Plastic products have long entered our life, successfully replacing metal ones. Today, polypropylene pipes for heating are widely used, the technical characteristics of which made it possible to facilitate the work on the arrangement of heating systems. Even a non-professional will be able to make their installation on their own.

Features of polypropylene pipes

The main feature of polypropylene is considered to be resistance to high temperatures, and additional reinforcement is designed to protect it from expansion when heated. Due to the special hardness of the material, the pipes have a perfectly smooth surface, which positively affects their high resistance to corrosion and the influence of external factors.

Using polypropylene pipes for heating, taking into account the characteristics of the material and size, they carry out not only the installation of internal networks, but also the main ones.

Benefits

The popularity of polypropylene pipes is due to the following advantages:

- withstand pressure over 10 bar;

- aesthetic appearance;

- do not corrode, do not electrify;

- smooth inner surface eliminates dirt settling;

- attractive price;

- the chemical purity of the material allows it to be used in the food industry;

- ease of transportation, transportation is possible in bays.

disadvantages

Cons of polypropylene:

- does not tolerate direct exposure to ultraviolet radiation, under the influence of which it quickly collapses, additional protection is required;

- begins to melt at high temperatures;

- installation requires a special welding machine;

- difficulty in repair work and maintenance.

Views

Pipes are produced for various applications, for example, solid polypropylene products with a small inner diameter are successfully used for underfloor heating, and materials with additional reinforcement show themselves perfectly when laying a heating circuit.

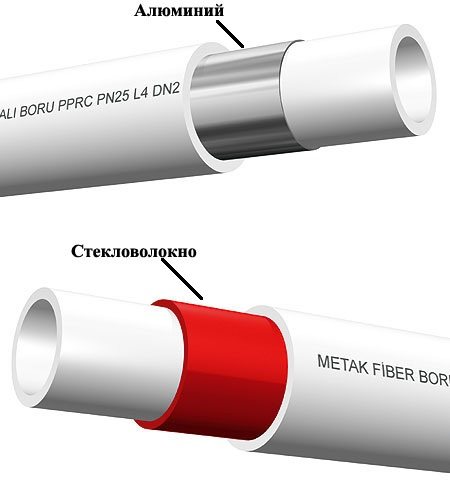

Fiberglass

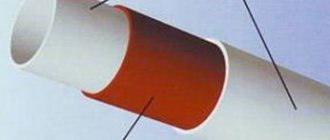

Glass fiber-reinforced polypropylene is made by coextrusion, where the fiber is embedded between two layers of applied plastic.

Features of products with fiberglass:

- less susceptible to stretching when heated;

- keep their shape well;

- withstand pressure changes in the network;

- do not delaminate during operation;

- considered the most durable of all varieties;

- during installation, they do not require additional cleaning at the soldering points.

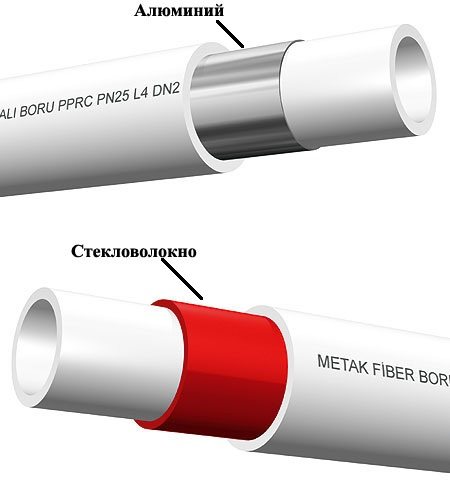

With aluminum

Materials with an aluminum layer withstand temperature fluctuations well, have minimal thermal expansion and practically do not lose their original shape at high temperatures, which is an indisputable advantage.

A feature of reinforced products during installation is the correct cleaning at the joints with the fittings. If you abandon this procedure, then the heating system will quickly fail, and you will have to redo everything during operation.

