Heating boilers on the market are represented by a wide range of popular Ukrainian manufacturers.

You can choose a unit to your taste and financial capabilities: a gas boiler, electric or solid fuel, with one circuit only for heating or with two circuits also for hot water, and so on.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the shops in your city. Delivery throughout the territory of the Russian Federation and the CIS countries.

Currently, boilers are produced in the Khmelnytsky region of Ukraine (brands Aton, Vulkan, Proskurov), Kharkov (brand Ross) and Rovnenskaya (brand Danko), etc.

If you decide to purchase a Ukrainian-made boiler, consider the following parameters:

- whether the structure depends on electricity;

- is there a hot water circuit or a boiler;

- measure the area to be heated and pay attention to the boiler output.

Aton

Boilers under the Aton trademark appeared on the market in 2003.

The boilers of the Ukrainian manufacturer Aton operate on different types of fuel. Gas-fired boilers in the product range contain several parapet models (without a chimney), which differ in power from 8 to 12.5 kW, as well as several models with a chimney with a capacity of 96 kW.

At the same time, Ukrainian-made solid fuel boilers Aton can operate on coal, wood, peat and briquettes and heat areas from 120 to 2000 m².

Aton has been on the market for over ten years. The advantages of this brand are difficult to underestimate:

- First, the quality. All parts for the unit are manufactured abroad. We can say that the thermoblock is assembled from ready-made components.

- Secondly, the price is not overpriced due to the quality. Anyone who chooses a heating system can afford such a unit.

- Thirdly. A wide assortment range, which makes it possible to choose a unit according to taste and capabilities, as well as depending on the heated area. Small structures with power from 8 to 10 kW, floor-standing power up to 1 MW.

- Fourthly, the boiler is quite easy to operate. When gas is burned on an open burner, soot is formed. To prevent gas consumption from increasing, it is advisable to clean the burner from time to time. This is not difficult as the front cover can be easily removed.

- Fifthly, a high level of safety and the impossibility of gas leakage. Due to the presence of a draft sensor, there is no need to worry that the gas extraction will return back to the furnace. If the pressure drops, then the automation signals the system shutdown.

Aton's innovations can be seen in the design of some units. The operation of the boilers has changed: the new element supports the combustion of the pilot burner, which accordingly reduces the gas consumption by an average of 13%.

The table below shows some of the popular series of gas boilers from the Aton manufacturer.

| Series | Characteristic |

| Aton ATMO 8-25 | Floor-standing gas heating boilers of Ukrainian production of the ATON ATMO 8-25 series are economy class constructions that have an atmospheric combustion chamber. Presented by the names 8ЕМ, 8Е, 8ЕВ, 10ЕМ, 10Е, 10ЕВ, 10ЕВМ, 12.5ЕМ, 12.5Е, 12.5ЕВ, 12.5ЕВМ, 16ЕМ, 16Е, 16ЕВ, 16ЕВМ, 20ЕМ, 20Е, 20ЕВ, 20ЕВМ, 25ЕМ, 25Е, 25ЕВ, 25ЕВМ. Equipped with one and two circuits. The power of the series is from 8 to 25 kW, so the units are capable of heating a space up to 250 m². The efficiency is 90%. They work silently due to natural smoke exhaust, lack of a circulation pump.The material of the heat exchanger of the structure is steel, plus copper in boilers with a DHW circuit. The nominal gas pressure is 13 mbar. The chimney is 110 mm in diameter. The temperature of the combustible products is 110 ºС. Heating correction in the range of 50-90 ºС. |

| Aton Atmo 30-50 | Ukrainian floor-standing gas heating boilers of this series have a capacity of 50 kW and can heat a room up to 500 m². These are more powerful units compared to the previous ones. Model names: 30EM, 30E, 30EB, 30EBM, 50X, 50XB. They have natural cravings. Noiseless. Equipped with a security system. The material of the heat exchanger of the structure is steel, plus copper in boilers with a DHW circuit. The efficiency is 90%. The nominal gas pressure is 13 mbar. Chimney diameter 145 mm. The temperature of the combustion products is 110 ºС. Heating correction in the range of 50-90 ºС. They do not need an external power source, have an attractive design and a coating resistant to external conditions, and are compact. |

