Home / Gas boilers

Back to

Published: 03/18/2020

Reading time: 7 minutes

0

438

The Cheetah boiler has won consumer sympathy in the domestic market for quality, safety and durability. This became possible thanks to the efforts of the Slovak company to achieve production quality in accordance with the European ISO 9001 standard.

Protherm boilers are double-circuit, capable of heating the coolant for heating systems and hot water supply, therefore, it is installed as a source of autonomous heat supply.

- 1 Manufacturer Protherm

- 2 Pros and cons of these boilers

- 3 Specifications

- 4 Fuel used

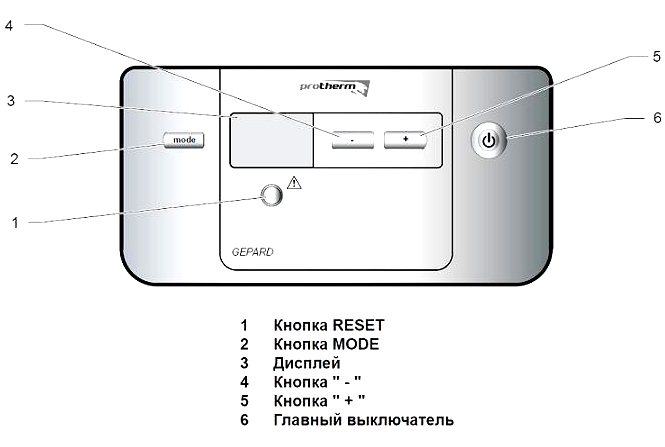

- 5 Boiler control Cheetah

- 6 Security system

- 7 Common mistakes and decryption

- 8 Boiler settings and operating instructions

- 9 Where to buy a boiler

Gas boilers from Protherm

Protherm was founded in 1991 in Slovakia.

Today it is part of the same holding with the recognized flagship - Vaillant, which allows us to confidently talk about powerful technological and consulting support... This condition has a positive effect on products - with an average price range designed for a mass buyer, the quality of equipment is not inferior to other representatives of this direction.

Gas boilers are one of the types of heating equipment manufactured by Protherm for export. All units are being adapted to the technological conditions of the area where they will be operated.

They are able to withstand fluctuations in power supply, operate at low pressures of water and gas.

Combined boilers Protherm - Proterm

| Name | Price | |

| Cast iron combined boiler for operation with a fan burner (diesel / gas / fuel oil) Protherm Bison 30 NL - Proterm Bison 30 NL | RUB 53,674.55 | Add to Cart |

| Cast iron combined boiler for operation with a fan burner (diesel / gas / fuel oil) Protherm Bison 35 NL - Proterm Bison 35 NL | RUB 58,494.30 | Add to Cart |

| Cast iron combined boiler for operation with a fan burner (diesel / gas / fuel oil) Protherm Bison 40 NL - Proterm Bison 40 NL | RUB 62,109.13 | Add to Cart |

| Cast iron combined boiler for operation with a fan burner (diesel / gas / fuel oil) Protherm Bison 50 NL - Proterm Bison 50 NL | RUB 71,639.13 | Add to Cart |

| Cast iron combined boiler for operation with a fan burner (diesel / gas / fuel oil) Protherm Bison 60 NL - Proterm Bison 60 NL | RUB 80,621.40 | Add to Cart |

| Cast iron combined boiler for operation with a fan burner (diesel / gas / fuel oil) Protherm Bison 70 NL - Proterm Bison 70 NL | RUB 89,494.09 | Add to Cart |

Views

Protherm gas boilers are available in different design and model options and can be divided into several groups that have certain characteristics.

For example, according to the type of installation, boilers are:

- Wall (hinged).

- Outdoor.

By the number of contours:

- Single-circuit (produce only heating of the coolant for the heating system).

- Double-circuit (provide the room with hot water in parallel with the preparation of the heat carrier).

In addition, they differ in the way they are heated.:

- Convection. Heat transfer takes place only in a heat exchanger heated by the flame of a gas burner.