Solid plastic

Solid plastic products are good for underfloor heating and for use in hidden wiring. The concrete base serves as an excellent reinforcing material, protecting the pipeline from external influences, helping to reduce thermal expansion. Ease of installation and reliability of soldering allow you to forget about the problem of leaking joints for the entire service life.

The positive aspects of using pipes include:

- flexibility;

- length reaching 200 meters;

- special molecular memory that helps to return to its original form during cooling.

Reinforced plastic

The heating system made of metal-plastic is advantageously used in houses where the temperature fluctuations of the coolant exceed 90 ° C. Pipes do not sag under high temperatures, keeping their original appearance. The weak point in the system is the connecting fittings, which can leak when the coolant cools down and therefore require constant additional maintenance.

It is not recommended to use this material for a hidden wiring device, for example, for underfloor heating and a water intake device without access to the connection points.

Why you need to choose the right diameter of heating pipes

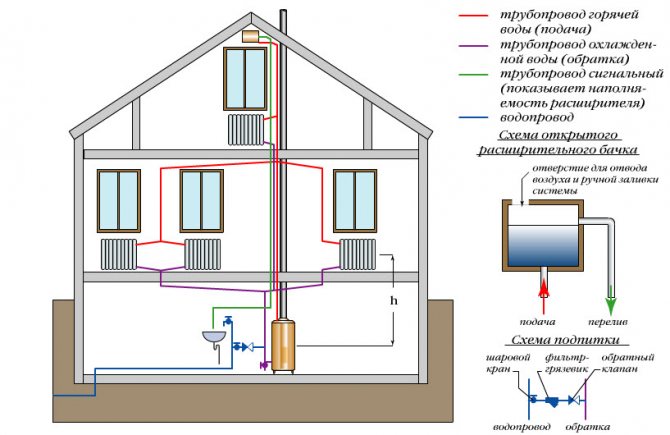

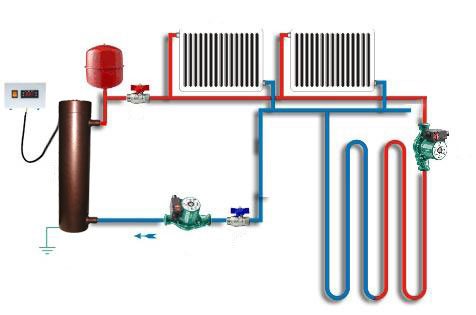

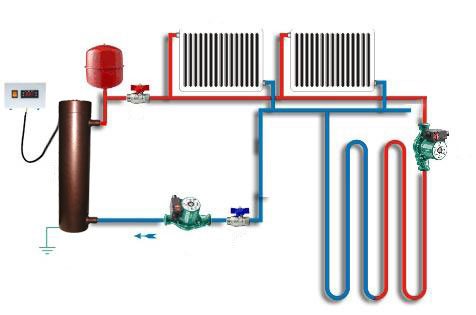

The simplest system of individual heating at home consists of: a boiler, heating radiators, an expansion tank and pipelines connecting all these elements. And if there are relatively simple calculation formulas for the boiler, tank and radiators, according to which the selection of parameters is carried out, then regarding pipes it is necessary to seriously begin to study heat engineering.

The fact is that how the heating will work depends on the correctly selected pipe size. And at the same time, the building will be provided with heat during the heating season. If the calculations are correct, the equipment will work in a balanced manner. The indoor temperature will be stable even on the coldest days, and the energy consumption will be low. It is another matter if the diameter of the pipes is less than necessary - the building will not warm up well. Accordingly, the heating boiler will operate in critical mode to achieve normal temperature.

When the diameter of the main pipes is larger than necessary, this will create problems of a different nature. The increased volume of pipes is filled with a coolant, the volume of which is greater than the calculated one. And this means that the heat loss during its transportation to the batteries will be significant. In this case, fuel consumption will increase significantly. Therefore, this will not mean a rise in the temperature in the house at all.

Specifications

The production of polypropylene pipes (PP) is regulated by the standards GOST 21553 and GOST 15139.

