Tips on how to expel air from a water-heated floor

Air accumulation in the heating system prevents its proper functioning. If not removed in time, performance will deteriorate. In such conditions, the likelihood of damage to expensive equipment increases. To eliminate unnecessary risks and unnecessary costs, you need to know how to pump the heated floor yourself. The technique is quite simple, therefore, in most cases, contacting specialized specialists is not required.

Checking and troubleshooting should be carried out before the start of the regular heating season.

Why is it dangerous to air a warm floor

The traditional heating system in the house continues to work even in cases where the circulation of the coolant is difficult due to the appearance of air masses in the radiators, the coolant passes through the jumper.

With the appearance of air layers, the floors completely stop working and heat the room. Stopping heating is due to the design feature and the small thickness of the pipes used to heat the room.

Although the air can be vented even after the start of operation, it is easiest to carry out this operation before the start of the heating season. After that, it will be necessary to ensure that the traffic jams do not appear again.

How problems arise

The parts of the system that are connected to the radiators can be quickly diagnosed. They are located indoors, so noises are heard when the air passes through. The lowered temperature of individual sections of the batteries is determined by touch, where gas "plugs" have formed.

But the pipeline, hidden deep in the concrete screed, is well insulated. If the cabinet with a manifold comb and a pump is installed away from living rooms, extraneous sounds will not be heard. Malfunctions are identified by a significant difference in heating in different circuits.

The following list shows the reasons that contribute to the penetration of air into the coolant:

- Replacement of cranes and other system elements;

- Faulty state of automatic devices that are designed to remove air from the system;

- Laying the pipeline route with large differences in height;

- Significant change in pressure level during operation. With a low head, voids may form at the top points;

- Excessive heating of the coolant, accompanied by the release of gases. Some types of chemical compounds can cause similar negative processes;

- The filling process after the summer period was carried out too quickly, therefore not all the air was removed;

- When installing the system or later, the tightness of the connections is broken. In the worst case, the leaks formed inside the concrete screed. For this reason, after the installation of underfloor heating, a thorough check is performed using increased pressure.

Exposure to electromagnetic waves

The harm of electric underfloor heating is much more pronounced. The waves created in the process of work belong to the electromagnetic spectrum, which has a significant effect on all systems of the human body. It is better to use cables with the fewest wires to reduce the electromagnetic load on the body.

Consequences of improper installation

Underfloor heating turns out to be a fairly simple technology and specialists who do not have the appropriate qualifications often undertake its installation. As a result of this approach, errors can be made that create inconvenience to users.

- Wrong choice of topcoat. Many types of flooring are not designed for constant heating. Parquet can crack, and linoleum can collapse or deform. Therefore, it is important to properly decorate the room and choose a suitable covering.

- Lack or insufficient number of thermostats. A decrease in the control over the created temperature worsens the general microclimate, leads to overdrying of the air.

- Lack of adapted ventilation. An increase in air temperature without adequate ventilation leads to stagnation of the air and stimulates the formation of mold.

In practice, non-professional installation and adjustment of the structure lead to a negative attitude towards the warm floor, although in fact the fault here is not on the technology, but on its incorrect use.

Why it is necessary to remove air

The formation of voids reduces the efficiency of the heating system. Pumping equipment, like other components, is less efficient. To provide a comfortable indoor temperature for users, more resources have to be spent.

With an increase in such voids, the pressure gradually decreases. After reaching the minimum level, the corresponding signal is sent to the boiler control unit. In addition to electronic devices, mechanical means of a similar purpose are used. This is an emergency situation, so the automation turns off the supply of gas or other fuel.

To turn it on again, you have to manually raise the pressure. But there are many gaseous inclusions in fresh water, therefore negative processes are accelerated. The equipment will shut down more often.

It is dangerous to leave it in this state unattended. If you do not remove the air while eliminating the original causes, the technique will completely lose functionality.

It should be remembered that oxidation that destroys metals occurs in the presence of water and oxygen. The addition of a new coolant activates the corresponding negative processes. In this mode of operation, the durability of the heating equipment is reduced.

The appearance of air "plugs" in the heat exchange units of the boilers should be excluded. These parts are exposed to very high temperatures.

If heating is not uniform enough, the heat exchanger will be damaged without the possibility of recovery

The above reasons are enough to understand the need for preventive measures. Their implementation will prevent complex breakdowns and costs associated with restoration work.

