Furnace valve design

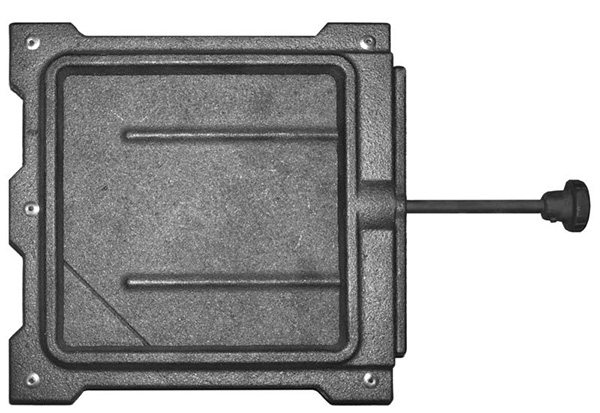

The furnace valve is a three-piece structure:

- Cast iron body - frames (sometimes steel is used instead of cast iron) with side slots.

- A shut-off part in the form of a panel damper, thanks to the movement along the grooves of which, the sealing of the chimney is controlled.

- The control part is on a panel damper in the form of a handle. This makes it easy to manually operate the panel damper.

The shapes of the valves must completely match the shape of the chimney, according to this parameter, they are rectangular, square, round.

A few words about rectangular valves

The rectangular valve can be of various sizes from the smallest to the largest, when the valve length reaches 600 mm. Large options are usually suitable for Russian stove chimneys, fireplaces, barbecues, etc. The design task is the same - to block the flow in the ducts.

The smallest stove valve has dimensions of 13x13 cm, and the largest is determined according to the individual requirements of the consumer. The most popular size for these structures is 26 × 13 cm, since this is the size of the chimney of an ordinary Russian stove.

Thanks to square or rectangular stove valves, it is possible not only to stop the air exchange in the chimney, but also to adjust the intensity of the fire by changing the draft in the chimney and the throughput. For this purpose, they simply do not close the damper completely, and then gradually pull the handle towards themselves, thereby controlling uniform combustion in the firebox.

Gate specifications

For the manufacture of gate valves for stoves and fireplaces, stainless steel is most often used - steel, the least susceptible to corrosive processes. The metal should be one millimeter thick.

The surface of the part is sanded to an absolute smoothness, which has no defects, so that it can be easily cleaned of the deposits of dirt and soot that accumulate over time. This circumstance contributes to the appearance of good draft in the chimney pipe, since there is no resistance to the exit of gas particles.

