The main types of insulation

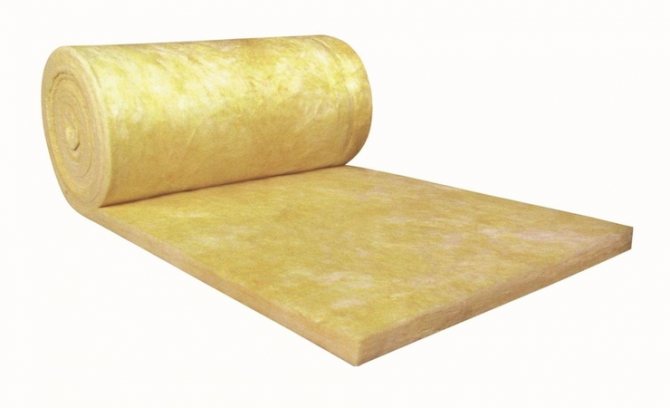

Thermal insulation in twisted rolls can be used for both external and internal filling. There are options specially designed for pipes and utilities. Roll insulation for walls directly under the wallpaper are also on sale.

The raw materials for their production are also used in different ways. Thermal insulation from mineral components is the most common. Foamed polyethylene is also popular. Natural heaters like corks are less common and used. Some species have an extra layer in the form of foil or paper. Let's consider each option in more detail.

Coated heat insulator

Coating the heat insulator with a layer of foil on one side provides better heat reflection, and also protects it from the action of ultraviolet rays and moisture. The foil is placed inside the room so that it reflects heat well.

Roll foil insulation is often used to insulate pipes. It was initially developed for this purpose.

The disadvantage of foil is the lack of vapor permeability. For good steam transmission, metallized thermal insulation is used. It reflects heat worse, and also peels off the insulation under mechanical stress.

Coating with paper is applied. It creates the best adhesion to the wall. If the roll insulation is supposed to be pasted over with wallpaper, it is better to have the covering on both sides. The method is used for indoor coatings. The base material can be different.

Special coating of thermal insulation

To improve the characteristics of their products, companies that produce roll thermal insulation add certain coatings. The basis under them can be different.

- Foil - tends to reflect heat. Basically, it is fixed on one side, the one that will face the interior of the room. This will protect the walls from moisture as well. Initially, the technology was developed for warm pipes, but over time it has been applied to other surfaces as well. Foil insulation is produced by almost all well-known companies in this field.

- Metallized coating, it differs from the previous vapor and breathability. But it has a drawback, the layer decreases from mechanical influences or completely disappears, which increases heat loss.

- Paper layerwhich improves the adhesion of the rolls to the walls. It can be on one or both sides. The latter option is used for subsequent wallpapering.

Roll-up alternative for thermal insulation

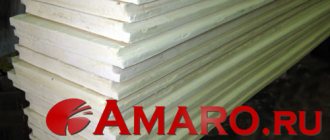

The development of comfortable and functional thermal insulation boards is an improved version of thermal insulation - roll insulation, which is equally effective both for walls and for ventilation ducts, pipes, roofs and other surfaces. This tool is distinguished by improved technical parameters and, unlike mineral wool, in slabs with high stiffness and density, and allows it to be used for elements with complex surface geometries.

Roll insulation is a heat-insulating material used to protect large surfaces, as well as to insulate long-term straight structures. Due to the fact that the heat insulator is supplied in rolls, installation is greatly simplified and the productivity of work is increased. Products come in different types and are produced under different brands.

Types of mineral wool in rolls

There are several varieties of insulation in this group. Their structure is the same, they differ in composition.

- Basalt wool.This material is made by melting rocks into the finest fibers, which are intertwined randomly. By adjusting the density of the material, manufacturers get hard or elastic cotton wool. The latter is applicable to rolls. The thermal conductivity of the material is the lowest of all such options. This allows it to be a fairly common type of insulation. The weight of one cubic meter of cotton wool ranges from 30 to 100 kg. The maximum temperature that it can withstand is 700 degrees. Manufacturers declare that the basalt components of cotton wool are safe for health. Over time, however, particles of fibers and binders are found in the air.