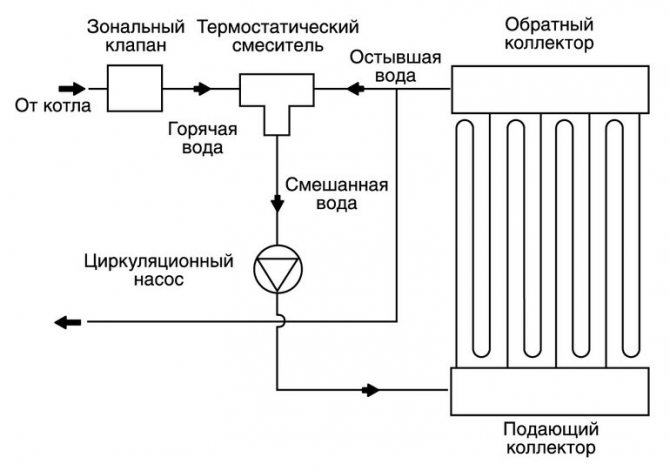

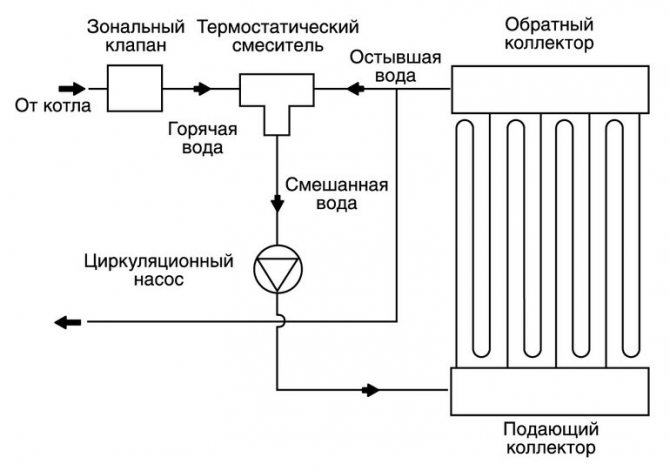

Design features

In advance, it is necessary to take into account the details that distinguish certain equipment. So, in some situations, the built-in boiler pump is used to circulate the coolant along all circuits. For a large facility, its performance may not be enough, so you will need to install a separate power unit.

When using radiator heating, routes are created with a minimum number of turns, without sharp corners. By adding slopes towards the boiler, natural circulation can be ensured by gravity.

Long pipelines with a lot of bends are installed in warm floors.

It is more difficult to pump water through such a system. They use exclusively compulsory techniques. In case of errors in the calculations, the power of the individual pump will not be enough for long-distance circuits. In this case, their poor heating cannot be eliminated by removing air plugs. The system will need to be upgraded.

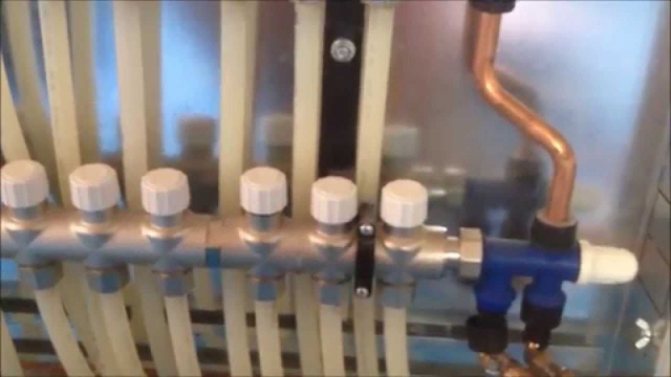

The rake regulators must be correctly adjusted beforehand. In addition to mechanical flow meters, valves with electric drives are installed. Such devices change the flow rate of the coolant taking into account the readings of the temperature sensors.

Air removal algorithm

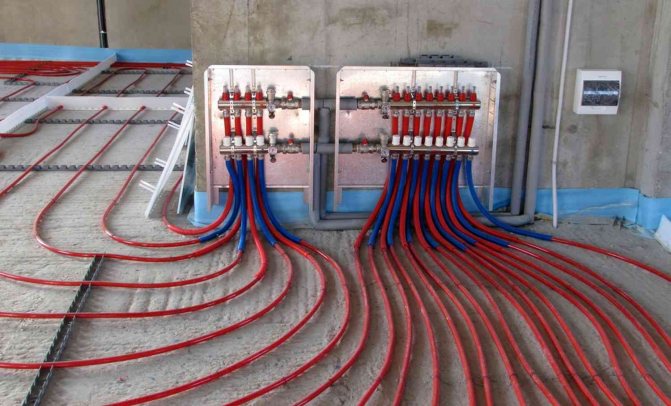

In the process of moving the coolant through the system, gas accumulates at the highest points. For the underfloor heating system, this is a manifold distributor (comb). During installation, Mayevsky taps or automatic air removal devices are screwed into them.

