Gas boiler with built-in boiler has a long service life and excellent performance

Every day there are more consumers who want to organize an autonomous heating system. The monetary costs that were when buying heating equipment and installing it will soon pay off on energy savings and the ability to adjust the power of the system. The best system for houses and apartments would be the option with a gas boiler with a boiler.

Boiler with built-in boiler: main advantages

The purchase of a gas boiler with a boiler will be the optimal solution when using several points of water analysis, it will provide a sufficient number of advantages.

3 main advantages:

- A positive and significant advantage is water heating at night, when the water pressure in the water supply is weak;

- To get started, a separate connection to the water supply and heating system is not required, but simply toss water, gas and electricity to the boiler;

- All variants of gas-type boilers are compact, since all the constituent elements of the boiler are assembled in one body.

All these indicators are possessed by the Vaillant and Nova boiler water heaters. They are the most popular brands on the boiler market.

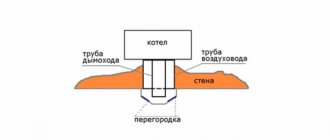

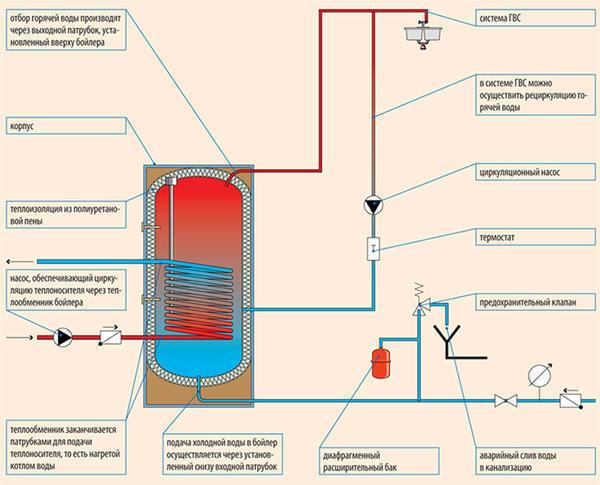

How does a boiler with an external boiler work?

Usually, the automation that controls the operation of a wall-mounted gas boiler is programmed to give priority to the heating system.

When the temperature of the coolant in the circuit drops, the burner turns on and the wall-mounted gas boiler with a boiler heats the water in the batteries to the required temperature.

After receiving a signal from the water temperature sensor in the circuit, the controller will switch all the power using the three-way valve to the DHW circuit. To maintain the hot water temperature at a certain level, a gas boiler with an indirect heating boiler is supplied with a built-in heating element, which is connected to the electrical network, and is controlled by the boiler automation controller.

How to connect a boiler and a double-circuit boiler

A boiler for a gas boiler is presented in the form of a storage tank, in the middle of which there is a heat exchanger.

This model inherently seems to be a two-circuit, since it has the ability to connect for heating and hot water systems.

The built-in flow-through heater is a double-circuit model.

About how double-circuit boilers are arranged, the principle of their operation, as well as how to choose, you will learn from our article:.

You can consider the option of connecting a double-circuit boiler to a separate boiler. Such an installation will refer to a technique with a layer-by-layer heating type. In addition, at specialized points you can see boilers both double-circuit and with layer-by-layer heating, they are combined by a gas boiler and can be either a complete set or separate.

The choice will depend on which option is best for you. It can be a separate or a holistic model that is easy to transport and install. If you are the owner of a single-circuit boiler, then you can give preference to a boiler with layer-by-layer heating, which includes an instantaneous heater. In the event that you want to save space in the room, then purchase a single-circuit type gas installation with an indirect heating boiler.

Differences and advantages of single-circuit and double-circuit boilers

A single-circuit gas boiler is designed exclusively for heating the house - it does not have a built-in water heater that provides residents with hot water. If you connect a boiler to it, it will heat water for various domestic needs.

The mechanism of double-circuit units is more complex and the price for them is higher.

The main advantage of a gas boiler with a built-in storage tank is that you do not have to additionally purchase and install an indirect heating boiler. In addition, the water heats up in it much faster than in single-circuit boilers.

For devices with two circuits, you can connect a separate boiler for more hot water. If you already have a single-circuit boiler, then in addition to it, you can buy a special layer-by-layer heating boiler, which is equipped with a flow-through liquid heater.

If you are the owner of an apartment that is small in area and you need to save space, then a single-circuit boiler with a built-in boiler will be the best option.

In order to avoid all kinds of problems that may arise due to incorrect installation of the equipment, specialists should carry out the installation.

Currently, you can find the following models of double-circuit boilers:

- with a flow-through water heat exchanger;

- with a built-in boiler for 40-60 liters;

- with built-in boiler for 80-599 liters.