- Glass wool. The same fibers are melted, but already based on glass waste... Differs in the lowest cost and density up to 25 kg / m³. Withstands high temperatures, its maximum is about 450 C °. Indicators above destroy glass wool thoroughly. She copes with her main task well. A negative aspect is the effects on the respiratory tract and skin during installation and use. Therefore, thermal insulation made of glass fibers is mainly assigned the role of only the outer layer.

- Slagged. The third type of insulation is produced from metallurgical waste (blast furnace slag). The price of rolls is also reasonable. However, this type of cotton wool is outdated, it was popular back in the USSR. Due to the fragility and allergy of fibers, it is not used in residential premises. The density of the material is different: cotton wool with an indicator of 75 kg / m³ is used for floors, 125 kg / m³ is suitable for walls. The hygroscopicity is high; it loses its properties when wet. Non-flammable, melts at temperatures above 300 C °.

Any kind of cotton wool should be covered with a vapor barrier, especially in rooms with high humidity. And it also holds back the smallest particles of fibers that appear over time, which negatively affect a person. Formaldehydes are often used in the composition of raw materials, which also affects health. Quality rolls should have a minimum of this substance.

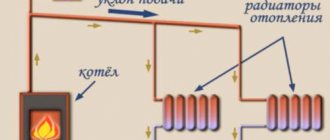

For laying mineral wool the installation of the frame is mandatory. On the walls, the panels that hold it are pressed strongly so that over time the canvas does not slide out. For the necessary protection from the cold, the number of layers can be increased.

Manufacturers often divide their products according to the purpose of the insulation. For ceilings and slabs, the rolls will be lightened. For base floors, walls, and other surfaces, the density of the material is usually increased. Due to this, the dimensions of the roll also change:

- length from 3 to 8 meters;

- thickness in 3 options (50 mm, 100 mm, 150 mm);

- width from 0.6 m to 1.22 m.

Tips for choosing thermal insulation in rolls: what you need to know

Summarizing all of the above, it remains to note several important nuances in relation to the choice of materials based on roll-type mineral wool for insulation. Experts recommend, first of all, to take into account the type of surface and purpose. It is necessary to select materials suitable for thermal insulation of certain surfaces: wood, concrete, brick, etc.

You should not write off the thickness of the base, taking into account the temperature indicators and atmospheric precipitation in the region, especially when it comes to outdoor insulation.

When buying materials for thermal insulation based on any of the listed types of cotton wool, you should pay attention to the integrity of the packaging. It is strictly forbidden for moisture to form on the material in the package.

Each of the types of insulators listed above has its own characteristics, advantages and disadvantages, so the choice must be made after careful analysis, depending on the required functionality.

Insulation wool manufacturers

Hardware stores offer a wide variety of mineral wool. Consider the features of the materials of some companies specializing in this area:

- Isover.This manufacturer produces mainly glass wool, which has decent characteristics. The materials are breathable and recover their shape well after mechanical stress. Do not emit harmful substances when heated. However, when installing any kind of mineral wool, it is necessary to use personal protective equipment... Roof options have high moisture protection and good sound insulation. Wool brand "Sauna" (for baths and other wet rooms) has an aluminum coating, reinforced with a reinforced mesh, which makes it possible not to use a vapor barrier.

- Ursa. Both universal and specialized glass wool are produced under this brand. For example, for hot pipelines or equipment that heats up to 270 degrees. And also the manufacturer offers a product with Pure one technology. It allows you to bend around irregularities due to the "spring" effect. Safe acrylic serves as a binder for raw materials, it does not allow fibers to break. It is a good option for rooms with children.

- Rockwool. Produces durable basalt wool for technical use that can withstand temperatures up to 1000 ° C. It is environmentally friendly and does not lose its thickness over time, as the manufacturer claims.

Views

The material is divided according to its purpose: for the roof, floor, walls. If desired, you can purchase a universal one designed for various surfaces.

Manufacturers offer two types of insulation:

- based on cotton wool (basalt, glass, slag wool);

- foiled on the basis of foamed polymers and mineral wool.

