By purchasing a gas boiler, each owner expects that this boiler will provide him with uninterrupted operation throughout the entire heating season. The boiler is the equipment that is mercilessly exploited, and therefore it is necessary to ensure a long duration of its service life by all possible means.

So, in what ways is it possible to increase the service life of the boiler, as well as to guarantee its normal operation.

Selection of heating equipment

When choosing heating equipment, key importance should be given to its power and materials of manufacture in order to avoid buying an expensive boiler, which does not have obvious advantages, and, at the same time, does not reach the required power, which means that it is forced to work at the limit of possibilities. Parameters such as the size of the house, the level of pressure in the gas pipeline, the thermal insulation of the walls, etc. It is they who form the value of heat loss, on the basis of which they select the boiler power.

Due to the nature of the material, cast iron boilers are the most durable. Therefore, if you want a boiler with the longest possible service life, you should pay attention to these representatives.

Series and models

Baksi units are available in floor and wall mounting options. The difference between these types is in weight and dimensions, and the complexity of the design. Floor standing units usually have a high efficiency cast iron heat exchanger.

They are represented by the Slim series, which has a wide range of units of different capacities..

The range of wall-hung boilers is much wider.

There are series:

- Baxi MAIN

- ECO

- Baxi NUVOLA3

- Baxi LUNA-3

All series have their own model line of units of different capacities with the same set of functionality. The user can select a sample that matches the power without losing any of the features inherent in this series of units.

NOTE!

The manufacturer constantly updates the functionality of the existing models and introduces new, advanced lines of gas boilers with improved parameters and characteristics.

Competent installation

In general, you need to remember that any work with gas equipment must be coordinated with the local gas service. And the work on installation, replacement and repair itself must be carried out by specialists who have the necessary permits and approvals.

To ensure stable and safe operation of the boiler, first of all, it is necessary to carry out the correct installation of the heating system. Commissioning work should be carried out to adjust the operation of the boiler in such a way that it is not influenced by various external factors. Commissioning is a mandatory operation, since, otherwise, the boiler will function at factory settings, which are not always suitable for a specific heating system.

The commissioning work, which has a serious impact on the boiler's service life, includes, among others, the correct setting of the burner to the gas pressure. If the gas pressure rises above the level that is required for optimal burner operation, the service life of the coolant and the flue exhaust fan will accordingly decrease, and a safety alarm may also be triggered for no reason.

BAXI gas boiler service menu commands

In the lines of the service menu, you can change some settings of the parameters of the operating mode of the gas boiler Baxi.

Line F01 - boiler type: 10 - with a closed combustion chamber; 20 - with an open combustion chamber. Factory setting = 10.

Line F02 - type of gas used: 00 - natural gas (methane); 01 - liquefied gas (propane). Factory setting = 01.

Line F03 - hydraulic system. Factory setting = 00.

Line F04 / F05 - setting of programmable relays 1 and 2 (See operating instructions): 00 - no associated functions. Factory setting = 00.

Line F06 - setting the maximum temperature (° C) of the heating system: 00 - 76 ° C (burner shutdown at 80 ° C); 01 = 45 ° C. Factory setting = 00.

Line F07 - configuration of the input device of the DHW circuit priority sensor (See operating instructions). Factory setting = 02.

Line F08 - maximum useful power of the heating system (0-100%): 80 - natural gas; 100 - liquefied gas. Factory setting = 80.

Line F09 - maximum useful power of the hot water supply system (0-100%): 80 - natural gas; 100 - liquefied gas. Factory setting = 80.

Line F10 - minimum useful power of the heating system (0-100%): 20 - natural gas; 00 - liquefied gas. Factory setting = 20.

Line F11 - burner waiting time between two starts (01-10 min): 00 = 10 sec. Factory setting = 03.

Line F12 - diagnostics (See operating instructions). Factory setting = - -.

Line F13 - type of heat exchanger: 00 - 270 mm; 01 - 225 mm. Factory setting = 01.

Line F14 - test to check the correct position of the hot water probe: 00 - off; 01 - always on. Factory setting = 01.

Line F15 - factory value. Factory setting = 01.

Line F16 - minimum useful power of the hot water supply system (0-100%): 20 - natural gas; 00 - liquefied gas. Factory setting = 20.

I recommend that you write down any changes you have made to the settings in the menu lines. Records should be attached to the instructions for the boiler.

Annual maintenance

In accordance with the Decree of 21.07.2008 "On the procedure for the supply of gas to meet the household needs of citizens", heating equipment must be subjected to regular maintenance. service. Many large manufacturers of gas equipment directly indicate in the warranty card that the boiler warranty is valid subject to regular maintenance.

