In the villages, the Russian stove has long been treated with ordinary whitewash, giving it a neat look.

It is believed that the most popular styles of stove decoration are Provence and Country.

In wealthy houses, it was customary to lay out the stove with tiles.

Nowadays, the choice of building materials is so wide that it is sometimes difficult to give preference to anything. Many do not know what to do if they inherited an old stove from an old village house or bought such a stove together with the household. With such a huge number of finishing options, many are interested in the question of how to update a sauna stove or paint a fireplace correctly. And if the stove is made of bricks, how to paint it?

If the stove is built correctly, then it is able to give the room at least half of its heat. In addition, the amount of heat radiated into the room directly depends on the material with which the surface is covered. With a smooth surface of the structure, less heat is given off compared to a rough one. If you paint a brick sauna stove with oil or enamel paint, it will radiate heat much better. The darker the color, the more intense the heat will be released.

What paints to use

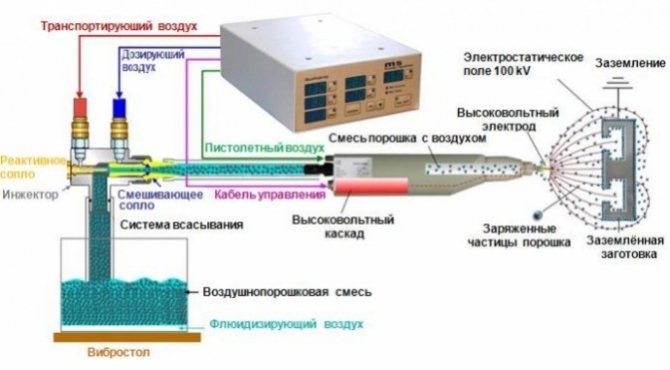

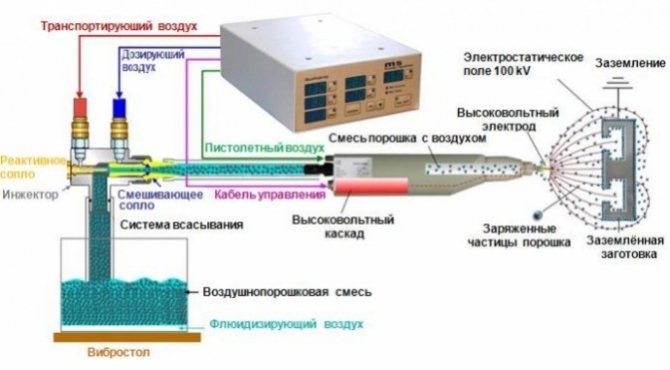

The principle of operation of the oven.

Decorative qualities are of great importance, but some peculiarities should be taken into account. For example, a shiny surface is much less capable of giving off heat. In this regard, it is better to refuse to cover the oven with glossy paints, for example, aluminum. If the stove is folded in accordance with all the rules, there is a sufficient thickness of the walls of the hearth, then the heating of the outer side can reach 80 degrees. Many synthetic compounds can withstand this temperature. These include pentaphthalic paints, nitro paints and others.

As for many oil paints, which are based on natural linseed oil, during operation they darken, especially in those points that are the hottest. There are many heat-resistant paints on the market that are ideal for painting fireplaces and stoves. The downside is that the choice of colors for such paints is quite limited. If you are not satisfied with this line of paints and the color scheme does not match the interior, try using latex paint to paint the stove. Before applying it, it is necessary to treat the surface with a rough primer.

How can you paint a fireplace?

The choice of paintwork materials for painting this attribute is an important point. When buying paint, you need to carefully study its composition and properties, since the fireplace is used in special conditions. If there is no desire or opportunity to spend money on an expensive coloring agent, you can simply whitewash the heat generator itself. Whitewashing is a budget and original way to decorate a brick fireplace.

What properties should paint have?

