are temporary phenomena.

Signs of correct chimney operation

As you can imagine, the chimney, namely the draft it creates, is the only variable beyond our control. Considering the fact that thrust depends on many factors (wind direction, ambient temperature, atmospheric pressure), it is not surprisingthat the draft exceeds the minimum required rate during most of the heating season. This, in turn, means that a huge amount of heat generated is simply thrown into the air.

During normal operation of the chimney, the speed of movement of gases inside it must comply with the standards specified in the passport of the solid fuel boiler. The yellow color of the flame with golden tongues testifies to the normal operation of the chimney. In the case of excessive draft, the speed of movement of gases inside the pipe increases, as evidenced by the light yellow, close to white, color of the flame, and the hum inside the pipe during the operation of the boiler.

How to make a traction stabilizer with your own hands

To make a traction stabilizer with your own hands, you will need to prepare tools for working with stainless metal and material for making the regulator itself.

To work you will need:

- Welding machine for working with stainless steel. It can be a gas welding or a DC inverter.

- Stainless steel electrodes diameter 4 or argon for gas welding.

- Grinder, cutting and grinding wheel.

Materials for the manufacture of the traction stabilizer:

- Metal sheet made of steel grade AISI 304 (analogue 08X18H10) or AISI 321 (analogue 08X18H10T). Metal thickness 10 mm.

- Bolts, nuts, metal rod with a diameter of 10 mm - all made of stainless, heat-resistant steel.

The installation diagram is as follows:

- It is required to weld a branch pipe from a sheet of metal - the regulator body. Calculate the diameter based on the diameter of your chimney. You will need to put the stabilizer on a tee or branch pipe extending from the main pipe. Therefore, the inside diameter of the stabilizer must match the outside diameter of the tee. Usually it is 115 mm, but it can be more.

- The metal for the body should be cut with the calculation of an overlap welding with a seam width of 1 cm.

- The cut sheet is rolled and welded. The seam is smoothed to smoothness on the outside and inside.

- Roll the boundary barrier at a distance of 40 mm from the edge at the end of the body. It will serve as a stopper when mounting the device on a pipe.

- On the other end of the body in the lower part, weld stoppers to prevent the damper from tipping inward. In the upper part or in the middle (depending on the shape of the damper), fasteners for the pivot shaft are welded.

- A shutter is cut out of metal. Its size is equal to the inside diameter of the outlet of your enclosure, or matches the contours of the outlet if you decide to reduce it.

- A hole is drilled in the lower part of the damper for the adjusting bolt.

- In the middle (for a symmetrical damper) or in the upper part (for an expanding form), a pivot shaft is welded.

- Install the flap on the body.

- Install a draft stabilizer on the pipe.

When installing the stabilizer on the pipe, coat the points of contact of the pipes with a heat-resistant sealant. This will make the connection more durable and tight.

What is a traction stabilizer and why is it needed

The chimney does not always work as it should. Its long length can cause too much thrust (resulting in a drop in pressure). On the contrary, during strong winds, pressure surges occur, and when firing up, the thrust also increases.

Sharp and short-term surges in draft cannot be controlled, since they harm the operation of heating equipment, for example, they knock down flames in gas boilers.

Important! Frequent repetitions of ignition damage the equipment.

Strong draft leads to a decrease in the efficiency of the heating unit, since some of the heat is dissipated with hot gases instead of heating the room. Worse, this kind of pulling force brings discomfort to the residents of the house.

To get rid of this kind of problem, engineers have invented a draft stabilizer that is mounted in the bottom of the chimney. Its main task is to equalize the pressure and reduce the pulling force.

Important! The draft stabilizer is initially installed in the chimneys of furnaces and boilers for long and ultra-long burning.

Let us now tell you more about it.

Draft regulator models

Today on the market there is a wide variety of models of chimney draft regulators produced by various manufacturers.

Let's consider the most popular and demanded ones:

- RCO. Models in this series are fixed with clamping clamps and only to a round pipe. They have found their application for chimneys with a circular cross-section along the pipe axis. The chimney draft stabilizer is installed at the very end of the pipe. Given the fact that modern chimneys usually have a rounded shape of pipes, such regulators have gained wide popularity. Such devices are the easiest to install.

- RCR. This stabilizer is installed directly on the chimney and is fixed by means of special clamps with the possibility of regulation in the range of 120-200 mm and is installed at the boiler outlet. The harsh domestic climate presupposes the use of such regulators for chimneys made of ceramics, steel and asbestos. Chimneys with a draft regulator in the range of 10-35 Pa cannot boast of high quality, however, if necessary, they can be installed.