Pressure resistant

In heating systems, it is not always possible to maintain a constant pressure; its indicators can vary depending on the temperature regime and the throughput of the collector. Therefore, when using PP in the heating circuit, it is necessary to take into account the margin of the internal diameter of the pipe, which will have a positive effect when the pressure changes and save the system from ruptures.

Paying attention to the marking, you can easily select the required bore, taking into account the stock. So, with a calculated diameter of 20 mm, a collector with a bore diameter of 25 mm is selected, where the margin for expansion is taken into account when the pressure in the system changes. The letters PN and two numbers on the marking indicate the pressure for which the materials used are designed.

Specifications

Glass fiber or aluminum reinforced polypropylene pipes can have an unlimited diameter, which is usually 16-63 mm, and this is not the limit.

Installation of polypropylene pipes for water supply, photo and video

Please note: one of the main technical aspects is based on the temperature resistance of the product. The maximum allowable temperature limit for polypropylene pipes is 95 degrees Celsius. In this case, the temperature can rise for a short time to 110 degrees Celsius. These indicators make the product ideal for heating systems (in the case of a heating fluid).

Polypropylene fittings allow pipes to be held together without losing heat and strength.

The working pressure of reinforced polypropylene is 10, 16, 20 atmospheres (depending on the type).

Polypropylene pipe fittings

What to look for when choosing

For a heating circuit with unstable input parameters, it is more correct to use reinforced materials.

Pay attention to the following characteristics:

- pressure;

- wall thickness;

- reinforcement;

- temperature regime;

- bore diameter.