The following is a typical sequence of correct actions:

- Many modern pumps of this type are equipped with a step speed regulator. It is set to position "1", which corresponds to the minimum performance. You will have to spend more time, but the removal of gases will be neat.

- Cover all but one contour. Further, similar operations are performed sequentially in other areas.

- The screw of the Mayevsky valve of the first circuit is turned counterclockwise with a slotted screwdriver. Before this, the polymer insert is turned with the hole down, a suitable container is placed to collect the liquid.

- After the air has escaped, the screw is turned in the opposite direction until the valve is completely closed.

- Despite the fact that the minimum engine speed is set, the circuit will have to be pumped repeatedly. After the first release of gases, the pump is turned off. Wait for the accumulation of air in the tap, open the tap. Then, power is supplied to the electric drive again, the coolant is driven off at a slow speed for several minutes.

- This procedure is repeated 3-4 times. After - shut off this circuit with a crane and go to the next.

Typical pump with a red shaft speed control knob

If the pump is installed above the manifold, or only a standard unit (heating boiler) is used, it can also be vented. To do this, slightly loosen the screw located in the center of the cover. In the picture above, it is marked with an arrow.

After completing the entire set of working steps, it will be necessary to raise the pressure to the nominal level. It should be understood that air will enter the system again during this procedure. Therefore, it is possible that you will have to release it again.

Components of equipment

It is worth considering in more detail the parts of the system that were mentioned above.

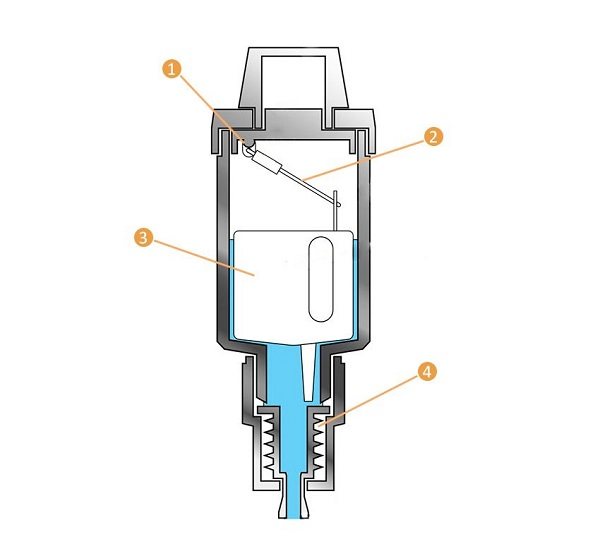

Disassembled crane

The principle of operation is described in the air release instructions. The design of the Mayevsky crane is easier to study with the help of this figure. Such a miniature product is installed instead of a plug at the top of the manifold manifold. There is a thread in the central part. A screw is screwed into it, pressing the plastic seal.

To ensure the tightness of the connection, a rubber ring is used. All listed parts are included in the standard equipment of the product. No additional consumables are required for installation and operation.

The use of automated devices greatly simplifies the implementation of the task. Without careful control by the user and additional settings, they are capable of performing their functions over a long service life.

Automatic gas diverter

Here is a schematic diagram of one of the devices in this category:

- The assembly (1) creates a rigid attachment of the rod (2) to the inside of the body at the desired angle. They regulate the level of opening of the exhaust valve.

- During operation, air accumulates at the top. The float goes down. In a certain position, it will open the shut-off device, which will release the gas to the outside.

- Then the float rises to its original position, the cycle is repeated again.

- A soft seal (4) is installed in the lower part, which ensures the tightness of the connection.

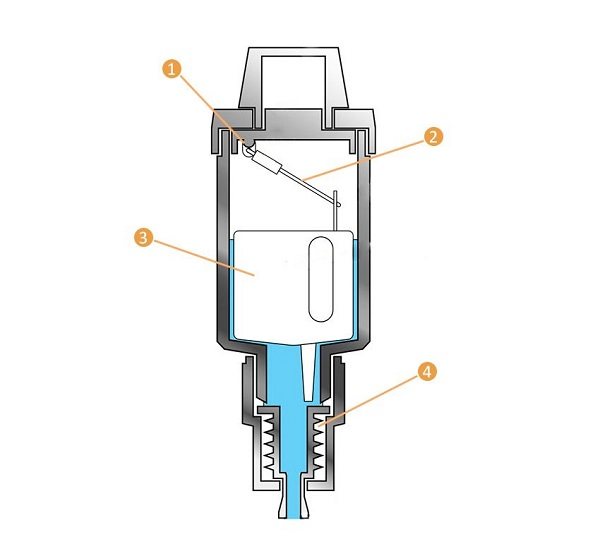

Separator

Such a device more effectively performs similar functions:

- Here is an example of an in-line separator. It is installed at the top point in the section of the pipeline using threaded connections (4, 5).