The latter is approximately 10% more expensive than usual, but at the same time surpasses it in terms of performance. It is water-repellent. The foil reflects heat (approximately 97%) back into the room, makes the product more elastic, and facilitates the installation process.

Foamed polyethylene for insulation

Has many positive qualities. It is obtained by filling heated polyethylene with gases. As a result, a mass is formed with many closed bubbles inside, which subsequently solidifies. For special strength, it is also "stitched", that is, the bonds of molecules are strengthened by chemical means.

Therefore, on sale there are two options: stitched and, respectively, unstitched... Both types have very low thermal conductivity, but the first one still has better characteristics, therefore it is more expensive (its density is 30 kg / m³). The general properties of materials are as follows:

- they are durable;

- absolutely do not absorb water;

- easy to assemble;

- do not harm the environment and humans;

- organic destroyers like bacteria and fungi are not afraid of them;

- the layer thickness required to retain heat is much less than, for example, mineral wool.

The difference is that cross-linked polyethylene foam is capable of absorbing sounds well, but its counterpart cannot boast of this. As a sound insulator, it works worse. Under mechanical stress, the unstitched version loses its shape irrevocably. Stitched has a high compressive strength, which means it can be used for thermal insulation of horizontal surfaces.

Due to the fineness of the material, the length of the rolls can be up to 30 meters, the width is from 0.6 to 1.2 m.The thickness reaches 1 cm.Negative nuances for polyethylene are flammability and current conductivity (electricity passing nearby should be well insulated) ... Special glue is required to secure the material to the wall.

Roll size chart

For comparison, insulation is taken, the thickness of which does not exceed 50 mm. This is due to the fact that more massive rolled thermal insulation materials fold much worse. The review includes fibrous coatings. Manufacturers of insulation in rolls:

| Material grade | Width, mm | Length, mm |

| Ursa M-11 | 1200 | The manufacturer offers two options: 7000 and 9000 |

| Heat Knauf Dacha | 1220 | 7380 |

| Isover Classic | 1220 | 8200 |

| Isover Sauna | 1220 | 12500 |

To compare the cost of the coatings and determine the most suitable option, take into account the number of stripes in the package.

Polyethylene foam of the Penofol brand

Insulation Penofol - appeared recently, but has already stood out among their own kind. It does not deteriorate from weather conditions and aggressive environments. Heat insulators of this company have several varieties:

- the foil coating can be fixed on both one and two sides;

- rolls with an adhesive layer (further simplifies installation);

- specialized type of isolation for communication networks;

- insulation for harsh conditions with a thickness of up to 40 mm.

The combined technology makes it possible to further reduce the thermal conductivity of the surfaces to be insulated. Moisture-resistant and durable material that does not require the cost of vapor barrier, can be used in various directions. Does not lose its properties in the temperature range from -60 to +100 C °.

Roll insulation for walls

Basalt wool is well suited for interior decoration. Usually it is laid under a plasterboard false wall.

Another group is polypropylene or polyethylene rolls.

Minvata is a good heat insulator. Polymers slightly improve the characteristics of the walls, but are not a full-fledged insulation. With cotton wool, work is more difficult, since the installation of a frame and drywall sheets is required. It needs to be reliably protected from moisture, which reduces the thermal insulation properties of the material.

For rooms with high humidity, only polymer insulation is suitable.

Cork surface insulation

An environmentally friendly and durable raw material for the production of thermal insulation is the bark of cork oak. Absolutely natural ingredients make rolls safe for health. The crushed bark is bonded with organic glue and pressed. The thickness ranges from 2 to 6 millimeters. The length of the roll reaches 10 meters, the width is mainly one meter. Most often, in this form, the cork goes under the wallpaper, on the substrate for the laminate or "warm floor".

Thermal conductivity index not inferior to mineral wool, but the layer is used much thinner. Cork insulation is low flammable, does not absorb water well and retains noise. However, its density is high, and accordingly its weight is large. The safety margin is high, the service life is declared up to 50 years. The negative side is the price for "naturalness", in comparison with the rest it is quite high.

