The most valuable building materials in modern construction are those that allow you to comprehensively solve several problems at once. Insulation Basvul has excellent characteristics, it is fireproof and perfectly vapor permeable. Thanks to such versatile protection, any surface acquires the required sound and thermal insulation properties; moreover, the use of this heat insulator ensures safety and a longer service life.

Description and main characteristics

Mineral wool Baswool is produced by Agidel LLC, one of the leaders in the production of thermal insulation materials. The insulation described in the article can be used for insulation:

The material is equally effectively used both in private construction and in the construction of industrial facilities. It is made from molten rock - basalt - at a temperature of one thousand degrees. It is thanks to this production technology that the insulation received its exceptional characteristics. Let's consider them.

- The weight of this heat insulator can vary between 25 and 225 kilograms per cubic meter.

- The moisture absorption indicator does not exceed 1 percent of the total weight, as well as 2 percent of its volume.

- Thermal conductivity, as a rule, does not exceed 0.038 W / m * K.

- Baswul has a high vapor permeability - at least 0.3 milligram / (h * m * Pa).

- The standard dimensions of the insulation boards are as follows (WxDxH) - 600x1200x30-200 millimeters.

- Finally, in terms of its flammability, it belongs to the A1 class.

Now let's take a look at what are the advantages of Baswool heat insulator and how exactly it differs from competing heaters.

Strengths of Basvul heat insulator

As we noted above, the basalt wool described in the article has numerous advantages, thanks to which it has gained immense popularity. Let's consider the advantages of insulation in more detail.

- It has excellent sound and thermal insulation properties.

- It weighs a little, which means that there are no special difficulties with styling.

- The vapor permeability of the insulation is quite high, and therefore the most comfortable microclimate is maintained in the insulated room.

- The material is easy to install.

- It is environmentally friendly, and despite the fact that its operational life is practically unlimited.

- During the entire service life in buildings, neither the dimensions nor the properties of the material change.

- Insulation shrinkage is minimal.

- Finally, it is hygroscopic.

In addition, Basvul insulation is a representative of the class of non-combustible materials, it fully complies with all fire safety standards and can even be used as fire protection in appropriate fences.

Note! The manufacturing company produces and sells a fairly wide range of mineral wool slabs for insulation, from the lightest (about 25 kilograms per cubic meter) to heavy (up to 225 kilograms).

Video - Basalt wool Basvul

Due to the characteristics listed above, Baswul compares favorably with other thermal insulation materials. The table below shows the comparative characteristics of the described insulation and its closest "competitors", that is, EPS and foam.

Table. Comparison of insulation materials

Parameter name

Thermal insulator

Baswul

Styrofoam

Extruded polystyrene foam

Among the many thermal insulation materials, mineral wool products have an advantage in terms of fire safety issues. One of them is Baswul.It is used when performing a wide variety of types of thermal insulation work. There are different types of this building material: Basvul Light, Standard, Flor P, ECOROCK, Basvul Vent Facade, as well as others, the technical characteristics of which indicate the high quality of products.

BASWOOL (Baswul)

The plant of heat-insulating materials LLC "AGIDEL" is located in the city of Blagoveshchensk, Republic of Bashkortostan, 10 kilometers from the capital of the region - the city of Ufa.

2007 - Start of construction of the plant for heat-insulating materials LLC "AGIDEL". A construction site was selected, a contract was signed with (Slovenia) for a complex supply of equipment for the construction of a line for the production of thermal insulation boards from mineral wool with a capacity of 10 tons per hour.

2008 - 2009 - In the midst of the economic crisis, the construction of the plant is carried out on time. The foundation is being laid. Production shops are being built. Delivery of technological equipment begins.

2010 - Installation of the main technological equipment is in progress.

In August, after a radical reconstruction, the canteen of the enterprise was put into operation, which made it possible to raise the food of the factory workers to a new quality level.

2011 - The construction of a plant for thermal insulation materials enters the home stretch. All commissioning works are carried out around the clock. During this period, all the necessary permits for the products were prepared, a certificate of registration of the BASWOOL trademark was received. In April, a group of engineering and technical personnel of the enterprise was trained in Slovenia on the production technology of mineral wool thermal insulation. In May, practical training of the enterprise personnel began on the basis of the plant. Process equipment is being run in and tested. On June 13, the furnace was first fired up. June 15 - a long-awaited moment - the first trial batch of products has been received.

