Design features of Russian stoves

They consist of three main elements:

- firebox;

- chimney;

- pipes.

The combustion compartment, an obligatory part of any unit, is a compartment designed for solid fuels. A blower is installed under the firebox, which provides the supply of oxygen necessary to maintain the combustion process, and in addition, ash from the burnt wood accumulates in it.

The purpose of the chimney is to remove smoke and excess heat energy collected in the firebox of the Russian stove. During its construction, several turns in a zigzag shape are laid out inside in order to heat one of the walls of the house. The surface inside the chimney should be smooth so that it is less covered with soot and dust.

With the help of a pipe, smoke is removed to the outside to the atmosphere. It should be properly insulated, as it heats up to a high temperature.

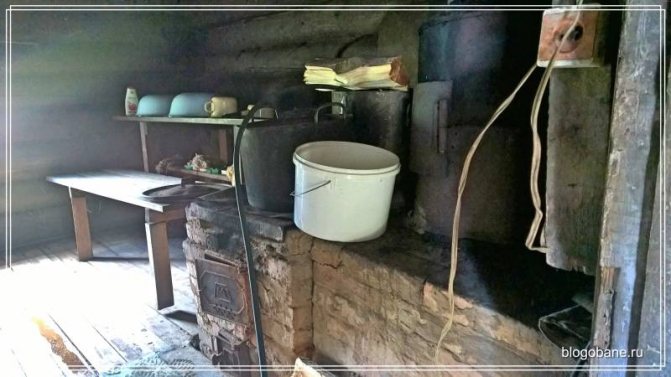

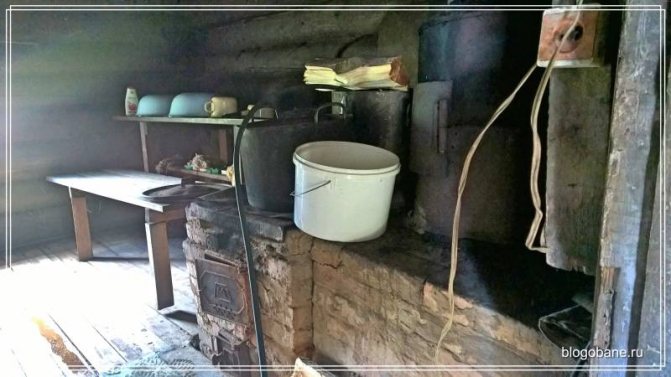

Also, at the very bottom of the Russian stove, there is a baking oven or baking oven - a special compartment for storing a stock of firewood. The pad was often used for crockery. The six is intended for the convenience of cooking.

Stoves, equipped in the unit, improve heat transfer and dry fruit blanks. The front part of the structure is called cheeks, and firewood is laid through the stove mouth. The crucible is the place where fuel is burned. The smoke is led to the chimney by the highlighter. The overlap is used as a warm stove bench.

How to heat a brick oven

Stone stoves are massive, require careful maintenance, long heating, a lot of wood and careful attention. A brick oven is heated much longer than a metal one. The brick heats up for a long time, after four hours of continuous heating, the walls of the stove are barely warm.

But, after the entire prepared supply of firewood has been heated, the water in the boiler has heated up and the bath is kept warm, the most magical moment comes! The firewood has burned out long ago, the stove is closed, and the brick walls begin to wake up and intensely give off the accumulated heat!

The longer the brick oven stands in the bath, the hotter it becomes in the bath kingdom. The sauna with a stone stove is warm the next day! In winter, a stone stove needs to be heated for a rather long time, about 5-6 hours, and left to stand for at least one and a half hours.

The correct kindling of the stove

After familiarizing yourself with the design features, you should figure out how to melt a Russian stove correctly. The rate at which the fuel burns is largely dependent on the delta between the temperature outside the building and inside it. If this value is small, then the traction force will be weak and it will be more difficult to drown.

The draft promotes the flow of oxygen to the hearth and the extraction of smoke from it. To make it easier to light the stove, the walls of the pipe are warmed by burning flammable materials - paper, birch bark. Next, you should put dry firewood in the crucible and firebox and kindle them.

If there is no urgent need to heat the unit, it is advisable to wait for the temperature regime to change. The fact is that, regardless of the time of year, it always gets colder in the evening and the traction force should be restored.

