Composition and production of extrusion insulation

The extruded heat insulator is made of small polystyrene granules and a blowing agent. The entire production process can be broken down into the following stages:

- Polystyrene granules are poured into an extruder and the substance is heated to 130-140 ° C.

- Foaming additives - porophores are added to the mass.

- The formed foam is squeezed out of the extruder, the composition is fed to the conveyor.

- The continuous sheet is cut into mats of the desired size and packed.

Extrusion method provides dense structure of insulation with the smallest pores. Freon evaporates from the cells, and atmospheric air fills its place.

To improve technical characteristics, in addition to polystyrene and porofols, the composition contains a number of additives:

- flame retardants - reduce flammability;

- antioxidants - prevent destruction during the operation of the insulation and prevent thermal oxidation at the stage of processing;

- modifiers, antistatic agents, light stabilizers - increase resistance to negative external factors.

Properties of Penoplex insulation boards

Obtaining a special closed porous structure, consisting of micro cells (one tenth of a millimeter), foam as a result of extrusion allows you to obtain the following properties:

- low level of thermal conductivity,

- low level of moisture absorption,

- indifference to chemical compounds,

- resistance to bacteria,

- insulation.

The agent used for foaming polystyrene is light freons and carbon dioxide. Penoplex boards have special strength and lightness.

The composition of the Peloplex slabs contains a fire retardant, which is a substance that affects the refractoriness of the material. An effective flame retardant prevents the rapid spread of fire, but begins to melt with prolonged burning. Peloplex does not emit things harmful to the human body, even when burning.

Penoplex plates can also protect against noise

The room, in which thermal insulation was carried out with these materials, is protected not only from cold weather, but also from noise, which is especially important for urban residents of block buildings.

Penoplex thermal insulation boards are suitable for places where temperature fluctuations during the year range from + 40 to - 30 Celsius. In such conditions, the slabs can last for many years, however, in order to ensure the effect of the heat-insulating material, a correctly calculated and performed installation of the Penoplex insulation is necessary.

Material specifications

The most popular representative of extruded insulation is Penoplex. The properties, pros and cons, as well as the features of the use of a thermal insulator, will be considered with respect to this material.

Specifications:

- density - 25-35 kg / m3, depending on the category of thermal insulation;

- compressive strength - 0.20-0.27 MPa;

- water absorption per day - up to 0.4% of the total volume;

- tensile strength - 0.25-0.4 MPa;

- fire resistance - group G3 - middle class (smoke temperature within + 450 ° С, burning duration - 300 sec);

- thermal conductivity index - 0.03 W / (m * ° С);

- operating temperature range - from -100 ° С to + 75 ° С;

- standard dimensions of slab insulation: width - 60 cm, length - 1.2 m, thickness - 20-150 mm.

Strengths of Penoplex

Numerical indicators will allow us to draw a conclusion about the operational properties of Penoplex insulation. The strengths of the material include:

- Low thermal conductivity. Closed honeycomb structure promotes heat retention - the effectiveness of thermal insulation is superior to that of mineral wool and isolon.

- Minimal water absorption. Moisture does not penetrate inside the material. Water can only seep into external damaged cells. Minimal water absorption allows you to lay Penoplex without additional waterproofing.

- Resistance to mechanical stress. Thanks to extrusion, the cells inside the porous material are evenly spaced, which significantly increases the strength of the insulation. Under heavy loads, dents about 1 mm deep are likely to form.

- Ease of installation. Penoplex slabs are lightweight, which means that there are no problems with raising the material to a height. An additional plus - no weighting of the structure.

- Durability of operation. Many manufacturers of extruded polystyrene foam give on their products 50-year guarantee... The term is not overstated - the insulation has passed multiple tests.

Useful: Insulation of the pipeline: types, installation features

How is the installation of Penoplex insulation

Installation of insulation boards is extremely simple. The material can be easily cut even with an ordinary knife. It is necessary to calculate the required amount of Penoplex in such a way that there are no gaps between the slabs.

To correctly calculate the number of penoplex slabs for your object, you can use the following penoplex calculator.

Keep in mind that the next time the material for the same room will come in handy no earlier than forty years later.

Disadvantages of extruded polystyrene foam

When planning the use of Penoplex, it is worth considering its weaknesses:

- High flammability and smoke generation. The self-extinguishing rate depends on the amount of flame retardant additives. After a ceasefire, the insulation emits acrid smoke.

- Toxicity. On contact with UV rays, Penoplex produces toxic vapors, so the material recommended for insulation outside the house.