| Aton COMPACT 7-16 | This is a parapet gas unit with a closed-type combustion chamber. Can be installed in houses and apartments. It has a simple structure, attractive design and small dimensions, which allows the boiler to look attractive in any interior. The series is represented by the model range 7E (mini), 7EB, 10E, 10EB, 12.5E, 12.5EB, 16E, 16EB. All boilers have natural circulation. Discharge of combustible products by means of a horizontal flue duct with two pipes through the outer wall of the room. The power of the units varies from 7 to 16 kW. ATON COMPACT is network independent. They are produced in versions with two circuits and one. The efficiency is at least 90%. |

| Aton Atmo Classic 10–20 | ATON Atmo Classic are Ukrainian-made gas floor heating boilers (names 10E, 10EB, 12E, 12EB, 16E, 16EB, 20E, 20EB). Open combustion chamber. They do not depend on the power supply. Suitable for systems with natural and forced water circulation. Series models can have one or two circuits. The capacity of the boilers is sufficient for heating areas of 100, 120, 160 and 200 m². The efficiency is 92%. Thermal power from 10 to 20 kW. Heating regulation in the range of 50-90 ºС. |

| Aton SAAB 20X-80XB | Models named SAAB - 20, SAAB - 30, SAAB - 40, SAAB - 50, SAAB - 60, SAAB - 80. They have two circuits. They imply natural and forced circulation of the coolant. Heat output ratings are in the range of 20 to 80 kW. Rated voltage - 220/50 V / Hz. The efficiency is at least 91%. Working water pressure - no more than 0.3 MPa Boilers are equipped with security systems. |

Now we will consider the models of solid fuel boilers manufactured by Aton from Ukraine.

| Series | Characteristic |

| ATON TRADYCJA | The Ukrainian-made solid fuel long-burning boiler is presented by the TRADYCJA series. Coal or wood is used as fuel. The heat exchanger of the unit is made of steel (steel 6 mm). Compact, but at the same time has a high performance. There is a water grid that allows an efficiency of up to 78%. Boilers ATON TRADYCJA imply combustion with a draft regulator, and units of the ATON TRADYCJA C series are equipped with an automatic control and a blower fan, so that combustion can last up to twelve hours. They have a power from 9 to 38 kW. They are easy to service, have a wide loading door, which makes loading easy. |

| ATON Multi | Implies manual fuel loading. Its design contains a heat exchanger with a horizontal convection channel (water sticks). The unit has a compact size, but the efficiency is 78%. Fuel can be coal and brown coal, firewood, peat, anthracite. Heat exchanger made of 4 mm steel. Mechanical draft regulator. Series with unit powers from 12 to 20 kW. |

| ATON TTK | ATON TTK series are cast iron solid fuel boilers of Ukrainian production. They are independent of energy, sectional, burn solid fuel (peat, briquettes, coal, wood) and have an open combustion chamber. The units have a capacity from 21 to 80 kW and an efficiency from 77.6 to 80%. Suitable for residential premises and public areas with forced and natural circulation of hot water heating. Heat exchanger with steel wall up to 6 mm. |

Model range of ATON double-circuit boilers

ATON Group produces 3 main series of dual-circuit models.

ATON ATMO 8-50

Floor standing atmospheric gas boiler is produced with different capacities in the range of 8-50 kW. It can heat an area from 100 to 450 m 2. The coolant temperature ranges from 50 to 90 ° C. The main heat exchanger is made of steel, the secondary one is made of copper.

