What you need to know when choosing a project for the construction of a warm house?

The simpler the geometry of the building, the more efficiently it can be insulated with less money and time. Therefore, all masters who are thinking about how to build a warm house, including on their own, should think about choosing the right project. This will allow:

- significantly save money on heating in winter,

- ensure that the required amount of solar heat gets in,

- to maintain the optimal temperature in the room in the summer,

- choose the most effective type of insulation,

- to install alternative sources of energy and heat.

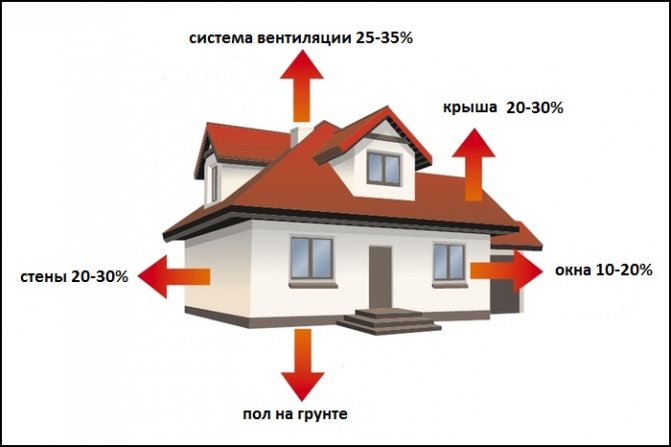

It should be noted that the roof can be made both gable and flat. Complex shapes, towers are best avoided. Their design is inseparably associated with the appearance of gaps over time. And this will affect the level of heat in the room. When choosing a material, you need to pay attention to the fact that the modern market offers many different products. The roof is soft, made of corrugated board, metal. High quality of the product, properly executed thermal insulation will significantly reduce heat losses.

Before building a warm house, you need to pay attention to the characteristics of the wall material, its ability to pass moisture, maintain a certain temperature, and resistance to environmental influences.

Features of the foundation device when building a house

Another part of the heat is constantly lost through the floor and foundation. Due to prolonged exposure to low temperatures in winter, the base is constantly damaged. Soon, this leads to visible defects, destruction. Warming can be a solution - the use of extruded polystyrene foam, special substrates. But the most effective is a warm foundation for the house. Its peculiarity is its unusual design and shallow depth.

What is the best way to build a house. Materials for construction - see here

A special soil cushion is installed that is not subject to swelling. For this, gravel, coarse sand is suitable, crushed stone is also possible, mixtures are used. Even severe frost will not affect their volume, and, accordingly, the structure of the base. A drainage system is required to ensure timely drainage of groundwater. It is noteworthy that not only vertical, but also horizontal thermal insulation is performed, which protects the structure from frost penetration. She goes deep into the dirt cushion. Above it, sand preparation is performed, a blind area. The walls of the house are covered with decorative trim.

The basement slab inside the room is insulated, vapor barrier is performed. Then the finishing coat is arranged. This technology is called "Swedish plate", but is better known as a warm foundation for a house and is more often used in suburban construction.

findings

Thus, we see that if you approach wisely the choice of the project and materials for your country cottage, then you can not only build yourself a very warm and durable house that will not require repairs in the coming decades, but also save very well on heating and other factors.

In private construction, the option to build "like everyone else" is not the best solution. It is more correct to study the properties of building materials and figure out for yourself which of them can bring savings, and at the same time save you from the constant hassle of repairs.

The choice of material for the construction of walls

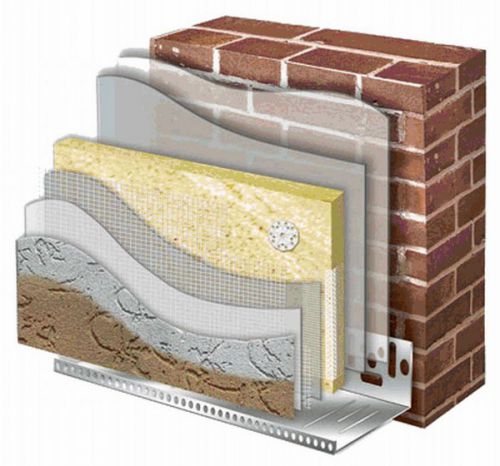

For the construction of walls in the house, brick, wood, various blocks are usually used.They all have different thermal conductivity and properties. But, one way or another, they require subsequent insulation.

