The device for waterproofing walls is the most important element in the overall complex of construction work. The penetration of moisture from the outside into the structures and the loss of dew on the internal surfaces of the building always brings a lot of harm. Moisture destroys the structure of building elements, contributes to the development of mold and fungi. Moisture-saturated exterior surfaces of a home are most susceptible to deterioration during the winter. The water turns to ice and breaks the base of the walls. The waterproofing of the walls of the house must be of high quality. Sealing of fences is done both inside and outside the house.

Sources of moisture

From the outside, moisture can penetrate into the building from groundwater, during floods, from atmospheric precipitation. Poor thermal insulation of the building envelope can contribute to a sharp temperature drop on the surface of the walls inside the house. This causes dew to fall out inside the dwelling.

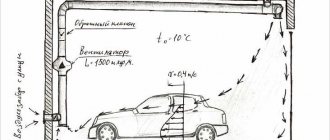

Inside the building, the presence of moisture is observed in basements, bathrooms and kitchens. Extensions to the building (garages, workshops, etc.) are also objects with a high level of humidity.

Varieties of materials for waterproofing

If we talk about the purpose, then there are 4 groups of materials:

- Sealing.

- Anti-filtration.

- For corrosion protection.

- Heat and waterproofing.

If we talk about the form, then the following types are distinguished:

- Coating type;

- Roll type;

- Injection.

Waterproofing internal walls and external walls can be done in different ways. To understand how to do it right, it is important to consider the features and characteristics of each waterproofing.

Bituminous mastic

Representative of coating products. Bitumen - a product from oil refineries, is a dark elastic mass. Usage: application to the wall with a roller, brush. A dense film is created on the wall, which is not afraid of water and does not allow it to penetrate inside. The film is durable and won't crack. Due to its viscosity, it penetrates into all cracks, crevices and pores of walls made of concrete, brick or blocks. The waterproofing layer can be used both independently and in addition to roll products. Scope of application: protection of the building exclusively from the outside, walls, plinth and foundation.

The advantage of bitumen mastic is ease of application and good efficiency. The process is fast and cheap. The mastic can be sold ready-made or as solid bars. The second option requires melting before work. Minus the material - the mastic hardens for a long time. And if you buy cheap and low-quality products, then they can crack over time.

Advice! The mastic has excellent maintainability. All cracks and defects of the previous layer can be easily covered up and hidden.

Polymer type mastic

Lubricating waterproofing in the form of a plastic adhesive composition. It is based on acrylic polymer. It is used both to protect internal walls and external walls, foundations and plinths. In addition, it has good thermal insulation characteristics.

Benefits:

- Ease of application, a beginner will cope with the task;

- The speed of work;

- After application, a dense and even coating appears that perfectly protects the surface. Additional finishing is not required;

- The material is protected from fire;

- Made from safe materials, can be used inside the house, even in the bathroom;

- Sold in a large assortment and in different colors;

- Not afraid of negative temperatures;

- Dries quickly;

- Elastic, slight deformation of the walls and the resulting cracks cannot break it, the film is stretched.

Substances of deep penetration

Also coated waterproofing, but the principle of operation is slightly different. If in the first two cases a protective film was created on the surface, which does not allow moisture to penetrate the wall, then here the protective layer is formed from the inside. After application, the composition penetrates into the pores and structure, and then crystallizes. This will prevent moisture from penetrating the structure. And even if the surface is damaged, it will not affect the waterproof properties.

The material can penetrate up to 1 m deep. It is used for both internal and external work. The best option if you need waterproofing for the walls in the apartment. For use, you need to prepare a dry mixture according to the instructions (by adding water) and apply to the surface. The process will be performed even by a beginner, everything happens quickly and safely.

Roofing material and roofing paper

Old or classic representatives of roll-type waterproofing. Sold in a roll. The installation process resembles working with wallpaper. Roofing material can be glued onto mastic or fixed by fusion. Both materials are used only outside to insulate walls, basement and foundation.

