What to look for when choosing a boiler

To make the right choice of a heating boiler for a private house, it is worth considering several fundamental points.

First of all, it is worth paying attention to the types of fuel available in a particular region. Both the cost of fuel and the possibility of its unimpeded purchase if necessary will matter.

The next important point is the availability of automation, that is, the ability to work without operator intervention. This condition becomes especially relevant if there is no one in the house during the day, and the equipment must work continuously.

When choosing a heating boiler, you need to take into account how simple and convenient this or that option is in operation, as well as what kind of maintenance it requires. If you do not want to regularly clean the boiler, then it is better to opt for an automated product, although it will cost significantly more.

It should be noted that all solid fuel boilers need periodic cleaning of burners and combustion chambers. Gas and electrical appliances require much less maintenance.

Gas boiler options

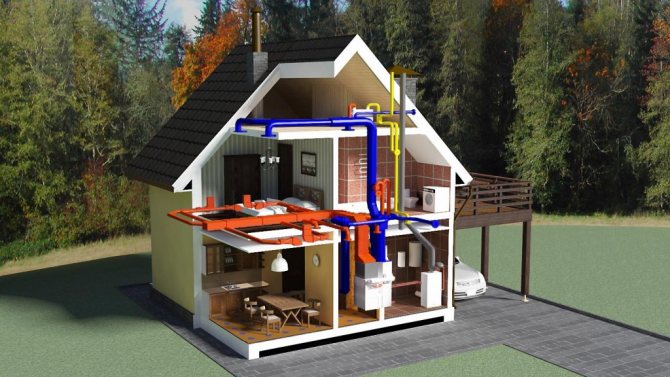

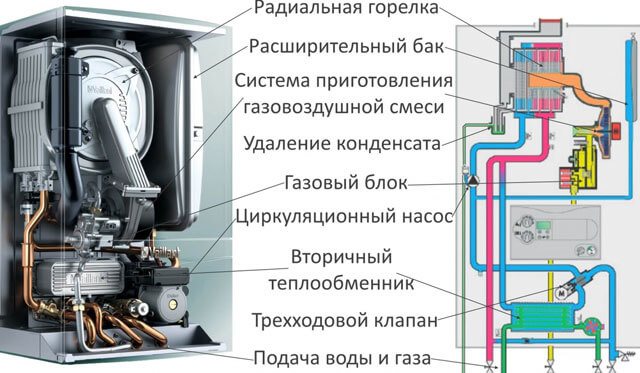

All gas heaters differ primarily in the type of installation - they can be floor-standing or wall-mounted. Wall-mounted boilers are designed for a maximum power of 60 kW, but floor-standing appliances are produced with a capacity of 100 kW or more. Some boiler models are designed to work in a cascade. It should be noted that one of the advantages of wall-mounted boilers is their compactness - they are easy to fit into the kitchen interior.

If you plan to install a floor-standing boiler with a capacity of more than 60 kW, you will have to allocate a separate room for it. It can be placed both in the house itself, and be attached to it and have a separate entrance.

It is far from always possible to connect directly to the main gas pipeline, however, this is not a reason to refuse to install a gas boiler. In this case, you can choose a gas boiler according to the parameters of your home, equipping it with a special burner for working with liquefied gas. How economically profitable such a solution will be can be determined only after preliminary calculations. To do this, you need to calculate how much 1 kW of heat will cost if you use several alternative fuels available.

Varieties of burners

There are two main types of burners - open (or atmospheric) and closed (turbocharged). Atmospheric burners require a chimney with good draft, and turbo burners are connected to a coaxial chimney that passes through the wall near the boiler.

When choosing a gas boiler by parameters, you should pay attention to the combustion chambers for different burners. They differ in the way they draw in air. The open-type burner draws in air directly from the combustion room, and therefore it is necessary to install powerful supply ventilation. But for turbocharged burners, the fuel chamber is supplied with one of the pipes of the coaxial chimney. In this case, there are no strict requirements for ventilation.

It is worth noting that one of the disadvantages of boilers with a turbocharged burner is the sensitivity of the chimney to atmospheric manifestations - frost or heavy snowfall. In this case, the boiler simply will not turn on.

Another fundamental point is that it is advisable to select a gas boiler according to the parameters of the burner, that is, how many modes it is designed for.

There are three options:

- Single stage... Such a boiler has only two modes of operation - on at full power and off. This is the cheapest type of burner that consumes too much gas. This type of boilers cannot be called energy efficient.

- Two-stage... The burner can be set to work at 50% and 100% power. The third mode is a complete shutdown. This is a more economical option for boilers that allow you to maintain the temperature in the room to some extent.

- Modulated... The most effective, but also expensive option. Smooth regulation of the power level allows the boiler to turn on both 10% and 100%.

Of course, when making a selection of a heating boiler according to the type of burner, it is most reasonable to stop at a modulated version. Excessive purchase costs will quickly pay off during operation.

Classification and characteristics of gas boilers for heating an area of 120 sq m

An affordable and inexpensive type of fuel makes a 12 kW device an indispensable assistant for heating rooms in the area under consideration.

