Have you already dealt with the harmful effects of scale exposure?

Washing machine, coffee machine, gas boiler ... Which of them was the last victim of limescale?

Want to know more - what is scale and how to deal with it?

Read our article! We have been dealing with the issues of protecting equipment from scale for a long time and we are sure that our knowledge will be useful for you!

Pictured: pipe scale samples taken by us for research

Why is scale dangerous?

Scale has an extremely low thermal conductivity.

For example: the thermal conductivity of steel is 39 kcal / m * hour * deg, and the thermal conductivity of scale is only 0.1 kcal / m * hour * deg. The difference is almost 400 times!

This means that when a boiler, kettle or heating element is operating, they have to spend more gas or electricity on heating and evaporating the liquid.

And that's half the trouble.

Napkin deposits damage equipment and devices, making them impossible to operate!

Scale deposited on the shades of washing machines leads to burnout of the heating element. Scale deposited in the jets of coffee machines makes it impossible to supply liquid. Scale clogging the gas boiler coil leads to its leakage and costly repairs.

Deposits arising from the operation of industrial boilers can lead to rupture of pipes and an emergency!

By the nature of our activity, we are faced with different boilers every day and sometimes we are surprised at how careless people are who operate high-power gas boilers ...

In the photo you can see that the boiler pipe is completely clogged with scale. Water does not pass through it, the pipe is constantly overheated and this can lead to an explosion! However, such a boiler continued to work ...

In the photo: scale in the boiler pipe DE-10-14

Thus, the occurrence of scale in heating equipment leads to the following negative consequences:

- Excessive consumption of fuel and electricity;

- Accelerated wear and tear of equipment;

- Impossibility to implement the technological process;

- The likelihood of an emergency;

Pipe cleaning in the traditional way

In most cases, the method of chemical cleaning of scale from pipes is used. Note that only aggressive descaler can help get rid of limestone build-up. These include sulfuric, mineral, nitric acids. Another important criterion for the use of chemical pipe cleaning is the availability of wear-resistant equipment, which is used to working with aggressive agents. If the laid pipes have been repaired more than once, their operational life has come to an end, then chemical cleaning can only aggravate the situation. Therefore, this work is carried out after an inspection by specialists, their approval.

Descaling in pipes by chemical cleaning is carried out using equipment: a pump supplying acid, hoses, a container for supplying a solution. The acid concentration depends on the degree of plaque in the pipes, the more plaque, the stronger the acid. However, this issue has its own nuances, the corridor of acid concentration values should not exceed 10% and not be less than 3%. Each millimeter of plaque is 1% acid, but the concentration should not be higher than 10%, since acid can remove not only build-up, but also eat up the walls of the equipment.

As preventive measures to combat the formation of limestone build-up, less strong acids are used: formic, phosphoric.They are able to fight small scale deposits, dissolve and remove them. The mechanical method of descaling pipes is often used. The cleaning procedure is carried out using scrapers, brushes, cutters. The mechanical method is not the most effective, because the top layer of the metal can be removed along with the scale. It is not recommended to carry out the procedure on an ongoing basis.

Scale types

The number of chemical elements from which scale is formed is quite diverse and, at least, it is classified into the following types:

- carbonate scale (carbonate salts of calcium and magnesium - CaCO3, MgCO3);

- sulphate scale (CaSO4);

- silicate scale (silicic compounds of calcium, magnesium, iron, aluminum).

For 15 years of work, our company has accumulated a significant number of scale samples from different parts of Russia. We have examined more than 1000 scale samples and determined their chemical composition.

|

|

The picture shows an initial sample of scale and its crushed form for research.

According to the results of the study, we found out that the scale content in the overwhelming majority of samples contains the following elements:

Ca / Mg - from 87 to 96%

Fe - from 0.06 to 7.5%

SiO2 - from 0.02 to 1.8%

Is it possible to find out its chemical composition by the appearance of the scale?

Based on the research carried out on more than 100 scale samples, we have determined that:

It is not possible to unambiguously determine the chemical composition of scale by its appearance!

Too many factors affect the color and consistency of scale - the original composition of the water, temperature, pressure at which scale is formed. In addition, scale contains many more elements, which are very small in quantity, but they affect the color and nature of deposits.

For instance:

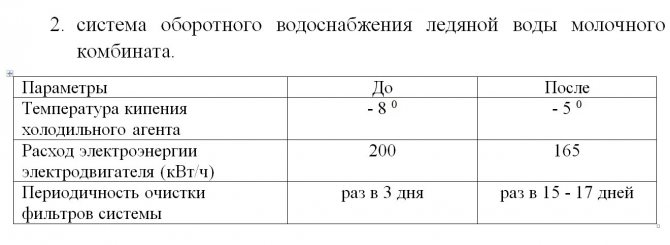

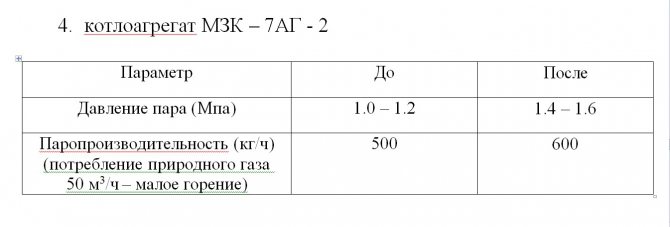

|

|

|

|

Pictured: Scale samples with different color and consistency

These images show deposits that differ significantly in color and physical structure. Surprisingly, these deposits have almost the same chemical composition! However, the different temperatures and pressures at which these scum samples formed resulted in such a difference in color and texture!

