Varieties

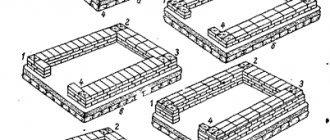

The cork is produced in the form:

- agglomerate - white and black;

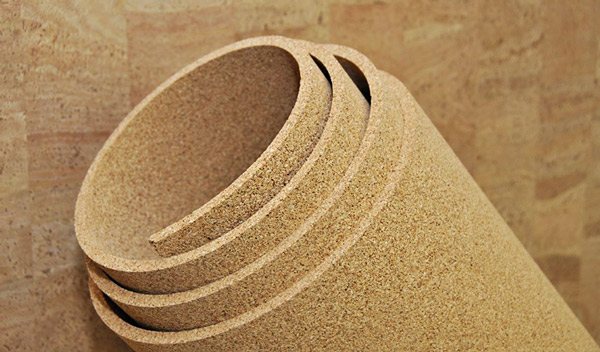

- roll material;

- dense slabs.

White agglomerate

This type of insulation is used for interior work and does not require finishing; it is obtained from the bark from the branches of a tree. Under the influence of high temperature, the crushed material is pressed using glue. Plates have:

- fire resistance class M3;

- high density up to 130 kg / m3;

- minimum percentage of moisture;

- and high sound absorption coefficient.

Due to its low weight and thickness, white agglomerate is suitable for interior insulation, interior decoration and as a sound insulation material.

Black agglomerate

Black cork insulation is used for interior work, it is produced in the form of slabs. It consists of compressed granules. They are heated and partially charred, which gives the material a dark color.

Black agglomerate is intended for insulation of roofs, walls, suspended ceilings, floors, and also as a sound insulation material. The panels do not absorb moisture, they are resistant to the formation of harmful bacteria and mold. Material properties:

- density from 95 to 130 kg / m3;

- thermal conductivity -0.040 W / mk;

- low vapor permeability;

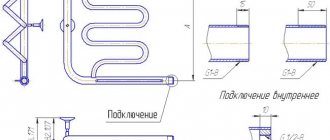

Roll option

It comes in a variety of grain sizes and thicknesses. On average, the roll length is 25 square meters. m., it is used as a substrate for parquet, laminate and as a heater for walls.

Roll cork is not used for underfloor heating. The material has high thermal insulating properties and therefore the heat from the source will warm up the floor, and not the floor and air in the room.

Tile

This is a thicker type of material, used for external and internal work during the installation of the roof, for insulation of the foundation and external walls. Used for suburban residential buildings and high-rise buildings.

Tiles can be single-layer or two-layer. The latter option is produced with painting, toning or varnished. Two-layer tiles do not need finishing and can be used in the interior of an apartment or house.

Getting a technical plug

The waste bark of the balsa tree is crushed and then pressed and steamed. Sometimes binders are used, but you can do without them, since the cork contains natural glue.

The technology for manufacturing cork products is called agglomeration. At the same time, they differ in color: dark - is obtained from the bark of the trunk, and light - from the bark of the branches.

Dark and light agglomerate

Note! The cellular structure of the material provides high sound insulation, and also does not allow gas and water to pass through.

Is it possible to insulate outside

Cork cover is also used for facades, as it has the following advantages:

- helps to keep warm;

- reduces noise level;

- does not collapse under the influence of temperature drops and atmospheric precipitation;

- has a service life of about 25 years.

For the finishing of facades, a liquid cork is used, which is applied to the surface in several layers using a spray gun. The material has a large color palette and is not demanding to care for.