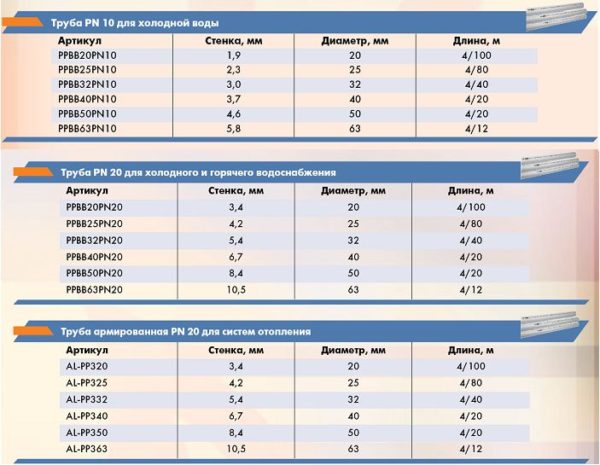

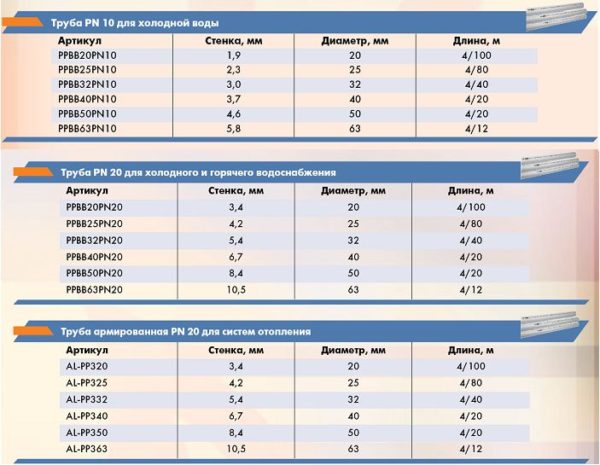

Types of pipes according to the maximum permissible pressure value

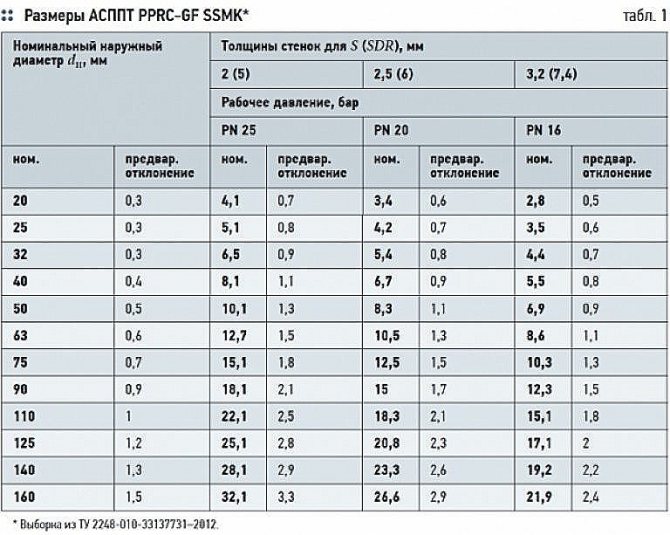

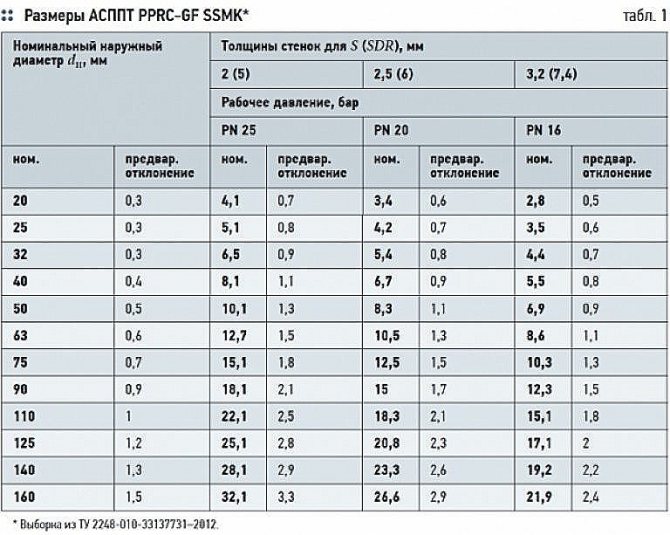

For correct selection, they are guided by the standard TU 2248-010-33137731-2012:

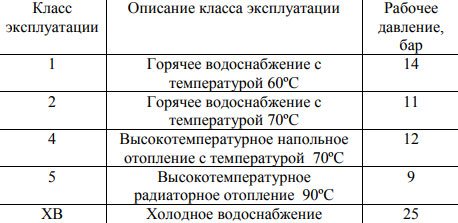

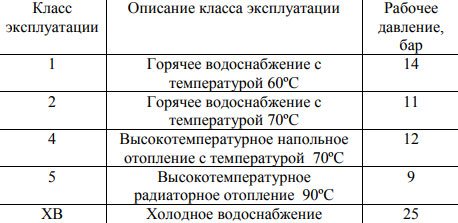

- PN 10 are designed for a pressure of 10 bar at a heating medium temperature not exceeding 40 ° C.

- PN 16 - 16 bar at a water temperature of 60 ° C, and with significant changes in temperature, performance decreases sharply.

- PN 20 - 20 bar, designed for temperatures up to 80 ° C and recommended for hot water supply.

- PN 25 - 25 bar - these are only reinforced products with a temperature regime not exceeding 95 ° C, suitable for heating systems in private houses.

Prices for polypropylene pipes of PN10 class

Polypropylene pipes PN 10

Resistant to high temperatures

When marking pipes, the manufacturer indicates the temperature regime for which the products are designed. So, on reinforced, this parameter is equal to - 90-95 ° С, on ordinary polypropylene - 60 ° С.

Rust is excluded

The main positive characteristic of polypropylene is corrosion resistance. Even with the most low-quality coolant, the collectors are not overgrown with dirt. Due to the perfectly smooth walls, a reaction that promotes the destruction of the material is excluded. At the same time, one should not forget about the radiators, which it is advisable to rinse from accumulated dirt before winter operation.

Low coefficient of thermal conductivity

Plastic has poor thermal conductivity, so this fact is taken into account when installing heating. The same temperature regime of the coolant and the wall has a positive effect on the absence of condensate on the surface of the circuit, which led to its use for the installation of warm floors. The calculation of the power of the heating system is made exclusively for radiators.

