Autonomous heating systems based on gas boilers are considered the most convenient and efficient.

They almost do not need constant attention, they are able to maintain a constant temperature, they have protection against possible problems - overheating, flame extinction, and other malfunctions.

However, most units are too dependent on the availability and quality of power supply.

Any voltage drops become the reasons for the failure of the control board or other devices, and a power outage completely stops the operation of the heating system.

To solve these problems, non-volatile gas boilers are used.

What is a non-volatile gas boiler?

Nonvolatile gas boilers operate only with mechanical assemblies and parts. They do not need to use electricity, which greatly increases their capabilities.

In the conditions of Russia, where in winter the temperature drops much below zero, it is important to ensure the continuity of the heating systems... At the same time, most of the power grids are overloaded, and in some villages there is no connection at all.

This makes non-volatile boilers a popular and preferred unit. All the main units of the unit are controlled only by mechanical methods, but this does not impair the quality of heating the house.

Non-volatile boilers are devoid of many parts, which simplifies the design and makes the operation more stable and reliable. Most users do not consider the lack of remote control and other additional functions a significant drawback.

Everyone understands that many add-ons make the device more vulnerable and unreliable.

NOTE!

The design of non-volatile boilers arose much earlier than more modern dependent units. The long period of existence has allowed manufacturers to work out assembly technologies and achieve high performance indicators.

Installation

Any gas equipment can be installed and put into operation only if there is a project for the installation and after agreement with the gas service. If the project was completed with errors, or if they were allowed during installation, the boiler will not be approved for use.

In order for the boiler to work normally, a number of conditions must be met:

- A positive temperature must be constantly maintained in the boiler room;

- During the installation of the boiler, fire safety instructions must be observed (for example, the walls near which the boiler is installed must be protected with non-combustible materials);

- When installing the boiler on your own, for its first start-up, it is imperative to invite a specialist who will be able to make sure with an experienced eye that the boiler is installed correctly and that there are no errors in its operation.

When designing a boiler installation scheme, you need to think not only about the unit itself, but also about the installation of the chimney system. The chimney must be installed in accordance with a number of requirements, which depend on the characteristics of the boiler and the characteristics of a particular building. Each individual boiler must have its own chimney, but if necessary, several boilers can be reduced to one chimney duct, the cross-section of which corresponds to the sum of the cross-sections of the outputs of each boiler.

According to the norms, if the chimney is brought out to the roof and installed at a distance of 1.5 meters from the ridge, then the height of the pipe must exceed 0.5 meters. In the event that the distance between the ridge and the edge of the pipe is from 1.5 to 3 meters, the chimney must be brought out at least one level with the ridge.

It is recommended to make the chimney completely straight, but if this is not possible, then you can make several turns (no more than three along the entire length of the chimney duct). The total length of the chimney must exceed 5 m. From above, the chimney is closed with a metal fungus, which prevents dirt and moisture from entering the structure.

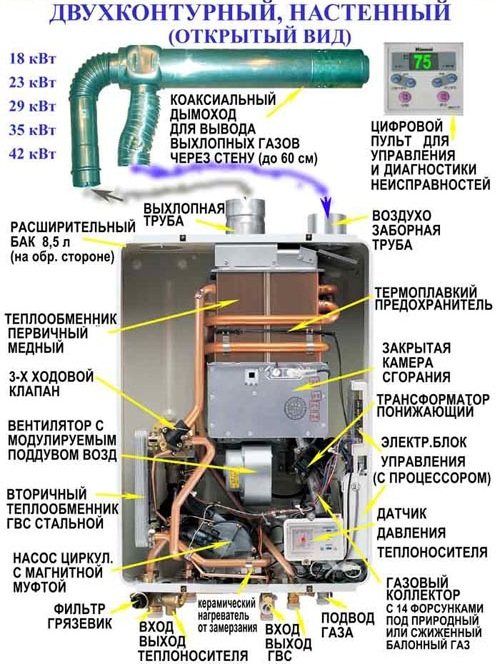

A private version of the chimney is coaxial pipes, the possibility of using which is determined individually (it is advisable to consult a specialist). Coaxial flues can be installed at a low height and lead directly into the wall. Installation is inexpensive, and its technology is extremely simple.