Therefore, new building materials are constantly appearing, including expanded polystyrene and polystyrene concrete blocks. Building houses with their use allows you to create a really warm house, the construction technology of which is becoming more and more popular. After all, it allows you to reduce heat loss to a minimum. At the same time, construction is being carried out much faster. Since the blocks are distinguished by the correct geometry, ease of installation.

When choosing polystyrene foam blocks, it is necessary to complete the foundation. After it dries, waterproofing and the first row are laid. A horizontal and vertical reinforcing cage is also arranged. This ensures the required strength and durability. After the first, the subsequent rows are also filled, filled with concrete. In this case, it is necessary to maintain a certain interval, laying out 5-6 rows per day. Upon completion of the work, the stage of finishing work begins.

Insulation of the facade of the house - read here

Popular materials for the construction of warm houses

There are other options for how to build a warm house, the technology, involving the choice of polystyrene concrete, allows this. In this case, the base is also arranged, the laying of blocks begins. The material is also available in the form of slabs. They are suitable for insulating facades, roofs, partitions. After the installation of the walls, finishing is carried out. The use of such blocks not only improves thermal insulation, but also increases the level of safety.

After all, the main components are practically not subject to combustion, high humidity, and mold formation. Also a warm house, construction technology allows you to reduce the weight of the building itself. And this significantly reduces the load on the base, extends its service life.

Of course, the use of other materials is also possible. There are construction methods using concrete slabs, composite panels. They also have attractive characteristics. We must not forget about natural wood - glued, profiled timber. Such residential buildings, subject to the technological process during the device, retain heat well and are environmentally friendly.

Thermal insulation of the house - read here

Quite often, a frame warm house is also used, the construction technology of which does not require a deep and powerful foundation. Even a columnar foundation is suitable. Accordingly, the costs are much lower.

How to make a warm floor with your hands

Underfloor heating is a great way to additionally warm the room. Firstly, it is the most natural and efficient way of heat spreading - from the bottom up. It helps to evenly warm up the entire room. Secondly, walking on a warm floor is very comfortable. Underfloor heating has several varieties, it is very important to choose the best option for yourself. All of these options are good, but they are designed for different operating conditions.

Underfloor heating the most economical in operation in terms of the fact that the same hot water is used for heating as in radiators, no additional costs. It is possible to use a water heat-insulated floor with any floor coverings, and in the presence of heavy furniture, since the pipes for the water supply in this version are reliably insulated. The disadvantages are as follows: the installation of such a system is very difficult: you need to change all the existing wiring, lay special pipes, usually metal-plastic, significantly raise the floor level (all this requires space). Not everywhere they write about this, but for the good work of the water floor, an additional storage device and a pump are needed for it. All this equipment must be purchased and placed somewhere.If the hot water is turned off, then the warm floors will not work either.

You can use a water heat-insulated floor with any floor coverings and in the presence of heavy furniture. Electric underfloor heating devoid of all these shortcomings. When laying such floors, the floor level either rises slightly, or does not change at all. They are somewhat more expensive to operate because they consume electricity. But on the other hand, they can be successfully regulated, and significant savings can be achieved. Electric underfloor heating comes in two varieties: cable floors and floors with infrared films. The only thing to consider is the severity of the furniture, and, if possible, do not lay such floors under the heaviest furniture.

If your apartment has electric underfloor heating, you will have to forget about heavy furniture In cable warm floors, respectively, an electric cable has been laid. There are two options. You can mount it directly into a concrete screed, or buy special mats, in which everything is already provided. These floors are very effective at raising the temperature in the room and are very easy to install.

Cable floors are very warm and easy to install Infrared underfloor heating do not require raising the floor level at all; they are the simplest to install. A special film "works" in them, which gives infrared radiation. The film contains carbon fibers, and electricity passes along the edges of these fibers through special conductors. Then these fibers begin to radiate heat. These floors are the most economical. They give slightly less heat than cable ones, but this is not perceived physically, since the property of infrared radiation is such that it heats not only the floor, but also any objects in the room, including humans.