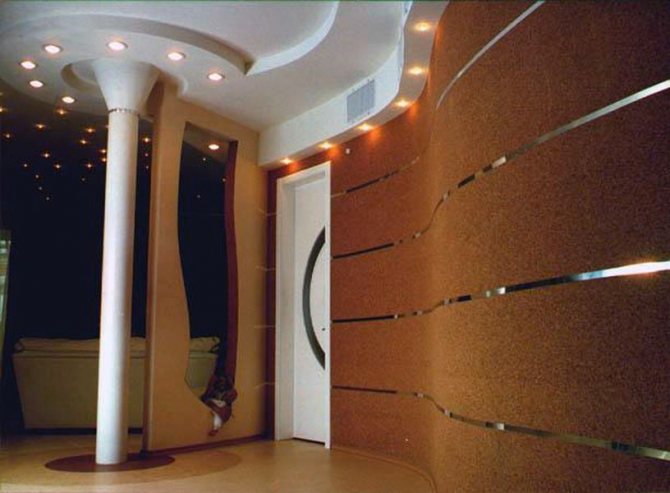

Cork coverings

The surfaces in the apartment can be insulated and protected from sound with different types of cork coverings, which are available in the following forms:

- Wallpaper.

- Panels or tiles.

- Rolls.

- Liquid coating.

- Technical plug.

Cork wallpaper

They are based on paper, which makes the coating thin, no more than 1 mm thick, convenient to use, thanks to this, there is no need to make substrates for cork wallpaper. Wallpaper is used to cover the walls.They are glued with ordinary glue. Cork wallpaper must be glued end-to-end, the service life is about 10 years. They are produced in the form of a continuous sheet, rolls, self-adhesive material.

Panels or tiles

Their dimensions can be 600 by 600 or 300 by 300, with a thickness of 3 mm. Panels or tiles are made from granular cork under high pressure, pressure and temperature. The tile can contain various blotches, be colored.

The panels have excellent properties and characteristics of sound insulation, serve from 10 to 30 years. The use of such material in an apartment will allow not only to get rid of noise, but also to keep the room warm in the winter, or to cool the apartment in the summer.

Rolls

This type of cork coating is produced in the form of a single two-millimeter layer, which has a width of 500 mm. The bottom of the rolls is made of press-processed granular cork, and the top is made of cork veneer. The cork rolls that cover the walls are waxed on top. Rolls are used as a substrate for laminate, wood, stone or ceramic surfaces.

Related article: Tecsound soundproofing review

Liquid coating

According to its composition, it is cork chips, which are bound with an acrylic substance. The liquid cork coating should be applied to the walls with a spatula or with a special spray gun.

This type of coating is characterized by the following properties:

- Soundproof and insulate the room.

- Suitable for cladding facades, walls outside and inside, ceilings.

- It is used to insulate attics and basements, to create a waterproofing system on roofs and terraces.

- It will be used to create warm floors.

Technical plug

Suitable for leveling walls, ceilings and floors. Possesses high properties of heat, noise and sound insulation. It is produced in sheets that resemble chipboard outwardly, in rolls, in the form of an acoustic bedding. Technical cork does not have a veneer top layer, so prices for the material are lower than for liquid cork coating. The technical cork also lacks wax and varnish. It is used mainly to insulate walls, replace carpet, linoleum.

Is it possible to insulate in the corridor

The cork in the form of slabs or rolls is suitable for internal insulation of the corridor in the apartment It can be used for those walls that border a staircase or staircase. Thanks to its high sound insulation performance, you can also reduce the noise level from neighbors.

The cork cover has a soft structure that is not resistant to mechanical damage. Therefore, it should not be glued to the lower parts of the walls without additional finishing if there is a small child or animals in the house.

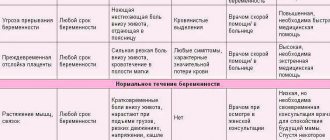

What is the soundproofing of walls?

In the construction industry, noises are classified into three groups:

- Airborne noise (sounds of animals, people, cars, etc.);

- Impact noise (sound caused by impact on a surface that is soundproofed);

- Structural noise (sounds of any nature that can be transmitted through the structure of a building in the form of vibrations).

Modern materials, with the help of which it is possible to produce soundproofing of walls, are able to extinguish noise of all three of the above categories. However, each material has its own vibration and sound damping coefficients.

How is cork insulation installed?

It is difficult to fix incorrectly glued cork insulation, as it will crumble when peeled off.