- Condensing. Preheating is carried out in a condensation chamber, where the precipitation of water vapor from the extracted smoke and exhaust gases is carried out.

By type of combustion chamber:

- Atmospheric or open. Combustion and smoke extraction are carried out by natural draft.

- Turbocharged or closed. For the process to proceed correctly, a fan is used to supply air to the burner and ensure that the smoke is removed.

NOTE!

Such an abundance of options creates an extremely rich assortment, allowing you to choose the right sample for any conditions and needs.

Floor series

The most popular option is "Bear". The heater itself and the heat exchanger are made of cast iron.A chimney draft monitoring system has been installed. If the thrust is lost, the burner goes out. All models have two circuits. There is an electric ignition and a smooth power control. You can connect a fan - to forcibly remove the combustion products.

All floor-standing versions of Protherm have an open hearth. There are "Bears" marked:

- PLO - piezo ignition. Two stage burner.

- KLZ - similar to the previous one, but with a 110 liter boiler.

- TLO are non-volatile. Atmospheric burner.

"Bison" and "Beaver" are also floor versions. They can operate on gas, solid and liquid fuels, therefore they have a large combustion chamber volume. All floor-standing modifications are capable of operating as part of a cascade. The cascade scheme involves the installation of boilers in a certain sequence - in order to increase the total power. It happens that one device is not enough to heat a large cottage, then a second one is added to it - with the same or less power.

Series

Protherm products are divided into series and model lines, which are united by a common name and design features.

For simplicity, the series are named after animals - for example, wall-mounted cauldrons belong to the "cat" group and consist of the following series:

- Jaguar. Basic, low-cost, convection-action two-circuit model with a power range from 11 to 24 kW.

- Lynx. Convection, later - a condensing apparatus with two circuits. Available in 11, 24 and 28 kW models.

- Panther. consists of 4 models with a capacity of 12, 25, 30 and 35 kW. There are single and double-circuit versions with atmospheric and turbocharged burners.

- Cheetah. Two models with a capacity of 12 and 23 kW. Compact and budget units with record low noise level.

- Leopard. The entire series is represented by one 24 kW dual-circuit model.

- Tiger... One of the most recent models. Combined with a built-in storage boiler. Power 12 and 24 kW.

Floor standing boilers:

- Wolf. Non-volatile single-circuit boiler that does not need to be connected to the network. one of the cheapest and most reliable models.

- Bear. A series of several lines with different design features, among which there is a piezo ignition of the burner, the presence of one or two circuits, etc. Model power from 17 to 49 kW.

- Grizzly. A series of devices with increased power from 65 to 150 kW. They are used in large residential buildings, can be installed in shops or public buildings.

- Buffalo... A series of universal floor-standing boilers capable of operating both on gas and on fuel oil or diesel fuel. can be assembled in a cascade with a high power of industrial value.

The series and model lines of Protherm boilers are constantly expanding, new devices are being developed and existing devices are being improved.

Technologies are moving forward, allowing to create more advanced models of heating equipment.

Wall series

The most popular option among apartment owners. They are economical and compact and can be installed directly in the kitchen. The Protherm wall-mounted boiler has the following features:

- Frost protection.

- The power is infinitely variable - 3,500-11,000 kW and 9,500-23,000 kW.

- The circulation pump is protected against seizure.

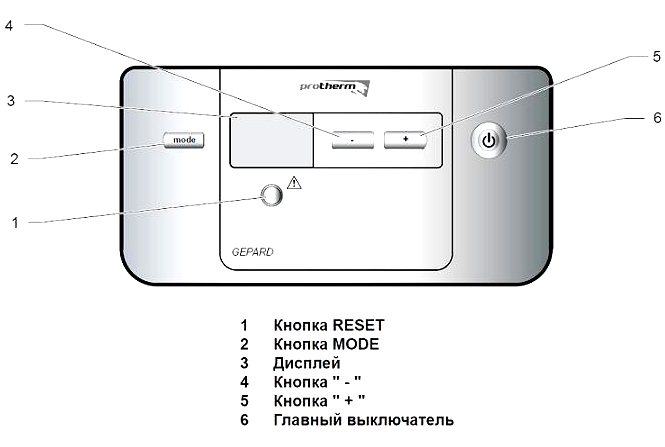

- The control unit has a display showing the current information about the work. There is a microprocessor.