The following works should be included in the regular maintenance:

- cleaning the combustion chamber;

- cleaning the burner;

- expansion tank control;

- pressure control;

- checking the heat exchanger;

- inspection of pipes and connections;

- checking the circulation pump;

- checking the correct operation of fuses and safety systems, etc.

As you already understood, regular maintenance also affects the life of the boiler.

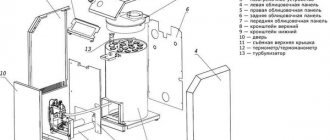

Wall-hung boilers with one circuit

Single-circuit gas heating boilers are designed to heat the house. They decided to make the wall-mounted Baksi more functional and installed special outlets for the installation of an additional boiler. It is possible to heat water in it for household needs.

Single-circuit boilers are quite simple. The burner that ignites the gas was placed inside a safe thermal jacket. The heat that accumulates in the combustion chamber is transferred to the heating circuit by means of a heat exchanger.

The material for the manufacture of the heat exchanger is copper, cast iron or steel. This type of boilers is designed for low power - from 14 to 31 kW. Wall-mounted Baxi are small in size, made with a closed or open chamber.

Factors affecting the duration of the boiler operation

- Hard water. If hard water circulates in the system, that is, water saturated with salt and various minerals, then scale will form, then limescale, rendering the entire system unusable. In industry, water hardness is measured under special laboratory conditions. You can check the level of hardness in ordinary home conditions using a litmus indicator (sold in pharmacies and household stores). Also, the material of the heat exchanger influences the level of plaque deposits.Plate heat exchangers made of steel are quite cheap, but, at the same time, they are highly susceptible to scale deposits. But more expensive tubular copper heat exchangers are very slowly covered with limescale. Elimination of salt deposits is the responsibility of a service specialist who performs maintenance and repairs of the boiler, routine maintenance, but, of course, it is better not to bring it to this.

- Low gas pressure. In principle, low pressure has no significant effect on the service life of the boiler. According to the standards, the gas pressure in the lines should be in the range from 120 to 300 millimeters of water column. It turns out that even with a minimum pressure value, the boiler must operate at the power level that is stated in the passport. This means that a pressure level below 120 millimeters of water will lead to a decrease in the maximum power of the equipment. The boiler itself will function as long as the security system is able to detect a flame.

- The heating system itself. There should be no leaks in the heating system, since their presence (also in conjunction with hard water) will cause clogging of the heat exchanger.

- Temperature conditions. When using the second hot water circuit, it should be set at 42 - 45 ° C: this mode, firstly, will avoid excessive salt deposition on the pipe walls, and, secondly, this temperature is quite sufficient for all household needs (wash dishes, take a shower, etc.)

- Non-freezing coolants. Antifreeze can be used as a coolant. However, given that this is a chemical compound, it can interact differently with the heating system, depending on the material of the radiators (it can be cast iron, steel or aluminum). Therefore, using antifreeze, it is necessary to pay considerable attention to the state of the coolant and remove it from the system in time.

- Power supply. In order for the boiler to function in accordance with the technical regulations, it must be grounded. The stable voltage of the boiler should vary within 220 V + - 10-15%. Therefore, the best solution is to install a voltage regulator. Grounding + voltage stabilizer = longer boiler life.

A little about service

Unfortunately, among consumers who install autonomous heating systems for the first time, they are trying to save on maintenance. Indeed, if you abandon it, you can save 10-15 thousand rubles per year. But even after one season has passed, the focus of the burner may shift, carbon deposits may appear, deviations in the operation of the automation and the pump from the passport mode may appear. The error of work, at first glance, is not great. But it leads to an unjustified risk, a decrease in efficiency, and in this regard, the cost of operating a gas boiler also increases. It is worth saying that it is still worth saving when purchasing a gas boiler, but this must be done competently and carefully so that later you do not have to regret.

Boiler accessories

Of course, to increase the service life of the boiler, its economical operation, it is advisable to use additional accessories. For example, a temperature regulator in the control room will provide greater comfort in the operation of the heating system, and will also reduce gas costs by 15 - 20%. Mechanical or electronic thermostat can be selected. Mechanical is more reliable, cheaper and easier to use, however, it does not always determine the exact temperature, and also requires an inconvenient cable connection. Electronic thermostats are very modern and comfortable, which makes them expensive.

Thus, it is not so difficult to increase the viability of heating equipment.It is necessary to competently approach the issue of selection and installation, timely carry out maintenance and know some of the specific features of the functioning of the heating system. And then your boiler will serve for many years reliably and uninterruptedly.