- A grid (3) is fixed in the central part. When the flow of water passes through such a structure, air bubbles are released from it (2).

- They rush upward. In this part, the same unit is installed as in the automatic gas vent. When the float drops below a certain level, the draft will open the valve (1) to release air to the outside.

- The sizes of the cells and other parameters of the grid are selected so as not to create unnecessary obstacles to the movement of the coolant. However, this design retains rust particles (6). They accumulate at the bottom (7). There is a screw cap here that can be opened to remove debris during routine maintenance.

Removing mechanical impurities reduces the load on different parts of the heating system. If you install a simple filter on the main water supply line, clogging of the radiator ducts and boiler heat exchangers will be prevented. This will also prolong the durability of the automatic air vent valve jets.

How do electric types of underfloor heating work

Electric floor based on cables

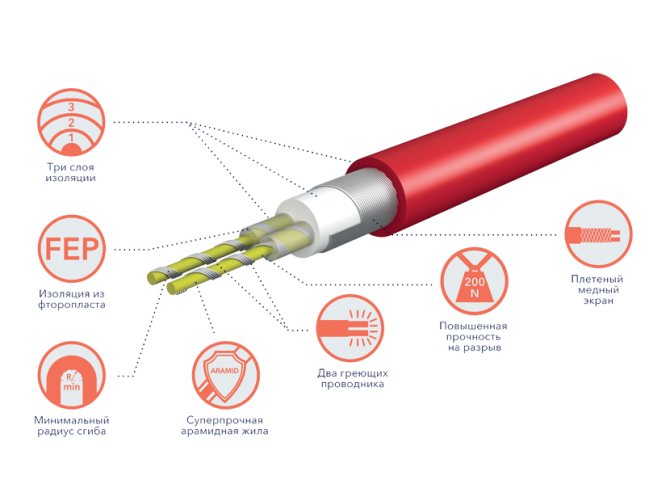

The work of a warm floor is based on the release of heat to the external environment through the transfer of electricity in the elements of the system. Standard types of wires are made of metals, which are aimed at reducing heat loss, but in cable heating systems, everything is exactly the opposite.

We recommend: What is the difference between Unimat underfloor heating models?

Metals are selected to release as much heat as possible into the environment. In this case, the wire consists of:

- metal threads that generate heat well;

- from polyfluoroethylene (Teflon) layers.

These types of cables are produced in the form of one- and two-core, and are used for installation for different purposes. Subject to the rules of installation and operation, the warranty for these types of cables reaches 15-20 years:

- two-core models are provided with an additional insulating layer, which is located between the outer cover and the layer of heat-resistant braiding of the conductors. The first conductor conducts current, and the second acts as a heating one. This arrangement is necessary to reduce the level of harmful electromagnetic waves;

- single-core cables work in the same way, taking into account the fact that they must be laid in a circle to converge in one place for connection.

These devices require compliance with the balance of heat that the cable emits, as well as its amount that goes to warm the room. Because of this need, the cables must be of the same type, otherwise there will be malfunctions.

At the final stage, the structure is poured with a layer of screed, which, after drying, is covered with a layer of floor covering.

Self-regulating cables are endowed with standard wires that conduct current. The heating element is a semiconductor matrix consisting of unconnected parts.

The principle of operation of a warm floor is that the semiconductors of the matrix measure the temperature of the room and react to changes by creating a huge number of threads through which an electric current circulates, heating the layers of the wire with the subsequent release of heat.

Resistance to electricity increases with the average temperature of the semiconductors, resulting in reduced heating of the room.

Resistive cable mats

Along with single and two-core types of wires, there are heating mats. These are the sheets in which the cable was originally mounted. They are widely used in the building materials market due to their simple installation, compared to separately attached heating cables.

We recommend: How is the underfloor heating installed on the balcony?

The set of this type of heating consists of:

- mats, which are rolled into rolls for convenience;

- adapters for correct connection.

The use of adapters is mandatory, since it is prohibited to connect the system directly to the network.

If the structure needs to be expanded, then the mesh for fastening is simply cut neatly, without touching the wires, and unfold in the desired direction. This method greatly facilitates the installation of a heating structure in a room of any shape and size, and also prevents overlapping wires.

Infrared Film Systems

The film version of heating differs in the way of heat transfer from other types. The film transmits heat by means of infrared radiation, like the sun.