Chimney draft regulator RCR series with adjustable clamp

RCP. With a draft regulator in the range of 10-35 Pa. Installation of such a device is carried out by overlaying and fixing the regulator to a flat surface. The chimney draft regulator for fastening is provided with hidden holes in each corner.

Chimney draft regulator RCP series for surface mounting

RCW. This regulator with a draft regulation range of 10-32 Pa, has established itself as a good draft regulator in ovens, boilers, fireplaces. For the manufacture of the case, stainless steel is used, thanks to this you can fix the device with glue, a special solution. You can also use the release springs and fix it to the ventilation grill.

Chimney draft regulator RCW series for brick chimneys

Summing up all of the above, it is worth noting once again that the chimney draft regulator is a very important element of the heating unit, which directly affects the functioning of the entire heating system.

Ways to increase chimney draft

The purpose of the draft regulator is to extinguish excessive vacuum in the chimney. The stabilizer cannot increase traction. What to do when the thrust is clearly insufficient?

To increase traction, do the following:

- They check if the chimney channel is clogged with soot, clean it.

- Check if there is air access to the room or air supply from the street to the heating unit firebox. If necessary, open a window or conduct a pipe to take in clean air from the street.

- Analyze whether the pipe is sufficiently insulated, whether the insulation is wet. In the case of modern ceramic or sandwich pipes, insulation can be considered sufficient; when insulating steel pipes with your own hands, unpleasant surprises are possible. It is also desirable to insulate traditional brick pipes.

- Find out if there is a baffle on the top of the pipe. Often, installing a deflector will solve the problem.

If all searches did not lead to a solution to the problem, it is worth inviting an experienced heating engineer - the safety of the family is above all.

If you have changed the heating unit to a more modern one (or moved the stove or fireplace), then you must:

- Calculate the minimum length and cross-sectional area of the hog, depending on the power of the heater (see my article on calculating the chimney).

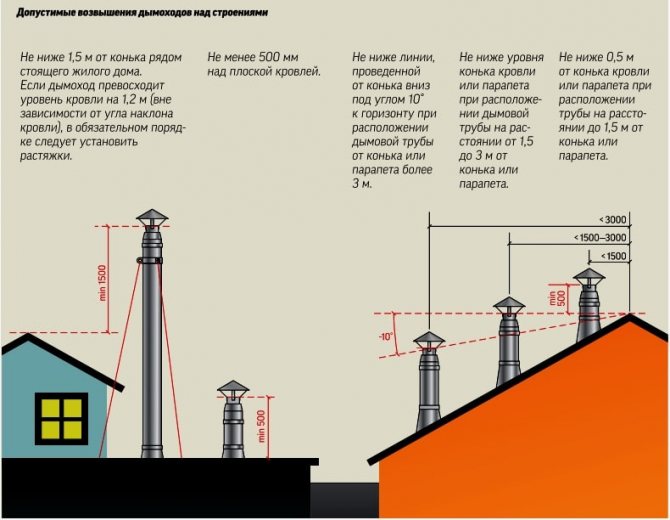

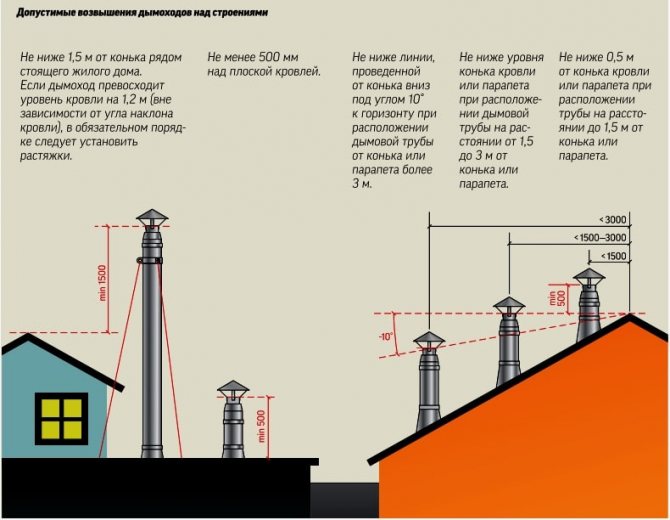

- Consider the required pipe height, depending on the location relative to the ridge and the wind support zone of tall buildings and large trees.

- If the chimney is of insufficient height and cross-sectional area, then either build it up or mount a smoke exhauster - a special fan.It is installed on the pipe head.

- If the old pipe has a cross section that is much larger than the calculated one, this problem is eliminated by using a gate or installing an insert. If the pipe is too long, a gate can also be used.

When replacing an old stove or fireplace with a modern boiler, the pipe will probably have to be modernized, since modern boilers have high efficiency, aggressive condensate and a low temperature of exhaust gases. Even modern solid fuel units have a lower smoke temperature than old wood-burning stoves.