True, even after changing the temperature outside, sometimes the stove still cannot be melted and then you need to stop trying to light it up until the reason for what is happening is clarified. Possible, chimney cleaning required. Experienced stove-makers advise to heat the unit gradually, especially if it is rarely used. Since it has rather thick walls, with sharp heating to high parameters, cracks can go along them.

Furnace preparation

When you decide on the choice of sauna fuel, it is time to prepare the stove itself for the fire dance.Things are not so simple here. In order to quickly light up the stove, good draft is needed. A fire will not burn without good oxygen supply.

For this reason, it is necessary to thoroughly clean the mouth of the furnace and the blower from combustion products - ash and coals. The grate on which the wood is stacked must be clean, its slots must not be clogged.

When the stove is prepared, water is drawn into the boiler and barrels, the stove valve is wide open - the most exciting moment comes. You can start to light up the stove!

I really love this mysterious process of making fire, when a tiny scarlet tongue of flame becomes a greedy red flower. He jumps from log to log, filling the entire mouth of the stove with himself.

Methods for kindling

Before stoking a Russian stove with wood, you must first free its inner space from the remnants of fuel, kitchen utensils, and the firebox from ash. It is necessary to clean the blower and the furnace. After that, start kindling. To keep the room at a comfortable temperature, you need to heat the stove at least once a day.

Most often, two main options for the firebox are used:

- Firewood is burned in the firebox.

- The kindling is carried out on the hearth.

The most economical way is when the fuel is burned in the firebox chamber. In this case, the heating structure is completely warmed up. Firewood is placed in the combustion chamber as tightly as possible, filling the entire space with them.

In the future, they are laid after the previous fuel raw materials have burned out to coals. But first, the firewood is moved away to prevent the sparks from crushing and damping. The second fuel fill, like all subsequent ones, is made one third less than the first.

When firing, the mouth flap is well closed. The stove latch is slightly opened, and the ventilation valve is closed. This procedure is performed to improve traction. When the stove has not yet had time to warm up, a slight return of smoke may occur during kindling. To eliminate such a problem, the ventilation flap is pushed back by 2-3 centimeters. It must be returned to its original position after a while.

There are several rules on how to properly heat a Russian stove with wood. In order for the combustion process to be stable, it is necessary to provide a constant supply of oxygen. To do this, the fuel must be periodically agitated with a poker, as a result of which the air reaches the lowest layers, and the degree of firewood burning increases.

Before opening the oven door, the blower is by all means closed, which helps to temporarily pacify the flame a little with close contact with it and reduce smoke.

You can light a fire in the hearth using the lower or upper method. The easiest option to implement is the first. In this case, flammable materials are placed under the firewood masonry in the center. This way you can quickly and easily ignite any fuel. But this is the disadvantage of this method, since oxygen burns out quickly, and the stove ignites unevenly.

It is better to use the upper ignition option. It consists in the fact that the starting material is placed in the upper part of the stack of firewood. At the same time, it is possible to perform uniform heating of the unit and achieve a smooth spread of fire throughout the masonry. All this allows to reduce the load on the firebox. During combustion, the blower door should be kept open 7 centimeters.

Another method is called kindling "in Russian", it is performed on the hearth. For this, the valve in the furnace is closed and at the same time the ventilation is kept open. The wood, which must be dry, is placed on the front edge of the well-shaped furnace, then ignited and slowly moved to its center.

This option is used when there is no need to quickly heat the room or if you need to use the stove as a fireplace.When using this method, the combustion process is closely monitored so that sparks and coals do not fall out of the unit.

On average, the heating time should be two hours to ensure long-term operation of the furnace and prevent cracking of its walls. After the completion of the firebox, the mouth and valves are invariably closed, as a result of which food is cooked faster and the house cools down more slowly.

Correctly selected method of stowing fuel in the hearth promotes quick ignition of the unit. Usually, firewood is laid out in parallel in the form of a well or a hut. Parallel stacking means that the logs are placed straight, stacked one on top of the other.

To ensure free access of oxygen, gaps are created in the masonry in a checkerboard pattern. Firewood is laid out in a "hut" in a circular manner and then tilted to the center, so that the result is a closed cone. With this option, the flame immediately engulfs the wood along the length, and they burn out faster.

It is believed that when choosing a method of how to properly heat a Russian stove, it is better to stop at using a parallel fuel filling.