Of the disadvantages of coaxial chimneys, some dependence on forced draft of air, which is created by an electric fan, can be noted. When installing such a chimney in combination with a non-volatile gas boiler, the reliability of the system will be reduced. In addition, condensation constantly appears in coaxial chimneys, and the complexity of its removal is also a disadvantage.

https://youtu.be/4Uzyya5lFr8

What is the difference from the usual one?

The difference between a non-volatile boiler is the absence of all nodes that need power. There is no built-in circulation pump, turbofan.

Control is carried out using mechanical devices - valves, mechanical sensors, regulators... This makes the design very simple and reliable, but all processes take place naturally.

For example, smoke removal is carried out using a stove draft in the chimney. Air is taken directly from the room. These features make the mode of operation dependent on the mass of external factors..

For example, chimney draft varies with weather, wind direction and strength. Drafts can disrupt flames. In addition, the room needs good ventilation, since the boiler actively burns out oxygen.

Many users solve these problems by installing external devices - a circulation pump and a turbo nozzle to enhance and stabilize traction.... This makes the operating mode more intense and even.

Types and general arrangement

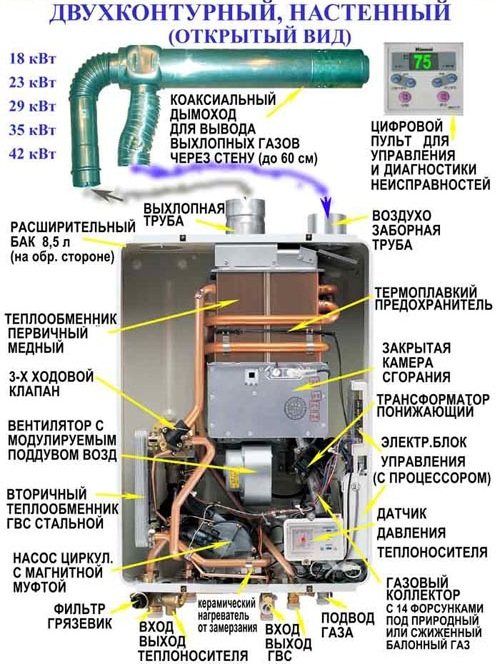

According to the installation method, heating devices are floor-standing and wall-mounted, according to their functionality - single-circuit and double-circuit. As in any other boiler, where water acts as a heat carrier, it is heated through a heat exchanger according to the principle of a water-to-water boiler.

And since these devices are capacitive and high-speed, the heating of the coolant is more similar to the operation of the capacitive one. Heating running water for household needs is more like using a high-speed boiler. Devices that perform both of these tasks are called dual-circuit.

Ignition

The gas in the combustion chamber is ignited by an igniter, which is ignited manually using a piezoelectric element. Piezo ignition works by analogy with an ordinary lighter equipped with a similar device.

Control

The mechanisms of automation, ensuring the stable and safe operation of the boiler, have a mechanical drive or are configured to use the temperature difference in different parts of the heating system.

Advantages and disadvantages

The advantages of non-volatile boilers include:

- there is no dependence on the availability and quality of power supply;

- simplicity of design, absence of minor details;

- guaranteed continuity of the heating process at home;

- the cost of the boiler and repair work is much lower than that of volatile models;

- maintenance and cleaning can be done by yourself.

Disadvantages are considered to be:

- the protection system is limited to a few sensors;

- there is no possibility to carry out remote control;

- the operation of the boiler depends on external factors that cannot be controlled.

IMPORTANT!

Despite some disadvantages, non-volatile boilers are a practical and reliable solution.In some settlements, they have no competitors due to power outages.

Where to buy a gas non-volatile heating boiler

In Moscow and Moscow region

- MirCli (https://mircli.ru/kotly-otopleniya/napolnye-gazovye-kotly/energonezavisimye/) - 8 (495) 666-2219.

- Teplodvor (https://www.teplodvor.ru/kotly-otoplenija/napolnye-gazovye-kotly/energonezavisimye.html) - +7 (495) 48-132-48, Balashikha-1 microdistrict, st. Soviet, 35 143902 Balashikha.

In St. Petersburg

- Gas boilers St. Petersburg (https://spb.kotel-gazoviy.ru/energonezavisimiy/) - +7 (812) 923-18-67, St. Petersburg, 5th Upper Lane, 15.

- Teplodvor St. Petersburg (https://spb.teplodvor.ru/kotly-otoplenija/napolnye-gazovye-kotly/energonezavisimye.html) -, st. Vitebsky prospect, 3 196105 St. Petersburg.