- Susceptibility to certain reagents. The thermal insulator deforms under the influence of organic solvents and petroleum products. Penoplex is afraid of kerosene, oil paints and polyesters.

- Poor steam permeability. It is important to consider this quality when insulating a wooden house or frame structure. The use of Penoplex for thermal insulation of walls leads to the appearance of a thermos effect in the room. The problem can be solved when arranging forced ventilation.

Application and installation

Facade

The use of foam for insulating a house outside has rather high quality indicators, but it will not be available to everyone, since the price of such a heater is several times higher than the prices for all similar goods (foam 25 or 35 density).

To carry out the work you will need:

- clean the walls from dust, debris and grease stains;

- using a front roller or a wide brush, prime the base to strengthen it before carrying out the main work;

- installation of each sheet of foam is made on special glue and then fixed with foam dowels;

- The finishing of such a facade after insulation with penoplex is most often decorative plaster - "Bark beetle" or "Lamb".

All types of foam and any thickness are used for walls.... The choice will depend on the financial capabilities of the consumer and the characteristics of the building itself.

Plinth

Dowels for fixing should be evenly distributed over the area of the sheets, ideally 5 pcs. per sheet

This insulation option provides for:

- gluing penoplex around the entire perimeter of the house at the level of the basement by the type of facade insulation - with glue, but with additional fastening to dowels;

- after that, the insulation should be covered with a special plaster on the insulation, which can isolate the entire penoplex as much as possible from the effects of the environment on it;

- the basement is finished in a variety of ways: basement siding, profile sheet, clinker tiles and even decorative plaster.

Related article: Do I need to prime the walls before plastering

Foundation

After the complete completion of the insulation work, the entire perimeter of the foundation must be covered with sand to cover the penoplex

Most of the heat goes through that part of the house that is closest to the ground - the foundation, so its insulation requires a special approach, and penoplex will be an ideal material for this.

The process of carrying out work on the insulation of the underground part of the building is very simple:

- The foundation - the load-bearing wall of the house, which is located below ground level - is cleaned of mortar residues.

- Further, waterproofing is applied over the entire area of the base to be insulated with foam. It can be bituminous mastic or dry waterproofing mixture. Work is best done with a wide brush. (You can read about how to properly waterproof a strip foundation with your own hands in this article).

- This is followed by the process of installing the penoplex - gluing each sheet separately on the same mastic or special glue for insulation. Foam dowels are used as additional fasteners. The only prerequisite is a continuous coating, which will make it difficult for heat to escape and prevent condensation from accumulating.

- Penoplex must be covered with a waterproofing film and only then carry out the accompanying drainage work.

It is best to use penoplex with a maximum thickness of 50 mm for insulation.

We also bring to your attention an article about the universal type of "Comfort" penoplex.

Balcony

Seams and joints between the insulation for reliability should be sealed with glue foam or liquid foam

This part of the apartment is responsible for the preservation of the heat that goes out through the balcony block, so you need to act here with all responsibility.

Work on the balcony insulation with penoplex is carried out in stages:

- Alignment of all insulated surfaces.

- The foam is fastened by driving in fasteners - dowels for insulation.

- Before decorative painting, the penoplex is completely plastered and kept for 12 -24 hours until the adhesive mixture is completely dry.

When using PVC or MDF lining, the process will be slightly different:

- the foam is fixed by driving in fasteners - foam dowels;

- foam sheets are very quickly and reliably fixed between the crate;

- finishing the balcony with clapboard does not require an additional insulating layer.