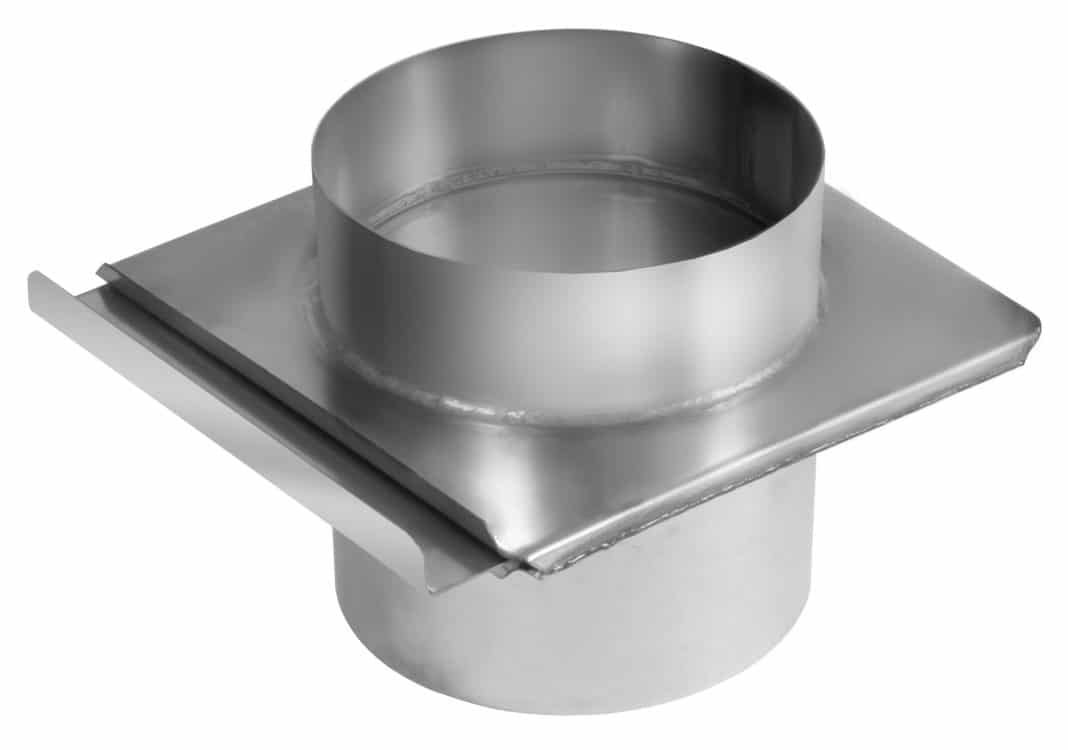

Round stove valve or view

A round stove valve is otherwise called a view. This is a special valve with a slightly different design than the conventional version.

The view consists of the following parts:

- Housings, in the form of a plate, which can be round or square with a round hole.

- A shut-off element in the form of a disc that closes the opening and closes the air exchange in the pipe.

- The control part, in the form of a conventional handle in the center of the disc valve.

It is impossible to use a view to control air exchange, since you need to remove the damper from the throughput manually, which is practically impossible in a heated stove, in addition to exhaust gases. The design is used exclusively as a shut-off element, often as an additional damper for a full-fledged result before igniting the furnace and after it has died out.

It is recommended to install both types of cast iron stove valves far from the firebox.

Gate for a brick chimney.

In fact, it would be more correct to call this node not a gate, but a gate valve

chimney.

For some reason, many people think that large valves should be installed in the chimney.

Then this huge, oversized tongue sticks out on the floor of the room and spoils the view of the entire stove.

Here I want to tell you how to properly install a valve of the right size in a brick chimney.

Installation of a chimney valve is a responsible and important event.

The efficiency of a heat-consuming furnace depends on the quality of the installation and the tightness of the valve.

After a heat-absorbing stove is heated, its chimney must be hermetically closed by a valve.

If the chimney damper is not airtight, the heat accumulated inside the stove will be lost through it, the stove will cool down faster.

According to modern fire regulations, a small hole should be left in the valve for the discharge of carbon monoxide gases.

A small amount of heat is lost through this hole, but safety is still more important.

The gate is available in steel and cast iron.

Steel chimney damper.

Steel dampers are mainly used for steel chimneys.

Steel valves can jam due to high thermal expansion.

Cast iron chimney damper.

For brick chimneys, cast iron chimney valves are more often used.

The valve should be selected in accordance with the section of the chimney.

The most common sizes of brick chimneys.

- The chimney is four - in the section of the chimney there are 4 bricks, the size of the channel of such a chimney is 130 * 130 mm.

- Pyaterik brick chimney - 5 bricks in the chimney section, channel size 260 * 130 mm.

- Brick chimney of sixes - 6 bricks in the chimney section, channel size 260 * 260 mm.

For brick chimneys, simple tongue and rotary valves can also be used.

In my opinion, cast iron rotary chimney valves are better than straight ones.

Butterfly valves are more modern and convenient, but they are much more expensive than sliding valves with a tongue.

I will tell you about the installation of a rotary valve in a brick chimney later.

How the stove valve closes, operating rules

The operation of a stove valve is quite simple in itself, but it definitely comes with some risks to human health. If you close the structure in a still burning stove or if the fuel has not completely burned out, then exhaust products can enter the room, poisoning the air.

