Design features of industrial furnaces

The main element of the furnace is a functioning pressure chamber, isolated from the environment. Outwardly, it looks like a huge oven. The processed raw materials or products are placed in this chamber, and then the device is turned on using certain technological parameters.

Additional equally important elements of electric furnaces are:

- Construction and engineering structures (casing, frame, foundation).

- A heat sink that safely cools recycled products.

- Automated control system of those. processes.

- Electricity and fuel supply devices.

- Chambers for utilization of combustion products and surplus heat energy.

- Conveying system.

- Devices loading raw materials and removing combustion products.

Furnace manufacturers continue to improve devices to this day in order to increase their productivity, durability and reduce the cost of those. maintenance, cost of the structure and its repair.

Counterflow ovens

The most perfect form - the efficiency can reach 90%. Such an impressive figure is possible due to the original design, in which the chamber with an open fire is separated from the chimney by a wall. As a result, smoke is removed through the lower part of the stove, and the room heats up evenly.

It seems that this is impossible - hot air always rises up! This is true. But the device has a special hood in which the smoke accumulates and cools. Cold gas particles move downward and are removed through the chimney, and heated air enters their place. This is how high efficiency is achieved.

Vimana oven

Such furnaces for heating have a number of advantages:

- the ability to build devices of any size and shape;

- a water heater, oven or steam generator can be installed in the hood;

- there is the prospect of automating the process.

Vimana stoves, retrofitted with an air recirculation system, can even be used in apartment buildings. Their only drawback is the complexity of the design. Not every craftsman can build this variety.

Stove Grum-Grigimailo

Another counterflow design developed by the Russian inventor V.E. Grum-Grigimailo. It has a round shape, so it can be stylized as a Dutch stove (which is what enterprising Russian stove-makers have been doing for the last 150 years). Its operation is based on the principle of free movement of gases.

In the middle of the firebox there is a hailo - a hole through which gases penetrate into the upper part, over which a cap is arranged. In this section, heat transfer occurs, the cooled gas goes down, and the heated air rises.

The Grum-Gryzhimailo device perfectly accumulates heat - the temperature in the room does not drop even if the stoker forgot to close the valve. Cold air entering the furnace through the ash pan does not allow the hot streams to cool down and therefore the device gives off heat for a long time, despite the relatively thin walls.

Varieties and classification of industrial furnaces

Each manufacturer has introduced its own flavor to the design of an industrial furnace, hence the devices appeared, similar in principle of operation, but differing in certain parameters. Because of this, scientists have decided to classify electric furnaces according to mechanical, thermal, or thermotechnological parameters.

Depending on the transfer of thermal energy, industrial electric furnaces are divided into:

- Heat generators.

- Heat exchangers.

Industrial furnaces-heat generators provoke the appearance of thermal energy inside the processed raw materials. Heat appears as a result of the flow of electric current under the influence of chemical reactions through metals. Such furnaces include: resistance devices, converter, induction electric furnaces.

Heat exchanger furnaces heat the recyclable materials, thanks to the combustion of fuel or the use of electric heaters. The transfer of heat to the raw materials placed inside in such devices can be carried out by convective or radiation mode. An example of the functioning of the first is a bakery oven, and the second is an industrial infrared heater.

The functionality of electric industrial ovens is characterized by electrical impulses. These furnaces include: arc, induction and electron beam furnaces. They are divided into 2 types:

- Vertical.

- Horizontal.

The first type is extremely rare. Mainly in industrial enterprises, horizontal furnaces are used. The temperature inside them can be maintained at the same level or change, depending on the length and time of the functioning pressure chamber. Devices that change the temperature inside the chamber are called batch furnaces, and those that maintain a given level are called continuous furnaces.

Russian stove for space heating

The device familiar to us from fairy tales holds the record for the number of alterations and improvements. Eminent stove-makers and unknown self-taught craftsmen worked on its construction. We will consider the classic type and will not touch on its varieties.

Improved Russian stoves can have an efficiency of up to 80%.

The central element is the cooking chamber or crucible. In the front of the structure there is a rectangular hole - the mouth (forehead), through which firewood is laid and dishes with food are installed. The mouth and the crucible are separated from each other by a ledge-wall, which completes the vault. As a result, the hot gas is retained in the cooking chamber, then enters its front and is removed through the chimney to the outside.

Due to the design features, the Russian stove has a number of disadvantages:

- uneven heating of the room - the temperature at the ceiling can reach 25 ° C, and at the floor it tends to zero;

- low efficiency - about 70% of the generated heat "flies" into the pipe;

- massiveness - some structures could occupy up to 50% of the hut area;

- poor heat transfer - the maximum heating area does not exceed 45 m2;

- long start-up - after a summer downtime, a daily warm-up is required.

