Before reducing the diameter of the pipe, you should study the theory well. Reducing the diameter of the pipe at home can be useful to anyone who makes repairs to various equipment with their own hands. Of course, if you need to reduce some element of the system, then it is best to use a special adapter and simply connect two pipes of different diameters. However, if you need to get a narrowed or bent tube from what is already available, then you can resort to rolling. Rolling is a plastic deformation of the product into the desired shape.

Types of rolling and bending

Rolling can be used to make a product of the required shape from the tubes. Moreover, using this method, you can not only bend a product made of any metal, but also reduce the diameter.

It is possible to reduce the diameter of the pipe using special equipment.

Bending and changing the shape of the pipe is called rolling. This process got this name because the tool that is used for this is the rollers.

Rolling is used for different purposes:

- To reduce the diameter of pipes made of different materials. So you can deform thin-walled products made of stainless steel, cast iron, steel, etc.

- With the help of rolling, you can bend the product. In this case, you need to bend according to a special template.

- Extension and straightening. However, this is not recommended, as the product loses its strength.

- Increase in diameter. However, this process is considered the most time consuming.

- Using a special pipe bender, you can bend the product into a coil with your own hands.

All processes described are used in the manufacture and repair of tubular products. With their help, you can even make elements bent into a ring to decorate wrought-iron gates.

Classification of pipes by conditional section

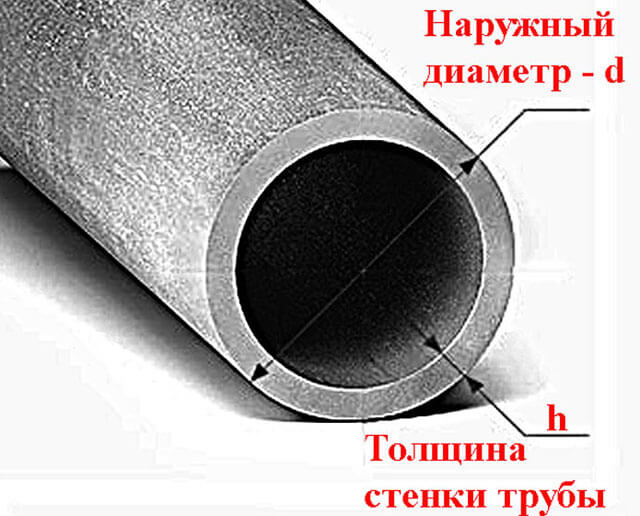

The nominal diameter of the pipe is one of the parameters that largely depends on the type of production of steel products.

In general, four types of pipes are distinguished, depending on the production technology:

- 20-500 mm - such products are produced by hot rolling in accordance with GOST 8732-78;

- 5-250 mm - similar values are determined by GOST 8734-75 for the cold rolling method;

- 10-1400 mm - this group of rolled pipes refers to welded products with longitudinal seams, and their parameters are specified in GOST 10704-91;

- 160-2400 mm are the size limits for welded steel pipes with spiral seams, given in GOST 8696-74.

In this case, steel pipe rolls are presented in 38 standard sizes, with nominal diameters ranging from DN 5 to DN 2400. These include four specialized groups that are provided for hydraulic and pneumatic systems.

It should be noted that the parameters of the nominal diameter of pipes are indicated not only in GOST with standard classification and characteristics of the assortment, but also in reference books, special tables. There you can also find data on the maximum values of the working pressure in the system, longitudinal and transverse loads, as well as other information that may be associated with the nominal diameter of the pipe roll and the type of its section. See also: "What is the nominal diameter of pipes - standards and norms."

Description of the essence of the process

Rolling is a rather complicated process. However, in some cases, it is quite possible to do it yourself. It is especially easy to bend thin-walled stainless steel and galvanized pipes.

Narrowing may also be needed during the construction of a metal pipeline. This method is used when you need to attach a pipe with a larger diameter to a product with a smaller one.

Self-contraction comes with some risks. The fact is that in such a process, two forces are acting on the pipe, directed in opposite directions. Therefore, the actions that can be performed with such elements are limited by several factors.

When reducing the pipe diameter, the safety regulations must be observed

What is the limitation of the applied pressure:

- First of all, the plasticity of the material is taken into account. The more plastic it is, the greater the radius it can be bent.

- You need to pay attention to how much thinner you can make the pipe wall for a particular product.

- It is necessary to check the tensile strength of a particular metal for bending. The more plastic the material, the higher this figure will be.

- The limiting parameter of the radius, the transition from the side wall to the end, also matters.

- You also need to pay attention to the surface quality of the product itself.

Each of these parameters must be considered. For each wall thickness and for each specific diameter, it is different.

When reducing the pipe at home, you need to look at the fact that a large number of folds do not form on the metal. They reduce strength.

