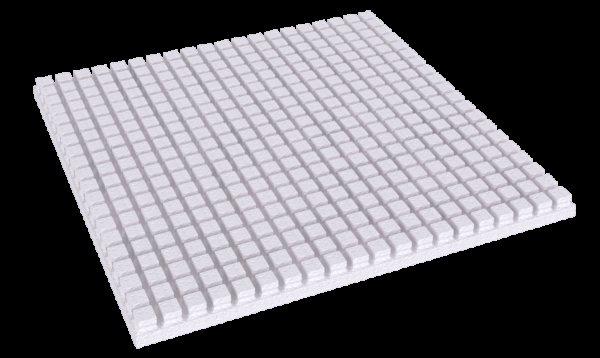

With lugs

Rectangular very high density expanded polystyrene foam mat... Substrate thickness from 10 mm to 35 mm. The lugs are cylinders or cubes 20–25 mm high. Pipes with a diameter of 14 mm to 20 mm are laid between the lugs. The protrusions serve as a reliable lock when pouring the mortar. The risk of the pipes moving is zero.

Attention

The price of the material with bosses is higher than for ordinary polystyrene foam mats, but it pays off during installation.

Benefits:

- curly protrusions facilitate pipe laying and fixation;

- additional fastening of pipes, extra layers before pouring the screed does not require;

- helps to evenly distribute the heat-conducting elements of the system;

- provides high noise, heat and waterproofing.

Boss slabs are available in both conventional and laminated mats. Conventional ones have low thermal insulation properties and are more suitable for a frame for laying pipes.

Under a warm water floor

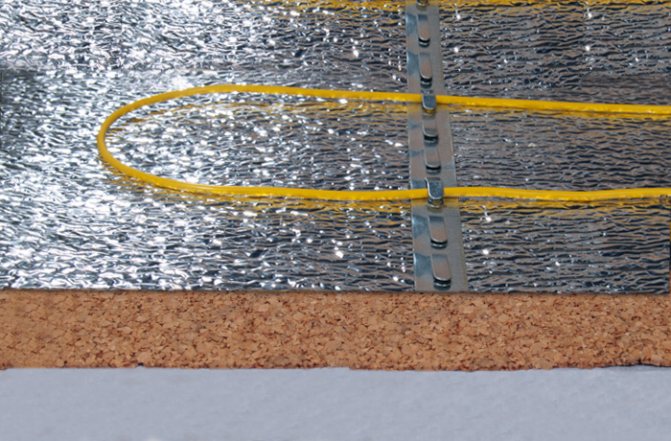

Water-based underfloor heating is quite popular due to its economical operation and ease of installation. When using a water system for underfloor heating, you must take care of the presence of a special layer in advance. It is made of expanded polystyrene, a little less often you can find cork lining or isoplata.

The correct underfloor heating will ensure that warm air rises upwards, thereby making the structure work optimally. Thanks to the high technologies used in production, polystyrene foam substrates have a lot of advantages:

- Provide additional heat and sound insulation;

- Virtually no moisture absorption, fireproof;

- They help to keep warm, which means they are economical and environmentally friendly;

- Maintain structure and integrity even with sudden changes in temperature;

- Very durable - the minimum service life is 100 years.

Foil

Products based on:

- plate extruded polystyrene foam;

- foam;

- polyethylene;

- cork material.

Advice

Foil film provides an increase in the technical characteristics of any base material, transfers its reflex qualities to it.

Aluminum and lavsan are used as a reflective outer coating. Depending on the thickness of the foil layer, the degree of heat-reflecting properties changes. Lavsan is highly resistant to aggressive environmental conditions - even with prolonged contact with a concrete screed, its reflective function and water resistance are preserved.

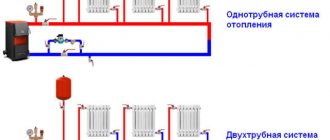

Heat-reflective materials for underfloor heating

Currently, there are several types of underfloor heating, but, regardless of the design of the heating system, in all cases, the use of a heat-reflecting screen is required. This material is used as a thermal shield, which increases the efficiency of the heating system and ensures the spread of heat fluxes in the desired direction. This ensures that the temperature near the floor is almost the same as the temperature at the head level for maximum comfort. Today there are many heat-reflecting materials, and the most widely used are special coatings isolon, infraflex and penofol.

Izolon

Izolon is a Russian trade mark under which polyethylene foam is produced, foamed in a special way. This heat-reflecting material is made on the basis of polyethylene and polyester, it has a coating of metallized lavsan. It is a modern, environmentally friendly material that stops heat. It is of two types:

- Gas-filled isolon (isolon NPE)

- Physically cross-linked isolon (isolon PPE)

Gas-filled isolon (NPE) is obtained in the process of foaming polyethylene (polymer) by introducing carbon dioxide into the polymer melted to a liquid state. For this, the most modern special equipment is used. As a result of processing, the smallest gas bubbles with a uniform structure and closed pores are formed in the structure of polyethylene.