Principles and rules of kindling

The rules for kindling the furnace have been passed down from generation to generation. Over the centuries, the technology has been honed, and today it has reached perfection. Many procedures for operating the stove formed the basis for the maintenance of modern heating equipment, for example, pellet boilers.

Preparatory work

Before melting the furnace for the first time after the end of construction work, you will need to wait until the solution is completely dry. The first stage is an external examination, while paying attention to the following points:

- Matching the thickness of the seams;

- the correctness of the brick dressing;

- correspondence of the verticality of the corners;

- ensuring the accuracy of the installation of tiles.

At the same time, deviations are allowed: for masonry without facing - up to 5.0 mm, and up to 2.0 mm for facing with tiles, vertical - no more than 2.0 mm per 1.0 m of height.

Next, check the density of the masonry. Typically, a material with a high emission of black smoke is used for this. A test furnace is carried out for several days in a row with a normal load of firewood. During the operation of the furnace, not only the uniformity of heating along the outer walls is determined, but also the uniformity of cooling. Next, the structure is checked for cracks and, if detected, they are eliminated in a timely manner.

Firewood bookmark

Before laying the wood, the ash chamber is cleaned to allow the blast air to flow without resistance through the blower to the flame. The stove is kindled only with dry wood.

After cleaning the furnace from ash residues, they begin to lay the logs in the firebox. This can be done in two ways: • a hut with a cone for a large furnace space; • in parallel with the observance of gaps from 8 to 10 cm.

Firewood is placed in the center of the furnace space or closer to the door until about 2/3 of the furnace is full. The top of the combustion chamber must remain free of at least 18–25 cm. Firewood must not be stacked against the rear wall.

Flame ignition methods

Next, they push the view to the desired level and a little the blower door. Use matches to light up paper in front of a pile of firewood. After lighting the firewood, close the furnace door. With uniform burning, cover the view. The combustion process is regulated by opening / closing the view and the blower.

The firebox door must always be closed. Open it only if you need to stir coals with a poker or toss up firewood.

Combustion control:

- White flames and noise in the smoke channels indicate a large draft, it is reduced by the blower door.

- A red flame with dark smoke from the chimney indicates low thrust and it is required to open the blower.

- The yellow color of the flame indicates the normal combustion process.

Nuances of fuel choice

A home stove is actually a universal heating device, since it can operate on different types of fuel: wood, coal, peat.In modern conditions, fuel manufacturers also offer new types of so-called eurowood and different versions of pressed briquettes.

The traditional fuel for the stove is birch, which has a high net calorific value. Its logs completely burn out, do not shoot or spark. The only drawback of birch is that if it is placed in the furnace above the norm, a strong fire can lead to a fire.

In terms of calorific value, the best fuel is oak, which burns for a long time and generates a lot of heat. Its net calorific value is almost 20% higher than that of birch. But since the price of oak is also much higher, before choosing, you need to make a simple calculation that it will be more profitable for heating in a given climatic region.

Oak firewood

Pine and spruce firewood has a heat transfer even lower than that of birch and oak. For the heating season, they are purchased more by 20-30%. The presence of resin in the logs causes not only a strong crackle, they also shoot, and can throw pieces of ash on the floor, if it is wooden, then a fire can occur. Therefore, when using this type of firewood, it is recommended to place a metal sheet in front of the stove.

Aspen and alder firewood is highly valued because, in addition to heat, they clean the chimney from soot, therefore, by right, they are still considered "royal" firewood.

Eurodrova showed itself well when firing a Russian stove, with a complete combustion process and a low ash yield. Their price is still high, equal to the cost of coal, but their calorific value is approximately the same.

Compliance with safety

Heating a home with a Russian stove means that property owners have to constantly interact with the fire. If you do not adhere to fire safety measures, the consequences can be the most negative.

You need to follow simple rules governing how to cook in a Russian oven, how to heat it, and enjoy the benefits that it has:

- It is necessary to light the fire with flammable materials and do not use flammable liquids such as gasoline.

- When operating the unit, you need to use wood, and household waste and polymer materials can make the chimney unusable.

- The firewood must be dry, otherwise heat is lost to dry it when burning. To do this, the required amount of fuel is harvested in advance for several days, storing them in the furnace.

- Keep the oven lid tightly closed to prevent fires, hot coals and sparks.

- Glossy printed materials should not be burned - the paint on them interferes with the combustion process and strongly clogs the chimney.