The main characteristics of wall-hung boilers with a flow-through water heat exchanger:

- at the same time they can heat rooms with a total area of up to 300 m²;

- they are compact, you can mount them in a niche in the wall;

- acceptable price;

- differ in simple installation;

- simple and convenient control.

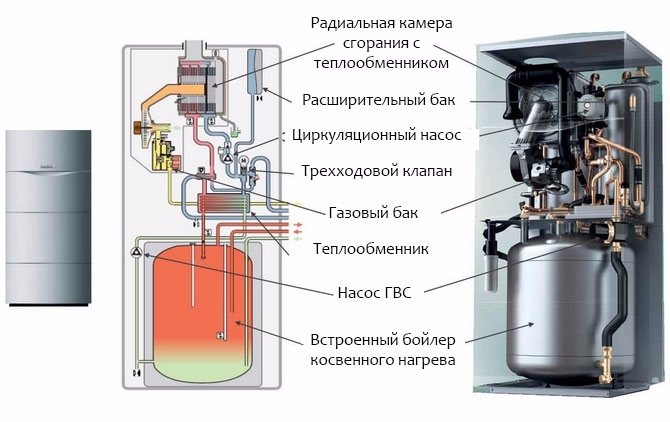

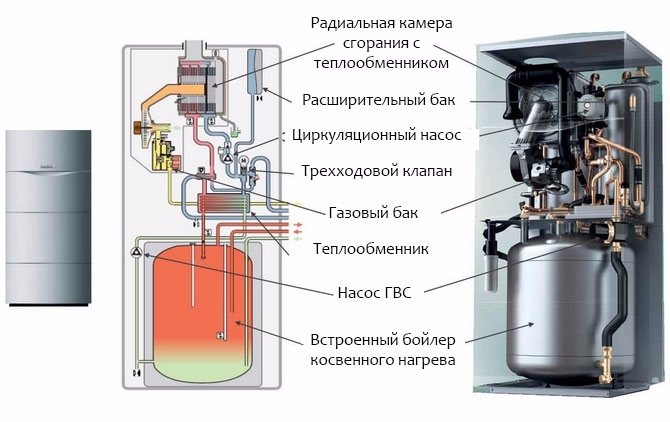

Gas boiler device with built-in boiler

Advantages of gas heating boilers with a 40-60 liter boiler:

- can heat an area of up to 300 m² and simultaneously supply water to 4 taps at once;

- easy to manage;

- have a self-diagnosis system.

Units with a boiler for 80-500 liters are of three types. The first two include devices that include all the necessary parts, they are compact and allow you to fully control the system. The third type includes boilers, for which you need to install additional equipment and buy other parts. As a result, in order to purchase all the missing items, you will have to spend a lot of money.

As already noted, most users prefer single-circuit gas boilers with a free-standing boiler.

Let's note the main advantages of such devices:

- Large internal cross-section of the heat exchanger, due to which much less scale is formed.

- They are distinguished by their reliability.

- The mechanism and principle of operation of the device is simple.

- Thermal energy is consumed expediently, as a result of which the efficiency increases, and fuel is consumed more economically.

- They are easy to maintain.

- With a gas boiler and a boiler, you are guaranteed to be provided with hot water at any time of the day.

What power does a wall-mounted double-circuit gas boiler with a boiler have?

The power of the gas burner in the boiler determines the rate of water supply to the flow-through wall heater. The heating rate also depends on the design of the heat exchanger. The peculiarity of heating the liquid lies in its prolonged contact with the heat exchanger, and that is why in order to warm the coolant to the required temperature, a lot of heat is needed. And to increase the heating performance, it is necessary to increase the power of the gas burner in the boiler and increase the gas consumption.

If you need to heat water up to 40 degrees, then you will need to adjust the burner. Its oriented power should be about 20 kW. If your boiler is not designed for such an indicator, then you will not be able to get a warm stream of water as a result, and you can forget about taking a warm bath or shower.

Most gas models have a power of 20 to 30 kW, it is important to decide for what purpose you will use it, because 10 kW will be enough for the heating system. For boilers of this type, special modulated burners have been created.

It is very important to know that every gas boiler, even if it has a weak power, has a limit value.

Exceeding the norm can lead to the fact that the burner will turn off and on. Such a defect will very soon lead to equipment breakdown or an increase in gas consumption. This problem leads to the fact that the purchase will not only be unjustified, but also unprofitable.

Read about how to calculate gas consumption per unit area of the house in the article:.

And it is for this reason that a boiler is built in double-circuit boilers, which collects hot water, and then gives it back in large quantities while taking a bath or shower. Thus, the layer-by-layer heating of water is optimal, it enables the normal operation of the equipment and does not lead to damage to the burner.