The unit has the following characteristics:

- Efficiency = 90%;

- natural gas consumption, depending on capacity, ranges from 0.94 to 5.6 m 3 / hour;

- DHW performance at ∆t = 35ºC and power 50 kW - 11.6 l / min;

- price - from 12 to 14,500 rubles.

Wall-mounted two-circuit gas boiler Aton of condensing type with a power range from 24 to 46 kW. The coolant temperature for the heating system is from 40 to 90 ° C. The device has a closed combustion chamber and an electric ignition system. The heat exchanger made of alloyed aluminum with integrated copper circuits is characterized by high thermal conductivity.

Emergency protection systems ensure the high safety of the boilers. It includes anti-blocking of the pump and protection against pressure in the heating circuit above the nominal. Automatic diagnostics identifies 30 types of malfunctions. The device of the heat generator assumes the possibility of connecting a boiler.

A high level of safety and reliability is ensured by systems of protection against freezing, scale formation and high pressure in the system.

Gas boiler ATON KOMBI KOMPAKT HRE has the following characteristics:

- Efficiency = 109%;

- the consumption of natural gas, depending on the capacity, ranges from 0.67-2.24 m 3 / hour;

- DHW performance at ∆t = 35ºC and power 24 kW - 10 l / min;

- price - from 9 to 12,500 rubles.

Parapet double-circuit gas boiler Aton with a chimney included. Equipped with a closed combustion chamber, piezoelectric ignition and EUROSIT automation. Available in a power range from 7 to 16 kW. The main heat exchanger is made of steel, the secondary one is made of copper.

This unit has the following characteristics:

- Efficiency = 90%;

- natural gas consumption at a power of 16 kW is up to 1.6 m 3 / hour;

- DHW performance at ∆t = 35ºC and 16 kW power - 12 l / min;

- price - from 9 to 11,500 rubles.

On the Internet, you can find a large number of reviews about Aton double-circuit gas boilers. This indicates the high popularity of the presented units. Many are pleased with the economical fuel consumption, reliability and ease of management.

The boiler is the heart of any heating system. The stability of her work and comfort in the house depend on him. Therefore, special attention is paid to his choice. Gas boiler Aton is a product of the Ukrainian company ATON Group. She was born in 2003, becoming one of the brightest representatives of the segment for the production of heating equipment. In this review, we will explore the most popular boiler models and introduce you to user reviews.

Proskurov

Proskurov is a Ukrainian company that produces boilers for space heating and hot water supply. The products are popular among consumers due to their high quality and reasonable prices.

The boilers have versatile functions, they are economical in the use of fuel.

Proskurov units are of excellent quality, high efficiency and a 100% manufacturer's guarantee.

All boilers of the Proskurov company have safety automation with a gas valve (from the German manufacturer Honeywell).

The manufacturer produces gas, solid fuel and electric boilers.

Gas units are presented in two types: parapet boilers and chimney.

Solid fuel boilers are divided into categories: with and without a fan.There can be designs with a plate (AOTV-K with a plate).

Some popular models are discussed in the tables below.

Gas boilers

| Series | Characteristic |

| Parapet gas boilers Proskurov | A number of models consist of the names AOGV-7, 10, 10U, 13, 13U, 16U. They have a closed combustion chamber, do not require electricity, and are equipped with a vertical chimney. Oxygen supply to the combustion chamber and removal of impurities is carried out through special ducts outside the building. |

| Chimney gas boilers Proskurov | These are gas boilers of Ukrainian production, represented by the models AOGV-10V, 13V, 16V, 24V, 30V, 50V, 98V. They are double-circuit, floor-standing, have built-in pneumatic automation (they are not afraid of electricity drops). |

Solid fuel boilers

| Series | Characteristic |

| Proskurov AOTV with a fan | Models of this category AOTV 16, 22, 28, 34, 40, 50, 75, 100, 150. The boiler runs on solid fuel, namely wood, wood waste, peat, coal, pellets. The raw material should be fed into the furnace every 8 hours on average. Suitable for heating areas from 160 m² to 1500 m². The weight category of boilers is from 220 kg to 750 kg. |

| Proskurov AOTV-N without fan | Presented by models AOTV-12N, 16N, 22N, 30N, 40N, 50N. They are safe to use. Designed for heating not only apartments, but also houses outside the city, cottages. Suitable for heating areas from 120 m² to 500 m². The weight category of boilers is from 120 kg to 240 kg. |

Danko

Danko has been on the market since 2002.