Advantages and disadvantages

The advantages of Baksi gas boilers are:

- High performance.

- Efficiency, high efficiency of all units.

- Environmental friendliness.

- Simplicity of settings.

- Stability of work, stability.

- Adaptation of all units to Russian technological conditions.

- The presence of self-diagnostic systems, protection against freezing and other external threats makes the operation of the units reliable and stable.

The disadvantages of Baksi installations are:

- The high price of equipment and, in particular, components.

- Inability to replace boiler parts with cheaper counterparts.

- Demands on the composition of water and the quality of the supply voltage, forcing users to install voltage stabilizers and water softeners.

Knowledge of the features of the equipment will allow timely avoidance of failures or breakdowns of important plant units. Operation, carried out without taking into account some of the weak points of the units, leads to the appearance of system failures and requires immediate elimination of errors.

The service life of boilers determined by the manufacturer

Each manufacturer assembles its products from a wide variety of materials. Accordingly, the service life of a particular gas boiler model can vary greatly.

Important!

As a rule, equipment manufacturers set a life cycle of 10-12 years.

The duration of operation depends on the model, operating conditions and the type of boiler.

However, application practice shows that with proper care, the life of the boiler can be significantly extended.

In addition to timely maintenance, the durability of the boiler is influenced by many factors

.

These include:

- hardness of water;

- equipment class;

- pressure;

- factors and operating conditions;

- the type of room in which the boiler is installed and much more.

The influence of the class and price of the device should not be underestimated. In the so-called "low" class, low-quality Chinese materials are used

.

The absence of an electronic display reduces overall work efficiency. In the middle and premium segment, much higher quality parts of European production are used. Expensive models have a self-diagnosis function and more fine-tuned functionality.

, which has an extremely positive effect on the functioning of the device.

List of works

To understand what exactly should be cleaned, checked and adjusted in the boiler, with what frequency, it is enough to look at the instructions and technical documentation, which must be attached to the boiler when purchasing it. These documents provide a complete list of components and components involved in the equipment, service requirements and the frequency with which to check the status, perform service and update settings as necessary.

It is categorically impossible to rely on this information for self-cleaning of a gas boiler. This information provides a clear indication of what to expect from a service company with which a gas equipment service contract is to be entered into.

The works are conventionally divided into three groups:

- Regular work carried out before and after the start of the heating season, preparing the boiler for summer inactivity.

- Capital service. Work carried out every few years and aimed at servicing elements with an initially long-term operation (flushing the heat exchanger, replacing oil seals and valves, maintenance of fans, etc.).

- Repair in case of breakage. The order of actions and mandatory work in the event of an emergency situation, breakdown or the consequences of external factors.

Seasonal service regulations

Before the start of the heating season, the boiler should be put into proper working condition, the operation of the sensors responsible for safety should be checked. Only then is the boiler switched on for operation.

If the manufacturer is allowed to carry out routine maintenance only once a year before starting, then in addition to commissioning, the main elements of the boiler are cleaned, with the exception of flushing the heat exchanger and a complete bulkhead of the control units. If MOT (maintenance) is carried out after the season, then cleaning is assigned to this stage.

Required list of works:

- General inspection, removal of dirt from internal and external surfaces.

- Cleaning of filters (air, gas, coarse water filters).

- Cleaning and checking the burner.

- Cleaning the firing section of the combustion chamber.

- Checking the tightness of the internal gas channels.

- Checking the ignition electrodes (piezoelectric element and burner).

- Test and diagnostics of the electronic control unit.

- Test and diagnostics of sensors and automation responsible for safety.

- Boiler parameters adjustment, combustion adjustment. The process is accompanied by a waste gas analysis. According to the composition and concentration, the master judges the accuracy of the boiler setting.

- Checking the condition of the shut-off valve.

- Checking the supply gas pipeline from the main to the gas equipment.

- Checking and adjusting the pressure in the expansion vessel.

Major overhaul

In addition to the routine maintenance carried out every season, during the overhaul of a gas boiler, elements with a limited warranty period are replaced, the inner surface of the heat exchanger, the banners of the oil seals and valves are cleaned. The main task is to replace elements that are not subject to maintenance during routine maintenance, but still have a service life.