Therefore, it is extremely reasonable to use a valve that allows you to save heat in the furnace longer, that is, you should close the structure on time. It is known that due to the cast-iron valve, the heat in the furnace and, accordingly, in the room remains for a long time. The use of such fuels as coal increases the temperature inside the furnace by about 60-700C.

Sometimes, in order to save fuel, the valve is closed earlier, before its complete combustion, which is highly undesirable. After all, human health and life are higher than any savings. Closing the damper earlier than necessary increases the risk of carbon monoxide poisoning. Carbon monoxide is a combustion product that is poisonous. Therefore, in order to avoid such situations, you need to use the chimney valve correctly, following some rules:

- Before closing, it is imperative to stir up the coals to avoid the presence of completely unburned pieces.

- At the initial attenuation of the coal, when the blue fire is no longer visible on the surface, the shutter must be slightly closed, but it is not recommended to close it completely. After all, the presence of coals does not mean that they are completely burnt out. If there is a need to seal the pipe, then this should be done after the coal has completely burned out.

- Next, you need to open the blower so that traction is formed, and the remaining coals completely turned into ash and ash.

Functionality

To understand why you need a gate in a chimney system, you need to study the scope of the device. It is used in pipeline systems where it acts as shut-off valves. The gate serves as a limiter for the flow of liquid, free-flowing mixtures. From the scientific point of view, such a device is called "overhead".

By installing the latch in the system providing the ventilation process, the device is used as a regulator of the air mass flow rate.By moving the damper horizontally, the amount of air consumption changes, which overcomes an obstacle in the form of a structure. Thus, a partial or complete partition is created in the path of movement of air flows. The device is called "regulating".

In the chimney system, the slide device is installed as a regulating element that provides partial or complete blocking of the smoke channel. This reduces the loss of heat generated inside the steam room after the firebox. The gate provides adjustment of the traction force, since it acts as a damper in the direction of smoke movement.

With a decrease in the cross-section of the chimney as a result of the movement of the damper deeper into the structure, the pulling force decreases. With full overlap, it stops completely. When the vane element completely opens the channel for the movement of smoke, the thrust increases, the combustion process is better, the room heats up faster.

To understand the purpose of this part for a chimney structure, you need to figure out what a gate is in a furnace. The damper provides a change in the thrust force in the unit by adjusting the combustion of fuel in the furnace.

This element has an important advantage - it has a low resistance against the remaining gas bubbles, which must be removed outside the room. When the chimney is inoperative, then the damper is completely closed.

Since the gate is the main traction regulator inside the house, the intensity of fuel combustion depends on it. To reduce the draft and the intensity of the flame in the firebox, you just need to close the damper. To increase the fire, the opposite actions are carried out.

Modern gate models can be installed in both single-walled and double-walled boilers. If the fireplace or stove is not in use, then at this time the chimney gate valve must be completely closed. Most often, craftsmen install a damper on the first meter of the chimney, since this area is not insulated.

This device regulates traction

The main functionality of the damper includes:

- Partial blocking of the chimney duct.

- Quality traction control.

- Control over the intensity of combustion of the flame in the furnace.

The need for valves and views in the chimney

The damper is an integral part of the stove, which closes the chimney after firing it. In combined furnaces, such as cooking and heating, this design allows you to switch between the flue ducts.

The damper is usually installed in the chimney when laying the stove, securing it with several rows of bricks. Often, two valves are installed, especially in rooms in cold climatic conditions, when temperature differences are more significant, which leads to rapid heat transfer.

The view is installed in the chimney in the same way, but it is usually used in Russian stoves. Such a valve is closed from the outside with a special door. If it is necessary to ventilate and cool the oven, all this can be organized in a closed view door.

The design of the kiln view eliminates the installation of an additional valve, because it completely copes with the sealing of the chimney. When using a second valve, it is installed below the view.

Types of gate valves

The design of devices for adjusting the thrust supply to the fuel system is made of two types:

- Horizontal retractable flap. Such a gate is installed mainly in brick chimneys. The fixture has an inner plate that attaches to the inside of the frame. Due to its extension, an increase or decrease in the area of the chimney section is carried out. The product is distinguished by the simplicity of contraction and installation.To prevent the shutter from completely blocking the chimney when closed, several small holes are made in the platinum for fire safety.