- Self-diagnosis function.

- Overheating protection.

- Separate power control for heating and DHW.

- Built-in boiler for 25 liters.

- Electronic system SPIN - to monitor the temperature and rate of heating water.

Specifications

General specifications are easier to study in the form of a table:

| Options | The values |

| Boiler type | Wall-mounted or floor-mounted |

| Number of contours | One or two |

| Type of fuel | Natural or LPG |

| Efficiency | 90-93% (for condensing models 109%) |

| Power range | 12-150 kW |

| Hot water consumption in instantaneous heating mode | 12-17 l / min |

| Combustion chamber type | Open or closed |

| Average gas consumption | 2.8-3.2 m3 / h |

| Maximum pressure | 3 bar |

| Power supply | 220 V, 50 Hz |

Error codes and how to fix them

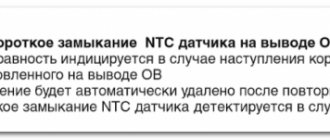

Thanks to the self-diagnosis function, modern boilers themselves determine malfunctions, and information in the form of digital or alphanumeric codes is displayed on an electronic display. Having understood what is hidden under this or that code, you can from the table posted in the installation and operating instructions.

An example of an electronic display of a Panther boiler with three digital blocks. The two lower digital displays show error codes for heating and hot water systems

The Proterm brand produces many modifications under different series, and the error codes for different models may not coincide. To clarify the meaning, be sure to study the documentation for your unit.

Consider the errors of gas boilers "Proterm", which are most common in popular models.

Models "Jaguar 11" and "Jaguar 24"

The main problems faced by users relate to either sensor breakdowns, or changes in performance indicators to critical ones. Consider the errors of the Proterm Jaguar gas boiler, represented by two popular models with a capacity of 11 kW and 24 kW.

For example, when the coolant overheats to + 98 ° C, the boiler stops its operation, and an error is displayed on the display F01.

Functioning often improves when the temperature returns to acceptable operating parameters. To resume activity, you need to restart the boiler by pressing the "reset" or "start" button

Ignition often does not take place, and when trying to ignite the flame again, an error appears F04... There can be two reasons: breakage of the ionization electrode or interruption of gas supply.

The easiest way is to check if the gas cock is open. If everything is fine with the fuel supply, the point is in the ionization system, which not everyone can repair on their own. The manufacturer recommends contacting the service center.

A blocked chimney of a gas boiler is signaled by a code F05... If the air supply is restored, the unit will continue to operate. The same error indicates changes in voltage: if it falls below 165 V, the boiler stops working until the operating parameters stabilize.

Codes F02, F03, F09 notify about malfunction of various sensors.

If, when the hot water sensor breaks down, the device is still working, then the failure of the remaining sensors will stop its functioning.

Replacing elements requires skill and experience - and if you do not have them, we recommend contacting a service center.

An error appears quite often on the display F10associated with pressure. One of the reasons is the breakdown of the pressure sensor, the replacement of which is better to entrust to gas workers with whom a contract for service and gas supply has been concluded. But if the matter is in changing the pressure parameters, the situation can be corrected independently.

The working pressure range is 1-2 bar. If the value falls below 0.3 bar or rises above 2.7 bar, the unit stops. To return it to work, you need to return the operating parameters.

How it's done:

- find the make-up valve in the lower part of the boiler, near the contour pipes;

- turn it counterclockwise until the pressure returns to normal;

- close the valve by turning it clockwise - when not closed, the pressure will continue to rise.