In the model range, you can see solid fuel boilers with a capacity of 12.5 to 50 kW. They all have an individual design and quality. There are several gas-fired options. Wall-mounted units have a capacity of up to 23 kW, parapet units - 7-15.5 kW, floor-mounted units - 96 kW.

The Danko company provides a quality guarantee for its products up to three years and guarantees high productivity up to 91%.

Popular series of Danko gas boilers are discussed below.

| Series | Characteristic |

| Danko - 23 VKE / Danko - 23 3KE | These are medium-class Ukrainian-made gas boilers with a capacity of 23 kW. They have two circuits. Installed on the wall. They have an open and closed combustion chamber, as well as two heat exchangers (the main one is a copper heat exchanger for heating water in the heating circuit, the secondary one is a stainless steel plate heat exchanger for supplying hot water). The series has compact dimensions, modern attractive design. They function perfectly at reduced pressure up to 2 mbar. The design is equipped with electronic ignition, anti-freeze function. |

| Steel gas boiler Danko | The series is presented in a wide model range with a power range from 8 to 24 kW. The letter "B" means that the boiler has the function of heating water. The letter "G" means that the boiler has a horizontal flue. There are both single-circuit and double-circuit models. 3mm steel tubular heat exchanger. The average efficiency is 91.5%. |

| Cast iron gas boiler Danko | This is a series of gas floor boilers with a cast iron heat exchanger. They have an open combustion chamber and one circuit. Model capacities vary from 16 to 50 kW. The working pressure reaches 0.2 MPa. The temperature of the coolant at the outlet is up to 90 ° С. The models are characterized by high heat dissipation, resistance to rust and a long service life (over 25 years). The efficiency is 90%. Danko's cast iron gas boilers operate in open and closed water heating systems, with forced and natural circulation. |

The following are Danko solid fuel boilers.

| Series | Characteristic |

| Danko-TL | The lineup includes nine items. All boilers run on solid fuels, namely coke, wood, coal.You can also use shavings, pellets, sawdust, peat briquettes. The units are designed for heating rooms up to 470 m², in systems with forced and natural water circulation. The series is easy to operate and maintain. The service life can be up to 25 years. The solid fuel boiler of Ukrainian production has a durable cast-iron heat exchanger, a water-cooling grate. The efficiency is at least 75-80% |

| Danko-TN | This long-burning solid fuel boiler of Ukrainian production has a steel heat exchanger and operates on solid raw materials, namely peat, wood, coal. The model range includes four items with capacities from 12.5 to 27 kW. The service life of the units is more than 15 years. |

| Danko-T | The lineup is represented by three items. These are Ukrainian solid fuel boilers with a steel heat exchanger. Raw materials used: anthracite, coal, wood. The units have a modern design, are distinguished by their reliability and quality. The total heating area is 720 m². Designed for heating individual houses and other areas. |

| Danko AKTV | This is a solid fuel boiler represented by the Danko AKTV-15 and Danko AKTV-20 models. Has a steel heat exchanger, cast iron cooking plate. Wood, coal, anthracite are suitable as fuel. The total heating area is up to 200 m². The special design allows you to adjust the cast iron grate to different levels and use the boiler rationally, depending on the season outside the window. |

Grouping by type of fuel consumed

Heating boilers for a country house, depending on the energy carrier used, are:

Important parameters

The exact power can only be calculated by a heating engineer. But it is possible to "estimate" the required power based on the fact that a well-insulated house with a volume of up to thirty cubic meters can be heated with one kilowatt of boiler power. This is the average. If there are additional conditions, for example, heating a glass veranda, a summer kitchen, a winter greenhouse, then the power must be increased.