Heat spreads evenly over the surface of the room, heating all objects. Most people prefer this particular heating method due to the ease of installation and relatively low prices.

The film consists of carbon plates with copper strips mounted on the sides. The direct heat is generated by the carbon portion of the film.

The sheets have a width of 30 cm to 1 m, and their length reaches 40-50 meters. To separate the film into parts, cut lines are drawn. It is only along these lines that it is allowed to divide the film, in order to avoid damage.

The sheets are laid on the prepared base under the flooring layer. The system does not require a screed.

Infrared mats are heated using rod-shaped radiators, which are located in the gap between two conductors.

The mats are divided into sheets up to 80-83 cm wide, and the length can be in the region of 20 m. Rod radiators are mounted at a distance of 8-10 cm, which makes it easy to separate them in the central part.

It is worth noting the automatic regulation of this type of heating. The point is that when the required temperature is reached, the film stops emitting heat. This significantly reduces power consumption.

The mats must be placed in a cement screed with a thickness of at least 2-3 cm, otherwise the temperature cannot be independently regulated.

We recommend: Which pipes are better to choose for a warm floor?

Compatible with all types of flooring.

Additional recommendations

As the complexity increases, the cost increases, but the overall reliability of the equipment decreases. The control valves on a manifold can be used as an example. Mechanical drive designs cost a little.

Their characteristics have been worked out by many years of practice, so breakdowns are rare. Servos are more expensive. The corresponding systems contain electronic components, miniature electric motors, wire connections, sensors. There are more components that can fail.

Components for removing air from the system should be selected taking into account design features. Simple Mayevsky cranes are capable of performing their functions flawlessly for a long time. They do not need to be adjusted during operation. Automatic devices are more complicated and more expensive. They can be damaged by dirt, so protection from mechanical impurities is needed.

Sometimes the intense formation of air jams indicates a violation of the integrity of the joints, other damage. Automatic diverters are so efficient that you won't notice problems in the early stages.

Why does air appear in the system?

Before pumping the warm floor, make sure that the heating equipment is installed correctly and that technological standards are followed. So, airing the circuit causes:

- high temperature of the coolant;

- pressure drops in any circuit;

- broken tightness of connections;

- improper installation of the manifold, lack of automated pressure relief valves;

- pre-leveled floor, incorrect pipe slope;

- lack of air pumping before starting the system.

What is the threat of air jams in pipes?

The voids reduce the heating efficiency, up to a complete cessation.If you do not pump the underfloor heating circuit, the voids will increase, which leads to a decrease in pressure. When the minimum pressure value is reached, a signal is sent to the boiler control unit. The fuel supply is automatically turned off, the system stops functioning.

You can increase the pressure indicators manually, but this will not help: when water is added, air enters the circuit. It further aggravates the process, leads to a constant shutdown of equipment.

In addition, the frequent addition of a coolant negatively affects the durability of the boiler heat exchanger: metals are oxidized and destroyed sooner.

To protect yourself from unpleasant consequences, it is necessary to take care of removing air jams after installing the floor, since it is easier to expel air from warm floors before the heating season.

Advantages and disadvantages

One of the main advantages of installing a warm floor is uniform heating of the entire area. The heated air spreads vertically, so that the legs are always comfortable, and the head remains relatively cool.

The most effective laying of such a system is shown in rooms with high ceilings. The air does not become excessively dry and the entire apartment is heated evenly. Installation of a water-heated floor is economically profitable in the future, since it consumes less energy than radiators.

Laying pipes in bathrooms has its own difficulties... Most often they are associated with a heated towel rail, which leads to excessive heating of the floor.

Also, difficulties appear in apartments with low ceilings.... This is due to the fact that the thickness of the screed must be substantial.

How to remove air from a warm water floor yourself

Use the given algorithm, and you will not have a question how to pump a warm water floor.

- We transfer the pump to the state of minimum performance.

- All paths overlap, one remains open.

- When using a "Mayevsky" valve for venting air, it must be turned counterclockwise with a screwdriver or a special key. Air masses will come out with a characteristic sound. Wait for the process to complete and turn the tap back. Repeat the procedure for each circuit.

- When you start the system at high speeds, there will be a lot of bubbles inside. How to bleed air from the warm floor in this case? It is necessary to completely turn off the pump. The coolant will stop moving, the bubbles will rise up to the collector. In a few minutes, we open the Mayevsky crane and let the air out. After that, we turn on the pump at low speed, run the system, turn off the pump, wait and open the tap again. So it is necessary to repeat several times with each circuit until the plugs are completely cleared.