It is better to aim for the 1.5 bar indicator - the positive results of the actions will immediately be reflected on the display. If you overdo it and raise the pressure to 2.5 bar, the boiler will stop working again. During make-up, you must not block the branch pipes to which the DHW and heating pipes are connected.

Floor-standing boiler "Bear"

Most of the malfunctions of the "Bear" gas boiler are eliminated in two ways:

- automatically, after elimination of the cause (for example, F.10 - short circuit of the temperature sensor in the water supply circuit, F.73 - short circuit on the body or disconnection of the hydraulic pressure switch, etc.);

- by pressing the fault clearing button located on the control panel (for example, F.20 - signal from the temperature limiter, F.28 - lack of ignition at the 1st start, etc.).

Some breakdowns or malfunctions can be adjusted / repaired manually without contacting the representatives of the gas supply and service company.

If the boiler refuses to turn on and work, does not heat the water, there are many reasons for this "behavior".

Perhaps the gas tap is simply closed or the power supply is turned off - then it is enough to turn the handle of the tap or resume the power supply, and then repeat the ignition procedure

Sometimes the boiler “protests” due to incorrect temperature settings - it is necessary to adjust the flow temperature, as well as the hot water temperature. If there is not enough pressure, you need to add water, and if there are air locks, release air from the radiators.

The situation changes if one of the functions remains in effect and the other fails. For example, the unit heats water in the DHW circuit, but refuses to heat the house. Most likely, the program settings have gone astray and the boiler "thinks" that the room is already warm enough. It is necessary to adjust the calculated temperature value in the house, and the heating circuit will start.

If, on the contrary, the heating is normal and cold water flows from the hot water tap, it is necessary to increase the temperature of the hot water.

One of the most alarming signals is water under or near the unit. This indicates a violation of the tightness. Most likely, you cannot cope on your own, and specialists will be required to solve the problem

If the boiler turns off unexpectedly and the display shows the code F.20, the manufacturer recommends unlocking the high limit safety cut-out.

Procedure:

- Wait for the unit to cool down.

- Using the device diagram, remove the front casing from the body.

- Find the fuse under the junction box.

- Turn and remove the cap.

- Press in the pin as deeply as possible.

- Press the fault clearing key.

- After making sure that the boiler is working, replace the front panel.

If the problem recurs regularly, it is better to contact the service.

Wall-mounted boiler "Cheetah"

Error codes and recommendations for correcting them are similar for all Proterm wall-mounted boilers, but there are slight differences, since the technical characteristics also differ.

For example, the operating pressure range is from 0.8 bar to 2 bar, therefore, only after the reading drops below 0.8 bar, the unit will generate an error. To make the device work again, you need to add water to the heating system.

How to fill the heating system:

- Open the thermostatic valves.

- Open the filling device.

- Slowly pour in water until the network pressure reaches the operating parameters.

- Remove air from radiators.

- Close the filling device.

During the procedure, do not forget to monitor the changes in pressure values on the display.

The maximum threshold upon reaching which the boiler stops is 2.8 bar. If this happens, the pressure must be reduced by draining the water through the safety valve.

One of the most common mistakes is the failure of the gas pressure regulating valve (error F.28-29), so we will analyze how to fix the Proterm gas valve on our own.

Disconnect the inlet gas supply and power supply. Then remove the front metal panel, find the gas valve for repair and carefully unscrew it.

The gas valve is a complex part, consisting of several small parts - some of them can be removed for cleaning or replacement

If the valve is simply clogged with poor quality fuel, you need to disassemble it and wipe all the elements, being careful. If the blockage is due to wear and tear of parts, the valve must be replaced. Most often, plastic elements break, which can be simply changed.

The reason may also be hidden not in the valve itself, but in the power supply system - you need to check all the contacts and make sure that the power supply is stable.

To correct the errors of the Proterm Gepard gas boiler, you need to refer to the technical documentation, which contains the manufacturer's advice. If the sensors of the gas boiler and other elements fail, they must be replaced.

If you are unable to replace the temperature sensors, electronic board, fittings on your own, it is better to contact the service center. While the unit is under warranty, you also cannot repair yourself.

