One of the important measures to improve the energy efficiency of a house is to insulate the building facade. Until recently, this procedure was very laborious and required many technical measures. Now the task has been simplified due to the appearance of innovative heaters on the market. Thermal insulation Bronya is several times superior in terms of parameters to mineral wool and polystyrene, but at the same time, its application to the surface can be performed with a minimum expenditure of effort, time and improvised means.

What is Bronya thermal insulation?

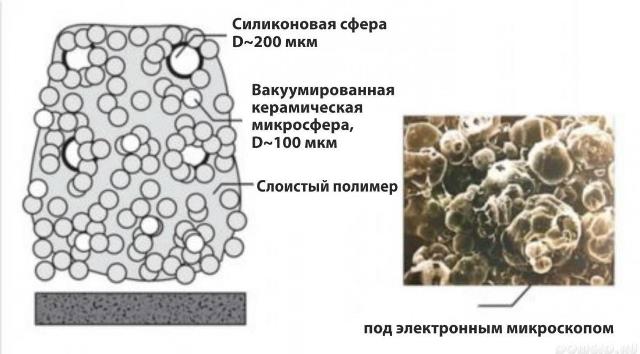

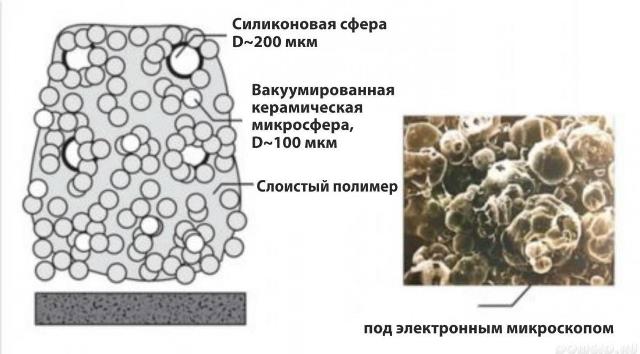

Armor is a liquid thermal insulation containing micro-granules of ceramic

The coating "superfine thermal insulation" is a substance similar to paint in appearance, method of application and structure. This mastic contains the following components:

- base acrylic bond, in a fractional ratio - 5 part of the total mass;

- polymer fixatives;

- catalytic substances;

- a filler made of microspheres, in a fractional ratio - 4 parts of the total mass, has a ceramic origin with micro-thin walls and rarefied air inside (up to 80% rarefaction).

Antiseptic and anticorrosive additives are present in the structure as auxiliary components.

Heat-insulating paint Bronya is more often produced in the form of a white suspension, which, after hardening on the surface, creates a dense film with a matte shade. The material is elastic to the touch; in terms of the quality of interaction with the environment, it is resistant to all types of impact. The thermal insulation effect is due to the inability of the rarefied air limited in the sphere to conduct thermal energy (the principle of vacuum space).

Initially, ceramic-type thermal insulation was planned to be used for the purposes of the space industry.

Polymer insulation Astratek

Astratek coating has excellent insulating and performance characteristics. Ease of application and high quality make it popular among users. Astratek is a liquid thermal insulation, the reviews of which are the best. This coating has the appearance and consistency of putty rather than paint, and at home it is more convenient to apply it not with a brush, but with a spatula. Or diluted with a spray bottle.

In the reviews, users who applied this sprayed insulation with their own hands emphasize surprisingly effective results even from one layer.

The only noticed drawback is the need to use only primers and topcoats compatible with thermal insulation, as well as a fairly high cost of the material.

Although, given the fact that the insulation did not require the involvement of construction companies, the price is even lower than using traditional materials. However, you can always type on the Internet "Astratek liquid thermal insulation reviews" and see for yourself.

Varieties of liquid insulation

Types of thermal insulation depending on the purpose

The manufacturer offers several product modifications. Each type of composite has a base base and certain additives, depending on the purpose of the paint. Options for insulating facades differ from each other in climatic design, where composites have been developed for more severe regions, designed for a greater number of cycles of exposure to negative temperatures. Specialized mixtures are more focused on protection against moisture, fungal elements and fire.

Basic coatings

The following brands of mastics are produced under the basic ones:

- Classic NG, Classic;

- Facade NG, Facade;

- Anticorrosive;

- Winter NG, Winter.