At the base of roofing material is cardboard or fiberglass, which are impregnated with bitumen. After gluing, a protective layer is created that does not allow moisture to pass through. Roofing felt is a cardboard sheet that is impregnated with a tar-based composition. The quality is better for roofing material, and the price is less. Although, these materials are among the cheapest. But they do not carry out waterproofing of walls inside the house.

Film or membrane

Representative of roll materials. Made on the basis of PVC or synthetic rubber. Scope of use: inside and outside for walls, plinth and foundation. The film is glued to the surface, not allowing moisture to pass through. Easy to use and affordable.

The main disadvantage is that it can be easily damaged. Soil or rodents can disrupt the integrity of the waterproofing layer of walls or foundations, the won will start to fall on the base. Therefore, even during installation work, it is important to be careful.

Pastes or injection materials

Representatives:

- Epoxy substances;

- Acrylate based gels;

- Polyurethane substances.

Designed to protect the material from the inside at the structural level. Method of application: holes are made along the entire wall at a distance of 40-50 cm. A paste or injection mixture is injected into them under high pressure (from this name, the process resembles an injection or injection). This is an expensive method and requires special equipment to implement it. Such waterproofing for walls inside is rational only in cases where other manipulations cannot be carried out.

Types of insulating materials

The types of waterproofing on the construction market are represented by many types of insulating materials. It can be liquid mastic or a film coating.

The most widespread use of materials as external waterproofing of walls was obtained by roofing material, roofing felts and bituminous mastic.

Bituminous mastic

Bitumen is one of the products of oil refining. Mastic serves as a means for gluing bituminous roll materials such as roofing felt and roofing felt. It is a homogeneous mass of bituminous binder with the addition of an antiseptic - sodium fluorosilicate.

The mastic is supplied in paper-wrapped sticks weighing about 20 kg. They use it in a heated liquid state, bringing the heating up to 1500C.

Warm-up conditions allow for open flames. When working with this material, you must strictly follow the fire safety rules.

Bituminous mastic has high adhesion and firmly "sticks" to any surface.This universal property and low cost of this substance make it one of the most attractive insulating materials.

Polymer mastics

In addition to bitumen mastic, there is a large selection of polymer-based coating materials. They are easily applied to the walls from inside the room with a spatula or brush. The mastic dries quickly (within a few hours), forming a surface with high adhesion.

This video demonstrates the use of such a mastic:

Roofing felt and roofing material

Roofing felt and roofing felt - roll insulating coatings intended for waterproofing building structures.

The basis of these coatings is technical board impregnated with soft bituminous compounds. A distinctive feature of roofing material is the presence on the outside of the dressing of asbestos crumbs, talc and quartz sand. This is mainly done to protect the upper layer of roofing material when laying it on the roof of the building.

Roofing felt and roofing material are "glued" to the walls with hot mastic. The resulting surface becomes a powerful barrier to moisture penetration. Thus, waterproofing of the concrete walls of the foundations is done from the outside.

Waterproofing the outer walls of the house with roofing material, laid on bitumen mastic, is considered one of the most optimal options for protecting the structures of the building from moisture.

Polyethylene film

Modern waterproofing materials include a wide variety of polymer coatings. They are used mainly indoors or in severe conditions of excessive humidity and for foundations, plinths and basement walls.

Polyethylene film is an irreplaceable material for waterproofing when performing many types of construction work. The film is absolutely waterproof, lightweight and durable. The thickness of the polyethylene coating can be between 0.5 and 3 mm.

Polyethylene wall covering is called a waterproofing membrane.

The film is very flexible, it is easy to install it on any surfaces of complex configuration. An important advantage of the material is its low cost.

When waterproofing internal walls, the base of the fences is covered with a film, followed by the installation of a polymer or metal mesh under the plaster.

The basement walls and the outer surfaces of the basement walls are also covered with plastic wrap.

Polymer coating

The waterproofing polymer membrane is quite durable (up to 50 years), resistant to oxidation and decay, and is not subject to corrosion

There are insulating materials based on complex polymer compounds. Roll material is laid on the walls on special adhesives.

Injection waterproofing

These tools include various primers. They have a penetrating property. The liquid applied to the wall surface penetrates into the depth, filling microcracks and pores. This forms a waterproofing layer.