2012 - The second stage of the plant was put into operation, the production of briquettes was launched (workshop No. 2). This made it possible to largely resolve the issue of by-products of the main production.

The beginning of the development of the dealer network throughout the Russian Federation.

First deliveries of products to Kazakhstan.

LLC "AGIDEL" participates in:

- at the specialized exhibition "Mosbuild-2012" in Moscow

- in the XV specialized exhibition "Construction Complex of the Big Urals" in Yekaterinburg.

The Federal Accreditation Service of the Russian Federation accredited AGIDEL LLC as a technically competent Testing Center in the Unified National Accreditation System (accreditation certificate No. ROSS RU.0001.22CN73, issued by the Federal Accreditation Service of the Russian Federation by Order No. 3874 of October 30, 2012).

2013 - Reaching full design capacity. Increase in warehouse space by 2 times. The sales volume increased 1.5 times. Organized 5 additional places of loading, which made it possible to increase the loading speed up to 100 trucks per day.

Participation in the specialized exhibition "Mosbuild-2013" in Moscow.

We are constantly working on expanding the geography of thermal insulation supplies.

2014 - The farthest shipment in the history of the enterprise was made - BASWOOL mineral wool boards in Yuzhno-Sakhalinsk.

At the beginning of February, he started to release new products BASWOOL Fire Protect and BASWOOL Heat Protect

Participation in the Spring construction forum "Everything for construction and repair - 2014" Ufa, VDNH-EXPO together with the general dealer of TD "BashPromTorg"

We hope you will appreciate the quality of our products.

What is Baswul?

Stone wool is made from basalt rocks. To obtain this fiber, raw materials are processed at temperatures above 1000 ° C. The individual parts are held together with organic resins. Basvul is produced at a modern plant in Blagoveshchensk near Ufa. The first batches of insulation were released in the summer of 2011.

This basalt wool is used in the processing of private buildings, outbuildings, as well as industrial institutions. The price is affordable, therefore, even those who are not allowed to use expensive building materials can carry out thermal insulation work using this insulation.

Advantages of basalt insulation baswool

When compared with other materials of a similar purpose, then this insulation has a number of advantages. Consider them:

1. Increased strength due to the use of stone for the manufacture of stone wool. This feature allows the material to be used in almost any design. At the same time, the cutting of basalt wool is easy enough so that all the work associated with it is extremely simple.

2. The plasticity of the material is perfectly combined with resistance to mechanical stress. Because of this, it is used for work of any type of complexity.

baswool - high quality thermal insulation material

3. High resistance to high temperature ensures fire resistance.

4. Excellent water repellency. Ideal hydrophobicity completely excludes the possibility of the emergence of living microorganisms.

5. Basalt wool perfectly insulates heat, thus providing good energy saving performance.

6. Vapor permeability. The material removes moisture from the insulation and the structure as a whole, maintaining the necessary microclimate in the building.

7. Quite good acoustic performance. Soundproofing basalt wool creates the most comfortable conditions in all rooms. This is achieved by a unique fibrous structure in which the fibers are arranged in a chaotic manner.

Material specifications

Given the location of the application area of the mineral wool, the description of its technical characteristics will vary. Below are the main parameters:

- Density - from 25 to 225 kg / m 3.

- The thermal conductivity index is from 0.035 to 0.042 W / (m * K).

- Flammability class - A1. This level is assigned to those subspecies that are not subject to fire, that is, they stop the spread of fire.

- Water vapor permeability is about 0.3 mg / (m * h * Pa).

- Moisture absorption - no more than 1% of the weight, no more than 2% of the total volume.

Composition and features

Mineral wool is one of the most effective modern insulation materials with a fairly wide area of use. The manufacturer offers material of various densities with high performance.

It contains mineral fiber made from environmentally friendly raw materials and high-quality binders, thanks to which the material will retain its performance even under extreme operating conditions.

The material has a homogeneous structure, hydrophobic. It is able to maintain its characteristics for a long time. It is lightweight, non-flammable. It has low thermal conductivity.

Advantages and disadvantages

This building material can be used for facades, interior works.