These are standard modifications of the heat insulator for operation at positive and negative temperatures.

Budgetary coverage

Thermal insulation for metal pipes is cheaper, but has lower quality characteristics

Budget composites brands are represented by the following options:

- Universal NG, Universal;

- Wall NG, Wall;

- Metal;

- Nord NG, Nord.

A series of analogs of basic brands has lower performance indicators and a lower price niche.

Specialized thermal insulators

Modifications of specialized mixtures:

- NG Standard, Standard;

- Light NG, Light;

- Fire protection Nord, Fire protection;

- Volcano.

Thermal insulation coatings have additional properties.

Characteristics of paint for thermal insulation Bronya

The composition of the insulation is clearly visible only with an electron microscope

The developer has endowed the product with the following properties:

- the mass has a uniform structure of a white shade;

- the composite has a density of 0.558 g / cm3;

- the structure contains non-volatile substances in a mass ratio of 44%;

- vapor permeability for brands of facade mastics - 0.013 Mg / m h Pa;

- heat transfer coefficient - 1,380 W / m, degrees Celsius;

- thermal conductivity coefficient - 0.0012 W / m, degrees Celsius;

- resistance of the film to water and alkali during the day - the film retains its appearance;

- exposure to negative temperatures over 50 cycles - the film retains its properties;

- adhesion to concrete - 1.33 MPa, to steel - 2.20 MPa, to brick - 2.04 MPa;

- resistance to high temperatures up to 200 degrees Celsius - the film retains its integrity and properties.

The substance in question is not a combustible material and a flame propagation medium.

Positive and negative qualities of mastic

1 mm of liquid thermal insulation replaces a 5 cm layer of mineral wool

Positive properties possessed by Bronya insulation:

- A thin layer of mastic of one millimeter can replace mineral wool 5 cm thick.

- The product is universal - it is a heat insulator, anti-corrosion agent and a kind of antiseptic.

- The paint can be easily applied with a regular roller, brush or using a fine dispersion spraying unit.

- A wide range of operating temperatures allows the material to be used in all climatic zones.

- The mass of the thermal insulator is negligible and does not exert a load on the supporting structure.

- The mastic has excellent adhesion to any type of surface (with the exception of oily and greasy surfaces).

- The paint does not absorb moisture, it is stable against ultraviolet radiation.

- The coating is elastic, withstands light loads and has good maintainability.

In an example of the negative qualities of a heater, one can indicate its high cost, reaching up to 1000 rubles per liter of paint, a drying period of at least a day and the inability to work as a thermal insulator at an ambient temperature below +7.

Material qualities

Thermal insulation prepared for use Bronya looks like a viscous, relatively thick substance. The main part of the substance (about 80%) is formed by air-containing ceramic microgranules. Together with the binder acrylic polymers, the granules create a viscous mass that can be diluted with ordinary water, thus creating a moisture-impermeable, lightweight and durable film.

As for the heat transfer coefficient, here this indicator is no more than 0.018 W / m2. This is currently the record for liquid thermal insulation materials.

Insulation Armor practically does not absorb moisture. The indicator of its absorption with the full content of the insulator in water throughout the day is equal to a scanty 0.02 g / cm3.This quality shows how effective a given substance is as a waterproofing agent.

The material does not lend itself to combustion, and due to its complex chemical structure, insects and other small pests do not spoil it.

Liquid thermal insulation has excellent adhesion. The material effectively covers any surface: brick, concrete, wood, metal, plastic and even glass. A completely cured heat insulator is converted into the thinnest film, which, despite the scanty layer width, reliably protects objects from thermal energy losses.

Another important point is the ease of application of the insulating base. You can cope with the task with a regular brush, roller, spatula or spray.

As for the consumption of a liquid heat insulator, in laboratory conditions this indicator is equal to one liter per 1 m2 when the substance is applied with a layer of 1 mm. Depending on the availability of certain conditions, the thickness of the insulation coating may vary.

Options

The technical indicators of the material are as follows:

- Appearance - a homogeneous, even matte white surface.

- The resistance of the material to the effects of temperature extremes is within the range from -40 to 60 ° C.