By the type of installation, devices are:

- floor-standing;

- wall (hinged).

By the design of the combustion chamber, there are 2 types of devices:

- Open. Has a high degree of reliability and ease of use. The disadvantage is the intake of fresh air from the room.

- Closed. It has good insulation of the working area and does not pollute the atmosphere in the room, it is economical on fuel. Disadvantage: May shutdown at the most inopportune moment due to network problems.

There are 2 options for the type of fuel used:

- natural gas (central highway);

- liquefied (balloon filling).

Many models have a factory switch from one fuel to another. Some boilers are equipped with a self-installation nozzle.

According to the type of burner, designs differ:

- atmospheric;

- modulated;

- injection;

- turbocyclone, etc.

Purposes of using the gas unit:

- heating the room;

- hot water supply.

These goals can be achieved in a complex manner (using a double-circuit boiler design).

Main technical characteristics of 12 kW gas units:

- high efficiency (efficiency) - 90-96%;

- pressure in the gas supply line - no more than 13 mbar;

- coolant temperature in the heating circuit - from +30 to +90 ° С.

- control system - mechanical (manual) or electronic;

- gas consumption - 1.2-1.6 cubic meters m per hour.

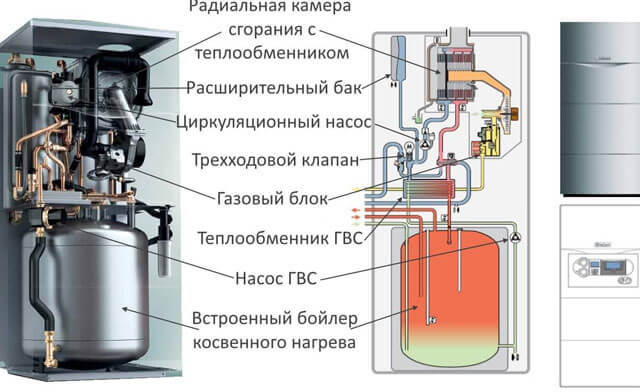

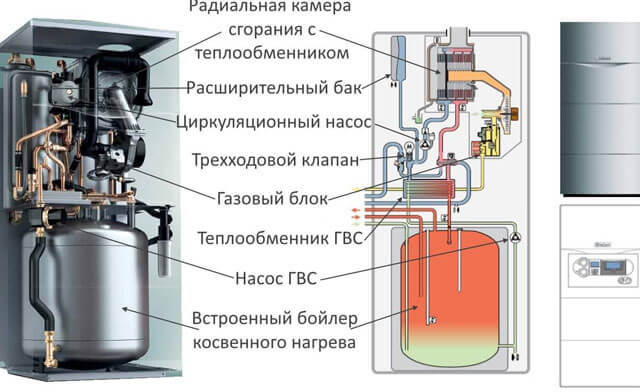

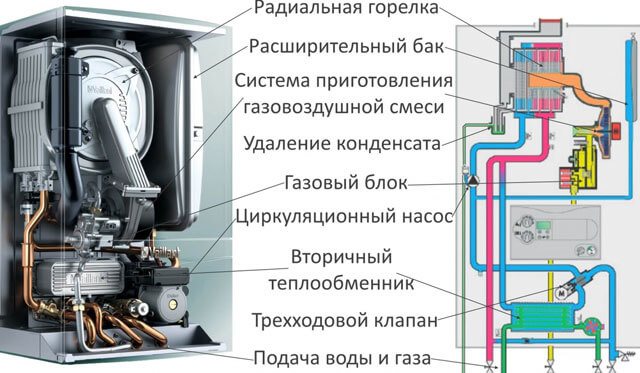

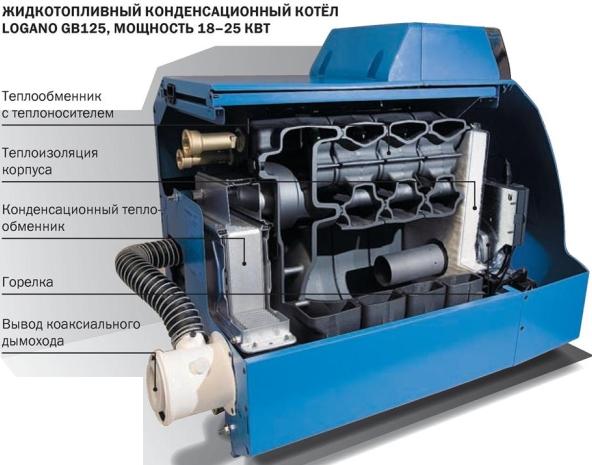

Condensing gas boilers

The gas boilers described above refer to high-temperature devices, the temperature of the coolant at the outlet of which is 45-50 ℃ and even more. They are ideal for installing radiators.

A feature of condensing boilers is that they can effectively operate with temperatures not exceeding 40 ℃ in the return pipe. In this case, an economical consumption of gas is achieved, since heat is transferred to the coolant due to the condensation of hot steam contained in the flue gases.