Physically cross-linked isolone (PES) is manufactured using a special technology consisting of three separate processes, each of which is foaming the polymer in different directions with the help of air. In this case, polyethylene is brought to a liquid state, due to which the material receives a coherent transverse structure.

Isolone and NPE technical characteristics PPE determines the substance of which its base consists. Currently, polyethylene foam of various thickness, density and structure is produced, therefore, the technical characteristics of the isolon vary depending on the characteristics of the expanded polyethylene.

The technical characteristics of Isolone and PPE and NPE are determined by the substance from which it is made, namely, pure polyethylene.

Isolon general properties:

- Possesses unique thermal insulation properties. Its thermal conductivity coefficient is minimal. The thermal conductivity of the PPE isolon is 0.031 W / mK at a density of 33 kg / m3, and the NPE isolon is 0.040 W / mK at a density of 26 kg / m3.

- Differs in low hygroscopicity. The water absorption coefficient of this material is less than 1%. Due to its closed porous structure, it does not allow steam and water to pass through, and does not absorb moisture.

- It is a flexible soft material with a low specific gravity that does not lose its flexibility at temperatures down to –60 ° C. It has low permanent deformation and does not break on bends.

- Differs in durability. Its service life is 80-90 years. It does not deteriorate and does not rot, it is resistant to external weathering and high temperatures.

- It is an environmentally friendly material that is safe for health and the environment and does not pose a hazard even in contact with food and human skin. When ignited, the isolon decomposes into water and carbon dioxide, without emitting toxic substances.

- Possesses excellent insulating properties even with the smallest web thickness.

- Resistant to chemical attack.

- It has a high heat reflectance, reflects up to 97% of heat, and emits only 3%.

Infraflex

Another widespread material is Infraflex. This is a heat-reflecting film based on polyester and polyethylene, on one side covered with a layer of metallized lavsan with a special printed pattern. Infraflex is an environmentally friendly, lightweight, flexible and thin material that is able to stop heat, store and transfer it in the right direction.

In terms of its technical characteristics and operational properties, Infraflex practically does not differ from Isolon, its use is possible when installing a warm floor under any floor covering.

Penofol

No less often, when laying a warm floor under a laminate, a heat-reflecting coating such as penofol is used. It consists of a layer of polyethylene foam and one or two layers of aluminum foil. Penofol has unique properties and combines the unsurpassed heat-insulating characteristics of air bubbles and the high heat-reflecting characteristics of aluminum foil. This combination made it possible to create an excellent material for use as a special layer in warm floors under laminate flooring.

General properties of penofol:

- Has a high heat reflectivity. Due to the unique natural properties of pure (up to 94.4%) aluminum, this figure is 95% -97%.

- Has a low heat-emitting ability. The same aluminum layer reduces this figure to 3% -5%.

- The surface of penofol remains practically cold even at a sufficiently high heating temperature of the warm floor.

- Creates additional thermal resistance and prevents heat loss.

- Has a low coefficient of water absorption and vapor permeability.

- Does not require the use of additional vapor barrier and waterproof films.

- Protects the room from harmful electromagnetic radiation and reduces their level by more than 20 times.

- Provides protection against radon radiation.

Styrofoam

Industrial foaming of polystyrene forms the material of expanded polystyrene... The finished product consists of only 2% of the main substance, auxiliary additives and 98% of gas. The air is contained in hermetically welded cells, which gives the material good thermal protection properties.

Important

Expanded polystyrene with a thickness of 10 cm in terms of thermal conductivity is similar to wood with a layer of 35 cm, in a reinforced concrete wall at 480 cm, in a brick wall - 150 cm.

Benefits of expanded polystyrene:

- low thermal conductivity;

- high water resistance;

- low moisture absorption;

- resistance to deformation.

Of the shortcomings, they note:

- low sound insulation capacity;

- flammability;

- deformation when exposed to kerosene, solvents, turpentine, acetone.

It is not recommended to use unpressed or autoclaved polystyrene foam due to their increased fragility.

Heat reflective

Polypropylene is an excellent material for insulation... For laying under warm water floors, polypropylene is chosen, which has a special foil or metallized layer of lavsan. The metallized or foil-coated component has high heat-reflecting properties, so the heat does not go down.

Metallized film

Attention

The metallized film is obtained by combining three layers of polystyrene foam (lavsan, cork material, foamed polyethylene), foil and polymer film.