This insulation is mainly produced by Portuguese companies: Wicanders, Izora, Amorim. They offer a wide range of insulation rolls, which can also serve as wall decoration. Installation is also simple, basically the cork is "put" on glue.

Modern technologies provide a huge selection of heat insulators for any premises and structures. The selection criteria are based on which surface should be covered and how much the buyer is willing to pay for it in order to maintain comfort in their home.

Insulation for wallpaper roll

Features of the choice of insulation for wallpaper

If you want to glue wallpaper on top of the insulation from the inside of the house, then the choice of the insulation used must be approached as carefully as possible, since not every material is suitable for this.

Natural crustal insulation for wallpaper

In this article, heaters will be presented, which are the best options for subsequent wallpapering. Their technical characteristics will be considered, as well as the technology of mounting these materials.

1 Can wallpaper be glued over styrofoam?

The most popular insulation was and remains polystyrene foam - ordinary foam. Due to the minimal cost and good thermal insulation characteristics, this material is used everywhere - for insulation of walls, facades, ceilings, floors, etc.

Of course, the rationality of using this insulation is difficult to dispute, but it should be understood that expanded polystyrene is not the best choice for direct wallpapering.

Firstly, the surface of the foam plastic does not have sufficient rigidity, as a result of which, even with minimal external impact (someone leaning against the wall, or the wall is caught by some object), the wallpaper will break through.

Secondly, since the foam, like the Izover Optimal insulation, is a slab material, while for effective insulation from the inside of the walls you will need at least a 5-centimeter layer of insulation, the joints of the foam after pasting will stand out very much under the wallpaper.

Thirdly, when the moment comes for redecorating the room, and you need to change the wallpaper, along with them you will have to change the insulation, since you will not be able to tear the wallpaper from the surface of the foam without damaging the latter.

And the last factor, because of which it is impossible to glue wallpaper on polystyrene, is the issue of fire safety, since according to SNiPs, expanded polystyrene must be insulated with a layer of non-combustible material.

If you want to insulate the walls from inside the house with polystyrene foam, then for subsequent wallpapering, you can either sheathe the thermal insulation with plasterboard, or cover the insulation with a reinforcing plaster composition using fiberglass plaster mesh. But for such a case, it is sometimes easier to buy a polyurethane-based insulation in Kirov.

Plastering foam using a reinforcing mesh

Now let's talk about heat-insulating materials on which wallpaper can be glued without any additional preparation.

1.1 Polyphom

One of the most easy-to-use materials is polyfom - a roll insulation made of foamed polyethylene foam.

From the side adjacent to the wall, the polyfom does not have an additional coating, however, from the outside, the material is covered with special high-density paper. The paper surface has good strength, which makes it possible to stick both ordinary and heavy vinyl wallpaper on such insulation.

Polyform is produced in roll form. The insulation has the following dimensions: length - 14 m, width - 50 cm, thickness - 5 mm. The density of the material is 30 kg / m³.

Thermal insulation with polyphom as well as insulation for siding. despite the small thickness of the material, it is quite effective, since the insulation has a minimum coefficient of thermal conductivity, which is 0.03 W / mk, which is similar to a 12 centimeter brick wall, or 5 centimeters of wood.

Due to its minimal thickness, Polyfom does not take up free space

Advantages of polyform, in comparison with other heaters for walls under wallpaper:

- Polyphom, in addition to insulation, significantly increases the sound insulation of the walls. The noise reduction index of the material is about 30 dB, while it copes equally well with both impact noise and sound transmitted through the air;

- The polyphom has a structure of closed cells, due to which the polyphom is not prone to water absorption and vapor diffusion. Insulation of walls with foam from the inside does not require additional vapor barrier and waterproofing;

- Mechanical strength and resistance to deformation - the base of the polyphoma is made of molecularly cross-linked polyethylene, which guarantees the maximum strength of the material (with an external load of 2000 N / m², the elastic modulus of the polyphoma is MPa);

- The minimum weight (260 grams per 1 m²), and the high elasticity of the material make wall insulation with polyphom extremely simple and problem-free;

- Chemical inertness - none of the modern adhesives for wallpaper will do any harm to the polyphome (even glue for polypropylene and polyethylene);

- Durability - microbiological resistance, together with mechanical strength and chemical inertness, guarantee a long service life of the polyphom, which is about 50 years, without losing the functional properties of the material.