- It is categorically impossible to heat the hearth with small wood waste - sawdust. If they are evenly distributed in the place of combustion, they will prevent the appearance of good traction and the access of oxygen, and with a sharp air flow, an explosion may occur.

- Combustible materials should not adhere to the walls of the unit, so as not to provoke a fire, and in addition, heat transfer to the room worsens.

- The recommended heating time should not be exceeded, as the heating structure will quickly become unusable. It is advisable to use a special oven thermometer, which will constantly monitor the combustion temperature, and maintain it at around 70 ̊ C. It is better to heat more often, but with a lower degree of intensity.

- In newly built houses, you need to start kindling the stove only after the completion of the construction of all walls and ceilings. The fact is that the heat must be retained in the building, otherwise the internal elements of the unit may overheat.

The first thing I want to say is that you need to understand that the BRICK FURNACE has a completely different principle of the firebox than the metal one.

It has thermal inertia, which means it will not give heat immediately. But when it heats up, then in an insulated house it will last for a long time.The heating time of a brick oven is from 1 hour to two hours. It is not necessary to heat the stove for several hours to achieve a specific temperature in the room. Long-term fireboxes on the principle of a metal furnace will lead to structural destruction, which means to repair or complete re-installation. Correct operation will give you a lot of comfort and save you money! ************************************************* ********************************

Before, how to start heating the stove, it is necessary clear ash pan and grate from ash (so that air passes to the fuel).

Further lay firewood... “First, a small ball of birch bark, shavings or dry grass is placed on the bottom, not far from the mouth of the furnace. In the modern version, crumpled newspaper or paper is used. A hut is built over the paper from splinters or dry chips. Then the hut is covered with short thin chocks set at an angle. After that, logs of medium thickness are used. If the logs are birch, then they are placed in a birch bark hut inside. "

Firewood is laid loosely so that there is space between the logs (log onto log obliquely), so that at least 20 cm remains to the top of the firebox.

Before the beginning furnace furnace open the smoke damper, furnace and blower doors, as a result of which traction appears in the channels of the brick oven (there is, as it were, the ventilation of the oven).

“Now it is enough to set fire to birch bark or paper, and it will immediately pass the fiery baton to the splinters. From them, the flame after a while moves to thin, and then to thicker chocks. "

When lighting the stove try to use dry wood. The use of flammable liquids - gasoline, kerosene, diesel fuel - is strictly prohibited. As this can lead to burns to the hands, face, and sometimes fire.

On a note: In order for the fire to flare up more strongly, housewives in the old days poured a few pinches of table salt onto the smoldering firewood and immediately put several well-dried logs on top.

After kindling, the combustion door must be closed, and the blower door must be left open, and she regulate traction. The draft in the furnace is regulated by a damper (view) and a blower door. It should be sufficient, but not redundant. When the wood fires up well, the smoke damper is gradually closed, decreasing the traction force. Care must be taken to prevent smoke from entering the room. The stronger the thrust to the stove, the more the damper should be closed.

If stove thrust has decreased over time, then the stove may need cleaning or repair. If you do not have the knowledge, experience and skills, then it is better to contact a specialist, since "self-treatment" can lead to a larger repair, up to the re-laying of the furnace (these are not advertising words, but experience in carrying out repair work).

If there is insufficient air in the firebox, smoke appears, if there is an excess of air, the stove "hums".

Burning should be even and calm, and the flame should be light and bright (straw-colored). The dazzling white color of the flame indicates an excess of thrust, dark red indicates a lack of it.

The fire door should be opened as rarely as possible. Preferably before by opening the firebox door, close the blower doorso that the smoke from the furnace does not enter the room, but is carried away by the incoming air into the furnace. During the heating of the stove, it is enough to mix the wood once or twice so that they lie flat on the grate and there are no empty places through which air could go into the smoke circulation, bypassing the fuel layer.

The duration of the heating of brick ovens is from 1 to 2 hours. After firing, the surface of the brick oven must be heated to a temperature of 70-80 ° C, in extreme cases, up to 90 ° C. At higher temperatures, dust on the surface of the stove burns, giving off an unpleasant odor. Therefore, the front walls of the stove should be systematically cleaned of dust and dirt, especially at the beginning of the heating season.Now there are quite effective means for removing soot from bricks, tiles, metal without much difficulty.

It is not necessary to overheat a brick oven with a long-term firebox. this can lead to the formation of cracks and breakdown of the oven masonry.

