In almost all gas boilers, a circulation pump is included in the design. If it is installed separately, then the purpose is the same as that of the pump. A circulation pump is required to circulate the heat carrier in the heating system. In addition, it increases the productivity of the gas boiler and reduces fuel consumption.

What is the difference between a double-circuit boiler and a single-circuit one

Scheme of operation of single-circuit and double-circuit boilers

Gas heating equipment can be classified according to the following criteria:

- number of heating circuits provided;

- thermal power that the unit can give out;

- equipment level;

- purpose - household or industrial appliances.

All these plants have one thing in common - they work by burning natural gas.

Hot water supply and heating

In a single-circuit boiler, the heating of the coolant is designed only for radiators

Systems in which only one heat exchanger is provided, designed for connecting radiator lines, is usually called single-circuit. Products of this type have a mechanically simple and reliable design.

In addition to heating, double-circuit units are designed to perform another task - to provide the house with hot water. If there is only one heat exchanger inside, the redistribution of the coolant flow between the circuits is carried out due to the operation of the three-way valve. The priority here is the heating of the liquid, which is used for domestic needs. Systems with two heat exchangers make it possible to connect a separate circuit to each of them.

Overall parameters and power of the installation

The more powerful the device, the larger its linear dimensions will be. The heat output of single-circuit units is selected based on the area of the building, which is equipped with this type of heating. Double-circuit heaters have a peculiarity of poor heat transfer when hot water is drawn from two points. Therefore, in order to avoid the appearance of cold water in the hot tap at the moment of opening the second one, it is necessary:

- install a boiler with a capacity of over 16 kilowatts, if the house has a shower room;

- use units with a heat output of at least 18 kilowatts for apartments with bathrooms;

- use boilers with a capacity of at least 28 kilowatts for rooms where two or more hot water extraction taps are installed.

An area of space of 130-160 squares suggests that a double-circuit or single-circuit gas boiler can often turn on, risking a quick failure of the heat exchangers.

Equipment

Boiler piping elements in the heating system

The complete set of a double-circuit gas heater assumes the presence of:

- valves to protect against high pressure;

- a three-way valve;

- circulation pump;

- expansion tank of membrane type.

Some manufacturers equip boilers with additional heating and hot water filters.

Devices of a single-circuit type, as a rule, are not supplied with associated equipment.

What is a built-in pump for?

Electric heating boiler device with circulation pump

In electric boilers, there are no dimensional or massive elements that are an integral part of the design of other heat sources. Therefore, heating electrical installations are made, as a rule, in a wall-mounted version. At the same time, they are maximally completed with additional elements in order to simplify installation and piping of the boiler on site.One of the most important piping elements built into the heater design is a circulation pump. Its presence in an electric boiler is more than appropriate, especially if the latter provides a secondary circuit for hot water supply. Circulation pumps for boilers solve two problems:

- Forcing the coolant to flow through the pipelines of the heating system at a certain speed.

- In double-circuit electrical installations, they drive the coolant through a flow-through heat exchanger to prepare water for hot water supply.

In single-circuit boilers, the pump only solves the problem of forced circulation of water throughout the entire heating system. Here one nuance arises: the manufacturer supplies its product with a pump, the parameters of which approximately correspond to the power of the electrical installation - the average value of the hydraulic resistance, which the system of a given thermal power should have, is taken.

Wilo circulation pump for heating systems

But there are an infinite number of options for heating schemes, some of them have greater hydraulic resistance than a standard pumping device of a heat generator can overcome. Then an electric boiler with a pump will not be able to supply the coolant to all branches of the system.

A simple example: a standard pumping unit WILO-STAR-RS is able to provide a capacity of 6 m3 / h of heating medium, developing a pressure of 0.8 bar or 8 m wc. If the heat source is located in the basement of a three-storey cottage, then only to overcome the lifting height will require a pressure of about 0.6 bar. And you also need to deliver the coolant along the horizontal branches, the resistance of which is taken in aggregate according to the following ratio: 10 m of the length of the horizontal pipe is considered as 1 m of the riser. And as a result of the calculation, it turns out that an electric boiler with a built-in circulation pump will not cope with its task, the circuit will not function.

Advice. If we are talking about heating buildings with a branched system, long branches or large differences in height, then it is better to perform an enlarged calculation and check its result with the parameters of the pumping device, after consulting with a sales representative of the manufacturer of heat generators. This will save you from buying unnecessary equipment later.