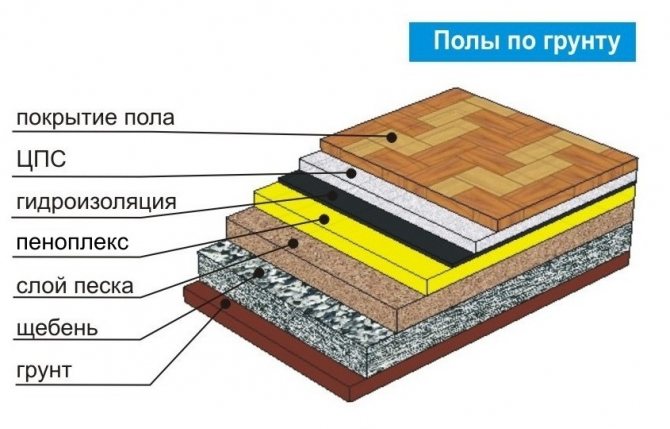

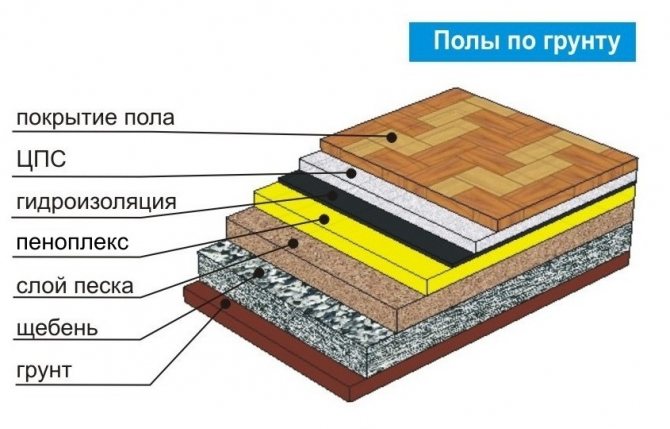

Thermal insulation of the floor under the screed with extruded polystyrene foam occurs by connecting the sheets using the existing grooves.

If it is planned to install a wooden floor, then the sheets of the penonex are stacked between the logs, having previously covered the floor with a waterproofing film.

The device of a warm floor on such insulation as penoplex is quite safe even without the use of additional insulation.

Thermal insulation of the floor in an apartment building will also create an additional layer of sound insulation. It is advisable to use insulation sheets with a maximum thickness of 40-50 mm.

Read how to insulate the floor in a private house with your own hands here.

Considering all of the above, we can conclude that such insulation as penoplex can be used in any room and under any weather conditions. The described options are far from all, for example, with penoplex, you can insulate a bathhouse and even a garage. The only condition will be the thickness of the foam sheet, on which the quality of the insulated surface directly depends.

We bring to your attention a video on the comparison of different types of penoplex:

Scope of application of the pressed insulator

Penoplex is actively used to insulate various structural elements of buildings.The material is in demand when performing the following works:

- Insulation of the foundation. Barrier insulation reduces the depth of soil freezing, prolongs the waterproofing period.

- External insulation of the house. Massively used for private houses and thermal insulation of apartment buildings, offices. It is possible to insulate a frame house with Penoplex, provided that there is effective ventilation.

- Insulation of the floor, interfloor ceilings. Penoplex is sometimes used as a substrate for underfloor heating.

- Thermal insulation of roofing cake, attic room.

- Insulation of balconies and loggias.

Reviews of those who insulated, prove the effectiveness of Penoplex. The measures taken significantly reduce heat loss and reduce heating costs.

Penoplex types: application features

Insulation is classified by purpose. The manufacturer took into account the peculiarities of using the material in different conditions and "corrected" a number of parameters.

It is not difficult to understand the classification. The name itself speaks of the scope of application of the pressed insulation:

- Penoplex-Wall. External insulation, installation under plastered facades. Plinth finishing increases the energy saving of the house, creates a noise barrier... The density of the material is 25-32 kg / m3, the strength index is 0.20 MPa.

- Penoplex-Foundation. In addition to the main area, it is in demand for warming septic tanks, arranging garden paths on a cement-sand base. Density - 29-33 kg / m3, strength - 0.27 MPa.

- Penoplex-Roof. Suitable for warming the attic, used as a heat-insulating layer in the composition of the roofing cake. Density - 28-33 kg / m3, grade strength - 0.25 MPa.

- Penoplex-Comfort. A universal material used for floor insulation, loggias, walls, roofs. The density is 25-35 kg / m3, the compressive strength is 0.20 MPa.

Penoplex 45 fits for thermal insulation of flat roofs and areas subject to significant traffic, such as highways. The density of the brand is 34-47 kg / m3, the strength characteristics are 0.50 MPa.

How to properly insulate a house

The tactics of performing work is determined by the scope of use of the extruded heat insulator. Fixation on vertical surfaces is often carried out with glue for insulation; on horizontal coverings, sheets are fixed with dowels.