If it is necessary to spend energy on heating water, then the power is automatically doubled.

However, a simple power calculation is not enough to select a model for a gas heat generator. The location of the heated equipment in the house is also important. Calculations are made taking into account the total strength of all devices.

When installing a heating boiler in a country cottage, you must follow the points of the instructions that regulate the location of units that are designed for hot water supply and heating. According to this, a boiler for heating a private house must meet several requirements:

- the unit for heating is installed in the premises of the first, basement or basement floor with an emergency exit from the room;

- the presence of effective ventilation and forced ventilation, which ensures sufficient air exchange in the room;

- the presence of sufficient natural lighting for the service.

Ross

Manufacturer Ross has been producing products since 1991.

A wide model range is represented by brands of boilers operating on solid fuel (power from 16 to 100 kW, heat exchangers made of cast iron or steel), gas fuel (power up to 96 kW, depending on the floor or wall construction), and electricity.

The main advantage of Ross boilers is their safety and ease of use. The company is focused on the production of reliable and at the same time attractive in appearance units.

On gas

| Series | Characteristic |

| Ross AOGV | The series is produced in floor and wall versions. Floor standing gas boilers Ross do not depend on the electricity network, they have two circuits. They are economical and autonomous. They can have a steel ("Lux" and "Premium" class boilers) or cast iron heat exchanger.All units have distinctive features and advantages, long service life. Wall mounted gas boilers Ross can be with one circuit (for heating only) and with two circuits (for heating and hot water supply), with an open and closed combustion chamber. They have a low price. They heat both apartments and private houses, production workshops, residential complexes. |

Solid fuel

| Series | Characteristic |

| Ross KOTV-S | Boilers of the KOTV-S series are units with a steel heat exchanger designed to provide heat to residential buildings, utility rooms and workshops. Models of the series are represented by the names KOTV-15-S, KOTV-15-S-V, KOTV-20-S, KOTV-20-S-V. Where the number is the rated power, the letter "C" stands for the steel heat exchanger, "B" stands for the hob. The coolant temperature is 90 ° C. Working pressure - maximum 130 kPa. There is a possibility of cooking (there is a hob available). The efficiency is at least 75%. |

| Ross KOTV with automatic temperature control | The model has a steel heat exchanger that automatically maintains the coolant temperature. Heats workshops, residential buildings and other objects. It can work with natural and forced water circulation system and with pressures up to 200 kPa. It uses wood, brown coal and briquettes as raw materials. There is a possibility of heating with coal. The efficiency is up to 78%. The large volume of the loading chamber leads to a longer combustion process. The model is easy to maintain. |

| Ross KOTV-30 | It can operate in closed and open heating systems, with forced and natural water circulation, with an excess pressure of up to 200 kPa. Peat briquettes, wood and wood chips briquettes are used as fuel. In a closed system, wood pellets, lignite and hard coal can be used. Boiler power can be changed within the range of 10-35 kW. The efficiency is up to 80%. The heat exchanger is enlarged, made of steel with a thickness of 3 mm. |

Thus, there is a large selection of Ukrainian-made boilers on the market. They operate on various types of fuel, have different technical and economic characteristics.

Source: teplofan.ru

Installing a wood-burning boiler in a garage: basic requirements and standards

There are a number of rules associated with the installation of such equipment. Let's note the most important of them:

- The solid fuel boiler should be located at a distance of at least 50 cm from any structures.

- The walls and floor of the garage must be covered with non-combustible finishing materials (plaster, ceramic tiles).

- Rags, old magazines, fuels and lubricants and other flammable products are not stored in garages with a solid fuel boiler.

- For pyrolysis-type models, it is necessary to equip a high-strength concrete base (devices with two combustion chambers are heavy).