The installation of automatic air vents simplifies the process, since it is easy to release air from the warm water floor in this case. Air plugs are removed by opening the valve on the air vent. It is not necessary to close it, since excess air is removed automatically during operation.

In addition to automatic gas vents, separators are used to remove air bubbles. They also work automatically and are undemanding in service and maintenance.

We examined how to remove air from a warm floor with our own hands. The process will not be inconvenient if everything is done consistently, correctly and regularly. If you have any difficulties, call the indicated phone number or leave a written request on our website.

How to prevent air congestion

In order to prevent the airing of water heated floors, the following rules must be observed:

- Regularly inspect the system for leaks and other defects;

- Periodically monitor the temperature and pressure of the coolant;

- Systematically remove air from the circulation pump housing and collectors;

- If it is impossible to perform maintenance work or replacement of faulty equipment, you must contact the specialists yourself;

- It is also better to entrust the adjustment of the collector comb to the master. You can find a specialist at the portal for the selection of private masters.

We hope that after reading the publication, you have learned how to remove air from a water-heated floor. This article written by engineerspecializing in heating and water supply systems. If you have your own tips on how to bleed air from a warm water floor - write them in the comments. Don't forget to share the post with your friends

Loading ...

Reasons for the appearance of air in warm water floor systems

Before considering the question of how to expel air from the underfloor heating pipe, let us determine the reasons leading to the airing of heating systems. The formation of air jams is usually caused by violations of the rules for the design, installation and operation of warm water floor systems.

Distinguish the following reasons for the appearance of air in them:

- Incorrect calculation of heat loads.

- Errors in calculating the lengths, number of branches and diameters of pipelines.

- Incorrect selection of pumping equipment, safety and shut-off and control valves.

- Laying pipelines with unacceptable differences in height.

- Use of defective equipment and materials when installing a warm floor.

- Poor performance of installation work associated with leaking joints and threaded connections.

- Non-observance of the sequence of the algorithm of actions during the initial filling and starting the system into operation (initial, as well as subsequent ones after repair).

- Failure to comply with the temperature regime during operation.

- Leakage of the pipeline due to a defect or long-term operation.

- Disruption of the circulation of the coolant in individual circuits (branches) of the system, caused by a decrease in the pressure and performance of the pump due to its malfunction.

- Failure of the automatic air vent, safety and shut-off and control valves.

- Allocation of gases contained in the coolant due to the special temperature regime.

Consequences of air congestion

Possible consequences depend on the installation site, as well as the design features of the heating system.

- Underfloor heating from a centralized source of heat supply: partial or complete cessation of heating, possibly freezing of pipelines in corner rooms;

- Houses with underfloor heating and heating devices from a centralized source of heat supply: partial or complete cessation of floor heating;

- Underfloor heating from an individual heating source: partial or complete cessation of heating, an emergency stop of the boiler and freezing of the heating system is possible;

- Houses with underfloor heating and heating devices from an individual heating source: partial or complete cessation of floor heating, frequent stoppages of the boiler.

Taking into account the specific design of the "warm floor" heating system, namely: the presence, depending on the area, of one or several water circuits per room and a separate wiring for each room, it is practically impossible to completely stop circulation.

Only in the event of air jams on all horizontal branches at once in all rooms, the movement of the coolant and the functioning of the system will stop.

Can be used with other types of heating

Electric ceiling heating without serious investment can only be used in conjunction with electric convectors. Indeed, for the installation of air or water heating, you will have to install a boiler and lay pipes or air ducts to each room. The same problem with electric underfloor heating. At the same time, water or air underfloor heating can be used in conjunction with radiator or air heating.After all, the boiler has already been installed, and the channels for supplying the coolant to each room have already been laid. It remains only to connect to them and install an additional heating system. According to this parameter, the leader is a warm floor.

We expel the air

It is a well-known fact that air in heating systems accumulates at the top points of the system. For underfloor heating systems, this is a collector comb, where air discharge devices are installed (Mayevsky taps, automatic air vents or conventional ball valves).

Mayevsky's crane installed on the underfloor heating manifold.

To remove air from the underfloor heating system, you must perform the following steps in a specific sequence:

- Shut off all horizontal branches on the manifold.

- Remove air from the circulation pump housing.

- Open the Mayevsky valve or the ball valve on the comb (in the absence of automatic devices).

- Open the first water circuit, start the pump, setting the minimum capacity on the regulator.

- After waiting for the appearance of water from the air outlet of the pumped branch, turn off the tap and turn off the pump.

- With an interval of 5 - 6 minutes, repeat the operation several times until the air is completely removed.

- Do all the operations with the rest of the contours in the same way.