Before starting work, you need to check the base, if necessary, level it. This will provide a more convenient gluing of the boards or roll cork. Then you need to apply a primer to the surface.

Roll material is glued in the same way as for ordinary wallpaper:

- First, a vertical line is applied on the wall, along which the first sheet is aligned.

- Then the roll is cut into pieces of the required length.

- On the back side, glue is applied and applied to the wall, then gently leveled.

- 4. When installing the slabs, it is necessary to make markings on the wall. To do this, you need to draw vertical and horizontal lines. You need to glue the plates in rows parallel to the floor. It is better to start work from the bottom of the wall.

The cork adhesive is the one recommended by the manufacturer. You can also use an all-purpose acrylic adhesive.

Insulation made from natural material does not emit toxic substances into the room. Therefore, it can be used even for children's rooms. The only drawback of cork insulation is its high price. But do not skimp on high-quality sound and heat insulation.

Wall soundproofing prices.

Considering that the area of apartments in which half of the population of Russia lives is small, then the estimate for the soundproofing work will be quite acceptable. For example:

- Gypsum for grouting cracks and sealing holes in the wall - from 5 rubles per kilogram;

- Metal profile for laying soundproofing material and fixing drywall - from 20 to 75 rubles per running meter;

- MaxForte is a standard, sound-insulating material, the best that exists in the vastness of Russia - the price per square meter is 790 rubles;

- Drywall, depending on its characteristics (moisture resistance, flexibility, thickness, and so on) - from 230 to 1500 rubles

- plus various costs, for example, for assembly foam, paint for decoration, wallpaper, and so on.

According to the area of your apartment, you can calculate how much peace and quiet in your house will cost, which means that it is a great opportunity to relax after a working day in the circle of relatives without listening to the abuse of neighbors behind the wall.

Video

Correct application of cork to floor, wall and ceiling at the same time provides an effective sound barrier against external sounds. When performing work, it is important to understand the sources of noise and how to reduce it.

Cork is used to insulate walls, ceilings and floors in an apartment or house. This material is made from the bark of cork oak, which has a cellular structure, does not transmit sounds and does not get wet. Therefore, a cork backing for wallpaper is great for complete sound and noise insulation of an apartment.

Cork soundproofing: a look from the inside

The range of uses for cork bark is not very wide. The main direction is the production of bottle caps, lifebuoys and shoes. In the manufacture of these products, about 60% of waste is generated. In economical Europe, namely in Portugal, Spain, France, where this type of oak is grown and the vast majority of cork products are produced, such waste is unacceptable. They are looking for a new use for waste from production, and in our case, this resulted in a cork covering.

Why is it good? First, the coating is natural and environmentally friendly. There are no harmful vapors, odors or environmental impacts from it. the material itself is organic. The chemical composition is as follows:

- Carbon 62-67%

- Hydrogen 7-8%

- Oxygen 21-27%

- Nitrogen 1-3%

The percentage varies depending on the method of processing the bark of the tree. Secondly, a low level of thermal conductivity - 0.042 W / (m * K). It is due precisely to the high content of gases in the structure of the material. For comparison, 3 centimeters of cork covering in terms of thermal insulation properties is equal to 3.5 centimeters of mineral wool, 10 centimeters of pine, 15 centimeters of oak, 20 centimeters of aerated concrete or 40 centimeters of brickwork.

Third, good sound insulation. The sound absorption coefficient at 2.1 kHz is 0.85.This material most effectively absorbs high-frequency sounds (screaming, barking, TV sound). The situation is worse with low frequency noise and vibration. A noise reduction of 40 decibels is achieved with a coating thickness of 1 centimeter. To achieve equivalent results, you will need 1.5 cm of mineral wool, 10 cm of wood, 30 cm of aerated concrete or 70 cm of brickwork. It is worth noting, however, that oak bark, like any other noise-canceling material, does its job best when it is directly in front of the noise source.