If the structure in question is not just an interior item, but is also used for its intended purpose, it cannot be painted with the first paint that comes to hand. The fireplace is exposed to high temperatures, therefore the paintwork must first of all be resistant to fire, otherwise the coating will quickly crack and begin to bubble.

The outer surface can be heated up to 90 ° C. Not every paint can withstand such a high temperature. If the structure is built according to all the rules, it must give the room at least half of its heat. In addition, the efficiency of the heater depends to a large extent on the type of coloring compound with which the fireplace is covered.The heat transfer of a smooth surface is worse than that of a rough one, therefore it is better to refuse the use of aluminum paint and its analogues.

Another important point is paintwork color. The darker it is, the more intense the heat transfer will be. Among other things, the coloring composition should not emit harmful substances, since fireplaces are usually found in living quarters. All these nuances must be taken into account when buying paint, otherwise the result will not meet expectations.

Suitable types of paints and varnishes, brands

The table provides information on the types of paints for painting brick fireplaces:

| Types of coloring compositions | General information | Marking options | Decoding |

| Alkyd | Designed for painting surfaces that warm up to 100 °. They have a pungent odor, allow you to create a not too strong coating, poorly withstand temperature expansion of the base. | KO-811 | The paint marked in this way is intended for coating metal elements, stone and bricks. It is resistant to sudden changes in temperature, and when heated, its coating becomes more durable. |

| Heat resistant acrylic | Penetrating deep into the pores of the material, they create a strong film on its surface. They have a wide range of colors. | KO-813 | Paints with this marking are used for painting stoves and fireplaces installed in dry or damp rooms. Due to the content of aluminum powder, they can withstand temperatures up to 500 degrees. They have antiseptic and anti-corrosion properties. |

| Organosilicon | Suitable for painting all types of heating ovens, regardless of whether they are located indoors or outdoors. They have an affordable price, high adhesive ability, strength, moisture and heat resistance, durability, elasticity. They have a small assortment of colors. | KO-8111 | Paints marked in this way are the most heat-resistant. They can withstand temperatures over 600 °. |

Information about some popular brands of paintwork materials for painting brick ovens-heat generators:

| LKM brand | Colour | Shine | Maximum temperature, degrees | Packaging |

| Elcon (varnish) | Transparent | Matte / semi-gloss | 250 | Spray can, can |

| Elcon (paint) | 250 shades | 250–1000 | Spray can, can, bucket | |

| Rust-Oleum Specialty High Heat | Transparent, black, aluminum | Matt | 1090 | Spray can |

| Motip | Transparent | 650 | ||

| Decorix | Glossy | 250 |

Modern oven design

Furnace device.

In the modern design of the fireplace and stove, designers attach great importance to color solutions. In addition, tendencies are now prevailing with a focus on the naturalization of elements and details that make up the interior. One of the most stylish elements is the fireplace, as well as the Russian stove. Rustic styles such as Provence and Country are extremely popular these days. For fans of these styles, there is an opportunity to make the Russian stove a real masterpiece, and the fireplace will perfectly complement the interior. What is required for this?

You can use clear paint and a unique element will be provided to your home. Before you start painting a brick oven in this way, you need to prepare it accordingly, that is, give it an aesthetic look. If the outer surface has dents, potholes and other defects are found, then they need to be filled with putty. To make your own putty, you need to take latex paint and add brick flour to it.

Furnace surface treatment before painting

Spray gun device diagram.

How is the surface of the stove you are going to paint to be reanimated? For this purpose, an ordinary red brick is taken and flour is rubbed out of it. Add 10 pre-whipped proteins and milk to the resulting powder.The mass that you get should have the consistency of thick sour cream. The mixture should be applied with a brush to the surface of the oven while it is still warm. The entire outer surface can be treated with a similar composition. It will have a solid red color. In addition, the superimposed layer has qualities such as abrasion and heat resistance.