In conclusion, we can say that volatile models are more advanced and functional. If there are no problems with the power supply, then the choice is obvious in their favor. Non-volatile analogs are an excellent solution in situations where there is no uninterrupted and high-quality power supply, and there is no desire to equip the boiler room with a voltage stabilizer and a generator.

Gas boilers

Device

The main elements of non-volatile units are the primary (main) heat exchanger and gas burner. They provide the main function of the boiler.

In addition, the structure includes:

- three-way valve, in which the temperature of the coolant is brought to the set value;

- gas equipment providing control and fuel supply;

- secondary heat exchanger (only for dual-circuit models);

- temperature and pressure sensors.

The list of units is small, but this is the main advantage of non-volatile boilers. The fewer parts, the higher the strength and resistance to loads of the structure as a whole.

Heating equipment manufacturers

Non-volatile gas boilers are not in such great demand as conventional appliances. But they are in demand in those areas where there are frequent power outages.

Moreover, they are used not only for heating residential buildings, but also for such objects where the presence of volatile devices is undesirable, for example, in saunas, baths.

The main manufacturers of such boilers today are:

- Protherm (Czech Republic)

- Alphatherm (Italy)

- Attack (Slovakia)

- Beretta (Italy)

They are also produced by local manufacturers, but their products are not in such demand as foreign models.

Views

There are not so many varieties of non-volatile boilers as there are more modern dependent models. For example, there are no turbocharged units (with mechanical air supply).

There are the following varieties:

- single-circuit. Provide only heating of the heating agent for the heating circuit;

- double-circuit. They perform two functions - heating the coolant and preparing hot water.

By installation method:

- wall. They are installed in a hinged way on load-bearing walls or strong vertical surfaces;

- floor. installed on the floor or on a non-combustible stand. Most non-volatile units are made in floor-standing design;

- parapet. These are units that have the characteristics of several groups of gas boilers. They have a lot of features that make them practical and user-friendly.

NOTE!

As a rule, non-volatile boilers have a floor-standing single-circuit design. This is the simplest and most reliable option. This approach allows you to guarantee an uninterrupted supply of coolant to the heating system in difficult conditions.

Viadrus G36 (BM) boiler

This boiler model is available with a power range from 12 to 49 kW. It is necessary to select a specific modification taking into account the requirements of the individual characteristics of the heating system and the building.

Viadrus G36 is a wall mounted gas boiler capable of operating without electricity. The boiler has a special thermoelement that ensures the smooth operation of the gas valve. The system is also equipped with a sensor that prevents various abnormal situations arising from traction.

The boiler of this model is quite effective and can heat the coolant to temperatures from 45 degrees. If necessary, a circulation pump can be connected to the boiler, providing forced circulation of the coolant in the system.If the supply of electricity in the local network is not stable, then the system should be supplemented with a good uninterruptible power supply.

It is best to install such a unit together with a separate chimney, but if this is not possible, then a coaxial pipe is quite suitable. The boiler has special nozzles, to which you can connect an indirect heating boiler to provide residents with hot water.

Principle of operation

The operation of a non-volatile boiler is based on flow heating of the coolant in the flame of a gas burner. The liquid enters the boiler, goes through the heating stage and enters the three-way valve.

There, a colder "return" is mixed in a certain ratio. This allows you to give the coolant the temperature set by the mode. EIf the boiler is double-circuit, then a secondary heat exchanger is installed between the main heat exchanger and the three-way valve to prepare hot water supply.

The smoke is removed by natural draft, therefore, a connection to a communal chimney of sufficient length is required.

Liquid circulation also occurs naturally, which requires compliance with the regulatory slope when installing the system.

Features of the operation of non-volatile equipment

Such devices have two burners - pilot and main. Pressing the button activates the piezoelectric element. It ignites the pilot burner, and the main burner is ignited from it. The latter, when burning fuel, heats up the heat exchanger and works until the water reaches the set temperature.

Then the gas flow is reduced and the burner goes out. When the heat exchanger cools down, the temperature sensor is triggered again and the process is repeated. In modern models of non-volatile boilers, there is a valve that shuts off the gas supply with a complete or partial absence of traction. It is designed to reduce the safety level of the devices.

Rating of TOP-5 non-volatile gas boilers

Consider the features of some models of non-volatile units:

Lemax Premium-12.5

Non-volatile floor-standing boiler of domestic production. The power of the unit is 12.5 kW, so the area of the room should not exceed 125 sq. m.