Advantages and disadvantages

It is customary to refer to the advantages of Protherm gas boilers:

- High quality workmanship and assembly of all units and parts.

- A wide range of design and assembly options.

- Many modifications are available, optimally suited to work in difficult conditions.

- Environmental friendliness, safety of equipment.

- A self-diagnostic system is used that monitors the condition of all units of the unit.

- Economical consumption of gas and electricity. Non-volatile models available.

There are some disadvantages:

- Dependence on the presence and correct connection to the power supply network, sensitivity to surges or voltage surges.

- High cost of spare parts, difficulties with supply in some regions.

- Low level of professionalism among the technical staff of service organizations.

IMPORTANT!

Complaints about the lack of training of service personnel should not be understood as a flaw in the design of Protherm boilers, since the problem is of an organizational and administrative nature.

Features and Benefits

Proterm's products are modern technology that fully meets European quality and safety requirements. The developers are constantly improving and expanding the range, introducing advanced technologies and using the best technical solutions.

Wall-mounted gas boilers Protherm and floor-standing units are characterized by high build quality, ease of use, and reliability. Products of a well-known Slovak brand are more affordable in terms of financial investments in comparison with boilers from leading world manufacturers, while they are not inferior to them in terms of operational properties.

The main features of Proterm gas boilers include

:

- wide model range, which includes boiler units of standard design, convection and condensing heat generators;

- high efficiency, which is achieved through careful design and use of high quality components;

- unpretentious maintenance;

- adaptation to Russian conditions - the units function effectively even with reduced pressure in the gas pipeline and water supply system.

The manufacturer offers gas-fired heating boilers designed for installation in residential buildings, in utility and industrial buildings, in administrative and commercial buildings.

There are several lines of Protherm gas boilers on the Russian market: double-circuit and single-circuit units are called any of the animals.

Wall execution

Wall-mounted gas boilers Proterm are easy to install, take up a minimum of space, and have a stylish laconic design. The design of the unit includes all the necessary elements for the connection and safe operation of heating equipment as part of an autonomous system.

Proterm Panther series. Includes single-circuit and double-circuit boiler units, with atmospheric or closed combustion chamber. Models are available from 12 to 35 kW. The heating heat exchanger is made of copper. The double-circuit units have a plate heat exchanger (the material of manufacture is stainless steel), which ensures rapid heating of water for local hot water supply. The productivity reaches 16.8 l / min. Due to the use of composite materials, the durability of the valve body is increased.The safety system has been improved, thanks to the use of the eBus communication bus, thermostats and wireless heating control systems can be connected to the boiler, which increases the convenience of using the unit.

In the video - a review of the Protherm Pantera gas boiler:

Proterm Gepard series. It includes double-circuit heat generators, the power of which ranges from 12 to 23 kW. Protherm Cheetah 23 MOV, 12 MOV are atmospheric combustion units that are connected to a standard chimney. Heat generators Protherm Cheetah 23 MTV, 12 MTV have a closed combustion chamber, a coaxial chimney is used to remove combustion products and supply air to the burner. Heating water for hot water supply is carried out by a stainless steel plate heat exchanger, the unit capacity is 11 l / min. The Proterm Cheetah boiler in new modifications is equipped with a display with increased backlight brightness. The valve body is made of modern composite material, due to the use of a new development, the SIT pneumatic gas valve, the noise level during the operation of the boiler is reduced.

Proterm Jaguar series. It includes the Jaguar 24 JTV, a dual-circuit model, with a capacity of 24 kW. The combustion chamber is closed, the heat exchanger for rapid heating of hot water is plate, made of stainless steel. The hot water is heated at a rate of 10.7 l / min. The compact double-circuit gas unit is designed for houses with apartment heating. Jaguar 24 is designed for operation in Russia and is able to operate stably at reduced pressure in the gas pipeline and / or water supply system.