The disadvantages of polyphoma can be attributed only to the lack of fire resistance, but this is typical for all heaters made of foamed polymers.

The polyp is coated with white thick paper

The installation of the polyphoma is performed in the following sequence:

- The height of the walls is measured, and the roll of polyphom is cut into pieces of the required length;

- Old wallpaper and a layer of damaged plaster are removed. All cracks, potholes and other defects found on the surface of the walls are putty;

- The wall is covered with a deep penetration primer. This can be omitted, but the presence of a primer will significantly reduce the consumption of the adhesive;

- After the primer has dried, glue is evenly applied to the surface of the polyphom and to the surface of the wall, after which the insulation is fixed on the wall. It is important that at the same time the temperature in the house is higher than +10, and the air humidity does not exceed 70%;

- Polyphome joints are glued with masking tape as materials for thermal insulation of the attic. after which the insulation is left for 72 hours, which are necessary for the material to dry. After the expiration of time, the walls are wallpapering.

- Environmental friendliness, and, as a result, complete safety for human health;

- Durability;

- Cork is a non-static material;

- Microorganisms do not start in cork insulation, moreover, such insulation does not grow moldy even with very damp indoor air;

- Cork thermal insulation, in addition to improving the temperature regime in the house, guarantees high-quality sound insulation of the home;

- A cork backing for wallpaper allows you to hide defects and unevenness in the walls.

1.2 Cork insulation

The only completely natural thermal insulation material that can be used for direct wallpapering is cork insulation.

The technical characteristics of cork heaters are as follows: thermal conductivity coefficient - 0.04 W / mc, density 100-130 kg / m³, flammability class - G3 (normally combustible material), nominal weight - 200 kg / m³.

As an insulating substrate for wallpaper, as a rule, cork thermal insulation 10 mm thick is used.

Natural cork insulation for wallpaper

Cork insulation has the following advantages:

As evidenced by reviews, natural cork insulation helps to maintain an optimal temperature regime inside the house.

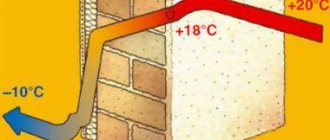

In winter, cork thermal insulation allows, with a similar heating of the house, to obtain a temperature 2-3 degrees higher than in an uninsulated building, and in summer, traffic jams prevent heat transfer from warmed-up walls to the air inside the room, as a result of which a comfortable coolness remains in the building.

The only drawback of cork thermal insulation is the cost, since natural material costs an order of magnitude more expensive than artificial insulation.

The technology of wall insulation with cork insulation is as follows:

The structure of cork insulation

2 Reviews and opinions

Study the reviews of people with experience in using the heaters considered in the article in order to make the right choice of thermal insulation materials for wallpapering.

Andrey, 35 years old, Rostov:

Having moved to a new apartment, I faced the problem of mold on the walls, which the old landlord, having hidden the problem area with furniture, happily kept silent. To solve this issue, it was necessary to insulate the facade of the apartment with polystyrene, and from the inside of the house, glue the walls under the new wallpaper with polyp.

I can only say positive things about this insulation - it is not expensive, easy to install, effective. About four years after the move, I did not find any peels on the wallpaper, they stuck tightly, like on a wall. At the same time, I forgot about the mold immediately after the installation of the polyphome.

Mikhail, 49 years old, Moscow:

Choosing a material for thermal insulation of walls from the inside of the house, I settled on cork insulation. Friends convinced me of the rationality of its use - from all my friends who had experience with a cork heat insulator, I heard only positive reviews.

I did the insulation with my own hands, since the installation of the roll insulation turned out to be approximately simple. In an insulated room, with constant heating, the temperature rose by almost 3 degrees. In general, I was completely satisfied with the result.