Long service life

Manufacturers have endowed the plastic with characteristics that allow it to retain its original qualities for a long time, of course, subject to the operational rules. The warranty period is over 25 years.

What PPR pipes are suitable for heating

Polypropylene pipes began to be used for heating systems relatively recently. Prior to that, their place was taken by solid steel pipes. Such structures were connected by welding, were durable, but difficult to install and expensive to manufacture.

Polypropylene pipes have undergone a number of important metamorphoses in their short history. By itself, polypropylene does not have the heat resistance that the companies developing it were supposed to receive. That is why the first heat transfer systems with such pipes quickly fell into disrepair, and they began to be skeptical about the material itself.

At the moment, polypropylene pipes have been significantly improved. There are various models that are used for supplying cold and hot water, heating and drainage. When carrying out repairs, it is important to choose pipes that are designed for specific purposes, otherwise the structure will not be serviceable.

It is important! At the moment, there are many companies that produce and sell pipes for heating systems. It is advisable to buy pipes along with all components from official suppliers in specialized stores, since there are many low-quality fakes.

Varieties of PPR pipes

Polypropylene pipes are used in various fields, but not all are suitable for heating. In pursuit of cheap material, you might buy the wrong kind of pipes that can withstand hot water under pressure. It is important to be able to distinguish one type of pipe from another.

The classification of polypropylene pipes is as follows:

- PP-H. This is the first generation of polypropylene pipes. This model has all the properties of the base material. PP-N are hermetically sealed and resistant to high pressure, in addition, they do not enter into chemical reactions. However, the melting of such a pipe can begin already at a temperature of 50 ͒С. Such pipes are used in the cold water supply system, ventilation and for industrial purposes;

- PP-B. In the production of this type, the formula of the material was slightly changed. The pipes turned out to be stronger and more durable, but the temperature fluctuations still could not withstand. Such pipes have the advantages of the previous generation and, in addition, better tolerate exposure to hot temperatures. However, they are unsuitable for a heating system and even hot water supply. Such pipes are often used in the construction of sewers;

- PP-R. In the production of these pipes, ethylene is used in addition to polypropylene. This allows them to withstand high temperature loads. In addition, such pipes are usually reinforced, which allows them to withstand temperatures above 100 ° C. Reinforced PP-R pipes are the most suitable option for a heating system.

We recommend that you familiarize yourself with: Service life and capabilities of polypropylene pipes