This film has a high density, which ensures reliable fixation of fasteners. Suitable for installation under all types of underfloor heating, including under water.

Benefits:

- heavy duty;

- quickly restores its original form;

- resistant to fire, temperature changes;

- can be laid on uneven surfaces;

- easy to assemble;

- retains its heat-reflecting function for a long time.

Of the minuses, they note:

- afraid of moisture, it is necessary to lay waterproofing over the substrate;

- additional pipe fittings are required.

Secrets of installing substrates under the infrared floor

In order for the film system to function correctly, it is necessary to install the components as efficiently as possible.

The correct laying of the underfloor heating is very important, and when working with it, it is worth knowing some features:

- If the underfloor heating is made of fiberboard or magnesite tiles, it is laid on a screed covered with aluminum foil;

- If it is made of a polymer metallized film, then it is placed under a film with infrared resistors, reflecting side up;

- The insulation material is applied in a continuous mass over the entire surface.

If individual elements of the substrate require connection, this can be done with tape or ordinary adhesive tape, which will give additional vapor and waterproofing properties.

Substrate under a modern warm floor is very important when installing the system. This detail will allow you to fully experience the capabilities of heating systems, and will help the house keep warm inside.

Cork

The cork lining contains crushed compressed bark pellets and binders. Produced in separate sheet mats or rolls. Thickness in rolls - 2–4 mm, in sheets - 4–10 mm.

Cork advantages:

- natural, environmentally friendly;

- hypoallergenic;

- resistant to deformation, quickly returns to its original shape;

- has high noise insulation due to porosity;

- good thermal insulation;

- easy to cut and lay.

Cons of a cork product:

- afraid of water;

- waterproofing over the substrate is required;

- does not withstand large static loads.

In addition to the cork lining, there is a rubber-cork lining with rubber. Waterproof, with increased sound and vibration isolation, it is more suitable for a warm water floor. However, it is no longer completely natural.

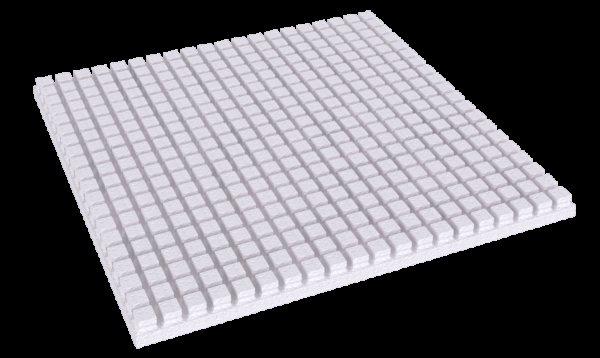

In the form of mats

Styrofoam mats are covered with foil or foil, sometimes with both materials. They have the advantages of expanded polystyrene boards, but are improved by the presence of several layers.

Advice

On some models, the film has a self-adhesive backing protected by a backing. When installing these mats, you do not need to use waterproof tape.

Mats are realized in the form of panels, but for ease of installation it is better to take them in separate fragments in order to easily fit to each other and connect using a foil film covering, produced in the form of a roll. The mat backing allows a large surface area to be covered immediately. Harpoons are used to attach pipes to mats. But you can also use mounting strips tied to the reinforcing mesh.

Installation of polystyrene mats is quick and easy... For example, without a screed construction, it will take about an hour to install a substrate in a room of 10-15 m2.

Foamed polystyrene mats are made by hydropellant stamping, the density of the products is 40 kg / m3, the thickness is from 20 mm to 50 mm.

Clips or tapes are used to connect the mats. With this method of connection, hollow seams are not formed, the noise level is reduced to 25 decibels.

Here are the advantages:

- no fixing fasteners required;

- it becomes possible to quickly lay heating circuits;

- easy assembly speeds up installation;

- consumables are included with the mats.

The disadvantages include the inability to lay pipes with a diameter of more than 20 mm.

Varieties and characteristics of the substrate

So, when buying a heat-insulating flooring, you, first of all, have to navigate in its variety of types:

- Lavsan - coating on a film basis (foamed polyethylene) with a metallized reflective top layer. It is characterized by resistance to aggressive environments. Lavsan underlay under the film warm floor fits perfectly.

In the photo, laid lavsan.

Note! This type of insulation is characterized by a certain specific power. Therefore, the choice must be made taking into account the topcoat.

So, when installed under a tile, the UM of lavsan is 220W per m²; for laminate / parquet - 150W per m²; under carpet / linoleum - 220W per m². If you install the film with a PA higher than the specified one, then the floor covering may deteriorate from overheating.

- Expanded polystyrene - cellular insulation. Differs in a high temperature threshold: from -180 ° to + 180 °, crease resistance. It is an excellent sound insulator, has increased resistance to bacteriological effects. Has a foil or polypropylene coating. It is considered an excellent substrate for a water-heated floor.