The next step in the process of restoring a stove or fireplace is coating the surface with linseed oil, due to which a beautiful dark red hue is achieved. You should be aware that the surface treated in this way will be matte. If you want shine, use synthetic or oil varnishes. The presence of a shiny surface ensures painting with latex paint. This type is widely recommended by experts, since the surface has sufficient density and roughness, which provides good heat radiation.

How to make painting materials for a brick stove yourself

The price of lime and chalk is the lowest. Such materials are in abundance in any hardware store. To breed them, you only need water.

The difference between solutions from each other is as follows:

- After painting the first layer with a chalk solution, you need to wait until it dries completely.

- When painting with a lime solution, all subsequent layers are applied immediately.

To paint the stove, you need to prepare the right solution with your own hands:

- One kilogram of chalk or lime.

- Water - 1.5 liters.

Tip: After applying such a composition to the oven, the strength characteristics of the coating are not very high quality. The surface will smear the clothes and begin to crumble. To avoid this, you need to use table salt. For 2 kilograms of paint, 0.3 kilograms of salt is added. The result is excellent strength characteristics.

Instead of salt, you can use wood glue, just 0.1 liters of glue per 10 liters of paint. Such formulations may have a yellowish tint. To achieve the classic white color, add 20 milliliters of regular blue to the solution. A color additive should be used to obtain the desired color.

Advice: When using the additive, the instructions for its use must be strictly followed in order to obtain the required color.

How to make natural varnish for the oven

Our ancestors used an ordinary chicken egg to prepare varnish when painting ovens.

This will require:

- Egg whites.

- Milk.

- Brick dust remaining after adjusting and trimming bricks when laying the furnace.

After experiments, it was determined that the best composition is obtained with a 1: 1 ratio of egg whites and milk. To finish a square meter of the oven surface, you will need about 0.25 liters of milk and 8 proteins. The amount of brick dust is determined independently, it only affects the color characteristics of varnish made from natural materials.

In the manufacture of the composition:

- Flour is rubbed from red brick.

- Beaten egg whites and milk are added until a thick consistency is formed.

- The mixture is stirred.

- The oven is painted with a new brush on a preheated surface.

- The coating turns out to be an even red color. Possesses heat resistance and increased abrasion resistance.

- The stove is covered with linseed oil, after which the dark red surface becomes matte.

- To obtain a shine, a special synthetic varnish is used.

After applying such varnish to the surface of the oven and drying it, the brickwork is not very much, but it will stain. To eliminate this disadvantage, one layer of a solution made from pure egg white can be applied to the stove. The disadvantage of this coating is that it emits the aroma of baked milk in the room, when the stove is used.

How to paint the stove correctly

Tools for performing work:

- Metal trowel for surface preparation and filling.

- Brush to brush away the remnants of the former trim.

- Small special container.

- Soft brush.

After choosing how to paint the red brick stove, you can perform preparatory work.

For this:

- The surface of the stove is carefully leveled with plaster (see How to plaster a brick stove with your own hands).

- Roughly, the protruding fragments of the clay solution located between the bricks are scraped off with a special scraper.

- The surface is prepared with sanding paper to improve the adhesion of paint and bricks.

Tip: Sometimes the surface should be treated with a heat-resistant primer, which will not damage, but it should be used without corrosive additives so that they do not come out in the room at high temperatures. In the absence of a primer, the surface of the oven should be treated with water before paint is applied.

- The paint is applied in two or three thin layers, with a new brush or roller. The brush gives the surface texture, and the roller distributes the paint more evenly, which makes the surface smooth.

- If desired, patterns are mechanically applied to the dried coating layer, as in the photo.

Today, among homeowners, interiors decorated in the following styles are very popular:

- Country.

- Chalet.

- Shabby chic.

Their distinctive feature is the naturalization of various elements and decorative details. In such interiors, as well as possible, a bright and stylish addition is a Russian brick stove or fireplace. To do this, you can simply paint them with transparent paint. How to properly prepare surfaces, and then paint them, the video in this article will show.