- The distance from the boiler door to the opposite wall must be at least 1.2 m.

- In the water circuit system, it is necessary to equip a safety group that will automatically release the coolant pressure.

- The chimney must be made of materials that are resistant to strong temperature fluctuations. In the places where the pipe passes through the floor slabs and the roof, fire separators are provided.

It is important to understand that a garage is a fire hazard room. Therefore, all equipment intended for such buildings must meet the strictest fire protection requirements. It is important that it can work autonomously, without constant human supervision.

Parapet equipment Aton

The design of a parapet boiler is in many ways similar to the design of condensing equipment. The main difference from similar atmospheric equipment is the presence of a closed combustion chamber.As a result, the air consumed during gas combustion enters the furnace not from the room, but from the street. The Aton gas parapet boiler is connected to a horizontal coaxial chimney.

As a result of such a device, the efficiency and efficiency of the equipment increase, and the possibility of environmentally friendly gas combustion is achieved.

Some parapet gas heating boilers Aton, in addition to the traditional heat exchanger, have a built-in convection casing, which allows heating the room with greater efficiency. Attached models of parapet equipment are mainly volatile and cannot work without electricity. Floor-standing versions are non-volatile.

Features of operation

The boiler was produced, of course, at the factories of the USSR, made from domestic raw materials and equipped with locally produced electronics. The quality of workmanship was at a high level, but the automation failed in the overwhelming majority of cases already in the first heating season. But the equipment worked fine without it, so no one paid attention to such a defect.

But the boiler was reliable and durable in all other respects. The level of gas consumption was indeed incredibly low, although the efficiency barely reached 70%, which is extremely low for gas installations. But still, for private houses, this was the only way to heat a home with a modern unit, and not with an old wood-burning or coal-burning stove. And in multi-storey buildings, such a boiler made it possible to improve living conditions, since residents could regulate the temperature of the internal premises themselves.

The factory glass thermometer also quickly failed, and had to be replaced with a better product. But for the repair, you could use parts from any other technique. The main thing is that the size and shape fit, and the craftsmen found how to fit them in place without problems. In general, the model had an incredible amount of custom modifications.

Wall mounted boilers

This category includes equipment designed for simultaneous heating and hot water heating. The Aton two-circuit wall-mounted gas boiler is distinguished by a number of technical features that affect its operation:

- The heat exchanger is made of special steel and has a thickness of 3 mm.

- The design of the heat exchanger provides for the use of fire tubes of a special profile, which allows to increase heat transfer by 15%.

- Aton gas double-circuit hinged boilers use a silent burner. Small size and compactness, absence of extraneous noise during operation makes it possible to install equipment without the use of additional sound insulation.

- The burner is manufactured in England, and the automation of the Aton boilers in Germany and Italy.

Replacing the floor boiler for heating

Another pressing issue, the inevitability of a solution to which will ever come, is the failure of the heating element. The forced replacement of a heat exchanger in a country cottage can be solved in two ways: either only a new device is installed, or more effective measures are taken to replace the entire heating system.

Of course, the installation of a new modern floor-standing gas boiler instead of an ineffective or broken unit can be limited. Then a small reliable device that functions simultaneously for heating water and heating living space is the best option.

The second version is more expensive, but undeniably preferable to the first. The problem of dirty heating pipes with long-term "deposits" of scale and dirt, which greatly reduce heat transfer, will be immediately solved. If you do not remove the cause of contamination, it will clog up new equipment in an instant, which will cause an early breakdown.And the old device of the gravity heating system warms up unevenly and heat is supplied to the batteries remote from the floor gas boiler with a lower temperature.

The question of which gas equipment to choose for heating a private home, wall or floor, needs to be addressed in a comprehensive manner.

Floor heating equipment

Stationary boilers Aton are efficient and powerful installations with a capacity of 16 kW and above. One of the latest developments of the company is capable of operating with a power of 1 MW.