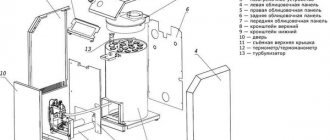

Description of the series

Floor-standing gas boilers with a modulating Krafter BMOD burner are easy to install, as they are compact in size. The units are used to create or upgrade a heating system in rooms with different configurations. Cast iron heat exchangers provide devices with low energy losses during the combustion of fuel, which is natural gas. The devices are easy to operate and are considered reliable equipment. Double-circuit boilers from the above series rarely require specific service and are designed for long and trouble-free operation.

- Floor standing installation

- High efficiency

- Open combustion chamber

- Frost protection

- Weather-dependent automation

- overheat protection

- Double-circuit gas boiler

- Modern design

- Long service life

- Circulation pump

- Electronic flame modulation

- Weather-dependent control

- Built-in boiler

- Modern automation

- Automated control system

- Load modulation

The main features of the layer-by-layer heating boiler

In models with a double-circuit layer-by-layer heating, water enters already in a heated state, this allows the boiler to very quickly bring the water to the required temperature.

There are a number of advantages that these installations have:

- Hot water enters the upper layer of the boiler after 5 minutes from the start of operation. Indirectly heated boilers run for a longer time, as they need to take time for convection from a heat source.

- Since there is no heat exchanger inside, the tank collects more water that can be used in everyday life. The performance of such a boiler is much higher than models with an indirect type of heating.

In most situations, people do not understand why a boiler is needed in a boiler. The answer is that such an organization can provide a more comfortable use of warm water. In addition, such a device guarantees the constant availability of hot water in the house, even when several water supply points are opened. Not a single loop boiler is able to cope with such a task. In addition, floor-standing models are similar to a refrigerator and can hold up to 100 liters of liquid, and this is enough to provide a large family with warm water. Floor standing models are compact and also a great alternative to large units if you don't have a lot of space in your home.

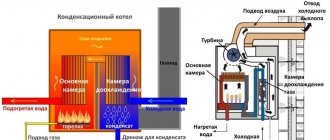

Baxi NUVOLA Duo-tec (12-20 kW) wall-hung gas condensing boilers with built-in boiler

The BAXI NUVOLA Duo-tec series boilers are distinguished by their high manufacturability (the most advanced technologies are used), environmental friendliness (they can significantly save fuel, reaching an efficiency close to 110%), environmental friendliness (low emission of harmful substances), comfort (maximum comfort in the consumption of hot water) , ease of use (remote control is possible).

Gas system of the BAXI NUVOLA Duo-tec boiler

- Smooth regulation of boiler power in heating and hot water supply modes;

- Smooth electronic ignition;

- Reduced content of CO and NOx;

- Burner made of stainless steel AISI 316L with premixing of gas and air;

- The boilers are fully adapted to Russian conditions. They work steadily when the inlet pressure of natural gas drops to 5 mbar;

- Flame diffusers on the burner are made of stainless steel;

- Patented air regulation system (closed chamber models);

- It is possible to reconfigure the boiler for liquefied gas.

Hydraulic system of BAXI NUVOLA Duo-tec boiler

- The primary heat exchanger and combustion chamber are made of stainless steel;

- Built-in storage boiler 45 l made of stainless steel AISI 316L, magnesium anode;

- Expansion tank of the DHW circuit;

- Two-speed energy-saving circulation pump with automatic air vent;

- Heating circuit pressure gauge;

- Automatic bypass;

- Post-circulation pump;

- Cold water inlet filter.

Temperature control of the BAXI Duo-tec boiler

- The range of temperature control in the heating system is 25-80 ° С;

- Built-in weather-dependent automation (the ability to regulate by a street temperature sensor);

- Regulation and automatic maintenance of the set temperature in the heating and hot water supply circuits;

- Digital indication of temperature;

- Possibility to control multi-temperature zone systems.

Boiler control and safety devices BAXI Duo-tec

- The liquid crystal display provides complete information about the operation of the boiler;

- Digital self-diagnosis system and fixing the latest errors in the operation of the boiler;

- Ionization flame control;

- Pump blockage protection system (turns on automatically every 24 hours);

- Three-way valve blockage protection system (turns on automatically every 24 hours);

- Protective thermostat against water overheating in the primary heat exchanger;

- Traction sensor for monitoring the safe removal of combustion products;

- Pressostat in the heating system - triggered when there is a lack of water pressure;

- Safety relief valve in the heating circuit (3 atm.) And hot water supply (8 atm);

- Frost protection system in heating and hot water supply circuits;

- Antibacterial protection system.

Features of condensing boilers