The model is equipped with a steel heat exchanger, overheating protection and a gas supply controller.

Basic performance characteristics:

- Efficiency - 90%;

- maximum heating water temperature - 90 °;

- pressure in the heating circuit (max) - up to 3 bar;

- natural gas consumption - 1.5 m3 / hour;

- dimensions (W-H-D) - 416x744x491 mm;

- weight - 55 kg.

Lemax gives a long-term guarantee for its boilers - the user receives technical support for 3 years.

Lemax Premium-20

Another floor-standing non-volatile gas boiler manufactured in Taganrog.

Its power is 20 kW, which is optimal for most private two-storey houses. The maximum area for this unit is 200 sq. m.

Boiler parameters:

- Efficiency - 90%;

- maximum heating water temperature - 90 °;

- pressure in the heating circuit (max) - up to 3 bar;

- natural gas consumption - 2.4 m3 / hour;

- dimensions (W-H-D) - 556x961x470 mm;

- weight - 78 kg.

The single-circuit design is intended for heating the coolant, but if necessary, you can connect an external indirect heating boiler.

Lemax Patriot-12.5

Non-volatile parapet model from Taganrog. A boiler with specific capabilities.

Non-volatile unit, but a closed combustion chamber. Boiler power 12.5 kW, suitable for heating 125 sq. m.

Main technical characteristics:

- Efficiency - 87%;

- maximum heating water temperature - 80 °;

- pressure in the heating circuit (max) - up to 2 bar;

- natural gas consumption - 0.75 m3 / hour;

- dimensions (W-H-D) - 595x740x360 mm;

- weight - 50 kg.

The main advantage of parapet boilers is their low fuel consumption - almost half as compared to conventional models.

Siberia 11

Products of Rostov manufacturers of heating equipment. BUTthe units are produced in single and double-circuit versions, which expands the choice.

The power is 11.6 kW, allowing you to heat a house with an area of up to 125 sq. m.

main parameters:

- Efficiency - 90%;

- maximum heating water temperature - 90 °;

- pressure in the heating circuit (max) - up to Bar;

- natural gas consumption - 1.18 m3 / hour;

- dimensions (W-H-D) - 280x850x560 mm;

- weight - 56 kg.

Rostov units are positively assessed by specialists and ordinary users.

MORA-TOP SA 40 G

Czech gas non-volatile boiler with a capacity of 35 kW is designed for use in rooms up to 350 sq. m. The massive structure is equipped with a cast iron heat exchanger.

Options:

- Efficiency - 92%;

- maximum heating water temperature - 85 °;

- pressure in the heating circuit (max) - up to Bar;

- natural gas consumption - 3.9 m3 / hour;

- dimensions (W-H-D) - 630x845x525 mm;

- weight - 151 kg.

The cast iron heat exchanger has a sectional design of 5 sections... There are pressure and temperature sensors.

Reviews of gas boilers operating without electricity: advantages and disadvantages

| Benefits | disadvantages |

| Independence from the power source, which ensures stable heating of the house | Less accurate and less stable temperature control in comparison with full automatic operation and flame modulation |

| Simpler and more reliable design, no expensive automation that could fail | The lack of some functions (work program, weather dependence, etc.), a lower level of security due to the lack of multifunctional automation. |

| Savings on the absence of additional electricity costs. Also, there is no need to install a UPS and voltage stabilizer. | For operation, a chimney with a sufficiently strong draft is required (creating a vacuum of 16-20 Pa in the firebox), otherwise the draft sensor will work, turning off the gas supply. |

| Easier installation and connection | For boilers with an open combustion chamber, it is recommended to have ventilation in the room |

| Often quieter operation due to the absence of a circulation pump, turbines, fans and other active elements. | Often lower (by 1-5%) efficiency in comparison with volatile boilers |

Installing the Floor Standing Unit

When connecting the floor boiler to the pipelines of the heating system, it is also necessary to comply with similar requirements, but given its location at the lowest point of the room, there are more options for choosing options for laying pipelines.

The scheme in which floor-standing gas boilers are used, regardless of whether they are single-circuit or double-circuit, is more functional and initially assumes a 10-15% reduction in costs when installing a heating system.

The specificity of the use of non-volatile boilers and their classification

Gas floor boiler Danko-8 VS

The specificity of the use of non-volatile boilers is based on the principle of their operation. Such installations can only be located where natural circulation of the coolant is implied. Water heating is carried out only thanks to the elements that ignite the gas burner without electricity.