Useful: Choosing a material for building a house

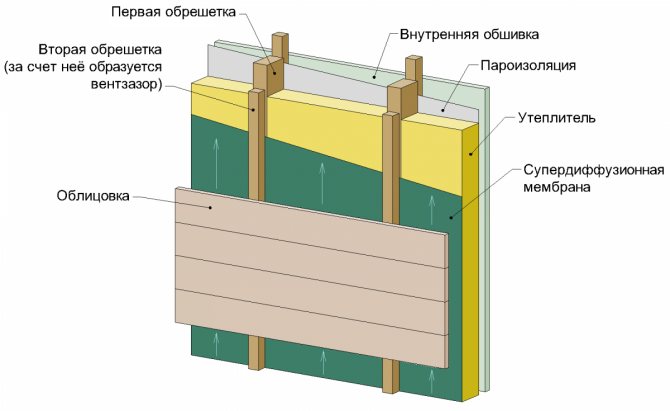

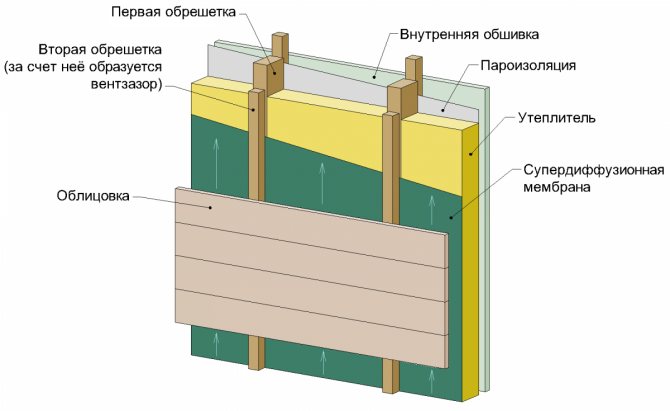

Wall insulation technology

The whole process of wall insulation on the ground floor you can do it yourself... For high-altitude work, it is better to attract professionals with special equipment.

During installation, be sure to use insurance. It is better to enlist the help of an assistant who will feed the panel material.

Sequencing:

- Training. Clean the walls of dirt, remove the remnants of finishing materials, dust the surface. Remove visible defects and irregularities - level with plaster.

- Bonding. Apply the glue in an even layer to the board and press the insulation against the wall. Installation is carried out from the bottom row, as a support - a basement profile.

- Anchoring. Fixation is carried out after 3 days - after the glue has completely dried. Dowels are fixed at the rate of 4 pcs. for 1 sq. m, near windows and doorways - 6-7 pcs. for 1 sq. m.

Finally, foam the joints between the sheets. If a two-layer insulation is required, the slabs are laid out in a checkerboard pattern.... The final stage is the installation of a reinforcing mesh and plastering.

An interesting option for insulation with siding is double-sided slabs. The inner side is extruded polystyrene foam, and the outer side is decorative trim. Such material greatly simplifies the work. In one pass, it is possible to thermally insulate and revet the walls.

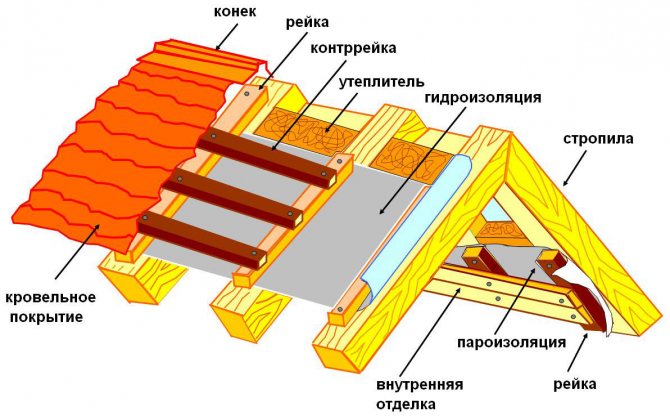

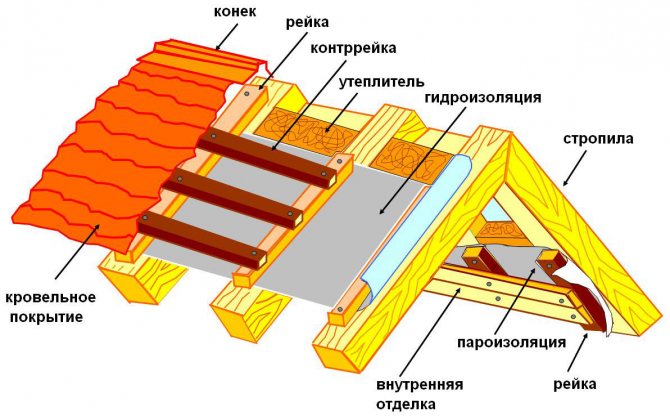

Roofing

The roofing cake is formed in the following sequence:

- Internal cladding.

- Lathing.

- Moisture resistant vapor permeable membrane.

- Penoplex.

- Rafter system.

- Windproof membrane.

- Roof covering.

Installation of insulation is performed when the rafters are assembled, the crate is nailed.

Stages of work:

- Install the starting rail at the bottom of the rafters.

- Lay out the slabs staggered.

- Fasten the material with self-tapping screws, glue the seams with tape.