- Rotary gate valve. A design feature is the fastening of a metal plate on a rotating axis, which is installed inside the chimney. Such a butterfly valve will be distinguished by its ease of use. Fixes it in the device in such a way that the plate rotates freely around the axis. The mechanism works under the influence of air masses, therefore, manual control is not required. The rotating mechanism has a disc that is easy to replace.

Rotary chimney damper

The butterfly valve is mainly used for stakes fueled by gas or other liquid fuels. In such cases, it prevents atmospheric precipitation from entering the chimney. For bath rooms, the installation of a throttle structure is impractical, since even in a closed form, the plate passes steam, and it is quite difficult to clean such a structure. Basically, the installation of a rotary damper is carried out when it is not possible to install a retractable gate.

How to install a damper on a chimney

The valve is usually installed during the construction and assembly of the stove. The process is carried out in several stages:

- Laying bricks around the fittings in a selected location at a specific stage in the construction of the chimney. In this case, the dimensions of the hole left must completely coincide with the dimensions of the valve. Often, a wire is installed in the corners of the body, mounting it into the body of the masonry.

- Installation of the valve frame with fixing the upper part with cement mortar.

- Application of cement mortar along the perimeter of the frame and a wire about 1 cm thick, followed by laying a row of bricks.

- Installation of a damper in the chimney.

A conventional cast-iron stove gate valve is locked by a shield shutter, which is mounted in the frame body through a slot. It can also be installed after the frame has been installed. The flap at the view is closed manually, therefore, a special door must be installed above the body of such a design, with which it will be possible to control the lid.

After this, the chimney continues to be laid accordingly.

DIY making

If desired, a gate of any type can be constructed with your own hands. For work, you need a welding machine and a grinder. Initially, you need to take accurate measurements of the pipe so that the slide valve does not fit tightly into the pipe. If the requirement is not observed, there is a risk of jamming the damper when the pipe heats up. Too much clearance makes it difficult to adjust the pulling force.

Materials used in the manufacture of a rotary chimney gate valve:

- stainless steel pipe blanks with an inner diameter of 6 mm;

- nails;

- stainless steel sheet 2 mm wide;

- bolts with a diameter of 8 mm.

Manufacturing:

- After measuring the inner diameter of the pipe, transfer the dimensions to the steel sheet.

- Cut out circles, sand.

- Fit the workpiece to the shutter and cut off the desired section.

- Drill holes for threads.

- Weld the shutters to the pipe.

- Make holes in the chimney, install dampers.

For the manufacture of a homemade slide-type gate, you will need a gate valve blank, a guide frame. The sliding element is pre-cut to the required dimensions, corresponding to the dimensions of the chimney. Bend one side to facilitate movement during operation. Grind. Cut out the plate for the sliding element. Connect the parts by welding and fasten to the pipe.

Qualified specialists always focus on the fact that even a novice master can make a rotary and retractable gate. Indeed, in order for the finished product to perfectly cope with its main task, you need to correctly make all the necessary measurements.If the finished damper fits tightly into the chimney, then over time it can jam, as it will be exposed to high temperatures. And when there is a large gap between the valve and the pipe, it will be difficult to adjust the thrust intensity during operation.

We offer you to familiarize yourself with: Steam room (78 photos): how to properly make a steam room in a bath with your own hands, sizes and step-by-step instructions

For the manufacture of this type of gate, you need to use a steel corner 30x30 mm, as well as durable sheet steel, the thickness of which is at least 1.5 millimeters. The manufacturing process itself consists of several main stages, which must be implemented in a strict sequence:

- Initially, you need to measure the inside of the chimney. This is done in order to prevent mistakes during the manufacture of the frame from the corner, which is fixed by the welding machine.

- On one side of the frame, it is necessary to drill a small hole (7-8 mm in diameter) exactly in the center. It is useful for the swivel axle.