After the firewood is burned, a lot of coal is formed in the firebox. !!! If the firebox of the stove is large enough and there is a place where you can collect coals in a pile, then this must be done. This is the very source of heat that will heat the stove for several hours. !!! If the firebox is small, then the coals remain on the grate, but this way they decay very quickly, and the stove's heat reserve will be much less. When there is no bluish-blue flame in the firebox above the coal layer, the furnace firebox can be considered complete. After 3-5 minutes, it should be tight close all doors, smoke flap and view... It is possible to recommend closing the smoke damper not completely, but leaving a small gap, that is, pushing it in completely and returning it by about a centimeter. This will avoid the ingress of combustion products into the heated room. It is worth remembering that a good stove, even without fire, has a draft and, if you do not close the damper - the view, the stove will draw heat out of the house !!!

Take care of the warmth in the house, because House-warmth is coziness and comfort for you and your family and friends!

To avoid accidental carbon monoxide poisoning, do not heat the stove just before bed.

Caring for the Russian stove

It is important to know not only how to heat a Russian stove, but also how to properly care for it. All furnace passages and working chambers should be cleaned up in a timely manner. The blower compartment is cleaned of accumulated ash every time after completion of the furnace. First, its remains in the hearth are swept away into a blower to remove it completely, for which they use a shovel - a special metal scoop attached to a long handle.

Typically, major cleaning is carried out once a year on the eve of the heating season. When carrying out cleaning, openings are used that are closed by doors that are provided in the structure. This procedure is performed with a poker. It removes the remains of ash and soot, which have formed on the inner surfaces of the walls, through open holes.

More thoroughly, you can remove plaque with a broom from hard twigs. After cleaning, the opening doors are tightly closed. The chimney is cleaned of soot, condensation or foreign objects once a year with a special hose or rope with a weighted end. But in this case, it is better to use the help of specialists.

How much to heat the stove

It is a difficult science to heat a sauna correctly and all skills come only with your own experience. It is necessary to constantly maintain the fire in the sauna stove, to ensure that the firewood does not burn out completely. The combustion temperature in the furnace must be constantly maintained at a certain level.

If you have not heated the bathhouse for a long time, then it will take longer to heat it up in order to thoroughly warm up the entire room. With regular use of the bathing kingdom, it takes much less time to prepare a bath.

There simply does not exist a definite time for the heating of the stove! Everything is so individual! In winter, the bath must be heated longer than in summer. The metal and stone stove heats up and heats the bath in different ways. The amount of time spent depends on how much water you heat, which heart of the stove (stone backfill) ultimately depends.

How to heat a metal stove

To heat a metal stove is not nearly more difficult than a brick one; it heats up quite quickly both in winter and in summer. Only the excellent heat does not last long and it differs from the dry heat of a sauna with a stove. I think this is due to the rapid heating of the water in the boiler. Sometimes it happens that the water is already boiling, and it is cool in the bath.

To establish a balance in this matter, it is necessary to constantly monitor the heating of hot water. If it boils, drain a bucket or two and add cold water.

A bath with a metal stove practically does not require standing, since the metal cools down very quickly.This is the fundamental difference between baths with a stone and metal stove.

Correct heating of the stove

The work of the heating structure largely depends on the correct laying of firewood. Three methods of stacking logs in the flow chamber of the stove are most often used:

- horizontal, when the firewood is laid in rows one after another with an even distance;

- conical, when a kind of wigwam is formed from the pegs;

- diagonal, when the first log is placed diagonally, and the rest - at an angle to it.

At the same time, do not hammer the firebox "to the eyeballs", about 1/5 of the part should remain free.

When using coal, firing is done with wood, and after they are ignited, a small amount of coal is poured - a layer of about 5-6 cm. Subsequent backfills can reach a height of 15 cm, but the layers must pass air well. It is recommended to periodically stir up the fuel with a poker.

How to light the stove after a long break?

In early spring, having arrived at the dacha, in order to warm up, you will have to melt the stove. But after a long downtime, it is worth lighting a fire in it so as not to damage either the heating structure itself or the residential building.

First of all, check the inside and outside of the stove for:

- chips;

- cracks;

- foreign objects;

- small animals and birds;

- soot deposits.

The presence of these inclusions can become a serious obstacle to the normal operation of the device.