- Then, switching the pump to maximum performance, bleed the entire system as a whole, periodically releasing air.

- Taking into account the likelihood of the formation of new plugs during the subsequent warming up of the system, it is necessary to release the air again.

How to bleed air from a warm floor

Malfunction or normal functioning of the heating system occurs due to the accumulation of air bubbles.

In this regard, the question of how to expel air from a warm water floor and improve performance is quite popular when installing heating.

Such equipment costs a lot of money, and in order to eliminate possible costs, it is necessary to pump the warm floor yourself. This technology does not require special skills, so you can do it yourself.

Harm or benefit of underfloor heating: arguments

The advantages of infrared underfloor heating over other design options are obvious, but even this type of equipment carries some harm. Underfloor heating systems used in modern construction have a set of practical advantages that determine their popularity:

- saving heating costs due to uniform and controlled heating in the room;

- selection of the optimal technology depending on individual wishes and tasks;

- uniform heating of the room and prompt correction of the microclimate in the rooms;

- reduction of morbidity due to the absence of sudden changes in temperature and constant maintenance of heat.

These are the recognized benefits of the technology. The main argument in favor of the technology is the equalization of temperature and the creation of a comfortable microclimate, which is especially important in houses with poor thermal insulation.

The negative points and harm from using the structure are the following points:

- negative impact on the human respiratory system due to changes in the level of moisture in the air;

- local overheating of the body due to contact with a warm surface;

- creation of an additional source of dust in case of improper installation or choice of coverage (dust from crumbling parquet).

The leading argument against the use of underfloor heating is the violation of natural biorhythms and thermal characteristics of the body due to excessive heating of the room.

The main reasons for the accumulation of air masses

The problem of the formation of air masses in modern heating systems is very urgent. All owners of private and country houses, without exception, face it.

One of the main reasons is the depressurization of the system itself, problems in the risers and untimely replacement of individual devices. Often, air locks are formed at the time of flushing and connection of individual elements to the heating radiator.

The formation of such problems can also occur if the work is carried out incorrectly, aimed at the installation or installation of the heating system. In any case, this problem requires an early solution.

A scheduled air release is required before the first start-up. The air must leave the underfloor heating system before it is heated.

Most heating systems are able to function even after air bubbles enter the system.

In this case, circulation will be hampered due to the appearance of bubbles in the radiator, but the warm floor will stop heating up if air enters its system.

The small thickness of the pipes, combined with the peculiarity of the system, will not allow it to heat up, and the floors will be cold.

You can get rid of air during the operation of the system, but it is much easier to do this before the onset of the first cold weather when the mechanism is not running. After some time, bubbles may appear again, so the system must be monitored and carefully checked, periodically bleeding air.

Bleed air in summer, before starting the heating system

Warm floor will warm the soul

"Warm floor" will warm the soul

Wherever you live, in a standard one-room apartment or a comfortable cottage, you equally want to create the maximum comfort and coziness of your own home. One of the main such indicators is the room temperature. This is especially true for the floor. It is very unpleasant to step on cold tiles or parquet, you have to look for slippers or wear woolen socks.

Thus, a cold floor creates a feeling of discomfort. To solve this problem, heated floors have been created - "warm floors".

Underfloor heating is the most convenient type of heating, in which there is a uniform heating of the air. This is more profitable than conventional radiators, since the entire floor surface acts as a heating device. As a result, environmentally friendly heat is distributed around the entire perimeter of the room.

Underfloor heating is of two types: hot water and electric.

In the water underfloor heating system, the heating elements are metal-plastic pipes with circulating hot water. Heat transfer occurs from the hot water to the floor, and from it to the heated room.

A water heat-insulated floor is more economical to operate, but more expensive to install than an electric one. However, we will consider the topic of the water system in detail next time, but for now we will study the electric underfloor heating and how to install it.

Despite the economy and durability of the electric cable heating system, it is not very popular with most consumers. This is explained by ignorance and fear to equip your home with something very difficult both in terms of installation and in terms of maintenance. However, this is a completely wrong opinion - in many countries of the world such a technique is no longer "exotic", but a common reality.

The principle of operation of this system is based on a special electrical cable that fits into the floor and heats up under the influence of a weak current, emitting heat.

The construction resembles a multi-layer sandwich. At the bottom, thermal insulation, wire mesh, electrical cable and leveling mortar are placed in turn on the concrete. A variety of materials serve as a top coat for a warm floor: linoleum, parquet, laminate, carpet, and even natural stone or ceramic tiles.

As you can see, everything is easy enough, you just need to know a few simple rules ... Here are the main ones:

- The underfloor heating cable is not laid directly under the furniture.