At what temperature does scale form?

Scale begins to form at temperatures of 40 ° C and above.

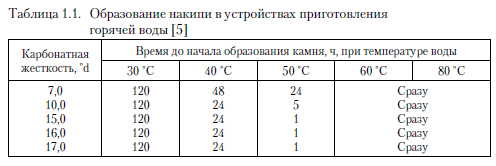

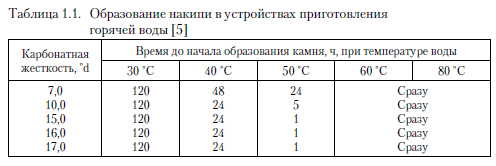

We found quite detailed information on the temperature and rate of scale formation in hot water preparation devices in the book by Vladislav Shaflik "Modern hot water supply systems", Kiev, "Taki spravy", 2010.

The table shows data on the dependence of the rate of scale formation on water hardness and temperature.

In the picture: data on the rate of scale formation as a function of temperature

Why fight hard water? Just remove the limescale!

Do you have new household appliances at home? Or are you just choosing a water heater, washing machine, boiler for heating?

Do you want this technique to serve you for a long time?

This rhetorical question rarely occurs to us, because a new expensive item is the quality and reliability of the brand, a guarantee, and careful operation.

That's all right. But this is not enough. Water contains dissolved hardness salts. There may be more or less, depending on the region where you live. During the operation of household appliances - a washing machine, dishwasher, boiler, boiler, water heater, they crystallize, forming solid deposits - scale. In some areas, new equipment can become "old" in just a year of operation!

What it looks like:

Have you bought good equipment in the hope that it will last a long time?

Unfortunately, scale is equally merciless to expensive and cheap equipment. It will shorten its service life - in a "fur coat" made of scale, without proper cooling, the heating element will overheat and fail prematurely. Scale will cover the nets and valves, they will start to "hang" - the equipment will start to malfunction.

Why is it important to protect new appliances from scale?

- to protect its "heart" - a heating element.

We proceed from the consideration that preventing a problem is often easier and cheaper than eliminating its consequences. In the case of limescale, this is the case.

It is possible and necessary to fight scale, otherwise its uncontrolled growth will cost much more. How much does it cost to replace heating elements, pumps, hoses inside your household appliances? How much will leaks and gusts cost? How long will the technician work after not always professionally made repairs? How to deal with limescale?

Install a set of filters? They are only able to filter out suspended particles, but not hardness salts that form scale. Some go further, and put a whole water treatment plant, which at the exit they give almost distilled water. Should you do it?

Doctors say - no! Salts dissolved in water are vital for the human body! Without calcium, bones will "dissolve"; without iron, healthy blood is impossible. It turns out that we need all the mineral salts in the water! Drinking distilled (or semi-distilled) water quickly turns into serious health problems.

It turns out that hardness salts are necessary for us, humans, but not entirely useful for our domestic helpers. Is a compromise possible, a kind of "golden mean"?

We suggest referring to foreign experience. In the West, anti-scale devices are installed in most houses and apartments. The most effective is the Hydroflow device.

It retains in water the mineral salts so necessary for our body and eliminates

the essence of the problem

- prevents the formation of limescale.

The Hydroflow system operates on the principle of electromagnetic resonance, which is controlled by an intelligent microprocessor. A weak electric charge that spreads through pipes reflects salt crystals from the walls of pipes, heating elements of household appliances. With the current of water, they leave your home. During the operation of the device, water does not change its composition, retaining all the useful minerals.

The Hydroflow system is a new generation of water treatment systems. The device is compact, installed in a few minutes, much more reliable, and much more efficient than all devices on the market. The efficiency (efficiency) of Hydroflow is approximately

10-12 times higher

than previous generation systems.

Hydroflow effectively fights scale where other methods have not yielded tangible results. The system is designed and manufactured in the UK.

In the West, technology has a long service life. Because the people there cherish her. Believe me, your new technique deserves protection!

Preventing limescale build-up

Softening

The main method used to prevent the formation of limescale is softening.

The term “softening” refers to the process of water purification from hardness salts (Ca and Mg), which are the main cause of scale formation.