Penetrating insulating compounds clog the capillary pores of the array. Such tools are used for monolithic and precast concrete structures.

Plaster plaster of walls

Penetrating waterproofing application

The plastered surfaces with the gypsum mixture become absolutely waterproof. When dry, gypsum, in addition to creating a surface with high adhesion, also serves as a waterproofing of the walls from the inside against mold.

Waterproofing walls inside the apartment

Obviously, too serious influences associated with the ingress of moisture into the apartment often do not exist. Despite this, it definitely makes sense to protect your home, especially if there are minor problems with dampness and other aspects.

Increased humidity primarily manifests itself in the corners (humid parts of the walls).This, so to speak, is the first bell that speaks of the need for immediate waterproofing, otherwise the situation may deteriorate significantly later.

- First of all, it makes sense to insulate the cracks. For this case, you will need to prepare a cross section of about 20x20 mm. After that, you need to fill the voids with polyurethane foam.

- The second step is the same surface cleaning. As we mentioned earlier when talking about basement waterproofing. It makes sense to remove all dirt and dust that is on the surface. It should also be borne in mind that there may be coatings on the surface (wallpaper, panels, other materials), which must also be removed, otherwise the main waterproofing process may not be the most effective.

- Ultimately, the concrete surface is coated with a special waterproofing compound.

Interestingly, for a high-quality result, it is often enough to use a special solution, which most often looks like a cement material, but it contains some additives that help get rid of the action of moisture or water. These additives begin to act the moment even the smallest effect of moisture occurs. The coating begins to block small channels through which moisture or liquid could penetrate. Accordingly, if the moisture could not pass further, then there will be no trace of any fungi and other organisms that usually appear at high humidity. At the same time, do not forget that the action of water or moisture may be too intense, and in such situations it makes sense to conduct a full analysis of the current situation and choose the most suitable waterproofing material. Attention should be paid to the fact that in modern construction, waterproofing of walls from the inside of a dwelling is carried out in almost all cases, so the need for this process is obvious.

Insulation cover location

The wall waterproofing device can be horizontal and vertical.

Vertical

This is a common method of waterproofing a wall in an apartment and on the outside of the house. The vertical insulating wall covering prevents moisture from entering the room horizontally.

Basement vertical waterproofing device diagram

Horizontal

The purpose of the horizontal insulation device is to prevent the penetration of moisture into the premises from below, from the subgrade.

It is arranged by laying roll materials on top of the foundation and plinth before erecting the walls of the building. The upper horizontal surface of the foundation is covered with 2 layers of rolled waterproofing (roofing material, roofing felt or polymer membrane). Ground moisture tends to spread upward and penetrate into the structure of the building's ground structures.

Horizontal waterproofing becomes an insurmountable barrier to moisture penetration from the bottom up.

Penetrating waterproofing of concrete indoors

The idea of penetration (penetrating waterproofing) was born in Europe in the middle of the last century. The mechanism of operation of cement materials is reduced to the reaction of free lime (and there is always it in an artificial stone!), Capillary water and ingenious active reagents. As a result a reliable protection is formed in the thickness of the bases, blocking the penetration of moisture.

However, not everything is so rosy. Due to serious chemical reactions, which it makes no sense to describe in detail, the chemical equilibrium in the system can be disturbed. A decrease in the pH-factor due to the binding of free lime can lead to early corrosion of reinforcement in reinforced concrete structures..

The material must be of high quality, with a well-developed quantitative composition of active chemistry

All this leads to the need for painstaking selection of penetrating waterproofing.In practice, the effectiveness of this solution depends on many "BUTs", for example, the actual state of concrete, the nature of the surface, the general dynamics of the structure. Sometimes it is more effective to attract additives to concrete at the preparation stage.

Benefits:

- quick set of strength;

- bulk waterproofing of concrete;

- environmental safety is a promising option for the construction of household and drinking water supply.

Disadvantages:

- the size of capillary cracks should not exceed 0.3 mm;

- concrete should not be subject to dynamic loads, carbonized.

Scope of application: interior walls for tiled cladding, floors and walls exposed to water, moisture.

Brands: Penetron, Vetonit, Lakhta, Kalmatron, Hydrotex.