Almost all non-volatile heating boilers are divided into two large groups - single-circuit and double-circuit. The first ones are used when it is necessary to organize only the heating of the house. The presence of the second circuit makes it possible to supply hot water for technical needs in one of the ways - flow or storage.

In models that provide a flow-through DHW supply, a second heat exchanger is installed. It can be located above the burner and be independent from the heating circuit. Or it can fit inside it, like a pipe in a pipe

When buying a model, you need to pay attention to this feature.

It is definitely difficult to say which option is better.It all depends on the conditions under which the installation is operated, and what the quality of the coolant is. We can safely say only one thing - it is easier to carry out service maintenance and repair the installation in the event of a breakdown of the heat exchanger where the second circuit is located parallel to the main heating circuit.

Usually, two-circuit non-volatile heating boilers are purchased when there is no need for a large amount of hot water, and only one or two water intake points are used. If more than three people live in the house, then the flow-through double-circuit boiler will not be able to meet the needs for hot water supply.

In this situation, it is advisable to purchase equipment supplemented with a storage boiler. Today, there are compact floor-standing models on sale, in which the storage tank is located inside the case. They cost a little more than conventional installations. The design of the latter implies the possibility of independently completing the boilers with the necessary technical elements, including a storage tank.

Note! Practice shows that the costs of installation, the purchase of fasteners and the allocation of a technical room are quite high. Therefore, it is better to immediately buy one installation and enjoy its presentable appearance, as well as ease of operation.

Right choice

If you want to install a non-volatile boiler, you must know at least its main advantages and pay attention to negative characteristics. Summarizing what was said above, we can note the disadvantages:

- high material consumption of the heating system;

- compliance with the accuracy of the slope when laying pipelines;

- increased gas consumption due to constant ignition of the igniter.

Advantages:

- operation of the device without electricity;

- the presence of piezo ignition;

- automatic regulation of the intensity of combustion according to the previously set temperature of the coolant;

- work at low gas pressure.

Summing up, we can say that gas boilers, which do not need electricity for their operation, both floor-standing and wall-mounted, are justified to be installed where their obvious disadvantages are covered by no less obvious advantages.

Models of non-volatile wall-mounted boilers

Protherm Cheetah

A popular model of non-volatile wall-mounted double-circuit gas boilers is the Protherm Cheetah 23 MOV unit. It has a rated power of 23.3 kW, its efficiency is 90.3%, and the heated area is up to 200 m². This model has a light weight of 31 kg. It is quite compact and easy to install on the wall yourself.

Ferroli Domina N F24

Ferroli manufactures a non-volatile model Domina N F24 with a capacity of 23.5 kW. This gas boiler has two circuits and a closed type of combustion chamber. This unit is capable of heating a room with an area of up to 180 m² and has a fairly high efficiency = 93%. The hot water heating system is capable of producing up to 13.5 l / min.

Find out more about gas boilers Protherm

https://oteple.com/chem-unikalny-nastennye-gazovye-kotly-rrotherm/

Which of the gas boilers is the most economical

When choosing a non-volatile boiler, you should take into account its features, analyze all the advantages and disadvantages, and then think about whether this unit can work effectively in the conditions of your region. Consider the fact that such a device is devoid of the convenience of electronic control, which boilers powered by electricity have.

Boiler working principle

Due to the lack of access to power supply, two-chamber boilers are equipped with special thermogenerators, which are responsible for the condition of the burner by stopping the gas supply to it. This process is provided by the action of the coolant on the regulator. An automatic system provided in the boiler restarts access to gas as soon as the coolant cools down completely.Ignition for this is provided by the operation of a piezoelectric element, the task of which is to ignite the pilot burner. if necessary, the piezoelectric element starts the ignition of the main element, which in turn is responsible for heating the liquid in the entire heating system.

Positive and negative aspects of non-volatile installations

Gas boilers: classification of types PARADIZZA

Before deciding to buy the described equipment, it will be useful to get acquainted with its advantages and disadvantages:

- The most important advantage is the lack of dependence on electricity. Where it is supplied with great interruptions, the described boilers help to solve rather complex domestic problems.

- Almost all models that represent single-circuit and double-circuit floor heating boilers. have sufficient power. It can be enough for connecting water radiators, for a floor heating system, for heating a boiler, or for providing the required amount of hot water in a flowing way.