All proposed modifications can be roughly divided into several types:

- Gas floor-standing double-circuit boiler Aton - designed for connection to the heating system and hot water supply. Water heating is carried out using a plate-type copper heat exchanger.

- Gas heating single-circuit boiler Aton - connection to heating is provided. Some models are supplied with a built-in boiler. Others, at the request of the customer, can be connected to the indirect heating accumulator. Requires an electrical connection.

- Aton non-volatile floor-standing gas heating boilers are simple in design water heating stations. Does not require connection to the power supply system. They are connected to a heating system with natural circulation of the coolant. The Aton chimney floor-standing non-volatile gas boiler has an atmospheric burner and uses indoor air to operate.

Benefits of the Aton brand

Ukrainian-made boilers AtonMASH are of high quality due to the fact that only imported components are used in the production of equipment. In fact, the company simply assembles a fuser from ready-made parts. It is for this reason that the technical characteristics of boilers are often not inferior to European expensive counterparts. What are the benefits of this?

- Low cost.

- High quality of assemblies - the operating mode of the automation allows you to accurately set the required temperature regime and reduce gas consumption. The heat exchanger is made from sheet steel by cutting on Finn-Power punching presses, followed by welding in a mechanized way, which ensures the integrity of the seams even during maximum heating.

- Performance - equipment for any heated area is presented. Small compact stations can generate 8-10 kW. High-performance floor-standing units have a capacity of up to 1 MW.

- Ease of operation - during the combustion of gas, soot appears on the atmospheric burner. Over time, as it becomes clogged, this affects the performance of the device, significantly increasing the gas consumption. The burner is easy to clean. The front cover is removable for access to the most important parts.

- Service maintenance - the simple principle of the boiler does not require much effort and time to maintain the device in operation. It is enough to check the operation of the equipment, no more than 1-2 times a year. At this point, you can adjust the gas supply and carry out other repair work.

- Safety - the principle of operation of the draft sensor helps to prevent situations in which the exhaust gases are returned to the firebox under a gust of wind. When the gas pressure drops, the automation gives a signal to turn off the system. Gas leakage is excluded.

What to look for when choosing a boiler

When choosing an Aton boiler, you should pay attention to the following parameters:

- Dependence on electricity.

- The presence of a DHW circuit or built-in boiler.

- Required performance.

Aton boilers do not have many of the functionality that European and Japanese manufacturers advertise. But if you need to purchase a high-quality and safe boiler at an affordable price, then you cannot find a better option.