- The subfloor must be dry and level.

- The heating cable cannot be shortened or lengthened.It is forbidden to cut it.

- The installation of the system must be thought out in advance, before the coating is laid.

- The warm floor turns on only after the concrete has completely hardened.

Everything is clear with the installation: economically, conveniently, quickly ... It should be noted that the installation of underfloor heating is carried out both with and without a screed. probably, many are scared off by the question of the safety of an unusual electrical installation. Do not worry, the used shielded heating cable meets all modern requirements, guaranteeing you absolute safety.

The press and other sources of information often talk about the harmful effects of the electromagnetic field on humans. However, do not forget that heating cables meet all existing standards for electromagnetic radiation, otherwise they would simply not exist in Russia. Therefore, such "myths" can be spread only by people who are not familiar with the peculiarities of the system, but who want to "loudly declare themselves." Remember that you have a microwave oven in your kitchen, and UHF sessions are held in the clinic, and you will understand that everywhere we are surrounded by electromagnetic fields, but you do not need to be afraid of them.

Now let's go back to the warm floor. Having talked about safety, one cannot help but touch on others. advantages :

- First, it is profitability ... Optimal temperature distribution can significantly reduce heating costs, since traditional systems no longer heat the floor, but the space under the ceiling.

- Secondly, You don't have to worry about repairing and maintaining your underfloor heating system - they are simply not needed! Once installed, the warm floor will last so long that it will bore you.

- Also no need to worry about the interior of the room ... The invisible cable system will not harm your design at all, and the wall thermostat will only add a sophisticated modern taste to your home.

Special thermostats for underfloor heating allow you to control the temperature automatically or manually. If desired, you can program the maintenance of the set temperature in the house or turn on the heating for a certain time.

The comfort with a warm floor is obvious! You will be able to walk barefoot at home without fear of harming your health, you will be calm for the children playing on it, and keep the natural humidity of the air.

Underfloor heating is used as a main or auxiliary heating system. The main (that is, the only) floor heating system is more suitable for the individual construction of a cottage or a country house, as it requires special design and calculation.

More often, this technique is used to complement an existing heating system. Let's take a kid's room as an example. With the heating turned on, you can open the window without fear of a draft and turn it off when the temperature becomes optimal for the child. In addition to the temperature regime programmed by you, it will become easier and more free to breathe in the room. Minimal heat fluxes do not cause dust particles to circulate in the air. For comparison: conventional radiators burn oxygen and dry out the air.

Underfloor heating is just a godsend for the residents of "Khrushchev". These buildings are referred to as “cold houses” because most of the heat escapes from them through the thin walls. At the same time, it is useless to install such devices as radiators - they are "doomed" to idle work.

As you can see, the "warm floor" heating system has many advantages and benefits, being one of the most efficient and comfortable. With it you can carry out any, a wide variety of projects!

Price also plays an important role. ... Of course, a warm floor is more expensive than a conventional radiator, but its benefits are much greater. In this case, the total cost will depend on the area of the room where the system is installed.You do not need to equip the entire apartment with underfloor heating, select only the most necessary places for it (for example, a bathroom and a toilet). This will significantly save your costs.

The most important thing is to remember that no matter how high the price seems to you at first glance, it will still pay off over many years of operation.

The formation of air masses in the underfloor heating system

How to release the air that has accumulated in the system will depend on the event that led to this result.

Some circumstances require prompt intervention, while others are not capable of causing severe damage to the system.

If the underfloor heating was installed with tangible differences, it is worth getting an additional pump for pumping the coolant.

It is recommended to install several automatic air vents to help release air masses from the system. One is installed on the return lines, while the second should be on the supply.

Running the circulating pump will also help drive out excess air. The more air has accumulated, the louder the circulation pump will work. It is worth noting that the pumping of the system should be carried out at maximum speeds. This will significantly save time and allow you to completely remove air from the system. If one has recently been pumped, but the air has already collected again, the problem may be in the pump itself.

Air vent

When the comb is installed, each circuit is closed in turn, while the air vent must be open on each of them. It is necessary to release the air gradually, therefore, after cleaning the first circuit, the next one opens. The descent is carried out in stages and only one circuit should be open at the time of bleeding.

If this procedure did not give the expected result, the next airing should be done no earlier than in a few days.

To properly clean the system, a person must understand the device of the comb and understand the principle of its operation. If you do not have the necessary knowledge, you should seek help from specialists. For more information on venting, see this video:

Recently, separators have become increasingly popular, whose function is to automatically remove air bubbles from the system, which greatly simplifies the further operation of the entire system.