- After familiarizing yourself with the installation requirements, you can easily select compact floor-standing options with many useful options and functions.

- Gas installations have a high efficiency - up to 92%. You can use them without fear for the safety and health of your loved ones. The fact is that each modern model is equipped with a thrust sensor and a sensor that monitors the gas pressure. In the event of a critical drop, the feed is shut off automatically. Therefore, the occurrence of dangerous situations in this regard is excluded.

- Nonvolatile floor standing boilers are an order of magnitude cheaper than similar volatile models. Low cost is sometimes a decisive factor in shaping supply and demand.

The disadvantages of the described heating boilers are few. Almost all of them are associated with the need to strictly adhere to the rules for installing a heating system with natural circulation of the coolant. All this has been described in detail above.

It is important to choose and install the chimney correctly, as well as to ensure high-quality ventilation of the room where the described installations will be located. Floor standing gas boilers can only be used where the gas pressure in the supply line does not fall below 5 atmospheres

Demanded manufacturers of non-volatile single-stage boilers

Some of the most popular models of non-volatile single-stage boilers are Baxi slim, Protherm Volk, Siberia AOGV, Zhukovsky AOGV.

This model of floor-standing gas boilers has 5 modifications, which stand out with a capacity of 22 to 110 kW. Baxi slim is equipped with a gas burner, cast iron heat exchanger and security system. Reviews say that it is better to connect a Baxi chimney to the boiler in order to remove leaks and other problems with the removal of combustion products.

These units are easy to maintain and operate, you can clean them yourself without the involvement of professionals. They are equipped with a self-diagnosis system that detects breakdowns and eliminates them on its own.

You need to pay attention! It is important to monitor the draft in the chimney so that the water pressure sensors do not fail. Gas water heaters Baxi slim are easy to set up using an LCD display that provides comprehensive information about the settings

Gas water heaters Baxi slim are easy to set up with an LCD display that provides comprehensive information about the settings.

Protherm Wolf

The gas single-circuit floor-standing non-volatile boiler Protherm Volk has a small power range - from 12.5 to 16 kW. This will be enough to heat a country house or trade area up to 140 m2. The efficiency of the unit will be approximately 90%.

The burner is ignited using a piezo ignition built into the firebox. The piezo ignition does not stop working with a standard battery, so it is best to always have them with a margin.

This boiler is equipped with a single stage burner.The combustion intensity can be adjusted by decreasing or increasing the gas supply using a specialized valve.

The security system has a meter that monitors the attenuation of the flame and automatically stops the gas supply if the fire is extinguished. There is also a meter in the firebox that protects the system overheating.

Siberia AOGV

Siberia AOGV is considered to be a light representative of our floor standing atmospheric boiler. It all depends on the model, they have a power from 11 to 50 kW, efficiency = 90%. The positive qualities of these units include independence from electrical energy.

Non-volatile automation includes the following functions:

- piezoelectric ignition;

- magnetic valve;

- flame control;

- modulating thermostat.

Siberia heating devices are distinguished by their unpretentiousness to the differences in the electrical network and gas pressure, as well as to the quality of water. Fuel combustion takes place in an open combustion chamber equipped with a Worgas burner made in Italy. It is considered environmentally friendly as no carbon and nitrogen oxide remain in the exhaust gases.

AOGV Zhukovsky plant

The non-volatile gas water heaters of the Zhukovsky plant were demonstrated in three modifications "Economy", "Universal" and "Comfort". They are equipped with a steel heat exchanger, temperature sensors, a gas burner, a draft sensor and a piezoelectric ignition. Automation controls the heating of the heat carrier from 45? up to 90 ° C. Gas-fueled units are perfectly used both with open fireboxes and with closed ones.

The AOGV "Universal" model, in contrast to the "Economy", is supplemented with a modulating burner, which gradually changes the combustion power, which helps to save fuel. The boilers are equipped with much more advanced SIT automation made in Europe. The security system blocks the operation of the unit during overheating or to eliminate a dangerous situation.

Units of the "Comfort" series are very common among consumers from the choice of boilers operating on gas from the Zhukovsky plant. They are demonstrated by 15 models of different power from 11 to 43 kW. The most productive device is capable of heating an area of up to 350 m2.

Floor-standing non-volatile single-circuit devices are a specific section of products that cannot be done without in regions where power outages often occur and in places remote from civilization.