Expanded polystyrene plates.

A distinctive feature of this heat insulator is that it is produced in slabs with ready-made markings (50 to 50), which greatly simplifies the subsequent process of floor installation. Slabs are available in various thicknesses: from 20 to 50 mm.

- Technical cork, cork backing... Differs in environmental friendliness, and therefore hypoallergenic. Its composition is pressed cork oak bark + astringent - suberin. It is not eaten by rodents. As a rule, cork is used as a substrate for a laminate on a warm floor.

Despite such its composition, the insulation is not combustible, and shows excellent resistance to mechanical stress. It is optimal for arranging a water floor.

Cork backing in sheets.

- Polypropylene (penofol)... Combined insulation consists of polyethylene foam. One side of it is covered with foil. Thanks to this structure, polypropylene has a high heat retention rate. It is somewhat inferior to the cork analogue in its qualities. Such a foil underfloor heating underfloor is distinguished by its practicality and durability.

Polypropylene insulation.

Note! The substrate should not contain aluminum as it conducts electricity very well. Therefore, in the event of a marriage of contacts, a short circuit is possible.

Functions of the insulating deck

If you are wondering whether you need a substrate for an infrared warm floor, then you should pay attention to the following functions of the flooring:

- The main task is to reduce heat loss. The underlay directs the infrared rays into the room, preventing them from spreading to the lower floors or basement of the building. Due to this reflection, heat is not wasted, and the system efficiency is 95-100%. The use of such insulation can reduce heat loss by an average of 20-30%.

- As mentioned above, the underlay acts as a waterproofing layer, protecting the floor from steam and moisture.

- It is able to smooth out minor surface imperfections, which is very important when using film-type floors.

- High-quality insulation, such as Valtec underfloor heating, can significantly reduce the amount of noise. It is made of expanded polystyrene and has a foil side.

Film floor device.

Note! Fiberboard can be used as the underlayment for coatings that require a solid base (support for a tile covering, for example).

How to choose a quality product

The main criterion for choosing this material is not the price, but the technical characteristics, which should be based on two criteria:

- Finish coating... For example, if you are planning to lay laminate flooring, you should choose a soft backing, as it perfectly levels the base. For linoleum, it is recommended to choose solid thermal insulation, since this coating is a soft material, therefore, together with a soft insulation, it can easily be pressed through by the legs of furniture.

- Evenness of the floor... If you are dealing with a coating that is characterized by significant level differences, then you should choose soft thermal insulation, since it is more ductile. If the unevenness is small, it is better to choose a harder flooring.

Expanded polystyrene smooth boards

Often the substrate for a warm water floor is made with smooth polystyrene foam plates for the underfloor heating system. Thickness - 4–5 cm, density - 40 kg / 1 m3, resistant to deformation. To protect the slabs from the aggressive effects of the concrete mix, before pouring the screed, they are covered with plastic wrap. The pipes are easily attached to the slabs with plastic clips.

Important

You can use polystyrene foam boards under a warm floor, which serves as the main heating of the room. The downside is the lack of markup on it. You will have to do it yourself before laying the heating circuit.

Advantages of expanded polystyrene boards:

- have a strong vapor barrier polystyrene foam layer, so condensation does not form;

- if there is a foil laminated coating on the plates, you can not be afraid to spoil the material with chemicals in the composition of the screed;

- easy to fit due to light weight and size;

- equipped with locks on the sides - there are no acoustic and cold joints when joining the plates;

- durable with proper operation - about 50 years;

- do not change the thickness under the weight of the screed.

Laminate underlay

Currently, laminate is almost the most popular flooring: it has a reasonable price, looks very similar to parquet, and its installation is very simple. If you plan to install heating under the laminate, you must take care that a lining is installed under the underfloor heating system, which will help protect the tree from overheating. Otherwise, on areas of the floor with a gap between the laminate and the base, backlash will form, and the coating itself will knock heavily.

To avoid such problems, a special thin (2-5 mm) part is placed under the laminate, which has increased thermal conductivity.

Such a move will not only avoid damage to the boards, but also become a heater, equalize possible height differences and prevent the laminate from squeaking. This backing is usually foil and is placed under a warm floor, where, in addition to the functions of leveling the laminate, it also helps to keep warm.

Foil underlay for laminate.

This component is mounted between the heating elements and the laminate. The manufacturers of wood flooring themselves advise using roll-type polyethylene for lining. A substrate made of such a material combines well with concrete and cement, it is poorly exposed to chemical compounds and living organisms. But in addition to being compatible with the final flooring, the substrate should be well combined with the selected type of underfloor heating, which will be discussed further.