- A similar hole must be made on the other side of the frame.

- The shutter plate must be cut from the steel sheet. This detail must fully correspond to the internal dimensions of the manufactured frame.

- To make a guiding axis, it is necessary to take a piece of wire with a diameter of 9 mm and a length that will exceed the size of the frame itself by 7 cm.On one side of the wire, it is necessary to cut a thread (a die is best for this task).

- The already finished axle is carefully threaded into the holes on the frame and fixed with a nut.

- All slices on the plate are sanded and inserted into the frame.

- At this point, the technician must weld the axle exactly to the center of the plate.

- It remains only to make a comfortable handle for the guide from quality materials at hand.

Modern dampers include the valve itself, as well as a special guide frame. That is why, before starting work, the master must measure the internal section of a pipe or brick chimney. According to the available measurements, a neat rectangle is cut out of sheet steel (thickness 5 mm). A small longitudinal fold is made on one side, the width of which should not exceed 30 mm.

These manipulations are needed in order for the finished flap to be conveniently pulled out. Each cut must be sanded, due to which the dimensions of the product are immediately reduced by 2 mm on each side. Such actions of the master will ensure the free movement of the damper inside the chimney.

When the gate is made for a brick fireplace, the frame itself can be made from thick steel wire, the diameter of which is within 6 mm. During this procedure, the metal workpiece is simply bent in the shape of the letter P in strict accordance with the available measurements.

If the chimney has a rectangular shape and is made of steel, then it is better to make the frame from a metal strip 2 mm thick and up to 35 mm wide. The prepared strip is bent lengthwise, leaving a neat gap along the thickness of the plate. Only then can small cuts be made in two places at an angle of 45 ° in order to give the workpiece a U-shape. All gaps in the cuts must be butt welded.

To connect the ends of a homemade damper, you need to use two pieces of metal, which should be positioned so that the gate leaf passes freely between them. At the end of all these manipulations, the master should have a rectangular frame with grooves for the shutter.

To make a valve in a round pipe, you need to take two identical metal sheets 2 mm thick. Round holes are cut in the center in accordance with the diameter of the chimney. The valve plate must be manufactured separately. After that, the sheets are connected to each other using a welding machine.

It is necessary to weld only three sides around the perimeter so that the holes of the finished gate on the pipe match exactly. A gap of 5 mm must be left between the top and bottom sheets. At this point, the manufacturing process of the gate can be considered completed, since the master only needs to insert the gate valve and fix the finished product on the chimney.

Summer damper and its meaning

Often in furnaces there is an element such as a summer damper, which has a specific purpose. The summer damper is used in fireplaces or Russian stoves that are heated irregularly or periodically at long intervals. For example, in stoves in a country or country house, when it is heated only in the summer season.

The summer valve has some design features and a special arrangement, which makes the heating process much easier after prolonged cooling, even in the most severe weather conditions.

The operation of this structure is carried out in the following way: The stove must be flooded with an open summer valve, then, when the flame in the firebox flares up and some of the firewood is completely burned out, the valve should be closed to prevent heat loss.

Stoves with a summer damper installed in them have a number of advantages, for example, by pushing the summer damper and blower, you can use the stove at any time of the year as a classic open fireplace. With the help of the damper, you can easily get rid of excess heat in the room. However, it should be remembered that it is recommended to heat such a stove no more than 20 minutes, since the temperature can rise a lot, which is a feature of such fireplaces.

Purpose and characteristics

This device allows you to control and regulate the draft into the smoke exhaust system. Translated from German,

gate ("schieber) means a part that is made of a specific metal.

Good traction is one of the key conditions for the proper operation of the fuel system. With good draft, the fuel burns almost completely, providing an efficient and economical heating process. If the draft is poor, then smoke and fire may occur in the room.

To eliminate these dangerous and unpleasant moments, a gate damper is installed in the chimney system. It prevents the division of gas bubbles, which should not undergo separation.

It is recommended to install a gate damper when heating with gas, coal, solid fuel.