2.1 Features of gluing insulation under the wallpaper (video) How to glue insulation under the wallpaper

Insulation for wallpaper Pasting of walls with roll insulation, features of insulation for wallpaper installation, its advantages, disadvantages and technology.

The content of the article:

- Preparation of the base

Insulation for wallpaper is a special substrate designed to retain heat in the room, level the walls, heat and sound insulation, as well as protect against mold, mildew and condensation. Installation of such material largely solves the problem of the durability of the finish coating of structures. We will tell you how to glue insulation on the walls under the wallpaper in this article.

Features of wall insulation using a wallpaper underlay

One of the types of wall insulation before wallpapering is roll insulation. It is performed using substrates with a thickness of about 8 mm, made on a different basis:

- Expanded polystyrene backing

... This material is produced in the form of rolls. To fix it on the surface of the walls, glue or a mixture containing gypsum fine-grained plaster is used. The wallpaper is pasted onto such a substrate using a special polymer-cement glue. The best adhesion to wallpaper has polystyrene foam insulation with an outer layer made of cardboard. Wall insulation with this material is quite effective, since it is reliable, absorbs noise and vibration well, is resistant to moisture and mold formation, but its thermal insulation properties are slightly lower than that of polyethylene substrates, which will be discussed later. The Thermo-Tap insulation has good reviews. The size of its roll is 10x0.5 m, the price of 1 m 2 of material starts from 500 rubles.

... The foam material consists of welded air-filled cells sandwiched between layers of paper. Therefore, no special compound is required to attach the substrate to the base. Wallpaper glue is quite suitable for the entire range of works. Such a substrate has excellent adhesion to any kind of surface. Today, this roll material is the most popular option as thin thermal insulation for walls. It is generally accepted that the Polyf insulation under the wallpaper is considered. It goes on sale in rolls of 0.5x14 m, material thickness - 50 mm, density - 30 kg / m 3. thermal conductivity - 0.039 W / m * K, sound absorption - up to 22 dB, the price of a Polif roll is 1200 rubles.

... It is flawless in terms of ecology, has excellent thermal insulation properties and absorbs sound well. Its presentable appearance eliminates the need for external wallpapering. However, the moisture resistance of such insulation leaves much to be desired, so the cork substrate is often impregnated with moisture-repellent compounds - wax, for example. For ease of fixing on the walls, the back of the cork backing is impregnated with glue. The material is sold in rolls from 5 m 2. the price of 1 m 2 is 400 rubles. and more.

... This material is a wallpaper, on the back of which insulation is glued. For the production of such products, aluminum foil, synthetic fiber and the wallpaper themselves are used. The cost of installing this insulation is minimal, but the variety of material does not differ.

Roll thermal insulation allows for repeated gluing of wallpaper to its surface, and at the same time its characteristics remain unchanged. Substrates with a paper outer layer adhere tightly to the walls, and foil ones reflect heat well.

Insulation under the wallpaper can hide only minor flaws in the walls. If it is not possible to level the surface before installing it, it will be better to use cork thermal insulation. It is able to hide almost all flaws, but special glue is required to attach the cork material.

Advantages and disadvantages of wallpaper insulation

Installation of insulation for walls under the wallpaper has a number of undoubted advantages. Let's designate the main ones:

- Insulation keeps heat well in rooms adjacent to unheated enclosed spaces such as stairwells.

The disadvantage of thermal insulation is the flammability of the coating, it is afraid of open fire and supports its spread during a fire. In addition, the backed wallpaper may dents after impact or strong pressure.

When choosing a roll insulation for wallpaper, one should take into account its technical properties, cost and the possibility of self-installation.

Wall insulation technology for wallpaper

The process of installing a heat-insulating substrate is practically no different from the usual pasting of walls with wallpaper. The difference can only be in the composition of the adhesive. The work is carried out in stages and consists of preparing the surface and materials, priming the walls and applying thermal insulation to them.