If you have a noisy neighbor behind the wall, then covering the wall with a 1 cm layer of cork, you will not feel much difference. The drop in the noise level will be about 20 dB (street noise is 70-80 dB, noise in office premises fluctuates within 50-60 dB, conversation - 40-45 dB). In other words, having pasted over the wall in the room, you will hear worse squabbles from neighbors, but they will not hear you at all. Therefore, for better insulation, you should take a comprehensive approach to isolating the room, or increase the layer of noise-suppressing coating. Fourthly, the cork is soft and elastic, washable well, does not absorb moisture and is antistatic, dust does not settle on it.

Top 5 materials for interior insulation of an apartment and a house

What materials for internal wall insulation can be used in an apartment or a private house. In a previous article, I shared my own experience with internal thermal insulation, now it's worth understanding the variety of heaters.

Compiled a rating of the most popular and optimal materials for internal insulation.

1. POLYSTYRENE FOAM (PS, PSB, PSB-S-20). Polyfoam can be used to insulate walls, ceilings, and even floors, since it is produced with different density grades. For floors, PSB-S-50 is recommended, which has a high density, is resistant to stress and any weather conditions.

PSB-S-15 is the least dense of expanded polystyrene foam. They are recommended to insulate outdoor loggias, balconies, attic rooms. The choice of density is yours, since the difference in price is not significant.

Pros:

- Excellent heat and sound insulation

- long service life

- do-it-yourself installation

- inexpensive price.

It is glued with special glue on previously prepared surfaces, fixed with "umbrellas" - special plastic dowels, putty.

Minuses:

- Low strength

- inability to use without decorative trim

- a noticeable reduction in the dimensions of your room (here it depends on the thickness of the material). This is a fly in the ointment, without which it is difficult to find any kind of insulation.

2. PENOFOL, YUTAFOL (AND OTHER FOILED HEAT INSULATION). Foil insulation with high heat and sound insulation properties and good waterproofing due to aluminum foil.

Related article: Do-it-yourself wall insulation with foam plastic inside the house

Its disadvantage is that penofol is attached to the wall by its crate, on which drywall is then installed, and this significantly affects the dimensions of the room.

Such foil insulation is recommended to be used in addition to the main thermal insulation - as a vapor barrier. The thickness of the material is up to 10 mm and it is sold in rolls of 10 m.

Foil penofol is well suited for:

- country houses

- unheated premises

- balconies

- loggias

- in places with a danger of dampness and moisture.

3. THERMAL INSULATING PLASTER. Sold packaged in bags of various weights. It is not inferior in its characteristics to expanded polystyrene. Fire-fighting properties at a height, environmentally friendly, does not require any additional materials (diluted with water). I will not write recommendations for use, each manufacturer makes its own adjustments. Thermal insulating plasters are mineral and organic.

- MINERAL PLASTER consists of mineral porous materials, expanded at high temperatures (such as vermiculite and perlite). Such mixtures are treated with water repellents, as they are too hygroscopic. In mineral fillers, a hollow foam glass ball is used, which does not absorb moisture, and its mechanical strength is high.

- ORGANIC PLASTER. Foamed polystyrene is used in organic fillers, these plasters are softer, unlike mineral mixtures. Also waterproof like foam glass balls. Carrying out work on applying plaster does not require special skills - it is applied directly to the wall, without using a plaster mesh. After drying, it is monolithically connected not only with brick and concrete, but also with glass and metal. There is a huge selection of such mixtures on the market.

4. LIQUID THERMAL INSULATION... The Internet is replete with advertisements of various types of this material. BUT! Nowhere can they reasonably explain the process itself, how this type of thermal insulation works. In the reviews and on the forums, basically the same questions are asked - how effectively and is it advisable to use liquid thermal insulation for walls, ceilings and floors in living quarters.

Although there are positive reviews on the use of such materials for pipelines and in places that are difficult to access for conventional types of insulation. There is a large selection of liquid insulation in the form of paints on the market, so if you want to take a chance, please. But in the reviews of those who have already used liquid insulation for living quarters, the preponderance is towards the negative. I have not had a chance to use a liquid heat insulator, so I will neither scold nor praise, I also would not like to duplicate advertising information here.