Reduce pvc pipe diameter

When designing and installing a heating system, the question always arises - what pipe diameter to choose. The choice of the diameter, and hence the throughput of the pipes, is important, because it is necessary to ensure the speed of the coolant in the range of 0.4 - 0.6 meters per second, which is recommended by specialists. In this case, the required amount of energy (the amount of coolant) must be supplied to the radiators.

It is known that if the speed is less than 0.2 m / s, then air congestion will stagnate. A speed of more than 0.7 m / s should not be done for reasons of energy saving, since the resistance to fluid movement becomes significant (it is directly proportional to the square of the speed), moreover, this is the lower limit of noise generation in pipelines of small diameters.

What type of pipeline to choose

Nowadays, polypropylene pipelines are increasingly chosen for heating, which, although they have disadvantages in the form of difficulty in ensuring the quality of joints, and significant thermal expansion, but they are extremely cheap and easy to install, and these are often decisive factors.

What pipes should be used for the heating system? Polypropylene pipes are divided into several types, which have their own technical characteristics, and they are designed for different conditions. Suitable for heating grades PN25 (PN30), which withstand an operating pressure of 2.5 atm at a liquid temperature of up to 120 degrees. FROM.

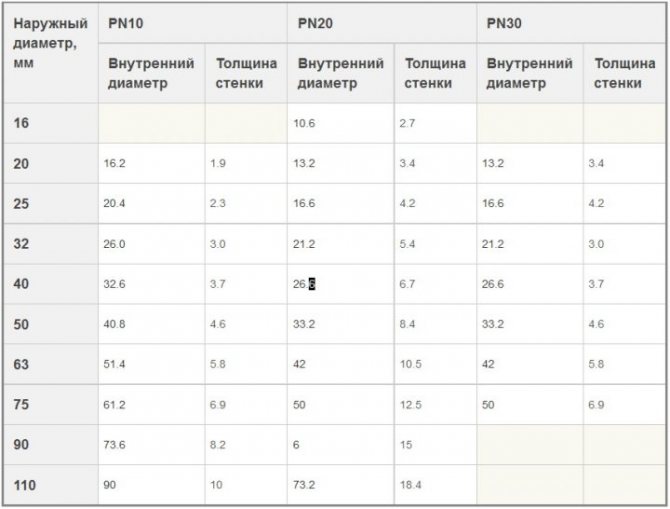

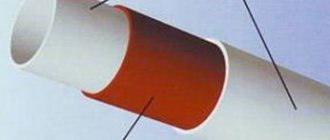

Wall thicknesses are given in the tables. For heating, pipes made of polypropylene are now used, which are reinforced with aluminum foil or fiberglass. The reinforcement prevents significant expansion of the material when heated.

Many experts prefer pipes with internal fiberglass reinforcement. Such a pipeline has recently become the most widely used in private heating systems.

Selection of the diameter of the heating pipeline

Pipes are available in standard diameters, from which you need to make a choice. Typical solutions have been developed for the selection of pipe diameters for heating a house, guided by which, in 99% of cases, you can make the optimal correct choice of diameter without performing a hydraulic calculation.

Standard outer diameters of polypropylene pipes are 16, 20, 25, 32, 40 mm. The internal diameter of pipes of grade РN25 corresponding to these values is 10.6, 13.2, 16.6, 21.2, 26.6 mm, respectively.

More detailed information on the outer diameters, inner diameters and wall thickness of polypropylene pipes is given in the table.

What diameters what to connect

We need to ensure the supply of the required thermal power, which will directly depend on the amount of the supplied coolant, but the speed of fluid movement should remain within the specified limits of 0.3 - 0.7 m / s

Then there is such a correspondence of the connections (for polypropylene pipes, the outer diameter is indicated):

- 16 mm - for connecting one or two radiators;

- 20 mm - for connecting one radiator or a small group of radiators (radiators of "normal" power within 1 - 2 kW, maximum connected power - up to 7 kW, the number of radiators up to 5 pcs.);

- 25 mm - for connecting a group of radiators (usually up to 8 pcs., Power up to 11 kW) of one wing (arm of a dead-end wiring diagram);

- 32 mm - for connecting one floor or a whole house, depending on the thermal power (usually up to 12 radiators, respectively, the thermal power is up to 19 kW);

- 40 mm - for the main line of one house, if there is one (20 radiators - up to 30 kW).

Manual bending of stainless steel

So, now you can talk directly about the narrowing process. This can be done either at the factory with a special tool, or at home with improvised means.

You can use a hammer. However, this method cannot be considered optimal, since in this case the pipe can be strongly deformed. In addition, the reduced part will turn out to be uneven, which will negatively affect the strength.

The best way is to use special pliers. They can be purchased at a specialty store, but they are not cheap. You can make a tool with your own hands. To do this, you need to take a pipe wrench, you can even use an old worn out product. From it you need to remove the sponge from the movable arm, and instead of this sponge, you must install an insert under the half-ring. Next, a half-ring of the required radius is made and installed on a movable arm. If you want to continue clamping pipes, you can make several rings with different diameters. This will increase the versatility of the products.