This type of boiler is ideal for heating a house with a warm water floor. As a rule, at the outlet of the boiler, the temperature of the coolant is 35 ℃, and in the return circuit - about 30 ℃. This type of operation makes the boiler economical and energy efficient.

Note that condensing boilers also have some disadvantages. First of all, it is a very corrosive condensate. In this regard, a very high quality stainless steel chimney is required. In addition, if you make a selection of the boiler according to the power parameters, then the price of condensing devices will be much higher than that of similar devices of the traditional type. The higher cost is due to a rather complex scheme of work, as well as the use of high-quality, condensate-resistant materials.

Cooking kettle square (rectangular) with steam heating

Application area. Main products. The square cooker is generally used in the food industry. The steam cooker is widely used in meat processing plants, canneries, fruit and vegetable industry, catering establishments, restaurants, canteens, etc. Appointment. Steam-jacketed rectangular cooking kettles are used for thermal processing of various food products, for example, cooking meat, fish, mushrooms, blanching vegetables and fruits, etc. Operating principle. The principle of operation of a steam digester is based on heating and cooking the loaded product to a predetermined temperature due to the thermal energy of steam. In this case, the preparation time of the product is determined by the technologist. In some cases, the digesters are equipped with an agitator. Basic design. A rectangular or square steam-heated cooker is a food grade stainless steel container with a lid. The container has an insulating layer. Depending on the specific purpose of the boiler, it can be equipped with additional devices, for example, a basket for cooking meat, fish, vegetables or a mixing device with a geared motor, etc. The space between the layers of a steam digester is called a jacket, and is filled with a heat carrier, which is water or food glycerin, heated by the thermal energy of steam. There are two options for the manufacture of a rectangular digester with steam heating. The first option is to use strips, the second option is to use a coil. The steam digester is supplied with a heating control system based on a temperature controller. Optional equipment. At the request of the customer, a cooker with a steam jacket can be equipped with additional equipment that significantly speeds up the operation of the installation, as well as facilitates the work of the operator:

- fully automatic control system of the digester operation cycle made on the basis of PLC (programmable logic controller);

- cover lifter (where appropriate). In this case, an automatic blocking system is used, which prevents the lift from going beyond the extreme limits of movement;

- sound and light warning systems;

- timer. Determines the cooking time of the product;

- frequency converters of rotation of electric motors (stirring device, etc.). They are used for smooth (from 0 to max) regulation of the speed of rotation of electric motors, as well as their protection, when the electric parameters go beyond the permissible values;

- coolant circulation pump. Significantly accelerates the process of heating the coolant;

- washing heads;

- immersion baskets for cooking products, etc.;

- mixing devices, cutters of various types. The stirring device allows the product to be heated more evenly, accelerates the heating process of the product. Cutters are used to grind raw material components (for example, fruit pieces);

- as well as other devices and systems required by the customer.

Rectangular or square cookers with steam heating are manufactured in any size and configuration.

Varieties of electric boilers

When selecting the power of the heating boiler by the area of the house, it is worth understanding the main types of such devices:

- Heating elements... This is the traditional and most common type of electric boilers. Multistage units are considered more economical, since they are capable of operating in several modes. Among the disadvantages can be called low efficiency due to heat loss for heating the heating elements. But the advantages include low prices for consumables (heating elements) and easy-to-perform repairs.

- Induction... In such equipment, the heating agent is heated at the moment the water passes through the inductive coil. It is believed that induction boilers are more economical in comparison with heating elements, they have no heat loss and practically no inertia. In addition, such boilers are very compact - they look like a piece of pipe from 35 cm to 1 m long. Among the disadvantages is the need for constant circulation of the coolant, otherwise, the boilers overheat and burn out quickly.

- Electrode... Many buyers, when they want to choose a boiler according to the parameters, stop at this type of equipment less often. Although they are considered the most economical, in most cases consumers are stopped by the need to circulate electrolyte through the pipes as a heat carrier, that is, water with certain additives. This requirement is due to the fact that heating of the coolant occurs due to the passage of current between the electrodes. When operating boilers of this type, it is necessary to monitor the condition of the electrodes and electrolyte. In addition, the entire installation works under voltage - this also frightens consumers a little.

Thus, if you do not know how to choose a boiler by the area of the house and which option to stay on, then pay attention to induction and heating elements.

What should be guided by?

Currently, the heating equipment market is filled with both imported and domestic models. And among a wide variety, it is sometimes very difficult to choose a suitable model, especially if the future owners of the boiler do not have certain special knowledge. How and where to buy a heating boiler - we will deal with this issue.

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of one or another fuel. In this context, we will highlight several types of boilers.

Gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive, it is available for a wide range of consumers. What are the types of gas heating boilers? They differ from each other depending on which type of burner is atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products go through a special pipe using a fan. Of course, the second version will be a little more expensive, but it is he who will not require smoke extraction.

Wall hung gas boiler

As for the method of placing boilers, the choice of a heating boiler assumes the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to supply hot water, then you can supply modern wall-mounted heating boilers. So you will not need to install a boiler to heat water, and this is financial savings. Also, in the case of wall-mounted models, you can discharge the combustion products directly into the street. And the small size of such devices will allow them to perfectly fit into the interior.