5. ROLL INSULATORS for walls for wallpaper and painting are presented on the market in several versions. These are CORK insulation and POLYSTYREN FOAM insulation rolls. A few words about these subtle, but based on experience and reviews - quite effective heat insulators.

- Cork roll insulation, as well as decorative wall coverings (wallpaper, or plates), are made from cork chips by pressing with cork veneer and wax applied. The cork covered with wax is used for decoration and insulation of walls, even in damp rooms. The thickness of cork insulation is from 2mm to 30mm, so the scope of its application is varied - from wallpaper to insulation of walls, ceilings or floors with plates or slabs. Cork insulation does not emit harmful substances during combustion, is not afraid of mold and mildew, is breathable, has low thermal conductivity, and is environmentally friendly. It is easy to stick it on yourself. One of the drawbacks is the high price for this material, but after gluing you can not do any finishing work, since the cork itself has a natural decorative effect and fits well into most interior styles. I put my subjective plus on the cork because it can be safely used in the nursery.

- POLY STYrene foam roll insulation is produced in rolls from 50 to 100 cm wide and up to 10 m long and up to 10 mm thick. It is made from a thin layer of polystyrene. On one side, the insulation is covered with cardboard or a thin layer of paper. It is glued like cork - on special glue. Expanded polystyrene insulation is an environmentally friendly material, since freon is not used for its production, and even during combustion it does not emit toxic substances and gases. Low thermal conductivity and vapor permeability, ease of use, environmental friendliness, rather low price have earned a good reputation for this insulation.

These are far from all the materials for internal insulation, but I tried to describe in a nutshell the most used ones that give results. Wrote an article on the pros and cons of internal insulation.

There is also polyurethane foam, polystyrene foam plates, mineral wool (by the way, it is very popular in the northern states of America for insulating private houses), foam concrete, foam glass and up to nanotechnology. BUT working with them requires certain skills and special equipment. So we will leave it to the specialists and try to cope with the problem ourselves.

Related article: Tolerances when laying walls from blocks

How to insulate the inside of the wall with your own hands with roll insulation

A common insulation is roll. DIY installation technique:

- The surface of the wall must be prepared: cleaned from the old coating, sanded irregularities and cracks.

- Prime and allow to dry completely. Sometimes it is necessary to repeat the procedure if the wall has large roughness.

- Then measure off the required amount of rolled insulation, be sure to leave a small gap. Cut into equal pieces.

- Prepare the adhesive solution strictly according to the instructions. Some types of Polyphome are self-adhesive.

- Next, you need to glue the insulation, in almost the same way as the wallpaper. It is important to smooth out and eliminate air bubbles.

- The last step is to seal all joints with masking tape.

Related article: How to seal the seam between the wall and the bathroom

After finishing the work, you need to wait a while, usually from one to three days. This is indicated in the instructions. Then you can carry out further finishing.

When making repairs in an apartment, you should definitely pay attention to the issue of keeping warm. Modern materials have great functionality, the main thing is to choose the right one and consult with specialists. The most popular are roll and cork insulation. By following the advice, the material is easy to install by yourself.

Noise insulation of walls

Cork works well on walls. Before applying it, all cracks in the walls should be repaired. The sound travels well through the holes for sockets and switches. In the presence of voids, they are laid with dense mineral wool, after which the hole is sealed with cement mortar or putty. The socket is then reinstalled.

Noise insulation of walls

In panel houses, noise is transmitted at the joints of the slabs. It can be significantly reduced by removing the plaster at the corners and filling the joints with polyurethane foam. This is not necessary in monolithic structures.

Coating features

Before gluing the cork, the walls are primed to increase the strength of the connection. The optimal thickness of the panels is 3 cm. If it is smaller, the wall covering does not give the desired soundproofing effect, and it is not profitable to make it thicker, since the plasterboard construction with mineral wool panels wins in terms of price / quality ratio. It can be combined here by gluing cork wallpaper to a soundproof plasterboard wall as a decorative finish.

Wallpaper is made on a paper base, on which the varnish is first applied, and then agglomerated cork veneer with a thickness of 1 mm is glued.