Seal cracks and chips with a solution, get rid of foreign objects. Use a special metal ball on a long rope to clean the chimney from accumulation of soot. The ball can be equipped with a wire brush, then lower it into the chimney and lift it up, repeating these manipulations several times, shaking off the soot after each rise.

Be sure to check the presence of draft if the stove has not been heated for a long time. Light the wood with all the doors fully open, then close them by adjusting the draft. Lay two logs parallel to each other at a short distance, then place the other two on top of them, placing them perpendicular to the first row. Put paper inside and light it.

After a long idle time, do not heat the stove at full power at once. The first combustion should not exceed half an hour, after 4 hours the kindling can be repeated, increasing the combustion time.

Types of fuel for stoves

The most commonly used fuel for home stoves are:

The choice of a particular type of fuel resource depends on its three main characteristics - energy efficiency, availability and cost. Let us consider in more detail how each of the listed types of fuel corresponds to these indicators.

Firewood

- They burn for a long time, giving an efficiency of up to 85%.

- Almost complete combustion with the release of only 1% ash.

- The combustion of one kilogram of wood produces 4500 kcal.

- Environmental Safety.

- Low cost.

- The wood must be cut down, sawn into logs or split into small fragments.

- Firewood absorbs harmful substances, so logs from forest belts, which are close to large cities, are harmful.

- Chopped firewood needs special storage conditions - they need to be placed over a large area in an area with the lowest humidity.

Coal

- There is no threat of spontaneous combustion.

- The percentage of ash formation is relatively low - from 25% to 40%.

- High calorific value - about 6,000 kilocalories per kg.

- Ease of storage.

- The complexity of the ignition. It is almost impossible to light coal without firewood.

- Not every stove can be heated with this type of fuel. For firing coal in the furnace, there must be an additional channel for supplying secondary air.

- Possesses a high degree of thermal conductivity.

- Burns for a long time.

- Ease of use.

- Does not spark.

- After combustion, it leaves peat ash - a useful fertilizer.

At the same time, peat has one, but a very serious drawback - flammability.Therefore, you need to be careful when using a cake for heating, and do not store it close to a heating device and an open fire. In addition, peat generates a lot of surface moisture.

What is the best firewood?

It is economically most rational to heat a stove to heat a home or a bath with wood. However, different types of wood give different efficiency indicators. The burning time of the logs depends on the density of the tree, therefore, the denser its structure, the longer the logs will burn and the more heat energy they will give into the room. This is important to consider when choosing firewood.

Which tree species is the hottest:

Procurement and storage of firewood

When harvesting firewood, use trees growing in dry places, they contain less moisture, therefore, they will burn with greater heat transfer. If there are no dry plantings, then the fallen logs must be thoroughly dried. The best period for logging wood for fuel is November-December.

Do not leave the sawn trees for a long time; if possible, cut them into several parts. The logs, which are intended for the heating of the stove, should be of medium size - 8-10 cm in diameter, the length depends on the dimensions of the combustion chamber.

After cutting the logs, it is better to split them and fold them in a special well-ventilated room, without excess moisture, protected from rain or snow. Therefore, it is impossible to store firewood in the cellar; it is better to put them in a shed or under a canopy with good ventilation.

One of the most effective ways to stack logs is in criss-cross cells:

Preparing the stove for kindling

The complete serviceability of the stove, namely the absence of cracks, chips and burnouts, is a guarantee of a long and irreproachable service of this heating device. Therefore, regularly inspect the structure and, if you find flaws, then eliminate them in a timely manner. Before firing, ensure good draft with a damper, clean the chimney from soot deposits, make sure there is sufficient ventilation in the building.

The use of a stove structure to heat a house or bath requires strict adherence to the basic fire safety rules:

- Timely repair, clean all units of the furnace structure.

- Whiten the outside regularly to find cracks and chips quickly.

- Do not leave a burning stove unattended for a long time, especially if there are small children in the house.

- To prevent the surrounding objects from igniting from flying sparks, nail a sheet of metal to the floor in front of the combustion chamber.

- Do not heat the stove for more than two hours at a time; it should be heated no more than three times a day to prevent overheating of the device.

- Don't light a fire just before bed. The fuel should be completely burned out 2-3 hours before going to bed.

- Do not place wooden objects, utensils and furniture near the stove.

- Use wood that is the same size as the opening of the combustion chamber.

- Close the chimney valves only after the fuel has completely burned out.

- Do not use flammable and explosive materials (alcohol, kerosene, gasoline, etc.) for ignition.