How to use the special pliers:

- Take pliers with a jaw at least half the diameter of the ferrule. Grasp the outer diameter with the throat.

- Bring the nut of the pliers close to the leash of the device.

- The movable arm can now be turned. Do this until it completely encloses the second half-perimeter.

- Then, with an effort to squeeze both levers and turn the key 30 degrees.

- All these steps must be repeated until the pipe reaches the desired diameter.

Before bending the stainless steel, you should first familiarize yourself with the recommendations of specialists

In this way, you can give the required size. It is worth stipulating in advance that this work requires physical strength.

Using a lathe

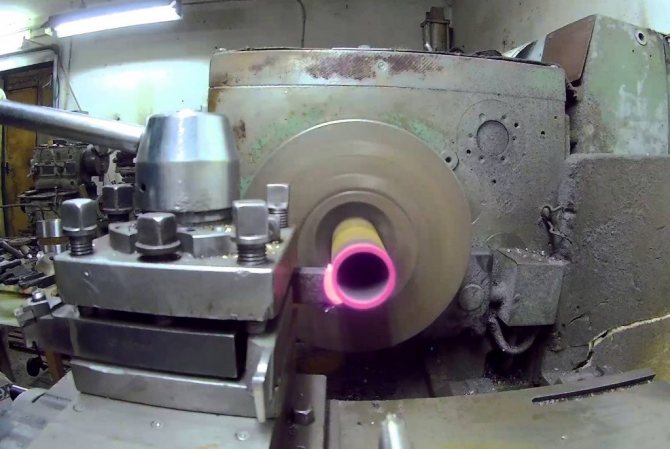

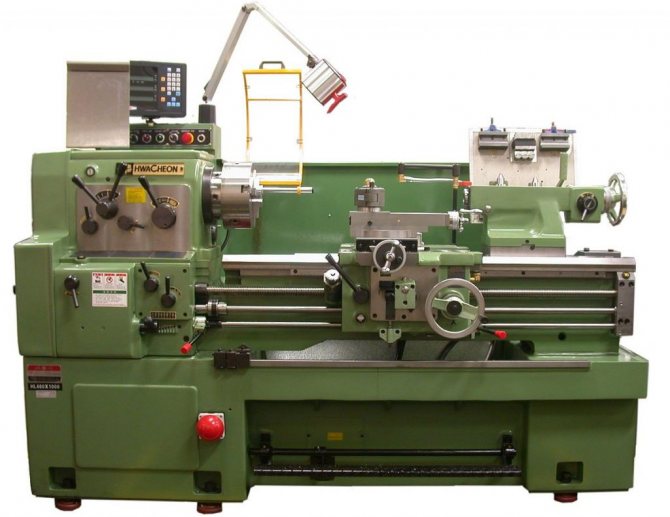

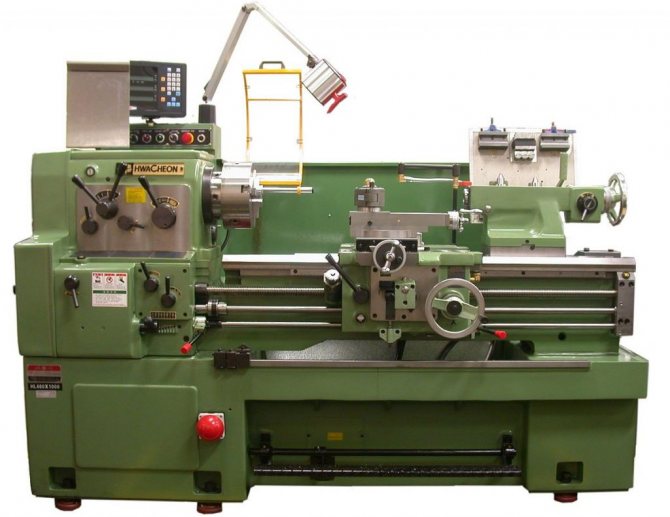

The easiest way to narrow the pipe is with a special machine. This process can be performed even by a person who does not have great physical strength. Indeed, in this case, most of the work is performed by the technician.

To work with a lathe, you must have certain skills.

Not only a metal tube can be bent according to the template. Such a device is useful for giving the required shape to a piece of thick wire. The wire can also be bent manually.

Sequencing:

- It is necessary to fix the pipe to the instrument holder. It is important to calculate the immersion depth of the workpiece. The stroke of the handle must match the place of the blind hole.

- When you turn on the machine, you need to bring the handle to the pipe. Next, click on the workpiece, and looping begins.

- The material starts to heat up. This reduces the force, but increases the ductility of the material.

- The handle must have at least 180 degrees of travel. And the tool holders should be the most popular hole sizes.

During the process, the product heats up and the material becomes pliable. Thanks to this, the diameter of the workpiece can be easily reduced to the required values. Squeezing a pipe with your own hands is difficult, but possible. To do this, you need to make a special apparatus and learn how to use it correctly.