- The service life of the insulating layer when processing metal, brick, concrete surfaces in a temperate climate (for example, Moscow) is about 15 years.

- The coefficient of permeability to water vapor is 0.003 mg / m2.

- The maximum permissible operating temperature of the insulating coating when short-term peak indicators are reached is no more than 260 ° C.

- The density of liquid thermal insulation at room temperature is 600 ± 10% kg / m3.

- The pH is from 7.5 to 11 pH.

- The mass fraction of volatile substances is about 40%.

- The time required for the complete solidification of the liquid heat-insulating layer at room temperature is no more than 24 hours.

- The level of adhesion to concrete, metal, brick surfaces is in the range from 1.3 to 2.2 MPa.

- Resistance of the insulating coating to water, 5% alkaline solution at room temperature - appearance and properties remain unchanged.

Scope of application of the suspension

Liquid thermal insulation is suitable for exterior finishing works

Brands of liquid insulation Bronya effectively insulate the following structural elements of the house:

- external walls of any configuration before finishing work;

- simple and complex roofs, both on the outside and from the attic;

- walls of loggias and balconies from the inside;

- concrete floor surface.

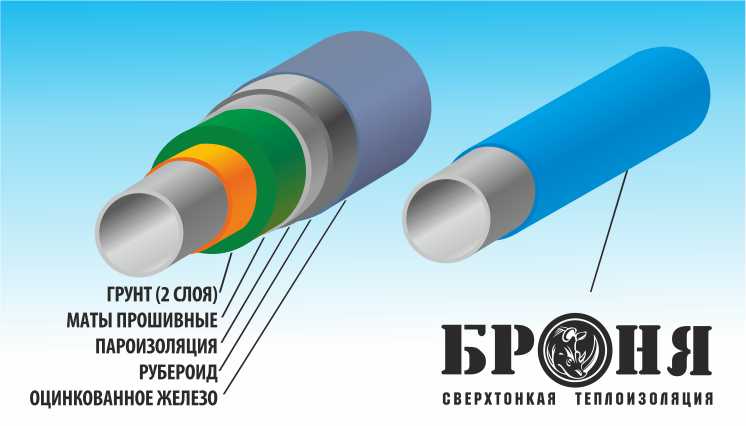

The coating has shown itself well when creating thermal insulation on boiler equipment, cold and hot water supply lines, centralized steam pipelines and heating mains, in air conditioning systems on air ducts, when insulating public and private vehicles, refrigerators, trailers, various tanks and containers, as well as sea transport. Often, the method of applying paint to cold water pipelines gets rid of condensation that falls on them.

Liquid Armor is a great alternative to traditional insulation

Since the presented heat-insulating material is mainly produced abroad, it has a high cost, which limits its mass use in construction, energy, housing and communal services, etc. Domestic counterparts sometimes leave much to be desired - poor quality and a colossal mark-up cause negativity and bias among consumers.

To avoid disappointment, we recommend that you pay attention to the availability of a complete package of necessary certificates that confirm the compliance of the product with the declared technical properties.

For information! One of the conscientious manufacturers of Armor is VIRC (Volgograd Innovation Resource Center).All liquid thermal insulation materials offered by him are certified, which guarantees excellent quality and an effective result after insulation. Also, one cannot fail to note the excellent price-quality ratio.

The composition of the Armor, which gives it unique properties

Based on this figure, we can talk about big savings when choosing Armor

Heat-insulating paint Bronya consists of the following components:

- acrylic binders;

- composition of catalysts and fixers;

- ceramic ultrafine microspheres with discharged air;

- special additives that exclude the formation of corrosion on the metal and the appearance of fungus on concrete.

This combination makes the liquid insulation surprisingly light, stretchable, flexible and adheres well to the surfaces to be coated. In consistency, Bronya resembles ordinary white paint, but after drying it forms an elastic polymer coating, which has anti-corrosion and thermal insulation properties that are high compared to traditional heaters.

Applications

Ultra-thin thermal insulation Bronya is highly effective in insulating the following structures:

Thermal insulation of a wooden attic with liquid Armor

- roofs;

- building facades

- internal load-bearing walls and partitions;

- floors;

- window slopes;

- pipelines (both cold and hot water supply);

- when insulating air ducts;

- steam lines;

- cooling systems;

- all kinds of containers, trailers, tanks, etc.