One of the advantages is its versatility - the stove is used for heating and cooking. Also, the pluses include the ability to work on any solid fuel, including straw and brushwood.

https://youtu.be/UjnSEn1HvPA

Features of electric industrial ovens

Moscow is a highly developed city. There are many enterprises here that already have industrial furnaces, but beginners also appear who need special equipment. That is why there are many specialized stores in Moscow that sell industrial electric ovens. When purchasing such equipment, it is important to understand its features and differences. This knowledge will help you choose the right device and ensure business profitability.

An electric oven is a large-sized structure powered by an electric current. It is intended for remelting ores and metals, drying them, annealing them, giving them plastic and changing their internal properties. These electric furnaces include induction, arc and resistance furnaces. The latter work due to the generation of heat in the material being processed.

Resistance furnaces

Industrial electric resistance furnaces can operate on a direct and indirect principle.In the first case, thermal energy is generated and released inside the processed material under the influence of an electric current, and in the second, due to heating elements in contact with electricity.

Resistance furnaces can be single-phase or three-phase, with power up to 3000 kW. Their functionality requires 380/220 V (50Hz) mains voltage. Devices are classified as receivers of electricity of the 2nd category (in relation to the continuity of current). In this case, the power can vary from 0.8 to 1.0.

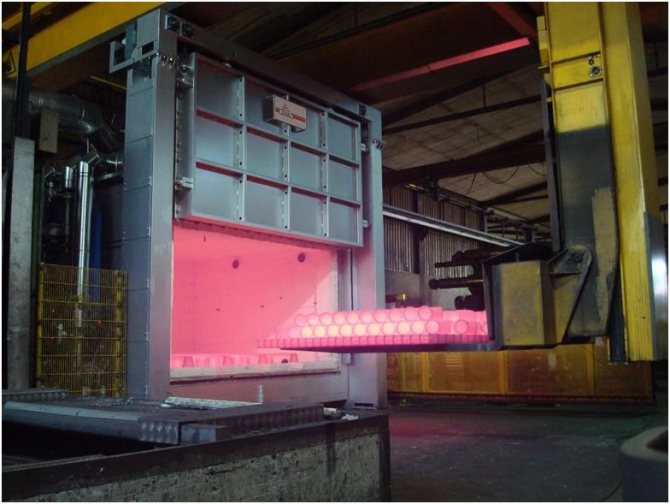

Electric arc furnace

This type of industrial furnace was named just that because of the arched thermal effect created by the device. They are well suited for the processing of non-ferrous and ferrous metals. The design feature is the melting chamber, closed by a removable roof and a casing with a fire-resistant lining. For normal operation of the device, a three-phase alternating current is required, which forms electric arcs formed by metal and 3 electrodes located inside the structure.

Industrial electric arc furnaces can also be:

- Straight. Arcs are formed and ignited through the material being processed.

- Indirect. Arcs are formed under the bottom of the device.

The required voltage for connecting electric arc furnaces to the network is 6-10 kW, through an oven transformer with a voltage of up to 100V (secondary).

Industrial induction electric furnace

Induction furnaces are most often used for melting steel, but this device can process aluminum, bronze and other metals, their alloys in a graphite crucible. The principle of operation of the device is similar to the functionality of a transformer with 2 windings. The first is a cooling inductor fluid, the second is the processed raw material, which plays the role of a load. Under the influence of an inductor electromagnetic field, induced currents appear, heating and melting metals.

The main components of an induction furnace:

- Frame.

- Inductor.

- Crucible.

The main element is an inductor made of copper pipe. It is presented as a water-cooled multiturn coil. Liquid and electricity are conducted directly to the inductor by flexible cooled cables. Power is supplied by a thermistor converter with a frequency of TFC-250 - 1.0 kHz. It converts a three-phase current (50 Hz) into a single-phase one. The power of the device can vary, depending on voltage fluctuations and automatic regulation of the melting process.

Modern Moscow stores are equipped with the latest models of industrial electric furnaces. Each of them is efficient, but the main thing is to choose the right device. In order not to be mistaken in your choice, consult a specialist. He will tell you which model is most suitable for your work.

Dutch stove for heating

The design was developed in the Netherlands, it is distinguished by a rectangular shape and a single-channel direct chimney. Until the middle of the 19th century, it was used in the homes of wealthy people, then it was supplanted by central heating systems. In the Soviet Union, such stoves were installed in country private houses, today they are used to create an original interior design.

Such devices are of little use for heating - their efficiency does not exceed 40%.

These species have a number of advantages that attract both oven-makers and residents of private houses.

- Simplicity of design - everything will work properly even if the master makes a minor mistake during construction.

- Modification availability - you can attach a hearth without reducing efficiency and special alterations.

- Different dimensions - if desired, the size of the firebox can be reduced to 50 cm2.

- Low construction cost - less material is needed for such a furnace than for a Russian or Swedish one.

- Extensibility - you can increase the length of the chimney without changing the area of the firebox.

- Rapid heating without wasting firewood.