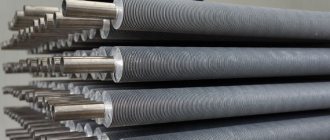

Reinforced pipes

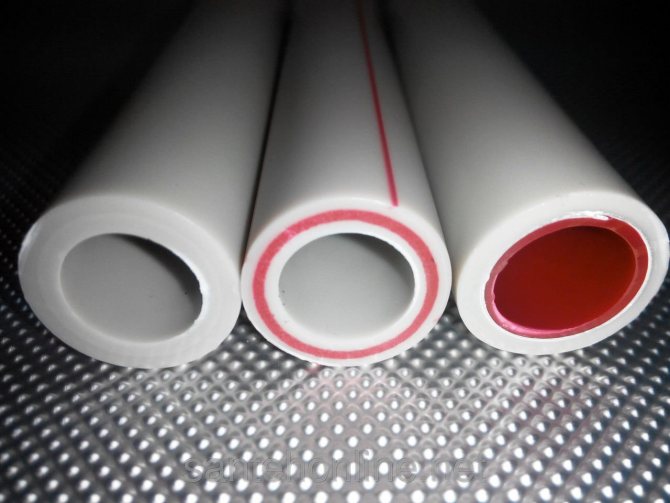

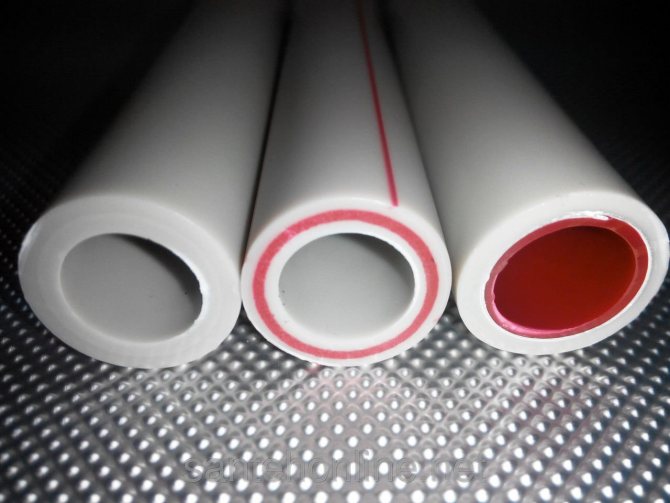

Reinforcement is the process of covering a pipe with a material that is superior in strength or other properties to the main material of the structure. In the case of polypropylene pipes, reinforcement is understood as the coating of the pipe with metal, which retains heat and prevents the pipe from deforming under the influence of high temperatures. Reinforcement can be of two types:

- Aluminum. In this case, the surface of the pipe is covered with aluminum foil. Sometimes this foil is embedded between layers of polypropylene. Aluminum does not allow the PPR to expand and change its shape. However, such pipes have one significant drawback - they can delaminate. Delamination occurs when a pipe is made of poor quality materials or is not docked correctly with another pipe;

- Fiberglass. Such a coating seems to be woven between layers of polypropylene. This makes the delamination process impossible. Such pipes are integral and do not deteriorate if improperly installed or used. The service life of PPR with fiberglass coating is longer, however, such pipes are more expensive.

Technical characteristics of pipes for heating

The characteristics of pipes are based on resistance to various factors that act during operation. When choosing pipes for a heating system, you must pay attention to the following parameters:

- High pressure resistant. Reinforced polypropylene pipes are able to withstand a pressure in the system of about 6 atm. at a temperature of 70 ͒С. The higher the temperature, the lower the pressure resistance. In the heating system, hot water is not supplied under maximum pressure;

- Resistant to temperature influences. Reinforced polypropylene pipes begin to melt at a temperature of 120 ° C. In the heating network, the temperature rarely exceeds 70 - 75 ͒С, which creates a reserve of heat capacity in the system. PPR frosts withstand worse than heat;

- Resistant to corrosion. The main disadvantage of metal pipes is the ability to react with water. Sooner or later, such pipes rust and cease to be airtight. Polypropylene does not corrode when exposed to water. Moreover, it does not react with salts and other impurities that may be found in the system;

- Durability. Manufacturers promise a pipe life of half a century, but do not give guarantees. In fact, the durability of the structure depends on the type of reinforcement, on the correct installation, the temperature inside and outside the pipes, and the pressure in them. If you follow all the recommendations about the repair, you can forget for several decades.

It is important! Polypropylene pipes can be installed outdoors only for residents of the southern regions.At temperatures outside the system less than -15 ° C, polypropylene becomes brittle and pipes may break. Such designs are only suitable for indoor piping.

Selection of pipes for heating

For a heat conductor, it is better to give preference to polypropylene with fiberglass reinforcement. However, pipes made of this material are also different. They differ in diameter and the ability to withstand a certain pressure in the system. The following categories of pipes are distinguished by diameter:

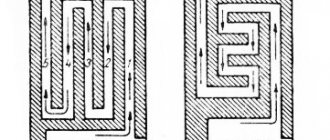

- Less than 1.6 cm. Such pipes are only suitable for underfloor heating systems. This diameter should be sufficient if the pipes are installed correctly;

- 2.0 - 2.5 cm. The most popular diameter when installing heating in a house or apartment. For the riser that goes into the apartment, a diameter of 25 mm is required, and pipes of 20 mm are placed into the rooms;

- 2.5 - 3.2 cm. This category is used in multi-storey buildings with centralized heating;

- More than 20 cm. Pipes of this diameter are needed for large organizations. For example, hospitals with many departments, wards and offices.