Attention! This type of insulation is used in the temperature range from -60º C to + 260º C. The service life of the liquid insulator is 15 years and more.

The principle of operation of Bronya from the point of thermophysics

First of all, it must be said that there are 3 ways to transfer heat:

- Thermal conductivity - transfer of heat in a solid using the kinetic energy of atoms and molecules from a more heated to a less heated part of the object.

- Convection - heat transfer in gases, liquids, bulk media due to the flows of the substance itself.

- Radiant heat radiation - that is, electromagnetic radiation that the substance itself emits with the help of its internal energy.

As a result of these laws of mutual transformation and energy transfer, temperature equilibrium is achieved in the entire thermal system. The method and efficiency, by which the insulation material blocks the process of temperature equilibrium, and determines its quality.

Liquid insulation Bronya has a complex multi-level structure, in which all 3 above-mentioned methods of heat transfer are minimized. It consists of 80% microspheres, and 20% of binders - this suggests that with such a heater, heat loss is insignificant.

In the photo - the principle of operation of liquid ceramic insulation

It's important to know! An important role in the effectiveness of any insulation is played by its thickness: the thicker it is, the better. The instruction manual indicates that the thickness of the heat-insulating layer Bronya can be from 1-6 mm (the subsequent increase will be meaningless, since the insulation will not acquire any new properties).

Varieties of liquid insulation

Today, ultra-thin liquid Armor comes in the following modifications:

- Classic. It is a basic, universal liquid insulation that can be used with surface temperatures from -60ºC to + 200ºC.

- Anticorrosive. Perhaps the only liquid insulation that can be applied directly to rust, without thoroughly cleaning the surface. It is enough just to remove loose rust with a metal brush and then, following the instructions, apply a layer of Anticorrosive Armor.

Anticorrosive - the ideal choice for metal surfaces

Agree, a noticeable saving of money and time - you don't have to specially prepare a work surface (for example, a pipeline). You just need to apply Antikor as the first layer, and for subsequent layers use the Classic liquid insulation (in order to save money).

- Winter. The uniqueness of the Bronya Zima insulation lies in the fact that it can be applied at outdoor temperatures down to -35ºC. The minimum temperature for applying other types of liquid Armor cannot be below + 5ºC.

With the Winter modification, weather conditions are not terrible for repairs!

- Facade. This liquid material can be applied up to 1 mm thick in one go! The process of insulating facades is significantly accelerated. In addition, this modification has an increased ability to pass steam through itself - and this is important for external wall insulation.

Special insulation for building facades

Helpful information! Soon, new modifications will be released - Anti-condensation (prevents the formation of condensation as much as possible) and Vulcan (retains its effectiveness at any high temperatures up to + 540 ° C).

Positive aspects of Bronya liquid heaters

Interesting brochure for your reference

- They can be applied to a wide variety of surfaces (and of any shape) - metal, concrete, brick, plastic and other building materials, as well as to air ducts, pipelines and equipment.

- They have excellent adhesion to any surfaces, which ensures their high-quality insulation from moisture, temperature extremes and precipitation.

- They significantly increase the anti-corrosion protection and prevent the formation of condensation.

- They have high thermal insulation performance: a 1 mm layer of liquid insulation creates the same insulation as a 5 cm roll material or a brick wall 1.5 bricks thick.

- They have absolutely no load on the surfaces to be insulated.

- In addition, they prevent deformations of metal structures that can occur due to temperature extremes.

- Layers of liquid armor are not destroyed by ultraviolet rays.

- They do not support combustion: at + 260ºC they carbonize, and at +800 ºC they decompose and release carbon and nitrogen oxides, which slows down the spread of the flame.

Operating temperature range of heaters Bronya

- They are non-toxic and do not contain harmful compounds, and therefore are environmentally friendly materials.

- Resistant to alkalis.

- Apply quickly and easily with your own hands using a brush or airless sprayer. Reduced time and labor costs are evident. By the way, the time for complete drying of one layer of Bronya is 24 hours.

- With such material, access to inspection of the insulated surface is always open. If damage is found, the thermal insulation layer can be repaired without problems.