The disadvantage of wall-mounted models is their dependence on electrical energy.

Also, these models have a weak heat exchanger. Comparison of heating boilers shows that the performance of such models will be inferior to floor-standing ones. But floor-standing efficient heating boilers only if there is a chimney with a draft.

Electric boilers

Next, consider electric heating boilers. If in your area there is no gas passing through the mainline, an electric boiler can save you. These types of heating boilers are small in size, so they can be used in small houses, as well as in cottages from 100 square meters. All combustion products will be environmentally friendly. And the installation of such a boiler does not require special skills.It should be noted that electric boilers are not very common. After all, fuel is expensive, and its prices are rising and growing. If you are asking which boilers for heating are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as spare heating devices.

Calculation of the power of the heating boiler

Electric boiler

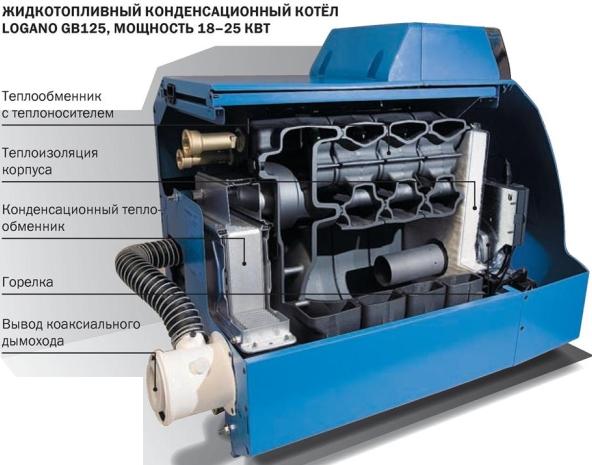

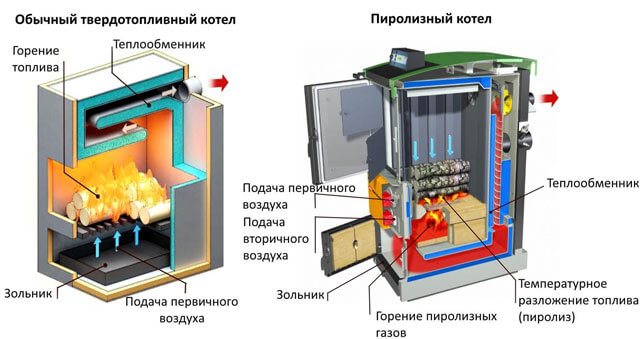

Solid fuel boilers

Now it's time to consider what solid fuel heating boilers are. Such boilers are considered the most ancient; such a system has been used for heating premises for a long time. And the reason for this is simple - fuel for such devices is available, in its quality can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not capable of operating in stand-alone mode.

Gas generating solid fuel boiler

Modification of such boilers is gas generating devices. Such a boiler differs in that the combustion process can be controlled, and the productivity is regulated within 30-100 percent. When you think about how to choose a heating boiler, you should know that the fuel used by such boilers is firewood, their moisture content should not be less than 30%. Gas-fired boilers are dependent on the supply of electrical energy. But they also have advantages over solid fuel. They have a high efficiency, which is twice as high as solid fuel devices. And from the point of view of environmental pollution, they are environmentally friendly, since the combustion products will not enter the chimney, but will serve to generate gas.

The rating of heating boilers shows that single-circuit gas-fired boilers cannot be used to heat water. And if we consider automation, then it is great. You can often find programmers on such devices - they regulate the temperature of the heat carrier and give signals if there is an emergency danger.

Gas-fired boilers in a private house are an expensive pleasure. After all, the cost of a heating boiler is high.

Oil-fired boilers

Now let's consider boilers for liquid fuel. Such devices use diesel fuel as a working resource. For the operation of such boilers, additional components will be needed - tanks for fuel and a room specifically for the boiler. If you are thinking which boiler to choose for heating, then we note that oil boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable from an economic point of view.

In addition to diesel fuel, oil boilers can also use gas. For this, replaceable burners or special burners that can operate on two types of fuel are used.

Oil-fired boiler

Solid fuel boilers

Often, during the selection of a heating boiler by area, consumers stop at solid fuel equipment. Although it has a number of disadvantages, it is still the most in demand.

As a rule, coal and firewood are used for kindling solid fuel boilers. The final choice depends on which raw materials are more readily available in a given region. It is worth noting that coal and wood boilers are different from each other. Wood-fired boilers have a large loading chamber that can hold a lot of firewood. Coal chambers have a smaller combustion chamber with thicker walls to withstand high combustion temperatures.

The advantages of solid fuel boilers are:

- savings on heating costs;

- the reliability and the prostate of the structure;

- the ability to work regardless of the availability of electricity.

It is worth mentioning significant disadvantages:

- Due to the cyclical operation of the boilers, the air temperature in the house is unstable, it becomes either cold or hot.To solve this problem, heat accumulators are installed, that is, containers with water that allow you to maintain an optimal microclimate constantly - during the combustion process, heat accumulates, which is then consumed to warm up the house.