The softening process removes calcium (Ca) and magnesium (Mg) ions from the water. This is done by passing water through a resin or salt containing sodium ions. In this case, calcium and magnesium ions from water pass into resin or salt, and sodium ions replace them and pass into water. Thus, the water softens and its overall hardness decreases.

There are the following requirements for water hardness:

Feed water for steam boilers and boilers (GOST R 55682.12-2013), mmol / l <0.02

There are a variety of softening installations that can be designed and matched to the initial water hardness, in addition, there can be several softening stages.

There are also reverse osmosis units that can produce practically distilled water at the outlet.

Anti-scale devices

Separately, it must be said about various anti-scale devices, positioned as a means to prevent the formation of scale. Our organization has accumulated significant experience in the operation of various anti-scale devices. In addition, we ourselves produce the ECOFOR anti-scale device designed to prevent the formation of scale and corrosion on steam and hot water boilers.

In the picture: explosion-proof version of the ECOFOR anti-scale device

Soon we will post on our website a summary of our experience in the operation of anti-scale devices. Now let us note that, unfortunately, they are not a panacea and a reason for abandoning the existing water treatment systems. These devices should be used as an addition to the existing softening systems. The effectiveness of these devices depends on a huge number of factors: dimensions, parameters of the coolant, the chemical composition of water, etc.

Measures to prevent limescale in steam boilers

The amount of scale in boilers can be reduced by using measures to prevent its formation:

- install aluminum heating elements with a heating power of up to 2400 W;

- regularly carry out maintenance;

- check the condition of protective coatings on internal parts;

- follow the manufacturer's recommendations regarding the quality of the water used;

- use water softeners: chemical compounds, magnetic converters, etc.

Before cleaning the boiler from scale, it is necessary to assess the thickness and composition of the layer, the technical conditions of the work, and then choose the appropriate method. This will determine not only the efficiency of removing deposits, but also the safety of the protective inner coating of the walls and surface of the heat exchanger. Only a competent approach to solving the problem will ensure the maximum boiler service life without breakdowns and with high efficiency.

Descaling

The second direction that ensures the maintenance of the cleanliness of heat exchangers is their periodic descaling. This applies to both household and industrial appliances.

There are several basic ways to descale equipment. Let's list the main ones: chemical washing, mechanical cleaning, hydrodynamic cleaning, electric discharge cleaning. Let's briefly describe these methods.

Chemical washing

Chemical flushing means the dissolution of scale in the equipment due to the circulation in it of a heated acidic or alkaline solution.

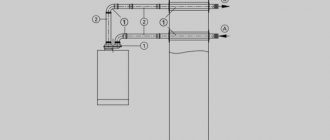

In general, a closed loop is created, which includes: the object to be cleaned, a chemical pump, an intermediate tank and acid-alkali-resistant hoses.

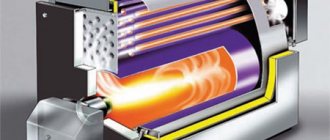

Pictured: chemical flushing of a domestic gas boiler

An acidic solution, for example, heated to a certain temperature, circulates in a closed loop for several hours, due to which the scale dissolves and the equipment is washed. As a rule, for chemical washing, hydrochloric, sulfuric, phosphoric and sulfamic acids are used.

The scheme of the chemical reaction during chemical flushing of equipment with sulfamic acid, for example, is as follows:

CaCO3 + 2NH2SO3H Ca (NH2SO3) 2 + H2O + CO2

Concentrates of low molecular weight acids (LMAs) are also used. In some cases, for example, to prepare equipment for start-up and clean it from industrial pollution: oils, rust and scale, caustic alkalization is used.

Chemical washing is indispensable for hot water tube boilers such as KVGM, PTVM, NR, ZIO of Russian production, as well as fire tube boilers of all types Viessman, Bosh, ICI, Loose and other manufacturers. This is due to the fact that, structurally, these boilers do not have open access to their pipes, which is why acid washing becomes the only possible way.

Mechanical descaling

One of the most common and well-known methods of descaling boilers and other equipment. The method consists in the fact that a mechanical cutter (drill, cutter) is inserted into the pipe to be cleaned, which rotates in the pipe due to an electric or air drive. Due to mechanical rotation, the sharp edges of the cutter effectively clean off the existing scale layer. However, with this method of cleaning, it is possible for the roller cutter to act on the surface of the cleaned pipes, which in some cases can lead to a thinning of their walls. Despite this, the method has its many supporters, and our company has equipment for mechanical cleaning available. The method is used for descaling steam boilers such as DE, DKVR, KE, ShB, E, tubes of heat exchangers in the sugar, chemical industry, etc.

Hydrodynamic descaling

The principle of hydrodynamic cleaning is based on the fact that water, under high pressure, is supplied through a high-pressure hose and a nozzle into the pipe, which ensures its descaling. This method is effective for equipment that has open access to the pipes to be cleaned - heat exchangers, boilers, steam boilers E, DKV, DE, KE.

Pictured: hydrodynamic flushing of the heat exchanger with a high pressure unit (GUVD)