Preparing the base for mounting the substrate

Before gluing roll insulation under the wallpaper, it is necessary to remove from the walls the old finish, peeling plaster, dirt, nails protruding to the surface, reinforcement and other unnecessary details. After cleaning, the revealed cracks and potholes should be sealed with cement mortar, and the influx of mortar or concrete should be knocked down with a chisel.

Due to the fact that the insulating substrate under the wallpaper smoothes out minor surface imperfections, it is not required to level it to an ideal state. But if there are drops of more than 5 mm on the walls, it is necessary to apply a thin layer of plaster on them.

After cleaning and leveling the surfaces, they should be primed. This stage of work is of particular importance: in addition to the fact that the primer layer exhibits antiseptic properties, it also increases the adhesion between the wall and the insulating substrate.

Work should be done with a roller or paint brush, all further actions are performed only after the applied primer has dried. The time for drying it is indicated on the packaging of the material.

Preparation of materials for wall insulation for wallpaper

This stage of work consists in cutting the insulation under the wallpaper into canvases of the required size and stirring the adhesive. When choosing an adhesive, one should be guided by the type of insulating substrate and its weight. The best option would be to purchase an adhesive mixture with the addition of fine-grained gypsum putty or glue for heavy wallpaper.

To cut the insulation, you need a tape measure, a knife and a ruler. First, you should measure the desired height on the wall, and then roll out a roll of thermal insulation and cut it into canvases of the appropriate length.

The required number of rolls for warming a room is calculated simply: you need to take the quotient of dividing the value of the area of the walls of the room by the value of the area of one rolled out roll of insulation. It is recommended to buy the material with a small margin of 5-10% in case of cutting it at the places where the structures are adjacent.

Before working with glue for insulation under wallpaper, you need to study the instructions attached to it, in which the manufacturer indicates the method of applying the composition, its drying time and the scope of application. It is recommended to use only a substance that is designed to work with the specific type of thermal insulation underlay. Stir the adhesive thoroughly before applying to the surface.

Installation instructions for wallpaper backing

When installing insulation on walls, the air and surface temperature should not be lower than + 10 ° C, the humidity of the environment is allowed no more than 70%. Before work, you should close the windows and doors of the room to avoid drafts, they are completely unacceptable.

The glue is applied with a roller and brush. With the composition, it is necessary to evenly treat the base and the back side of the thermal insulation sheet, which, after holding for 5 minutes, should be carefully applied to the wall in the right place according to the previously applied markings.

Installation of insulation sheets must be carried out vertically from top to bottom without joint-to-joint gaps. To remove air from under the glued thermal insulation, the substrate must be rolled with a roller from the middle to the edges of the sheet. After the canvases are securely fixed to the wall, their joints must be glued with masking tape.

A day after the completion of thermal insulation, the room can be ventilated. Sticking wallpaper to the insulation should be done only after it has completely dried, the time of which is 2-5 days.

Before pasting the walls with finishing material, check the strength of the fixing of the heat-insulating layer. To do this, its small area of 5x5 cm can be cut at the bottom of the wall.

How to glue the backing under the wallpaper - see the video:

If the technology of gluing insulation under the wallpaper is observed, up to 20% of thermal energy can be saved. A roll-up heat insulator is much more effective than wall hangings. In addition, under the windowsills of the apartment, warm wallpaper will relieve you of cold bridges for a long time and preserve the comfort of your home.

Related news Insulation under the wallpaper

When you make repairs, you want the result to be durable, and not just beautiful. You should also take into account the technical characteristics of your room, so that later it turns out that your new and beautiful design is simply useless, and the apartment is cold and damp. Preliminary wall insulation will help to solve this problem.

The main types of insulation for walls

At first glance, it may seem that it is impossible to do the insulation work with your own hands, but we hasten to assure you that this is not so. The main thing is to choose the right insulation for the wallpaper and follow the technical recommendations, which are huge on the Internet and on the pages of specialized publications.

When choosing internal thermal insulation, it is important to do this not at the expense of the size of the room. That is, without the use of complex structures and tile or fibrous materials. How to choose the optimal material for insulation, which will help reduce heat loss and will not be harmful to health. There are a lot of options on the modern market.