- The need for service. Any solid fuel will first have to be loaded, set on fire, control the intensity of its combustion, and upon completion of the process, clean the furnace and re-ignite the boiler.

- The system cannot work offline. As it burns out, it is necessary to periodically add a new portion of fuel so that the system does not freeze.

- Since a lot of dirt is formed in the process of filling fuel and cleaning the boiler, it is advisable to install the boiler as close to the inlet as possible so as not to spread it everywhere.

In general, a solid fuel boiler in the heating system of a private house does not seem very convenient. Although the fuel for them is easy to obtain and is relatively cheap, it takes a long time to ignite, so the savings are not always justified.

Optimum boiler output for 120 sq m

According to calculations, this figure is 12 kW.

In practice, it can depend on:

- The degree of insulation of the room. If the indicator is insufficient, a heating device with a power of 10-20% more than the calculated one will be needed.

- Number of storeys of the building. For example, less energy consumption requires a more complex structure.

- The region in which the premises are located. The farther north the territory, the stronger the natural heat losses become, and the boiler power from the calculated one can be increased by 5-20%.

- Central branches. If it is located far from the supply station (transit), then the gas pressure may be below normal (about 10-11 bar). In this case, the boiler will not work at full capacity, but 10-15% lower. Therefore, for heating 120 sq. m you will need a boiler for 14-15 kW.

- The functions used. If the device is used both for heating a room and for heating water, then it is desirable to increase its power by 15-20%.

Long burning heaters

Long burning boilers have been designed to maximize combustion efficiency and load spacing.

There are two variants of such equipment.

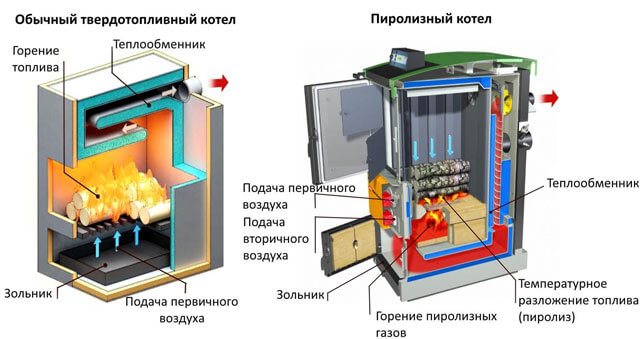

- Pyrolysis boilers... Such devices have two or even three combustion chambers. In this case, fuel combustion occurs with a lack of oxygen. As a result, a large volume of flue gases are emitted, most of them highly flammable. These gases enter the next chamber, into which air is supplied. As a result of mixing with oxygen, the combustible gases ignite again and generate even more heat than the solid fuel itself.

- Upper combustion appliances... In conventional solid fuel boilers, combustion spreads from bottom to top, that is, most of the load is burned at the same time. Due to too intense combustion, the system quickly overheats, which is not very efficient and uncomfortable for residents. If the principle of top combustion is applied, then ignition is carried out only in the upper part of the loaded fuel. At the same time, only a small part of them ignites, which significantly extends the fuel burning period. Thus, the room temperature is equalized.

The efficiency of long-burning solid fuel boilers is quite high - various wood-fired designs are capable of operating from 6-8 hours to a day on one tab, and on coal - from 10-12 hours to several days. However, such results can only be achieved with very high quality fuel materials. The main thing is that they are dry. Wet coal or firewood cannot even smolder, that is, such a boiler will not warm up. It is advisable to equip a barn for storing coal or a woodshed with a margin of 2-3 years. In this case, a long burning solid fuel boiler will be a really worthy choice.

Video description

In our video, we'll talk about heating in a private country house. Our guest is the author and presenter of the Teplo-Voda channel Vladimir Sukhorukov:

- Gas boiler

... It is used when a gas pipeline is connected to the house. In addition, this heating option is the most economical. If the house is used for intermittent residence, you can use a gas tank. But it should be borne in mind that in this case, the monetary costs will increase significantly.

- Solid fuel boiler

... For its work, firewood, coal or a briquette type of energy carrier are used. For the stable operation of such a boiler, there is no need to use a power supply. If the equipment has an electronic control circuit, while there is no electricity, power can be organized using a battery. But there is one drawback - it is required to equip a place for fuel.

Solid fuel boiler Source mybuilding.tips

- Liquid fuel boilers

... When using this heating option, it is necessary to adhere to all safety rules, since such devices are more susceptible to emergencies.

- Electric boilers

... Such devices are used both as an auxiliary element for heating water at a time when the main heating system is temporarily turned off, and as the main type of heating (if the use of gas or solid fuel equipment is unavailable).

On our website you can familiarize yourself with the most popular projects of houses with a total area of 80 - 100 sq. M from construction companies presented at the exhibition of low-rise country houses.

Liquid fuel equipment

It is worth noting that when selecting a boiler by area, liquid fuel equipment is rarely preferred.