Proterm Lynx series. These are condensation-type units, the combustion chamber is closed. The wall-mounted gas boiler of this series is a single-circuit model with a power of 25 kW or 30 kW, or a double-circuit model with a power of 18 kW or 25 kW. The double-circuit gas boiler is equipped with a system for independent regulation of the temperature of the liquid in the heating and hot water circuits. Due to the technology of heat extraction from flue gases, condensing units are characterized by increased efficiency and more economical use of fuel.

Wall-mounted gas-powered units are not inferior in functionality to electric models, while being much cheaper to operate. If the house is not supplied with gas, or there are regular interruptions in the supply of the main gas, it is recommended to use the Protherm Skat electric boiler as the main or additional source of heat, a single-circuit model with a capacity of 21 kW is popular.

Floor version

Floor standing gas boilers Protherm will provide heating of a house or buildings for other purposes. For hot water preparation, you can choose a model with a built-in boiler or connect a separate indirect heating boiler to a single-circuit unit. A wide range of models makes it possible to purchase a Protherm floor-standing gas boiler of suitable power and functionality, including finding a heat generator for a non-volatile autonomous heating system.

Protherm Bear KLOM is a floor-standing gas-fired cast iron boiler, which includes a modulating burner and an electric ignition system. Units of this series are single-circuit and require installation in a specially designated room with a chimney. The power of the heat generator depends on the modification: model Proterm 20 KLOM - 17 kW, Protherm Medved 30 KLOM - 26 kW, Protherm Medved 40 KLOM - 35 kW, Protherm 50 KLOM - 44 kW. The advantages of the series include the durability of the boilers due to the use of gray cast iron as a material for the heat exchanger.

Protherm Medved TLO is a series of single-circuit boilers with an open combustion chamber and a gray cast iron heat exchanger. The features of the series include piezo ignition, due to which the gas floor unit is electrically independent. There are 4 modifications of equipment in accordance with the power: 20 TLO - 18 kW, 30 TLO - 27 kW, 40 TLO - 35 kW, 50 TLO - 44.5 kW.

Floor-standing unit Protherm Bear TLO

Protherm Medved KLZ - boiler units with a gray cast iron heat exchanger and an atmospheric combustion chamber. An electric ignition system is provided. Floor standing gas boilers of the Protherm brand of this series are distinguished by a built-in boiler with a capacity of 90 liters. Floor-standing double-circuit units differ in power: 50 KLZ - 44.5 kW, 40 KLZ - 35 kW, 30 KLZ - 26 kW, 20 KLZ - 17 kW. Heat generators of this series are equipped with control automation and eBus communication bus for connecting temperature sensors and a remote control system. It is possible to work with a Thermolink P thermostat.

Proterm Medved PLO is a variant of Protherm heating boilers, the heat exchanger of which is made of durable gray cast iron. These are single-circuit units with an atmospheric combustion chamber, designed for installation in any type of premises, including residential ones. The burner is ignited by a piezoelectric element. The manufacturer offers 5 modifications of boiler units of various capacities: 20 PLO - 17 kW, 30 PLO - 26 kW, 40 PLO - 35 kW, 50 PLO - 44 kW; 60 PLO - 49 kW. Two-stage power regulation, anti-freeze and autodiagnostics systems are provided. The units are economical and have an efficiency of over 90%.

Protherm Grizzly KLO are single-circuit floor-standing Protherm units with an atmospheric combustion chamber and a cast iron heat exchanger, equipped with an electric ignition system. They work on main gas. According to the power, the KLO Grizzly models differ at 65/85/99/130/150 kW. The units are equipped with an automated control system, it is possible to program the boiler, which allows you to regulate the operation of the equipment and maintain a comfortable temperature level without constant monitoring. Grizzly boilers are suitable for cascade installation (up to 16 units per system). The advantages include a reduced noise level, a return heat carrier separator, thanks to which the heating circuit works as efficiently as possible.