In the event of a breakdown

In an emergency, when a breakdown occurs during operation, it is very important to react to the problem as soon as possible and return the boiler to working condition. If breakdowns do appear, then it is just during the heating season, for example, if the boiler has been operating for a long time at maximum power during the coldest period of the year. At this time, it is extremely difficult to find a specialist for quick repairs, but with a service agreement all that is needed is to leave a request so that the repair team will arrive in a short time to fix the problem. Since the service center keeps records of boilers, a specialist already arrives at the customer with a set of necessary tools and spare parts for a specific model of a gas boiler.

Choosing a service organization

It is expensive for a boiler manufacturer to open a branded service center in each region of the country. Instead, the existing maintenance companies are licensed to carry out the necessary work on the equipment installed in the area of responsibility of the service center. Licensing presupposes a certificate for the performance of a certain range of works, full access to technical documentation for the manufacturer's products, the ability to receive new boiler components for warranty replacement.

The actual information voiced determines the choice of a service center in which it is worth concluding a contract for the maintenance of a gas boiler:

- It should be located in the same region or city as the house with the installed boiler in order to reduce the response time of the service personnel.

- The center must be certified by the boiler manufacturer.

- The presence of an agreement that clearly spells out the obligations and rights of the parties, indicating all the necessary work performed by the service center in relation to a specific boiler model.

The list of certified service centers is available on the manufacturer's website, and any visitor can get acquainted with it.It is best to check the appropriate approvals and certifications with your local service center.

Heat exchanger BEFORE and AFTER flushing and maintenance

What is the best way to install a floor boiler?

The installation of a gas floor boiler is as follows: a place is selected for the installation of a gas boiler, the outlet of pipes for chimneys to the outside is prepared, heating equipment is mounted, connected to a water supply system, to an electrical network, a gas supply network, a chimney. The place where the boiler will stand must be flat and made of non-combustible material. All filters that are included in the kit, as well as pipes that must be installed in the process of connecting with the city gas service. When connected, a ball valve, a thermal shut-off gas valve, a gas meter and a room gas indicator are installed.

Classification of devices

The basic criterion for choosing a boiler is its ability to heat the designated area. In order for the device to work not at maximum loads, you need to choose an economical gas boiler with a small power reserve.

Experts recommend when choosing to be guided by the approximate value of 1 kW, which is designed for heating 30 sq. M. In this case, an insulated house with double-glazed windows and an insulated front door is taken as a reference point. In the absence of any of the elements, add 10-15% to the calculated value.

Such an indicator is conditional, but with its help it will be possible to select the necessary equipment.

It is worth choosing according to the accommodation option, because there are two large groups:

- floor-standing boilers;

- wall-mounted boilers.

Floor standing

The first option is in demand for heated premises with an area of more than 200 m 2. These units are used not only for direct heating of housing, but also for creating a special indoor climate. It should be noted that the efficiency of such a gas boiler will be lower than that of their wall-mounted counterparts. However, this is offset by a significantly longer service life, which, with proper grooming, reaches several decades.

These indicators are achieved through the use of optimal materials used in the manufacture of the heat exchanger. As a result, due to the low operating costs for large areas, floor standing appliances are classified as economical gas boilers for heating a private house.

Most of them use cast iron heat exchangers. Due to their physicochemical characteristics, the cast iron grades used withstand the influence of most negative internal factors. A good helper is the use of anti-corrosion materials that have effective rust-reducing additives.

Wall mounted

The wall-mounted gas heating boiler has a much lighter weight and smaller dimensions, so it easily fits on a vertical surface. Such a module must be connected simultaneously to several systems:

- gas supply to supply fuel to the combustion chamber;

- power supply for starting the automation and circulation of the water pump;

- heating system with an expansion tank and the required number of consumers.

All economical gas boilers have a process control unit concentrated in a single place. Here you can set the temperature, get data on the current pressure, or turn off the device completely.

Wall-hung boilers are characterized by the use of two types of draft:

Most economical gas boilers have a forced system. For its implementation, an electric fan and a discharge spiral cavity are used.

The main operational processes are regulated by automation. The positive factors of wall mounted boilers are as follows:

- saving useful space in the room;

- minimum weight that does not load the wall;

- in some cases, they can be converted for the operation of liquefied gas.

VIDEO: Which boiler to choose - wall or floor

Service life of units

Most modern economical gas boilers last about 7-12 years. Their service life is influenced by the quality of working elements that are in direct contact with water, such as a heat exchanger and a pump.

Gas boiler connection diagram

The service life of a gas boiler largely depends on the quality of the water.

In the presence of high values of water hardness, salt deposits form. To improve the quality of the coolant, polyphosphate filters are used. Due to the use of polymer salts in them, it is possible to lower the stiffness value to acceptable values. This reduces the cost of heating the coolant and thus contributes to fuel savings.