Types of insulation for wallpaper

If we try to classify the types of insulation for walls, then we get two main groups:

One of the best types of insulation

Plasterboard is often used for internal insulation, it retains heat well and helps to level the walls. But for its installation, a special frame is needed, and the insulation of the walls with the help of this material, as many reviews say, significantly eats up the space of the room. Therefore, in this article we will focus on the first two types of insulation for walls and consider the characteristics of each of them in more detail.

Features of insulation for wallpaper

It would seem, what could be easier than choosing materials for insulation? You come to the store, take the most suitable product for the price, and then let the masters deal with its application.

After all, not everyone can properly plaster walls, and therefore most resort to the help of specialists. But before handing the materials into the hands of the pros and entrusting them with the repair work, think about what kind of end result you expect. Compare your desires with the assortment offered in the store and try to make a deliberate and balanced choice, because you are not doing insulation for a year or two. And its alteration can cost you a pretty penny.

In the modern construction market, there are several types of heat-insulating plaster, which differs in the composition of the filler:

Please note that mineral plasters create a rough surface, on which a layer of finishing mixture should be applied before gluing the wallpaper.

Varieties and properties of roll insulation

A distant relative of modern roll insulation is old newspapers, which were used to paste over the wall in several layers before gluing the wallpaper.

But times have changed, and in the modern market there are more effective options for insulation made on a different basis:

Cork insulation for walls

Rolled wall insulation performs several more useful functions, in addition to thermal insulation:

- Soundproofing.

- Vapor barrier.

- Aligning the walls.

The undoubted advantage of rolled insulation will be that wallpaper can be glued to them more than once.

How to mount roll insulation for walls

Although the range of roll insulation for walls is simply huge, its installation takes place in several absolutely identical steps.

Installation of roll insulation

Only the glue substance used in the process of installation work and the time of its drying will differ.

How to glue insulation under the wallpaper

Stages of installation of insulation Polyform:

After all of the above, it remains only to wait from 24 to 72 hours, depending on the material and manufacturer. After finishing the gluing of the roll insulation under the wallpaper for the walls, you can start gluing the wallpaper and other decorative work.

Useful video on how to glue roll insulation:

- Insulation for walls inside the apartment under the wallpaper Features of the choice of insulation under the wallpaper If you want to glue the wallpaper over the insulation from the inside of the house, then ...

- How long does non-woven wallpaper dry How long does non-woven wallpaper dry? For those who plan to make repairs and use wallpaper with ...

- Warm wallpaper for walls Insulation under the wallpaper: tips for choosing In the photo - gluing a strip of thermal insulation to the base On ...

- What is the next wallpaper or stretch ceiling What is the first to glue the wallpaper or stretch ceiling: the right choice Skirting board fixing scheme. Conclusion We sincerely hope ...

Floor insulation

Insulation of ceilings is especially necessary on the ground floor, when they are located in close proximity to the ground or outside air. The best roll insulation for a wooden floor is mineral wool, and for concrete or in the presence of heating, expanded polystyrene is well suited.It has great strength and, judging by the reviews, is often used for laying with a screed.

The choice of insulation depends on the following floor parameters:

- indoor humidity and temperature;

- the purpose of the room;

- acting load;

- surface area;

- the height of the thermal insulation layer.

If there are noisy highways next to the house, it is necessary to use insulation with soundproofing properties.

Main manufacturers of insulation in rolls

The following brands are most popular with the consumer:

- Products of the German brand Knauf are distinguished by absolute safety and harmlessness, since they do not contain formaldehyde. The manufacturer guarantees a long service life and a wide range of products, as well as the possibility of insulating both apartments and suburban buildings.

- Rolled insulation Isover from the French manufacturer is presented to the consumer in a wide range, including foil-coated material. Excellent thermal insulation performance allows the material to be used for insulation of premises both inside and outside.

- The Spanish brand Ursa represents roll materials that are distinguished by a long service life without losing quality characteristics. The high quality of the products allows the use of insulation not only in the private sector, but also in industrial construction.