Baswool insulation in slabs is produced in a standard rectangular shape - 120 * 60 cm.The thickness of the slabs is produced in the range from 5 to 20 cm.

Different sizes of insulation allow you to choose products of exactly the thickness that is necessary for the purpose of high-quality insulation.

Application in different areas of insulation

- Non-flammability - it is completely fireproof.

- High level of sound insulation.

- Good vapor permeability.

- Environmental friendliness. Such material during operation will not harm those living in the house, which is insulated by it.

- The material does not rot, and is also not susceptible to beetles and microbes.

- It has a long operational period of 40 years.

Subject to the installation rules, mineral wool does not deform over time. Its properties do not change.

- Ease of installation.

- Has a low water absorption.Since moisture has a detrimental effect on insulation, this factor is important.

- As for any mineral wool, contact with water is undesirable. Although this model is hygroscopic, it should still be protected from rainfall as well as high humidity. This means that when performing facade work, it is necessary to start plastering the surface as early as possible (for wet facades). For ventilated facades, cotton wool should be covered if rain is expected.

- When performing installation work, you must provide yourself with all the necessary personal protective equipment. You need to work with gloves, glasses, and a respirator. Clothes should be long sleeves.

Characteristics of Baswool mineral wool

- Good sound insulation qualities

- Low thermal conductivity

- Resistant to low and high temperatures

- Fire safety

- Not afraid of exposure to chemicals

Mineral wool for Baswool roofing is presented in our catalog. The managers will tell you about the characteristics of both materials - contact us by mail or phone.

The cost of roof insulation with Baswool mineral wool will be calculated by the specialists of the Surkon company. We have extensive experience in carrying out such work.

What are the varieties

Each insulation has a wide selection of models used in different areas of insulation. The same can be said about Baswul.

Baswool Light 45

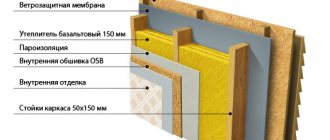

The parameters and features of Basvul Light 45 make it possible to use it when insulating frame walls, interior plasterboard partitions, roofs, interfloor floors, and attic. You can also insulate floors with it by laying it between the logs.

It is produced in slabs with a density of 30-50 kg / m 3. There are different models of insulation Light 30, 35, 45. The number indicates the density of the material.

Roof insulation

Baswool Facade

It is produced in slabs with a density of 110-160kg / m 3. This building material is used to insulate the facade, followed by plastering and decorative finishing. Speaking about the properties of Basvul Facade, one can note the thermal conductivity of 0.036-0.040 W / (m * K), the peel strength 15-21 kPa (the indicator depends on the density, the higher it is, the greater the peel strength).

Baswool Vent Facade

It is produced in slabs with a density of 80, 90 kg / m 3.

The name contains a number indicating the density of the mineral wool.

The compressive strength of these two models is 17, 20 kPa, respectively. Peel strength of layers - 6, 8 kPa. Water absorption by volume is 1.5%. According to the entire lineup.

Basvul Vent Facade is considered non-combustible, prevents the spread of fire.

Thermal insulation of the facade

Baswool Standard

This model is produced in slabs of different density - 50, 60, 70 kg / m 3. It is used as a layer in a wall made of small pieces. It is used for frame insulation indoors, outside the building. Facade insulation Baswool The standard does not imply plastering of slabs. This option is intended before siding.

Basvul Standard absorbs no more than 1.5% moisture (volume percent). The thickness of the slabs ranges from 3 to 20 cm.

Frame insulation

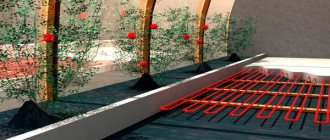

Baswool Flor

It is made for floor insulation. It can be laid under the screed of a floating structure. It is also used for heated floors. Baswul Floor has soundproofing qualities. Density - 100-120 kg / m 3.

Scope of application

Basvul heaters are used in private construction, in the construction of multi-storey residential buildings and industrial facilities. Basalt slabs are used for wall insulation using frame technology, when installing ventilated facades and insulating structures with a wet method.

The scope of application depends on the density of the mineral wool. Rigid slabs are recommended for high stress areas such as flat roofs, façades, floors.Lightweight heaters are suitable for heat and sound insulation of frame partitions of attic floors, pitched roof.