Infrared floors are the most economical

Installation of a warm roof

As you know, warm air masses in a room always rise. Therefore, it is required to insulate not only the foundation, walls, but also roofs. Especially if the attic space is residential or used for other purposes. In winter, the necessary warmth will be better retained, and in summer it will be cool.

The whole process is not very difficult if you know how to make a warm roof of a house correctly. The construction itself will consist of many layers. Hydro-wind insulation is laid even during the installation of the roof. It is necessary to protect the insulation from condensation. Since temperature changes, exposure to sunlight cannot be avoided. For this, special polypropylene films are used, vapor-permeable, with special coatings.

Next comes thermal insulation. Usually glass wool or expanded polystyrene boards with the best characteristics are chosen. The next layer is a vapor barrier, which is necessary to protect the insulation. Since moisture, getting on such a material, neutralizes its beneficial properties. All this should be taken into account, before making a warm roof of the house, take care of the quality of the materials used.

Home insulation with mineral wool - see here

Features of the choice of parts

It's one thing if you are thinking about how to make a warm floor in a bath, and another thing in a house or apartment. Why? It's all about the installation features - in the bathhouse the floor is wooden, and therefore it is quite simple to remove it, which cannot be said about the screed in a house or apartment.

Pipes and other heating elements should be bought only of high quality and reliable, because saving on them can lead to the fact that after a couple of years, if not earlier, you will need to tear off the floor covering to repair the warm floor.

If you are undecided, then we would recommend you electrical options, especially if the installation will be done under the tiles.

They are not afraid of fire and short circuits, because if parquet or laminate is mounted on top, there will be a protective layer of non-combustible material between the warm floor and the finish.

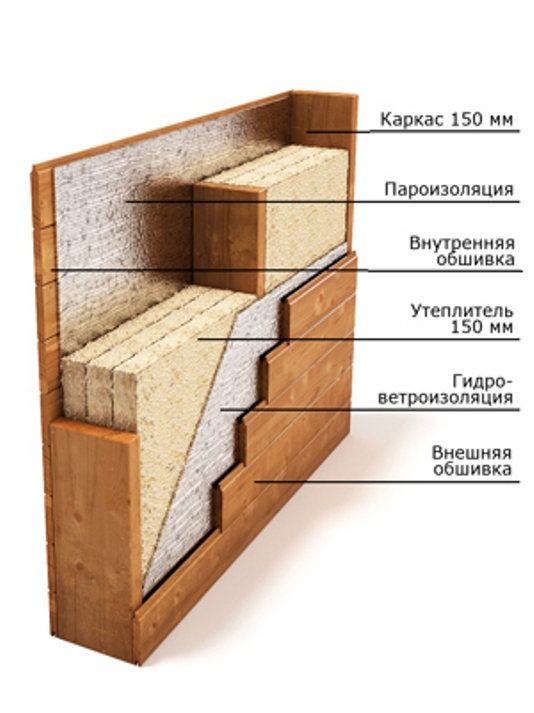

Frame houses, their features

The frame construction of cottages is quite popular today, as it requires relatively little financial costs and time. In terms of the quality of the structure, they practically do not differ from traditional ones. However, you need to know how to warm a frame house.Indeed, with improper insulation, it will be quite cold and uncomfortable for life.

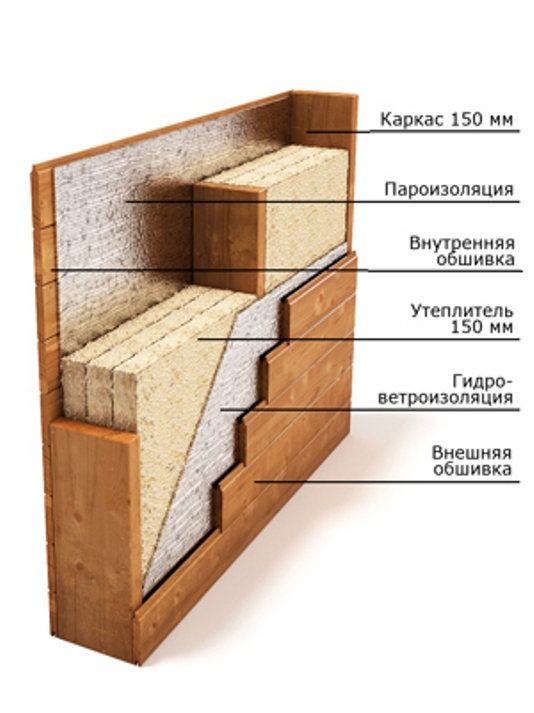

The main thing is the use of quality materials and strict adherence to the project and technological process. To begin with, a wooden frame is arranged. Panels, lathing, external, internal decoration will be sewn onto it. All materials must meet strict requirements and have thermal insulation qualities.