We recommend that you familiarize yourself with: How to make a collector for polypropylene pipes?

It is not difficult to determine the pressure that the pipes can withstand. It is enough to look at the PN marking and the number after it. So, PN 10 can withstand a pressure of 10 atmospheres at a temperature of 45 ͒С, PN 16 - 16 atm. at a temperature of 60 ͒С, PN 20 - a pressure of 20 atm. at a temperature of 80 ͒С, PN 25 - 25 atm. at a temperature of 100 and more ͒С. For the heating system, it is necessary to choose at least PN 16, preferably PN 25.

Thus, the best option for heating pipes is fiberglass-coated polypropylene pipes with a diameter of 2 - 2.5 cm and a PN 25 marking.

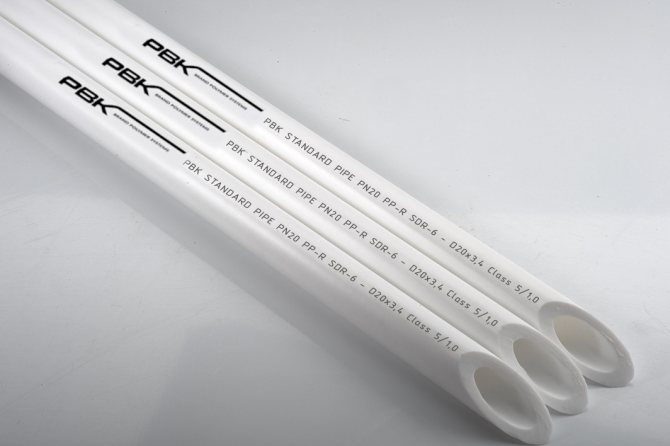

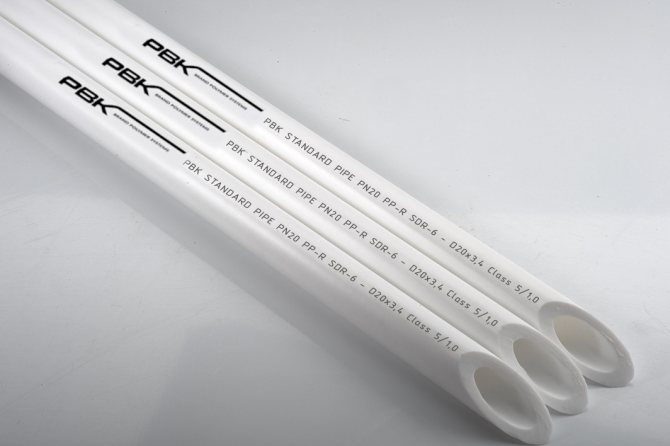

Meaning of markings on pipes

An important selection criterion is the marking applied to the surface of the manufactured product, where, in addition to the operating parameters of pressure and temperature, the pipe diameter is indicated. This is the main indicator for the heating system of a private house.

Product diameters:

- 16-20 mm - designed for underfloor heating and water supply;

- 20-25 mm - for the heating system in private houses;

- 25-32 mm - for centralized highways;

- 200 mm and more are used for heating administrative facilities.

Particular attention should be paid to the diameter of polypropylene pipes used for heating a private house, where one type cannot be dispensed with.

The correct combination and selection of materials with different markings contributes to an increase in heating efficiency several times. So, the transition from a larger diameter of pipes to a smaller one increases the pressure in the system, contributing to excellent circulation of the coolant and increased heat transfer.

Polypropylene pipes for heating technical characteristics

DIY heating installation

The heating system can be installed independently. The main thing is to choose the right materials, correctly match them and seal them together. The design itself is fairly simple to assemble and operate.