Cork wallpaper

A thin layer of cork reduces external noise if the following rules are followed:

- Layering improves sound insulation. A thin protective coating is unlikely to help, but a wallpaper backing made of technical cork will already be a little protection against sounds. The result is also given by a structure made of gypsum plasterboard with cork wallpaper glued to it from the outside and a layer of thermal insulation applied from the inside by spraying. You should not count on wallpaper only, due to their small thickness. They will only slightly muffle the sounds inside the room.

- Additional greasing of the joints of cork tiles allows you to obtain a one-piece coating.

- The joints of the upper layers should not coincide with the lower ones.

Can such sound protection be used if it has a directional effect? Obviously, yes, since there is no need to muffle the sounds of TV or audio equipment in the evenings, and children can safely play musical instruments.

Cork tiles should be staggered to the base. If they are thin, make a two-layer coating. In this case, it is better to make the outer layer with veneer, and for the inner one, a technical cork is quite suitable.

The choice of the type of cork covering

There is no particular variety in the form of products. They are available in rolls and sheets.The sheets are very diverse. Their thickness ranges from 2 mm to 50 mm. Panels without veneer are available in black or white agglomerate. The first one is more used for inner layers and a substrate, and the last one is better suited as a finishing material.

The top of the cork can be covered with other decorative material. The simplest is a layer of varnish. In rooms with high humidity, the walls are covered with a sealant varnish. It is applied with a soft roller. After hardening, the wall is not afraid of wet cleaning. If the protective layer is broken, it can be restored by reapplying the varnish.

Ceiling cork

High-quality insulation of an apartment can be done by applying a cork coating to the ceiling surface. To install tiles, rolls or panels, you need a square with a ruler, rubber roller, notched trowel, chopping cord, glue, sponge or rags.

The process of attaching cork material to the ceiling is carried out in stages:

- Check the surface.

- Remove varnish or wallpaper.

- Plaster with sandpaper.

- Level the ceiling with putty or plaster.

- Dry the surface.

- Inspect the plug for possible defects.

- Mark the ceiling using a cord, a square and a pencil, which will help to properly glue the cork panels.

- For large slabs and panels it is recommended that the gluing work be done from the center of the ceiling surface.

- The panels are fixed with waterproof glue, which is applied to the material with a spatula or roller.

- The panel is pressed against the ceiling, and then rolled over it with a roller along its entire length. Remains of glue must be removed with a cloth.

The room in which the work is carried out must be well ventilated, the temperature in it must not be lower than +18. The admissible level of air humidity is 40-60%.

During operation, the ceiling covering must be monitored carefully. During the heating season, the gaps between panels or wallpaper may increase or decrease. This is not a defect, but the properties of the cork coating. It is possible to maintain a stable temperature in the room with the help of different climatic equipment and equipment.

Once a month, the coating should be cleaned of dust and dirt using a damp cloth or vacuum cleaner. To remove stains that cannot be rubbed off with a rag, you need to take fine-grained sandpaper and peel off. Then wipe the place with a damp cloth, and when it dries, cover with wax or varnish.

Cork floors

The floor surface in houses or surfaces where cork is used for insulation is of two types:

The first type of cork flooring is produced in the form of tiles, the thickness of which varies from 2 to 6 mm. One of the sides has an adhesive backing, which makes them easy to attach to the floor. It is necessary to choose adhesive cork floors if long-term use of such material for the floor is planned. For 10 years, the adhesive cork will perform just fine. Then you need to clean it, dry it and apply a layer of varnish on top.

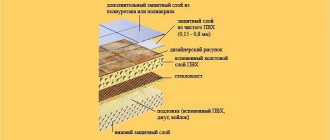

Floating cork floors are in the form of panels, with a thickness of 9 to 12 mm. The panels are fastened to each other according to the thorn-groove system. Floating panels sometimes include a vinyl backing. One of the advantages of such a coating is easy assembly and disassembly if it is necessary to replace the floor covering. There are other options for soundproofing wallpaper substrates.