Characteristics of solid fuel devices

Steel and cast iron boilers for solid fuels differ in that:

- easy to install, they can be assembled by hand, since this usually does not require the use of welding equipment and complex pipe connections;

- have a long service life - a well-made unit is able to serve without breakdowns for at least ten years;

- for the installation of solid fuel boilers with a cast-iron heat exchanger, no permits are required, the only condition is a good chimney design;

- they have a long burning period, although this characteristic is not available for all devices, but many manufacturers strive for this;

- have economical fuel consumption - this quality is the main reason why solid fuel cast iron heating boilers have gained wide popularity;

- efficiently distribute heat - it does not go into the chimney, but enters the room through special valves;

- quickly heat up the premises, especially for heat generators;

- in units of long burning, the duration of work on one tab of firewood reaches 10 - 12 hours;

- they have autonomous functioning, since the devices, as a rule, are non-volatile.

In order for cast-iron solid fuel heating boilers to function for a long time, when buying them, you need to pay attention to the service conditions offered by the manufacturing company, what guarantees it provides for its products.

The fact is that on the market for heating units, you can buy a fake - a device made by a handicraft method. Often, such steel and cast iron solid fuel boilers are of good quality, but they do not have service and warranty obligations. Buyers of such units in the event of a breakdown cannot make claims to anyone.

What to look for when choosing

When choosing a specific boiler model, cost is often the main criterion, but this is not an entirely correct approach, because reliability, ease of maintenance and a number of other parameters must also be taken into account.

From a technical point of view, you need to pay attention to the following features:

- whether there is a lining in the combustion chamber - the lining protects the walls from high temperatures. If it is not there, then the fuel consumption increases;

- insulation layer - it is desirable that the boiler is factory-insulated, this will help to minimize heat loss as much as possible;

- then you need to decide what the heating system should be. If you need to achieve maximum autonomy, then it is not recommended to use a smoke exhauster, pressurization, but if there are no problems with the supply of electricity, then pressurized boilers are a good choice. Due to this, traction will be good even in bad weather.

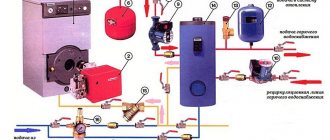

There are some subtleties when piping the boiler, especially if the installation is done by hand. It is necessary to ensure that the cooled coolant entering the boiler is not too cold - otherwise the heat exchanger may crack at the most inopportune moment.

To avoid this, a simple 3-way valve (with thermocouple) is added to the heating circuit. Thanks to him, before the cold coolant enters the boiler, hot water will be added from the supply pipe.

Connection example for 3-way valve

When choosing, you need to take into account one more point - in comparison with domestic manufacturers, imported counterparts sometimes have a much thinner wall of the heat exchanger.This is due to the more developed casting technology, so that the acceptable temperature difference will be different for each boiler.

Variety of types of boilers

In special shopping centers for heating equipment, in addition to steel and cast iron boilers for solid fuels, they sell units operating on waste oil, gasoline, diesel fuel, etc. A wide variety of these products allows you to choose exactly the device that can provide a comfortable stay in the house.

Solid fuel boilers are distinguished:

- coal-fired products;

- devices for which pellets are used;

- long burning ovens;

- heat generators.

Direct fired boilers

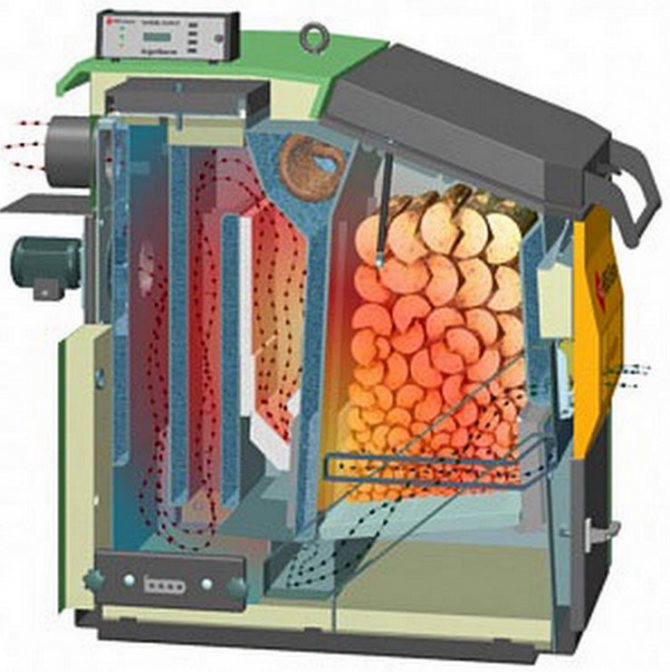

The simplest solid fuel heating boiler device has classic models. They consist of a combustion chamber, ash pan, heat exchanger and chimney. The transfer of thermal energy to water occurs due to the combustion of fuel in the furnace.

Direct combustion boiler design

The advantage of such models is reliability and simplicity of design. For the independent manufacture of a solid fuel heating boiler of this type, a minimum of tools and materials will be needed.