Which connectors to use

In order to attach one pipe to another, pipes to risers and radiators, pressure gauges and other devices, special connectors are needed. There are the following types:

- Straight (conventional couplings). They are necessary in those places where one pipe is connected to another of the same diameter, but not at an angle;

- Curved. Used in places where the system bends and turns;

- Triple. They are necessary if you need to make two from one pipe or one from two. For example, in the places where the branches from the main pipe to the radiator;

- Blind (stubs). They are installed in dead-end zones, for example, on extreme radiators;

- With a change in the inner section. They are used when changing from a pipe of a larger diameter to a pipe of a smaller diameter.For example, when connecting pipes to risers;

- With plastic and metal. Such connectors are necessary in a place where there is a transition from plastic products (pipes) to metal ones (radiators, pressure gauges, tanks).

Before starting the installation work, it is necessary to recreate the exact diagram of the proposed system on paper and calculate the number of connectors of each type. In addition, it is important to select connectors whose internal cross-sectional diameters will match the pipe diameters.

We recommend that you familiarize yourself with: Polypropylene pipe reinforced with fiberglass - a guarantee of reliability

Algorithm of installation work

After drawing up a heating scheme and purchasing all the necessary elements, you can proceed to the installation work.

To do this, you need a special set consisting of a soldering iron with nozzles (couplings and drones) and shaders.

It is not necessary to purchase it to install one heating system, you can rent it.

It is important! When carrying out work for the first time, it is recommended to buy more parts than necessary. After incorrect welding, the detached parts are no longer usable, therefore you will have to take new ones.

The installation work algorithm is as follows:

- Cutting pipes and unfolding connectors. This is a preparatory stage, which is important to follow strictly according to the instructions. The pipe is cut using special scissors.

- Shaver pipe cleaning. This step is only necessary when installing pipes with aluminum reinforcement. To do this, take a shaver and put it on the pipe, rotations are done manually or with a screwdriver.

- Soldering iron assembly. Couplings and mandrels of the corresponding diameter are put on the apparatus, after which it is turned on and waiting for heating up to 260 ͒С. At this time, a depth mark is made on the pipe corresponding to the connecting element.

- Compound. A pipe is inserted into the sleeve of a heated soldering iron to a certain depth, and a connecting element is inserted into the mandrel on the other side, after which the elements are soldered to each other for a certain time. Time is calculated as follows: with a pipe diameter of 1.6 cm - 5 seconds, 2.0 cm - 7 seconds, 3.2 cm - 8 seconds.

- All other sections of the pipe are collected in a similar way, after which the structure is attached to the heating system.

Features of installation in an apartment and a private house

It is easier to install a heating system in an apartment. As a rule, one radiator is installed in each room, which departs from the common riser. The pipes are connected according to the proposed scheme, and then they are connected to the riser and the radiator.

In the case of installing several radiators, you can choose two-pipe and one-pipe heating systems. In the first case, from each previous radiator, the coolant goes to the next. Accordingly, in all subsequent radiators, the temperature will be lower than in the previous ones. In the second case, there are two pipes: one for the inlet of the liquid, the other for the outlet.

Before carrying out work in the apartment, it is necessary to agree on the repair of heating with the housing office and the nearest neighbors. Replacement of risers, as a rule, is done centrally.

When installing a heating system in a private house, there will be more work... It is necessary to select the type of coolant, the type of boiler and the system for removing the coolant from the boiler and in the reverse order.

Installing the boiler itself in the absence of experience can also be difficult. A heat pipe is installed, as a rule, in the basement of the house. Then the boiler is connected with pipes to radiators in each of the rooms. Such systems are quite complex, but they also have advantages - the temperature and pressure in the pipes can be adjusted independently.

Selection recommendations

It is worth giving preference to reinforced products that allow high-quality installation of the heating circuit and forget about the problems associated with leaks for a long time.

Experts recommend:

- purchase materials from trusted suppliers, products must have a quality certificate;

- pay attention to the marking containing complete information;

- make a choice in favor of reinforced products;

- choose pipes with fiberglass reinforcement for the heating system. Long-burning stoves for wood-fired heating can be found on our website.

Fiberglass Reinforced Pipes Prices

Fiberglass Reinforced Pipes