Floor-standing unit Protherm Bear KLO

Proterm Volk KSO - a series of steel boiler units for non-volatile heating systems with natural movement of the heat carrier. A piezoelectric element is provided to ignite the burner. The lineup includes two modifications: Protherm Wolf 12 KSO - 12 kW and Wolf 16 KSO - 16 kW. The units have a one-stage power control and are characterized by high reliability due to their simple design.

Device

Gas boilers consist of the following components:

- Gas burner combined with a primary heat exchanger.

- Circulation pump.

- Three-way valve.

- Gas valve.

- Secondary heat exchanger.

- Turbocharger fan.

- Electronic control board with output of settings to the external panel.

- Self-diagnosis sensor system, closed to the control board.

The operation of the boiler is based on the circulation of the heating medium with heating in the primary heat exchanger. The temperature setting is carried out in the three-way valve by partial mixing with the cooled return flow.

Hot water is prepared in a secondary heat exchanger from the heat of the freshly heated extract air. Combustion is maintained naturally or by a turbo fan.

All processes are constantly monitored by sensors that signal problems that have arisen.

Common mistakes and decryption

The Protherm Cheetah boiler is equipped with a reliable electronic self-diagnosis system that displays an error code on the operating panel in case of violation of the technological modes of operation of the equipment.

Common errors of the Proterm Cheetah boiler:

- F00 / F01 - the primary temperature sensors on the supply and return of the coolant are faulty, the gas valve is blocked, the Cheetah gas boiler does not work.

- F10 / F11 - short circuit in the system of temperature sensors at the supply and return of the coolant.

- F13 - DHW temperature sensor is faulty.

- F20 - overheating in the heating circuit. There is no circulation, the circulation pump is faulty.

- F22 - lack of coolant in the system.

- F23 - a high temperature difference in the supply and return of the coolant in the heating network, it will be necessary to adjust the gas boiler and check the temperature sensor.

- F24 - leakage in the heating circuit.

- F25 there is no vacuum in the furnace, the chimney is clogged, a draft sensor must be installed.

- F26 - there is no voltage in the stepper motor valve system, boiler adjustment is required.

- F27 - failure in the flame control system in the combustion chamber, a check of the control unit will be required.

- F28 - there is no flame on the burner during the boiler firing up.

What kind of premises is it suitable for?

The vast majority of Protherm devices are designed to work in private homes or similar premises (public, office, retail).

It is possible to select the most successful modification, providing only heating of the heating system, or also performing DHW preparation.

When choosing the best option, one should be guided by functional indicators, as well as monitor the correspondence of the power and area of the room.

Major malfunctions

All possible malfunctions are immediately detected by the sensor system and displayed as an alphanumeric code.

Aggregate errors

arise for various reasons, among which are:

- Open or short circuit of a sensor.

- Lack of flame.

- Lack of water.

- Stopping the smoke output.

- Failure of the circulation pump.

- Fan stop, etc.

Most errors cause immediate shutdown of the boiler for safety reasons. Situations are possible when there is no one in the house, there is no one to respond promptly to the appearance of signals.

NOTE!

Therefore, the security system produces an emergency lock, which is reset by the owner upon restart. A complete list of error codes is available in the user manual.

It is a rather lengthy list, and there is no point in listing it entirely.

Electric boilers Protherm - Proterm

| Name | Price | |

| Electric boiler with pump, safety group and expansion tank Protherm Skat 12K - Proterm Skat 12K | RUB 41,625.17 | Add to Shopping Cart |

| Electric boiler with pump, safety group and expansion tank Protherm Skat 14K - Proterm Skat 14K | RUB 43,377.80 | Add to Shopping Cart |

| Electric boiler with pump, safety group and expansion tank Protherm Skat 18K - Proterm Skat 18K | RUB 46,116.32 | Add to Shopping Cart |

| Electric boiler with pump, safety group and expansion tank Protherm Skat 21K - Proterm Skat 21K | RUB 47,321.25 | Add to Shopping Cart |

| Electric boiler with pump, safety group and expansion tank Protherm Skat 24K - Proterm Skat 24K | RUB 48,416.66 | Add to Shopping Cart |