- High heat transfer - the possibility of heating a room up to 60 m2.

If you overdo it with the amount of firewood, the chimney will not cope with excess carbon monoxide, which is dangerous for the lives of people in the room.

However, the "Dutch" is not without its drawbacks, and low efficiency is not the most significant drawback. The device is sensitive to the quality of the firewood. High ash fuel leads to increased formation of soot, which doubles the risk of fire.

If you overdo it with the amount of firewood, the chimney will not cope with excess carbon monoxide, which is dangerous for the lives of people in the room.

Under Peter I, Russian stove-makers improved the Dutch design by replacing the canal system with a bell-type one. Such heating devices work on a counter-flow principle, can have a round, triangular or multifaceted shape and be installed in any room. The Europeans liked the innovation, so pseudo-Dutch women appeared.

Required materials and tools

To lay out a wood-burning stove for a house, you must first prepare the necessary components:

- cast iron hob with burners;

- a door for the combustion chamber;

- ash pan door;

- small doors to clean chimneys;

- grate;

- wire or steel tape to secure the doors;

- reinforcing steel strips;

- metal corner for edging the top of the device;

- summer smoke passage shut-off valve;

- metal sheet (pre-furnace) to ensure fire safety;

- oven, water heating container.

Brick ovens for the home - their drawings with orders, are designed for a certain amount of red and refractory bricks. In this case, the structure is pre-laid dry in order to correctly select the required material and understand the principle of operation of the heater.

It is also recommended to prepare a basic set of tools for building a furnace with your own hands:

- varieties of hammers: pick, oven and rubber;

- a spatula made of wood for mixing the solution;

- levels: horizontal and vertical;

- trowel (trowel);

- pliers, rasp, chisel;

- containers for solution, water;

- brush out of bristles.

Main stages and important features

All the nuances of how to lay out a stove with your own hands are presented in the ordinal drawings of brick stoves for the house. You just need to correctly use the material presented.

The calculation of the efficiency of the required device helps to select the most suitable furnace drawings. At the same time, the standard for heat radiation per square meter of the device area is considered to be 0.5 kW under normal conditions, and 0.76 kW during severe frosts. It is assumed that the house is well insulated from the outside.

To heat a living space of 100 sq. meters, it is necessary to build a stove structure 2.5 m high, with a useful heating area of 17.5 sq. meters. At the same time, in normal mode, 8.5 kW of heat is released, and during intensive operation of the device - 13.3 kW. The heat transfer of cooking ovens is slightly higher due to the metal plate, oven.

What furnaces are in terms of size, power, appearance, is taken into account when choosing a suitable structure. All parts of the structure are interconnected, therefore, when calculating how to lay the furnace of the device with a stove, the following requirements must be observed:

- the installation of the firebox according to the drawing always corresponds to the standard size of the laid brick. Therefore, it is recommended to pre-fold the stove dry;

- We lay out the device for summer cottage needs with thinner walls; for constant heating, it is better to lay a thick-walled firebox or purchase a ready-made cast-iron structure.

Advantages and disadvantages

Brick types of heating stoves differ in the thickness of the walls of the heating device:

- thin-walled (Dutch) - the wall lies in 1/4 of a brick (6.5 cm). The structure quickly heats up the room, but practically does not retain heat.It is beneficial as a stove for a summer residence, where the owners do not live in winter, but come for a short period;

- thick-walled (Russian stove) - wall thickness - 12-25 cm (1/2 -1 brick). The unit is heated for a long time, and the heat is maintained for longer than a day. Lack of construction - a lot of firewood is required for the winter;

- combined structures, in which the firebox is laid out with thick walls, and the chimney is 1/4 brick.

Characteristics of brick ovens in the house

When choosing which design to give preference to, it must be borne in mind that there are the following types of ovens, depending on functionality:

- heating brick oven designed only for heating the room. The structure is small in size (stubborn - Dutch);

- cooking types of brick ovens for the house are equipped with a cast iron stove, which is adapted for cooking, heating water. The stove is not adapted to heat the dwelling (Swedish);

- combined, universal heating and cooking structures with a hob, capable of heating various areas of a country house. Modern ovens are equipped with an oven, a niche for drying fruit and vegetable products. Stoves and fireplaces are often combined.

Choosing the location of the structure

A brick stove must not only be correctly selected, but also correctly installed in the building. This takes into account what is the area of the entire structure and the room in which the stove will be located

Additionally, it is important to remember the purpose of the structure, the safety of its installation and the number of rooms that must be heated using this equipment.

https://youtu.be/nFLmrISqlHw

With the right location, uniform and high-quality heating of the entire structure can be expected, as well as complete safety of using open fire in the stove.

Thus, there are many types of stoves, which differ in different parameters, characteristics of the furnaces, sizes and other characteristics. The choice must be reasonable and competent. so that the product you receive is safe and pleasant to use, and that it is effective and durable.