The low popularity of such boilers is due to the following factors:

- high fuel prices;

- the need for a place for storing diesel fuel, that is, a large capacity located close to the house;

- the need to ensure heating of the tank so that diesel fuel at low temperatures does not thicken and clog the burner;

- Since the operation of the equipment is accompanied by a high level of noise and an unpleasant odor, it must be installed either in a well-ventilated annex or in a separate boiler room.

In this regard, it is advisable to install an oil-fired boiler only if you have constant access to cheap fuel.

Selection of boilers and boiler equipment

Home »Selection of boilers

Advantages of heating boilers offered on the RussKotel website.

First of all, this is the use of high quality steel. Such steel is durable and resistant to corrosion. The steel used in heating boilers makes it possible to design heating systems for many years without suspicion of replacing heating equipment.

The second is environmental safety. You can absolutely safely use our boilers in apartments, houses and other residential premises, because there is no solvent in the heating element, which makes it possible to call heating boilers safe equipment. The scientific institute has given the highest degree of safety for our boilers, because when the fuel is burned, a small amount of NOX is emitted.

The initial task facing the consumer is the choice of a heating boiler. Nowadays, heating costs make up a significant part of the costs associated with the operation of a country house, summer house, cottage or bath. When choosing the optimal type of fuel and, accordingly, the heating system, self-sufficiency must also be taken into account, if possible.

As we wrote earlier, according to the type of fuel used, boilers are: liquid fuel, solid fuel, gas, and also combined.

Let's start with solid fuel - it is always cheaper, if you do not take into account the costs of your own labor, room pollution and the non-standard installation of the heating system.Coal is out of competition when time is not important. Coke is more convenient than ordinary coal for continuous burning furnaces.

Liquid fuels - oil and petroleum products - are more expensive fuels. But one of the disadvantages of liquid fuel is the need to have a storage facility that can accommodate all the amount of fuel required for the winter. If you place the fuel tank in the basement, then the latter cannot be used for other purposes. The tank can also be placed in the yard by burying it in the ground.

Naturally, gas is always more convenient than any other fuel. Well, firstly, it is affordable, secondly, it does not need any storage tanks, and thirdly, there is no need for additional costs for its own labor. The only BUT is the lack of gas supply to your settlement or your street. If there is a natural gas network in the area, then of course it is more advisable to use gas heating. If in the near future it is planned to gasify your area, then it is necessary to install a combined heating boiler, which can temporarily operate on liquid fuel, and then switch to gas without major reconstruction.

In turn, boilers are: conventional condensing and pulsating condensing boilers. Principle condensing boiler based on the use of heat, which gives off water vapor during condensation. This heat, due to the special design of the boiler, is also used to heat the coolant. Due to this, the efficiency of condensing boilers is 30-40% higher than that of conventional boilers. A pulsating condensing boiler differs from conventional condensing boilers in that heat is produced by micro-firing (115 per second). The air-gas mixture enters directly into the combustion chamber and produces micro-combustion, i.e. the principle is similar to the work of an internal combustion engine.

Our experts recommend buying regular condensing boilers, in addition, they are well suited for underfloor heating systems, during which the temperature of the water in the system can be below 60 degrees, therefore, with an underfloor heating system, the condensing boiler can be used all year round.

When choosing an economical type of fuel, one cannot rely solely on installation costs; long-term costs must also be taken into account. Our specialist will help you with this question. Our engineers with many years of experience will quickly determine where in the system (if it is already installed) the deficiencies, how to correct the position of the pipes and advise what needs to be done to avoid excessive fuel costs. Thus, you will, above all, reduce your costs during the heating season.

Also, when choosing a heating boiler, it is of great importance in which room you are going to install it - a new building or an already built house. In the case of a new building, the optimal variant of the heating system will be taken into account already in the finishing project. Distribution pipes will be placed in specially left holes, while when installing a heating system in a long-built house, due to the difficulty of knocking out masonry, pipes sometimes have to be led on the surface of the walls. Another important factor is the area of the heated room, the larger it is, the more power your heating boiler should have.

If we are talking about a summer house, a country house, or another room in which there is no need for constant heating, then you need to install a heating boiler that would quickly heat the room. To do this, it is necessary to use a high-calorie fuel (oil or gas) with forced circulation in the heat distribution network, in which the natural circulation of water is enhanced by a special pump installed at the heating boiler. In addition, forced circulation allows the installation of pipes with a smaller cross-section, and with the right choice of an electric pump, electricity costs will be small.Universal boilers allow the use of combined heating and the transition from one type of fuel to another. In the spring and autumn periods of the year, you can heat with liquid fuel, and in winter with solid fuel. The disadvantage of combined boilers is high fuel consumption.

Also, in the absence of main gas, the best option for heating your house, summer cottage or cottage is an electric heating boiler. Such boilers are also used as a backup heating option in case of problems with the main boiler. There are clear advantages over gas and oil boilers. First of all, the low cost of an electric boiler, secondly, the possibility of installation in any room without special permits and approvals, thirdly, small dimensions with a fairly high power and quiet operation, as well as ease of installation of an electric heating boiler and there is no need to additionally install chimneys.