| Electric boiler with pump, safety group and expansion tank Protherm Skat 9K - Proterm Skat 9K | RUB 41,077.47 | Add to Shopping Cart |

| Electric boiler with pump, safety group and expansion tank Protherm Skat 28K - Proterm Skat 28K | RUB 49,512.02 | Add to Shopping Cart |

| Electric boiler with pump, safety group and expansion tank Protherm Skat 6K - Proterm Skat 6K | RUB 39,982.08 | Add to Shopping Cart |

| Please note that in addition to traditional methods of payment for goods, our store provides the possibility of online payment through the service for accepting payments RoboKassa, which allows you to pay: by credit card, through Internet banking, electronic wallet, through payment terminals, in various other ways, including cellular operators. |

Owner reviews

We find out what the owners themselves, who are not interested in promoting or creating anti-advertising for boilers, say about Protherm gas units:

No recall found! Please insert a valid revocation ID

Complaints about the poor organization of service are heard from everywhere, from the first days of the start of deliveries. Protherm should have been worrying about the state of the repair service for a long time, since the demand and popularity of boilers depends on it.... So far, reviews on the quality of the technicians' work are extremely negative.

Testimonials

- Andrey G.“I have built a house, winter is on the way, we need to heat it with something. I wandered on the Internet, read reviews, and decided to buy a boiler from the Slovak company Proterm. I chose the wall option based on the area of the house. The boiler with the beautiful name Cheetah Model 23 MTV came up best. What can I say? It is very simple to operate with three buttons. The instruction is very intelligible and explains everything in detail. It makes a little noise, but does not interfere with falling asleep. Very compact. Maintenance is very simple - it is enough to occasionally clean the dirt filter and wipe the dust from the boiler. It performs its functions without problems. I did not notice any shortcomings. I recommend".

- Vasily V. “I decided to change my old gas water heater. And since in extreme frosts the heat from the stove is often not enough, I decided to install a modern gas boiler with the ability to heat water. The choice was determined only by price. I took an inexpensive Jaguar 11 JTV from Proterm. The boiler turned out to be surprisingly quiet, with a beautiful design. For 2 years I have never broken. There are no shortcomings. "

- Vladimir U. “I have been working for 11 years in a service center for the maintenance of heating boilers, including gas boilers. During this time, I had to install and repair all types of boilers of all firms that are sold in our stores. I can't say anything bad about Proterm gas boilers. With proper installation and proper setup, they work like a clock. But if the service specialists have neither the skills nor the experience, or the owners have adjusted something on their own, then problems in their work are inevitable and, as a result, bad reviews. "

Price range

The cost of Protherm gas boilers depends on the power and design features. Since the company offers a very wide assortment with a wide choice of design, configuration and capabilities of units, the price range is very wide.

Wall-mounted models cost about 36-45 thousand rubles, floor installations have a much wider range - from 20 to 100 thousand rubles. for models for private houses, and from 100 to 650 thousand for more powerful production units.

The offer is very extensive and allows you to find the best option for yourself.

Solid fuel boilers Protherm - Proterm

| Name | Price | |

| Solid fuel cast iron automatic heating boiler Protherm Beaver 20 DLO - Proterm Bober 20 DLO | RUB 62,766.36 | Add to Shopping Cart |

| Solid fuel cast iron automatic heating boiler Protherm Beaver 30 DLO - Proterm Bober 30 DLO | RUB 72,734.51 | Add to Shopping Cart |

| Solid fuel cast iron automatic heating boiler Protherm Beaver 40 DLO - Proterm Bober 40 DLO | RUB 80,292.75 | Add to Shopping Cart |

| Solid fuel cast iron automatic heating boiler Protherm Beaver 50 DLO - Proterm Bober 50 DLO | RUB 95,409.29 | Add to Shopping Cart |

| Solid fuel cast iron automatic heating boiler Protherm Beaver 60 DLO - Proterm Bober 60 DLO | RUB 105,377.40 | Add to Shopping Cart |