Technical specifications

| The foundation | Cement, quartz sand, additives |

| Number of layers | 2-3 |

| Layer thickness | 2-3 mm |

| Density | 1.1 kg / dm3 |

| Application temperature | +5 +30 degrees |

| Viability | No more than 45 minutes |

| Consumption | 2.8 kg / m2 for 2 layers |

Preparation of walls for waterproofing

The whole point of preparing surfaces before any coating is to remove all unnecessary from the walls. Remnants of old cladding, sludge of various solutions, dust and dirt - all this can contribute to the detachment of the insulating coating.

In different cases, the vertical surfaces of the premises are cleaned with various hard brushes, spatulas. It happens that you have to use a sandblasting installation. In general, there are many options for preparing the base of the walls. The main thing is to achieve complete cleaning of surfaces.

Waterproofing external walls of the house

External waterproofing of a house is not done very often, but it often becomes extremely useful. Most often, waterproofing is used at the level of the foundation, since it is often affected by various influences, including groundwater and much more. It is also recommended to waterproof the walls of the house in certain situations, and this issue must be approached as responsibly as possible.

- First of all, the surface is prepared for waterproofing. The point is that there are often dirt and other things on the walls that make the waterproofing process impossible. In addition, you need to get rid of oil stains and traces of rust. Immediately after cleaning, the surface may be damp and no waterproofing is carried out under these conditions. It is advisable to dry the surface, often, if it is necessary to quickly carry out the process, heat guns are used.

- Next, you need to create a base for waterproofing, and often it is a regular primer. Interestingly, experts often advise heating the primer and wall, which will significantly improve adhesion.

The use of coating waterproofing (for brick, reinforced concrete structures) is a fairly effective option, given the fact that this material often penetrates even the smallest pores on the surface. Ultimately, protection against moisture and water is at a sufficiently high level. However, there is also a need for a drainage system that will remove rain moisture and other precipitation that has a serious impact on the condition of the walls. Speaking specifically about materials, we are talking about the following products: Askovil, Cemizol, Stribit 2000. These resources are highly efficient even in rather harsh weather conditions.

Penetrating waterproofing is often used for houses built on the basis of reinforced concrete. In this case, the wall is cleaned with sandblasting equipment, and then the coating is applied. The material is distinguished by excellent permeability, which allows reducing the effect of even minimal moisture to a minimum.It is also important to remember that seams are often sealed between the joints of building materials.

Features of insulation when insulating premises

When the walls of an apartment or a private house are insulated, it is imperative to arrange a waterproof covering of vertical fences. Roll materials are glued to the base of the walls before installing thermal insulation.

Insulation is a hygroscopic material, therefore a waterproof layer is especially important. Otherwise, the insulating layer will get wet and lose its properties. Raw materials are subject to fungal and mold contamination.

Application of liquid waterproofing

Waterproofing bathroom walls and floors

When a major overhaul or redevelopment of a bathroom is carried out, a hydro-barrier is erected. This room is always very humid. Accordingly, under the influence of moisture, walls and ceilings are destroyed. Bathroom waterproofing is a layer of moisture-resistant material under the screed layer. The durability and reliability of this protection depends on the quality of the materials used and the work performed.

What can be used to make waterproofing

Today, on the building materials market, waterproofing materials are presented in a wide range.

Let's dwell on the most common types:

- Bituminous mastic.

- Sheet or roll material with bitumen impregnation. It is laid with the approach to the walls.

- Cement-polymer mixtures applied in several layers.

- Penetrating water protection.

- Rubber-based hydraulic barriers.

Do not use polyethylene-based film materials. Their vapor permeability is insufficient in comparison with the listed ones.

Not everyone can use the services of a specialized company or a professional team for waterproofing a bathroom. If you do not have such an opportunity, complete all the necessary activities yourself. Waterproofing the walls, which you can do with your own hands, will reliably protect your home from moisture penetration.

It is best to use materials such as bitumen mastic and any suitable roll material impregnated with bitumen for repairs. It is this combination of materials that allows you to perform really high-quality waterproofing.

The image below shows the places where waterproofing must be present.