- Fill the bars on top - the slats will provide a ventilation gap.

- Fill the crate for the installation of the roof covering.

Calculation of the thickness of the heat insulator

Figure 3. A 10 cm layer of Penoplex is required for high-quality insulation of reinforced concrete floor slabs.

When calculating the required Penoplex layer, the main indicator is the required thermal resistance of the structure. Data on this characteristic of walls, floors, floors are summarized in SNiP tables for different regions of operation. For example, in the Moscow region, SNiP standards recommend this parameter for capital walls 3 units, for floors, 3.9 units.

The area of all materials used in supporting structures is the same. The thermal resistance of each layer is different. Therefore, it is necessary to summarize this indicator of each layer, taking into account its thickness. A load-bearing wall usually consists of the following layers:

- facade cladding - siding, brick, panels, plaster;

- insulation - in this case, expanded polystyrene;

- construction material - timber, brick, concrete, wood-containing slabs;

- interior decor - plasterboard, panels, wallpaper, other materials.

The thickness of each of them should be taken into account individually, no two identical structures exist in nature.

For brick walls of one and a half stones, outside of which Penoplex is used, the calculation is as follows:

R = p / k, where k is the thermal conductivity of a given material, p is the layer thickness.

Layer-by-layer for all materials:

R1 = 0.38 m / 0.5 = 0.76 units (brick).

R2 = 0.01 m / 0.15 = 0.06 units (drywall).

Figure 4. Expanded polystyrene is 98% air, it is lightweight and inexpensive.

Subtracting the obtained results from the calculated resistance, the required parameter of the insulation layer is obtained. Its coefficient is known from the tables, it remains to find out the thickness of the layer:

R3 = 3 - 0.76 - 0.06 = 2.18.

P = 2.18 x 0.028 = 0.061 m.

The thickness of the Penoplex slabs of 6 cm is enough to ensure the calculated thermal resistance. Choosing a construction technology with a layer of insulation inside the masonry, you can get by with half of this thickness by laying the second one between the bricks.

When using expanded polystyrene on the floor to insulate the first floor, the results will differ:

R1 = 0.22 m / 1.3 = 0.17 units (reinforced concrete floor);

R2 = 3.9 - 0.17 = 3.73;

P = 3.73 x 0.028 = 0.1 m.

Thus, for high-quality insulation of reinforced concrete floor slabs, a 10 cm layer of Penoplex is required. Fig. 3.

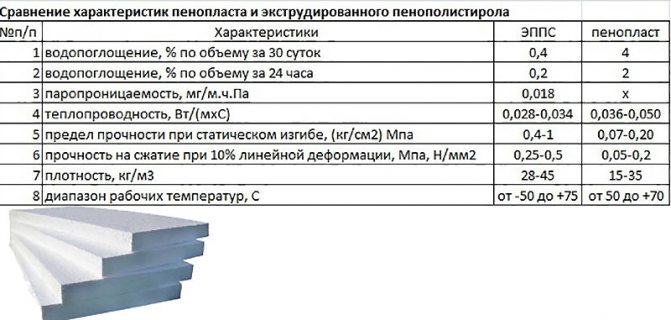

Penoplex and expanded polystyrene: comparison of materials

By insulation polystyrene foam is meant ordinary foam. Like Penoplex, it is produced in slabs, the maximum thickness of the heat insulator is 500 mm. For wall insulation, sheets of 50 mm or more are used, and a lower value is permissible for the ceiling.

Polyfoam is also made by foaming using expanded polystyrene granules. However, there is no compression extrusion step here. As a result, large cells are formed in the structure. This affects the strength of the insulation - foam is less rigid than Penoplex.

Expanded polystyrene is inferior in terms of thermal efficiency, density and water absorption. The level of vapor permeability of foam and Penoplex is comparable.

Knowing the purpose, forthcoming loads and operating conditions of extruded polystyrene foam, it is easy to choose the optimal type of Penoplex. Do-it-yourself installation of insulation, in addition to facade work at a height - in this case, you will need the help of construction climbers.

The use of insulation for walls Penoplex

On average, walls allow up to 50 percent of heat to pass through, so thermal insulation must be carried out with special care. Penoplex insulation is the optimal solution for any premises.Zero moisture absorption allows the use of insulation even in bathrooms, baths and saunas.

Safety and environmental friendliness, as well as the presence of a level of fire resistance, will ensure that the requirements of a heat-insulating material in any room are met.

The range includes L-shaped models for the insulation of docking structures.

It is possible to carry out installation of insulation for walls of Penoplex plates in any winter and summer.