Since ancient times, people have erected active hearths in the country or in country houses, which filled the rooms with warmth and made it possible to cook food. If such a structure is old enough and is subject to restoration, then a natural question arises of how to paint a brick oven in the house.

Here, two ideas should be repelled: either the owners pursue an aesthetic goal, or the safety item is of primary importance to them. In most cases, you can do this work yourself, the main thing is to choose the right tools and paints and varnishes.

Brickwork processing

The most spectacular fireplace colors

Equipment for powder coating of the oven.

Although the surface of the brick oven is quite dense, after drying, the latex paint retains its elasticity, thus preventing cracking. A fireplace in a private house or in the country, like a stove, is a catchy element of the interior. Therefore, painting or plastering these structures requires maximum responsibility. If high quality brick was used in the construction of the fireplace, then when painting it is much easier to emphasize the beauty of the material. According to experts, paint that imitates the color of old bricks looks great. In this case, it can be different shades of red and crimson.

If you are painting a fireplace, then silicone paints will do. Paints in aerosols are especially convenient. To liquefy silicone paints, solvent 646 or turpentine is used. Dry gouache can be added to correct the color to the desired shade. For this, liquid gouache is pre-dried and then ground into a fine, homogeneous powder. In order for the color of the fireplace to be of high quality, it is necessary to cover it in several layers. At the same time, remember that the layers should be thin and evenly applied. Otherwise, smudges and imperfections can arise that will ruin your entire work.

How to paint a fireplace correctly

Painting a fireplace includes several stages. Let's take a closer look at each of them.

Preparation of the base

We start with a close inspection of the surface.If there are areas with efflorescence on it, they must be cleaned. To do this, take a metal brush and gently clean off the resulting crust. Experts warn that it is impossible to use water in such cases, it will only aggravate the problem. After removing efflorescence, wait a few days to make sure it does not reappear. If the surface has been painted, remove all old paint with a stiff brush. Examine the surface again. Now we are interested in cracks.

We process them with a scraper and carefully remove the crumbling material. After that, we prepare a solution similar to that used when performing the masonry, and putty the cracks with it. Now you can start jointing. We carry it out with a chisel and a hammer, removing the damaged solution with them. In the course of work, a damaged brick may be found, it needs to be replaced. After the jointing is completed, carefully sweep away the dust and moisten the coating with water. This is necessary so that after applying the solution, the surface does not "pull" moisture from it. The joint is restored while it is still wet. After the completion of the joining work, the fireplace must be left for two to three days until it is completely dry.

The stabilizing solution is applied to the surface with a brush

Now we apply the stabilizing solution. These can be different in the composition of the mixture. If an oil based solution is used, you should wear safety goggles before applying as this is a rather messy job. Using a brush, cover the entire surface with the composition abundantly: both the seams and the bricks. We give the composition time to fully absorb. We heat the fireplace so that its surface temperature reaches about 50 ° C. Apply a water repellent to a dry, heated base. To do this, we use a roller or a brush, we immediately remove the drips of the solution.

Fireplace painting

Before applying paint to the prepared base, it must be thoroughly mixed. Heavier elements usually sink to the very bottom. And since these are most often hardeners, the composition can dry for a very long time. The fireplace can be painted only at positive temperatures. If the room is cold, be sure to heat it up. High humidity is also harmful to the paint, in which case it dries poorly. The composition can be applied with a roller or brush. Good results are obtained by using a compressor.

High-quality painting requires the application of several layers of coating. It should be remembered that a new layer can be applied only after the previous one has completely dried. The seams are painted in shades that are lighter than the base.

If it was not possible to buy the paint of the desired shade, you can prepare the following composition: turpentine and varnish are mixed in equal proportions. Gouache of the desired color is added to the resulting transparent liquid. The paint is thoroughly mixed. With a similar composition, you can, if desired, paint the surface of the heater.

A good result when painting a fireplace will be obtained only with a well-prepared base.