But along with the positive qualities, these boilers have a number of disadvantages. The main one is high fuel consumption. In reviews of direct combustion solid fuel heating boilers, they indicate the need for the constant addition of firewood or coal. If this is not done, the temperature of the water in the pipes will inevitably decrease.

It should also be noted such features of heating a private house with solid fuel using boilers of this type:

- Large indicator of inertia... The time for heating water in pipes to the required temperature can be from 10 to 30 minutes, depending on the type of system and its characteristics;

- Power regulation problems... As in solid fuel air heating stoves, this can only be done by restricting the air flow through the ash pan. Therefore, when designing a heat supply system, it is necessary to provide for the installation of safety devices;

- Low efficiency rate... Usually it is around 60-65%. This is due to the fact that some of the thermal energy leaves with carbon monoxide through the chimney;

- Equipment... The composition of steel and cast iron boilers for solid fuel heating does not include a circulation pump, a safety group.

It is also worth noting the absence of a second circuit for hot water supply. Alternatively, you can consider the possibility of connecting a tank of direct or indirect heating, if this is provided for by the design. In this case, when calculating a solid fuel heating boiler, the installation of additional equipment should be taken into account.

In most cases, in the device of a solid fuel heating boiler, the operating time on one batch of firewood or coal is from 4 to 6 hours. The higher the combustion intensity, the shorter the time for one cycle.

Coal fired boilers

The peculiarity of the production of these devices lies in the fact that for their manufacture they use a super-strong metal, for the welding of the elements of which a special technology is used. This design allows you to burn fuel in the combustion chamber without breaking its tightness.

Boilers of this type can operate not only on coal, they can also use pellets, sawdust, etc. Their disadvantage is that a cast iron solid fuel boiler of this model is expensive.

Properties of solid fuel boilers

It is worth highlighting, first of all, such features of boilers of this type:

- ease of installation - the device can be installed with your own hands, because in most cases no welding or complex pipe connections are required;

- durability... A well-made boiler will last at least 10 years without problems and repairs;

Advice: in order for everything to be really good, be sure to pay attention to what conditions of service the manufacturer offers, what guarantees he gives. Because now every now and then there are handicraft firms that make solid-fuel cast-iron boilers - and I must admit that very often they turn out to be good, but only zero maintenance. If a boiler breakdown occurs, then, in such a situation, the buyer is most often left alone with the problem.

- installation of the boiler does not require any special permits and conditions... Unless, of course, the chimney must be good;

Chimney diagram for standard solid fuel boilers

- long burning time... Not all devices of this type have this quality, however, it is precisely this property that almost all manufacturers strive for;

- efficient heat distribution... In this case, everything is really up to par - the heat does not go into the chimney, as is the case with potbelly stoves, but passes into the room through special valves;

- fast heating of the room... Heat generators cope with this task especially successfully;

- economical fuel consumption... But this quality is one of the main reasons why cast iron heating boilers for solid fuels have become so popular. In some boilers, roughly speaking, just buckets of firewood, the continuous combustion process can last at least 10-12 hours;

- autonomy of work... There are some peculiarities here, which we will talk about below, but in general this is really true - such devices are in most cases non-volatile.

Now let's look at what is the difference between solid fuel boilers and the features of each model.

Pellet boilers

They have an interesting design solution and are able to effectively heat the premises. The device of such a unit is simple: a special funnel for fuel granules is attached to its frame. At a certain time, small quantities of pellets are fed into the combustion chamber.

When purchasing such equipment, one should take into account the degree of its volatility. When it is connected with the operation of the funnel, that is, with the supply of pellets, this is acceptable, since when the power supply is cut off, the fuel can be filled up manually. But if the operation of the boiler requires the functioning of electronic automation, then you need to think about the feasibility of purchasing it.

Long burning ovens

Basically, such devices are standard stand-alone steel or cast iron solid fuel heating boilers. They are able to work using various wood materials (firewood, sawdust, brushwood), as well as fruit seeds, etc.

As a rule, they do not function from coal or pellets due to the fact that the technology of manufacturing the combustion chamber does not allow burning this type of fuel. Experts recommend that you carefully study the features of the selected model before buying a long-burning cast-iron solid fuel boiler.

Usually, such units are purchased for the following purposes:

- for heat supply of suburban households and summer cottages;

- for heating utility rooms;

- for installation and operation in greenhouses and hotbeds;

- for heating industrial buildings;

- for farm buildings.

If you have to heat large buildings with several rooms, then it is better to purchase a modified version of a long-burning unit, namely a heat generator. Of course, it costs much more, but this price fully justifies itself.