Perhaps the biggest disadvantage of an electric boiler is the operating costs associated with the high cost of electricity. And also the obligatory presence of a separate reliable electrical wiring. For heating large rooms, electric boilers are generally not cost-effective.

So, the key aspects in choosing a heating boiler are:

- Reliability

- Operating cost

- Room area

By contacting you will receive maximum assistance in choosing and purchasing the required heating boiler. Our qualified engineers will select the right boiler and your home will always be warm and cozy.

Home pellet boilers

Due to the design features of pellet boilers, they belong to a separate class. Sawdust compressed into granules serves as fuel for such devices. As a rule, a special shed or bunker near the boiler is taken away for storage of pellets. The period of independent operation of the equipment depends on the size of such a bunker. Usually about two buckets of pellets are required per day of work.

A special burner is installed in the pellet boiler, which allows you to burn the fuel almost completely. If the granules are of high quality, then as a result of combustion, about 3-5% of ash is formed. Therefore, cleaning the firebox is required only once a week or even several weeks. Thanks to the automation of the equipment, it can work autonomously for several weeks.

Among the disadvantages of modern pellet boilers are the high price and sensitivity to fuel quality. Pellets must be strong, not crumble or break, have low ash content and good calorific value.

In general, when choosing a boiler for the area of the house, a pellet appliance can be a good option if there is enough fuel for it.

Combined devices

Before choosing the boiler power for your home, you should pay attention to one more type of boilers - combined ones. This refers to devices that can work with several fuel options. Most often, consumers purchase solid fuel boilers with built-in heating elements. At the moment of burning coal or firewood, the system warms up in the same way as when using a conventional solid fuel boiler. When the fuel burns out and the boiler starts to cool down, electric heating elements are switched on to maintain the temperature in the house. By themselves, they are not able to fully heat the house, but they can maintain the temperature and prevent the system from freezing.

Combined boilers with oil burners are in fairly high demand. Such devices are equipped with two separate combustion chambers - for solid fuel and for liquid.

Despite all the advantages of such devices, they also have disadvantages. First of all, it is a high price. In addition, the efficiency of each of the boiler sections is average.Thus, it is difficult to unequivocally assess the feasibility of this type of boiler.

PELLET BOILER PRICE OVERVIEW

| Configurator | Boiler selection table |

When choosing a boiler, first of all, it is necessary to calculate the energy demand of the heating object. The parameters of the heating system are calculated according to the heat losses of the room, which depend on the size of the room, the thermal conductivity of the outer walls, internal partitions and ceilings, the difference between the external and internal air temperatures, therefore, the final determination of the boiler power should be trusted only by professional heating engineers. But it is possible to preliminarily determine the power of the boiler, and, accordingly, the cost of equipment and its other parameters. Roughly, you can use the following ratio - 1.2 kW of boiler power is required to heat approximately 10 m2 of a well-insulated room with a ceiling height of up to 3 m.

The defining parameters to rely on when calculating power are:

- area of the heated room (S);

- specific power of the boiler per 10m? premises, which is set taking into account the corrections for the climatic conditions of the region (W beats).

There are generally accepted values of the specific power for climatic zones:

- for the Moscow region - W beats. = 1.2 - 1.5 kW;

- for the Northern regions - W beats. = 1.5 - 2.0 kW;

- for the southern regions - W beats. = 0.7 - 0.9 kW.

The calculation of the boiler power (W cat) is carried out according to the formula: W cat. = S W beats. / ten

Often, for the convenience of calculations, an average value of W beats is used, equal to one. Based on this, it is customary to choose the boiler power at the rate of 10 kW per 100m 2 of the heated room.

Example: 1. The area of the heated room S = 100 m2; 2. Specific power (W beats) for the Moscow region = 1.2 kW; W cat. = 100 1.2 / 10 = 12 kW;

The table shows the approximate power of the boilers depending on the area of the serviced house (for the Moscow region).

| House area, m2 | Boiler power, kW |

| 60 — 200 | up to 25 |

| 200 — 300 | 25 — 35 |

| 300 — 600 | 35 — 60 |

| 600 — 1200 | 60 — 100 |

The type of water heating will depend on the area of the house. The system with natural circulation (due to low inertia) can be used for buildings no more than 100m2. For a larger area, forced circulation of the coolant will be required, which can be ensured by connecting circulation pumps to the system. They are usually installed in the return line from the heaters to the boiler in order to extend the life of the parts by eliminating constant contact with very hot water.

In addition, it is advisable to take into account that if, in addition to heating, you also want to receive hot water with the help of the boiler, then the required power can increase by another 20-50%. Since hot water is not prepared constantly, but periodically, the system is usually built with the priority of hot water supply. In this case, when there is a demand for hot water, all the boiler's power goes to its preparation, and the heating stops working. Usually (taking into account the short-term use of hot water), the temperature in the house during this time does not have time to drop significantly. In the overwhelming majority of modern residential buildings (cottages), three main circuits act as a load for boiler equipment:

- Radiator heating circuit;

- Underfloor heating contour;

- DHW circuit (domestic hot water preparation system).

|

We select a heating boiler

Given the wide variety of heating devices on the market, many consumers do not know how to choose the power of the heating boiler and which of the varieties to choose.