Source: AvtonomnoeTeplo.ru

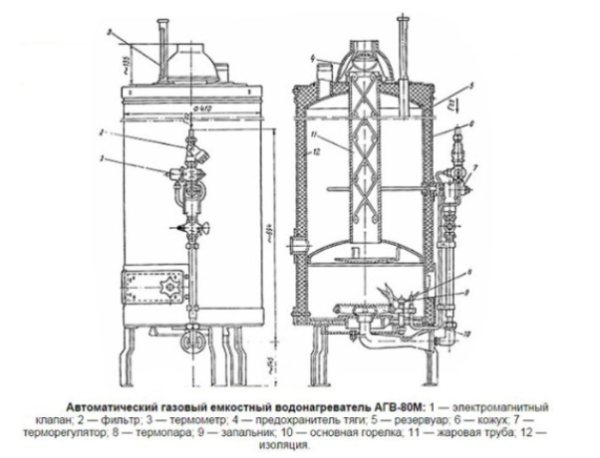

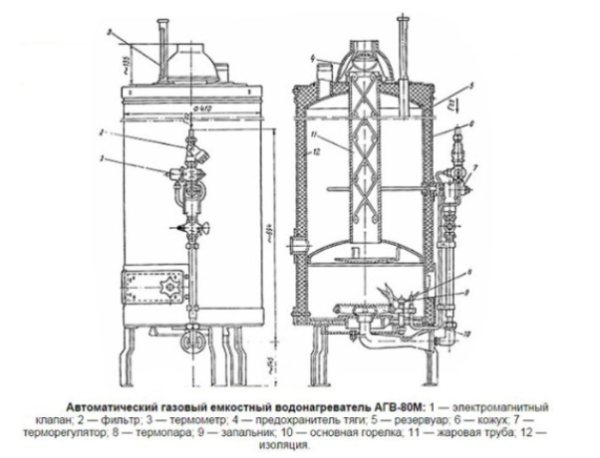

An example of a retro boiler - AGV-80 and modifications

AGV-80, the photo of which is given above, refers to boilers of the old type of heating. He has one circuit (heating water for domestic needs).The production of the model began in 1939 by the Zhukovsky Machine-Building Plant. The reason for this was the massive gasification in the USSR and the use of gas for heating household premises.

The boiler is a cylinder on three legs, in the upper part of which there is a chimney. The cylindrical tank is made of steel, hermetically sealed, with a volume of 80 liters. Inside the tank there is a flame tube, under the mouth of which an atmospheric burner is installed. To reduce the speed of heated gases leaving the pipe and to increase the degree of heating of the tank walls, a turbulator is mounted inside the pipe. The efficiency of the device reaches 80%.

Equipment:

- thermometer;

- traction fuse.

When the pressure drops or the maximum water temperature is reached, these devices allow you to shut off the gas supply.

The design of this boiler served as the basis for the company's developers to release improved models AOGV (for CO) and AKGV (with two circuits), the efficiency of which is up to 89%.

In addition to a similar design, the package of new generation gas boilers includes:

- coil (for supplying water for household needs);

- the flame tube is divided into sections, each of which has a turbulator;

- thrust sensor;

- air regulator;

- automatic start;

- automatic unit for regulating boiler operation and temperature.

Boiler device AVG-80

General information about Ukrainian gas boilers

Functional gas boilers of Ukrainian production, the price of which depends on the model and specification, are distinguished by ease of operation and ease of adjusting the settings. They can be installed on the floor or on the wall in the kitchen, boiler room or in any other room. Although Ukrainian gas heating boilers may have structural differences, they all work according to the same principle. They need natural gas as fuel, which is used to heat the coolant. When the gas enters the sealed combustion chamber, its energy is transferred to the coolant, then the liquid, using circulation equipment, moves through the radiator system and contributes to heating all rooms in the building.

Correctly selected Ukrainian-made gas heating boilers will become an effective, reliable and functional element of a home heating system. To choose a successful boiler, you need to familiarize yourself with the current offers on the market presented by Ukrainian manufacturers of heating equipment, as well as outline the main structural and functional differences between various models.

Nuances in service and connection

Now, as before, installing a gas heating boiler is not an easy task. To install such equipment you will need:

- coordinate actions with Gostekhnadzor;

- draw up a boiler connection project;

- prepare the room, connect the chimney, ensure the access of the main gas to the boiler.

A number of norms and rules have been developed that will have to be followed during installation:

- you will need a ventilated room for the installation of the boiler, with access to the street;

- the area of the room must be at least 100 m²;

- mandatory installation of automation, which is responsible for gas leakage.

Gas boilers of the old type were connected to chimneys with a length of at least 5 m, only with natural draft. These requirements were mandatory and contributed to the minimum formation of condensation - the main disadvantage of retro devices.

Now coaxial chimneys and circulation pumps are used, therefore it is allowed to provide forced draft and install the chimney through the wall or into the ventilation shaft, which facilitates installation and makes the chimney connection point neater. The photo shows the correct installation of the boiler.

Wall mounted boiler

The market is now offering mounting accessories and care products that extend the life of the devices and improve operating efficiency.

The compact design of the new heating devices and the light weight, which are especially characteristic of the wall-mounted gas models, allow the device to be installed in a matter of hours, as shown in the example video below, and can be used even in small-sized rooms.