Solid fuel heating boiler for long burning

This closed-type furnace uses the principle of slow-burning fuel.There are various options for such devices - for example, a solid fuel boiler for long burning on wood or other type of fuel, working on the principle of upper combustion. This is a grate, the operation of which is automatically controlled and does not require constant attention from the equipment owners. A large volume of fuel is immediately loaded into it, which is enough for about 12 hours of continuous operation. If firewood is used for heating, then they try to lay them as compactly as possible, if chips, shavings or dry leaves of trees are burned, then they are tamped. A press is installed inside the furnace, which, slowly descending, maintains a high density of fuel loading. As a result, combustion takes a long time and takes place only in the upper layer, to which air is supplied. There is a gap between the weight of the press and the walls of the device for smoke extraction. The heat exchanger is located in the upper part of the casing and heats up not only due to the thermal energy released during combustion, but also takes heat from the flue gases coming out. The outlet for the chimney of these devices is at the top.

A variation of this design is a solid fuel heating boiler with bottom combustion. It works in almost the same way, with the only difference that the press in the furnace presses on the part of the fuel that does not burn. Combustion air is supplied to the bottom of the fuel box. The location of the smoldering zone does not affect the power of the device: both variants of such boilers belong to the category of the most powerful heating devices. There are also no other differences affecting the consumer properties of the equipment between these modifications. Devices with a lower smoldering zone differ only in that the price for such solid fuel boilers for heating a private house will be slightly higher. The reason for this is that in models with top combustion, the smoldering zone moves along the entire body, alternately heating the entire surface of the furnace walls. For appliances with bottom combustion, it occurs in the same place in the combustion chamber, which is therefore subject to a higher risk of burnout due to prolonged exposure to high temperatures. To avoid this and extend the service life of the device, manufacturers install thick-walled furnaces made of metal sheets with a thickness of 4 mm or more in units with lower combustion (for devices with upper combustion, sheets with a thickness of 3 mm are used). This is what affects the cost of devices.

Heat generators

These are convection-type ovens to which an electric fan called a "snail" is connected. There are special openings on the surface of this equipment for connecting flexible pipes.

Heat generators function in a certain way: fuel is loaded into the combustion chamber, ignited and then a fan is turned on, which injects air into it. Thanks to this, the firewood burns better, and the heated air, moving along the sleeves, is faster at the target. Flexible pipes come in different lengths, and their ends can be bred into rooms.

Benefits of heat generators:

- duration of continuous burning on one filling is about 8 hours;

- economical fuel consumption;

- devices can be used to heat any premises;

- units are capable of heating very large areas;

- it is possible to increase the power if necessary, for which a section is added to the boiler structure.

The disadvantages of heat generators are as follows:

- the need to install flexible pipes to move warm air;

- in the absence of electricity, the fan, the air blower cannot work, which affects the distribution of heated air in separate "hoses".

Features of cast iron boilers

It should be noted that almost every cast iron solid fuel boiler can operate on wood and coke.It costs more than a steel product, but its characteristics justify the price. The fact is that their production takes much longer than assembling a device from steel.

A cast iron solid fuel heating boiler is more durable than a steel one, it is able to withstand higher temperatures. Cast iron cools down much more slowly, which saves fuel.

In addition, for cast iron appliances:

- there is a significant advantage - this is durability, since their service life reaches 25 years;

- they take up less space than steel units;

- cast iron is more resistant to corrosion processes than steel.

This heating equipment has disadvantages:

- A solid fuel boiler with a cast iron heat exchanger is sensitive to mechanical stress in the form of shocks. The cast iron body can crack under a certain load. For this reason, it should be handled with care.

- In the event of a sharp temperature drop, the cast iron can crack, therefore, experts do not recommend cooling such boilers with cold water or loading cold fuel into a heated combustion chamber.

- It takes a long time to heat up a case made of this material.

To even better understand the difference between a cast iron heating boiler and a steel one, you should familiarize yourself in more detail with the properties of solid fuel steel units:

- the impact resistance of devices is especially important during transportation, even if they fall or overturn, then with a probability of 99% it can be argued that the body will remain intact, and the tightness of the combustion chamber will not suffer;

- even large temperature drops are not dangerous for steel boilers;

- products are relatively lightweight;

- if one of the elements breaks off in the heating equipment, it can be welded without problems.

Among the negative points, it should be noted the susceptibility to corrosive processes, as well as the inability to increase power.

Double-circuit cast iron boilers

Sectional devices are subdivided into single and double-circuit. The first of them work only for heat supply. Heating equipment such as a solid fuel double-circuit cast-iron boiler is capable of providing both housing heating and hot water supply. The long-burning double-circuit solid fuel boiler has a built-in broiler, which can be located under the outer casing.

Such a structural device of a solid fuel cast iron boiler involves the installation of a pump to ensure water circulation. Double-circuit devices differ from other models in large sizes.

Summarizing

Despite a number of disadvantages, such as high inertia, somewhat higher cost and weight, cast iron boilers remain popular. Not least of all, this is facilitated by the high durability and resistance of the metal to corrosion.

The proposed material will allow you to get acquainted with the main features of heating solid fuel boilers made of cast iron and decide whether such a device is suitable for your heating system.

The video shows the strengths and weaknesses of cast iron and steel solid fuel boilers.

Did you like the article? Subscribe to our channel Yandex.Zen