Here are the basic requirements for such devices:

- Saving money... The best fuels are wood, coal and natural gas. The next step in terms of cost is pellets, liquid fuel and electricity. Nevertheless, it is worth considering the specific situation in each of the regions and the availability of a particular type of fuel.

- Autonomy... Gas, pellet and electric boilers can work without operator intervention. Such devices do not need constant supervision. Some control is needed over oil boilers. But solid fuel ones are distinguished by a minimum level of automation.

- Easy to connect... The most problematic is the process of registration and connection of a gas boiler to the main pipeline. In the presence of an electric boiler, a powerful line for heating should be allocated at the substation, if they have a reserve. All other equipment is connected much easier, but with the observance of safety measures.

Thus, taking into account these factors, it will be much easier for you to decide on the type and power of the boiler for your private house.

Calculation of the power of the heating boiler by area

For a rough estimate of the required performance of the heating unit, the area of the premises is sufficient. In the simplest version for central Russia, it is believed that 1 kW of power can heat 10 m2 of area. If you have a house with an area of 160m2, the power of the boiler for heating it is 16kW.

These calculations are approximate, because neither the height of the ceilings nor the climate are taken into account. For this, there are empirically derived coefficients, with the help of which the appropriate adjustments are made.

The specified rate - 1kW per 10m2 is suitable for ceilings 2.5-2.7m. If you have higher ceilings in the room, you need to calculate the coefficients and recalculate. To do this, divide the height of your premises by the standard 2.7m and get a correction factor.

Calculating the power of a heating boiler by area is the easiest way

For example, the ceiling height is 3.2m. We consider the coefficient: 3.2m / 2.7m = 1.18, round off, we get 1.2. It turns out that to heat a room of 160m2 with a ceiling height of 3.2m, a heating boiler with a capacity of 16kW * 1.2 = 19.2kW is required. They are usually rounded up, so that 20kW.

To take into account climatic features, there are ready-made coefficients. For Russia, they are:

- 1.5-2.0 for the northern regions;

- 1.2-1.5 for the Moscow region;

- 1.0-1.2 for the middle band;

- 0.7-0.9 for the southern regions.

If the house is located in the middle lane, just south of Moscow, apply a coefficient of 1.2 (20kW * 1.2 = 24kW), if in the south of Russia in the Krasnodar Territory, for example, a coefficient of 0.8, that is, less power is required (20kW * 0 , 8 = 16kW).

Calculation of heating and selection of a boiler is an important stage. Find the wrong power and you can get this result ...

These are the main factors to consider. But the found values are valid if the boiler will only work for heating. If you also need to heat the water, you need to add 20-25% of the calculated figure. Then you need to add a "margin" for peak winter temperatures. That's another 10%. Total we get:

- For home heating and hot water supply in the middle zone 24kW + 20% = 28.8kW. Then the cold reserve is 28.8 kW + 10% = 31.68 kW. We round up and get 32kW. Compared with the original figure of 16kW, the difference is twofold.

- House in the Krasnodar Territory. We add power for heating hot water: 16 kW + 20% = 19.2 kW. Now the "reserve" for cold weather is 19.2 + 10% = 21.12 kW. Round off: 22kW. The difference is not so striking, but also quite decent.

The examples show that at least these values must be taken into account. But it is obvious that in calculating the power of the boiler for a house and an apartment, there should be a difference. You can go the same way and use coefficients for each factor. But there is an easier way that allows you to make corrections in one go.

When calculating a heating boiler for a house, a coefficient of 1.5 is applied. It takes into account the presence of heat loss through the roof, floor, foundation. It is valid with an average (normal) degree of wall insulation - masonry in two bricks or building materials similar in characteristics.

For apartments, different factors apply. If there is a heated room (another apartment) on top, the coefficient is 0.7, if the heated attic is 0.9, if the unheated attic is 1.0.It is necessary to multiply the boiler power found by the method described above by one of these coefficients and get a fairly reliable value.

To demonstrate the course of calculations, we will calculate the power of a gas heating boiler for an apartment of 65m2 with ceilings of 3m, which is located in central Russia.

- Determine the required power by area: 65m2 / 10m2 = 6.5kW.

- We make an amendment for the region: 6.5kW * 1.2 = 7.8kW.

- The boiler will heat the water, therefore we add 25% (we love it hot) 7.8kW * 1.25 = 9.75kW.

- Add 10% for cold weather: 7.95kW * 1.1 = 10.725kW.

Now we round the result and get: 11 kW.

The specified algorithm is valid for the selection of heating boilers for any type of fuel. The calculation of the power of an electric heating boiler will be no different from the calculation of a solid fuel, gas or liquid fuel boiler. The main thing is the productivity and efficiency of the boiler, and the heat loss does not change from the type of boiler. The whole question is how to spend less energy. And this is the area of insulation.