A neatly painted fireplace is an interior decoration. Correctly selected and applied paint will last for many years without requiring special care. You need to understand that the seemingly simple procedure for painting a heater actually requires certain skills and experience. Especially carefully you need to prepare the fireplace for staining, carefully carry out the joining and restoration of the seams. Only in this case the result of the work will be flawless. If you didn't have to do such work before, it is better to invite professionals who will quickly and efficiently paint any fireplace.

Features of the painting of the furnace

Powder coating technology.

To provide the most decorative appearance of the stove, you can paint the joints between the bricks in a light tone. For example, sandy shades, yellowish and even white, work well. You can apply a composition such as a mixture of turpentine and varnish PF-283 in a one-to-one ratio.The coating is transparent and matte. If you add dry gouache of the required color to the mixture, it is easy to get paint. If the fireplace is made of poor quality bricks, the masonry is done carelessly or there are significant flaws, plaster is made with lime-gypsum or lime-clay mortar.

Before painting, stoves and fireplaces are thoroughly cleaned, while the seams are deepened by about 7 mm. The oven must be preheated so that the surface is slightly warm. The next step is to wet the surface with water. The solution is applied in two layers. It is understood that the first layer is liquid, with grouting. The thickness of the plaster, taking into account two layers, should be no more than 10 mm. After application, the surface is thoroughly leveled and rubbed. When the plaster is completely dry, all existing cracks are sealed, rubbed over with a solution. It is necessary that the plaster layer is monolithic and uniform.

Further processing of plastered fireplaces and stoves

To ensure high-quality painting of the plastered surface, the applied layer is treated with coarse-grained sandpaper, which is fixed to the bar. Next, you need to grind. For this purpose, you can use a swab made of bast, and a rag made of coarse burlap is also suitable.

After this preparation, the oven is ready for painting with various compounds. If you decide to apply painting to the fireplace, then you can make the paint for this purpose yourself. Choose a gouache of the desired color, dilute in a liter jar, add egg white to it. The mixture should be homogeneous.

Subtleties of coloring

Before puzzling how to paint a brick oven, you need to know for sure whether its surface has previously been plastering. If the structure is old, then, most likely, it was used for its intended purpose, that is, it heated the room and served as a place for cooking. Such ovens are white, because they were previously plastered, and then whitewashed with chalk or slaked lime.

It is extremely important to clarify this question, because on top of the old layer it is worth applying exactly the same material that was used earlier, otherwise the work will be useless. If you have special paint for stoves and fireplaces, then you will have to remove all layers of the old material, and only then carry out the new cladding.

Before painting begins, you need to clean off all crumbling material from the oven. For this, a construction brush with metal bristles (a brush) is useful, or a narrow spatula will do. If the material is well removed, then it may be more expedient to remove it down to the brick luggage, in which case any paint for fireplaces and stoves can be chosen.

The next step is to remove all debris and clean the surface of dust. Further, with their own hands or with the help of a professional, they fill in cracks, holes and seams. Now in specialized stores, ready-made mixtures are presented that are suitable for working with brick ovens.

Surface preparation for processing

Materials and tools

To prepare a lime-clay mortar, which is used to treat the surface of the oven before painting, you will need (in volumetric parts):

- clay - 1 part, lime dough - one part, fine sand - 2 parts, asbestos chips - 0.1 part;

- lime-gypsum mortar: alabaster - 1 part, lime dough - 2 parts, fine sand - one part, asbestos chips - 0.1 part.

Instead of asbestos, you can use finely chopped mineral wool in the same amount. To improve the quality of the mortar, liquid wood glue is sometimes added to it; one glass is enough for a bucket of mortar.

Directly for painting the fireplace, you will need:

- latex paint;

- dry gouache;

- brick flour;

- egg whites;

- coarse-grained skin;

- PF-283 varnish;

- turpentine;

- brushes for applying the mixture;

- work clothes.

Subject to all the rules regarding the pretreatment and painting of the fireplace, you can independently restore any fireplace and stove. If you do not have the skills of such work, it is better to trust the professionals.