The walls of such a house, floor, roof must be insulated. A film is used to protect against wind and moisture. Insulation is laid inside the walls, for example, polystyrene. It is possible to use additional insulating materials. Therefore, before making a warm frame house, it is better to consult with experienced specialists.

Basalt insulation for a frame house - see here

Quite often the question arises, are frame houses warm? Everything will depend solely on the craftsmen, the quality of their work, the technologies and building materials used. The construction of buildings using Canadian and Finnish technology is also popular. Only professionals should be trusted to carry out such processes. Any deviations, the slightest inaccuracies - and the house will be very cold. Therefore, experts-builders and clients who have used their services can tell whether the frame houses are warm.

Floor insulation in a frame cottage

Blowing is the main enemy of frame houses. Small gaps lead to severe heat loss. Accordingly, special attention must be paid to the flooring device. The method of insulation will depend on the type of foundation, the quality of the soil, and its moisture content. In order for the warm floor in a frame house to perform its functions with a strip foundation, it is possible to lay the lower layer of expanded clay for insulation. In this case, there must be airflows.

But more often a wooden floor is arranged, the basis of which is logs. Then, between them, insulation is covered, sewn up with plywood. After that, a finishing decorative coating is performed. Sometimes, in order to have a really warm floor in a frame house, you need to install special insulating films. They protect the coating from moisture and cold penetration. The optimal choice of building materials will depend on the design features of the building. Therefore, the advice of experienced experts will never be superfluous.

Design options

Among all the options for installing a warm floor in a wooden house, you should choose the most optimal, based on the technical features of the structure. Let's consider the most popular methods.

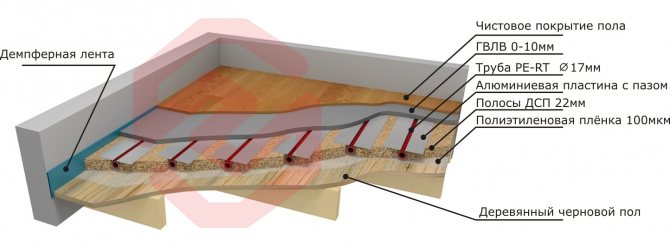

On the lags

With this method, insulation is laid between the lags along the rough filing. A layer of vapor barrier is placed on top of the insulation to protect the heat insulator from getting wet. Profiled plates are laid on top of the lag. They are used to reflect heat and form channels for pipes with a coolant.

A damper tape must be laid along the perimeter of the room. When the contours are laid, the finishing coating is mounted.

On expanded polystyrene sheets

Expanded polystyrene sheets for underfloor heating are produced with special grooves, into which a soft contour can easily fit. Such mats are laid on a pre-leveled plywood base or OSB boards. This method of installing underfloor heating in a wooden house is dry. After fixing the contour, DSP slabs and a finishing coating are laid on top. The advantage of this method is the simplicity and high speed of work.

In a screed laid on a wooden base

The traditional installation method is screed. First, the base is leveled, insulation and a layer of waterproofing are laid. A damper tape is fixed around the perimeter of the room. A reinforcing mesh with a cell of 10 x 10 cm is installed on special supports. The contour is attached to the mesh using plastic clamps.Beacons are installed and the screed is poured.

Between the planks stuffed on the floor

It is a low cost alternative to modular milled groove bases. In this case, the slats are fixed along the subfloor with a gap between adjacent elements. The thickness of the gap corresponds to the width of the loop pipe.

To reduce heat loss, the thickness of the laths is selected so that the distance from the upper plane of the pipe to the bottom of the finishing coating is minimal.

In the selected grooves

A flat wooden base is used as a mat for setting the contours. Preliminarily, grooves of the required width are selected by the machine on its surface. This method is economical as there is no need to purchase additional components.