A situation is possible when an electric boiler with a circulation pump has already been purchased, installed, and after that it turned out that the pressure of the standard blower is not enough. In this case, additional costs are inevitable, and the problem can be solved as follows:

- Perform an enlarged calculation of the hydraulic resistance of the system independently or with the assistance of a specialist.

- According to the calculation results, purchase a separate circulation pump.

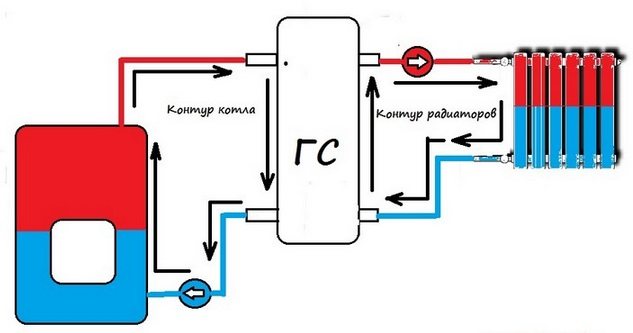

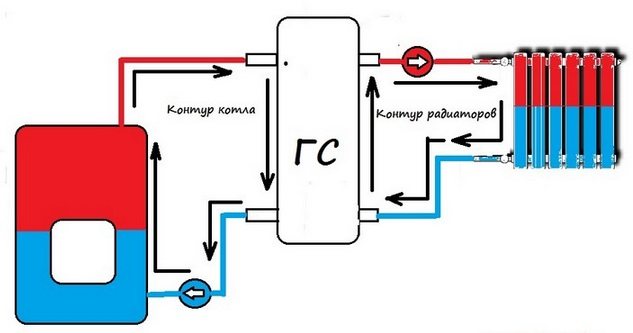

- Introduce a hydraulic separator (hydraulic arrow) into the circuit, then the heater blower will operate in a small circuit.

- Install a separate pump on a large heating circuit, as shown in the diagram:

Heating system with low loss header

How to choose a boiler

Choosing the device for the needs of the room, it is necessary to take into account, first of all, the power of the unit so that it is not less than the heat loss existing in the house. The second task comes down to determining the number of contours. The third - to the choice of the type of design of the device in the matter of the chimney. Other important points:

- The material from which the heat exchanger is made: stainless steel, cast iron or copper coil.

- The design of the product is a hinged device or a floor-standing version.

- Availability of modern automation and electronics.

- The efficiency of the device - the energy efficiency of heating directly depends on it.

Gas heating equipment must meet safety requirements during operation.

How to consistently integrate an auxiliary device into the heating system

To install the circulation pump, use one-pipe or two-pipe system heating. Before starting, be sure to read the instructions supplied with the device. During preparation, water is removed from the piping, then the pipes are cleaned from dirt, corrosion and scale. The device is mounted according to the plan, filled with a coolant and started to operate.

It is preferable to put the pump on the return, using bypass... The latter helps to shut off the fluid flow if it becomes necessary to replace parts or troubleshoot.

Consider the pipe diameter branch: it must be smaller than the main.

Cranes are placed on both sides of the bypass to protect against accidents. If necessary, they are covered. Another one is installed on the central part of the harness. It helps direct the working fluid to the circulation pump. It is advisable to put a filter in front of the entrance, cleansing water from impurities and solid salts.

Positive and negative sides

An indirect heating boiler is connected to a single-circuit boiler to save fuel

For the most part, single-circuit gas heating units have the following advantages:

- They have a more democratic cost than counterparts of the double-circuit type.

- Heat exchangers are simple in design, easy to maintain, reliable and durable.

- They can work in conjunction with an indirect heating boiler.

Weaknesses of installations:

- A sufficiently spacious room is required for the installation of the device and related equipment.

- System maintenance costs can be expensive.

Advantages of double-circuit gas installations:

- At the same time, they solve the problems of heating and providing households with hot water.

- Compact and complete with almost all the necessary additional equipment.

- Ultimately, the overall system on such a heater is much cheaper than with a single-circuit unit.

The disadvantages include:

- There is a time delay in heating the liquid.

- When opening several hot water taps, a drop in temperature may occur.

In some cases, it is impossible to put an additional circulation pump in the line in a flow-through type model.

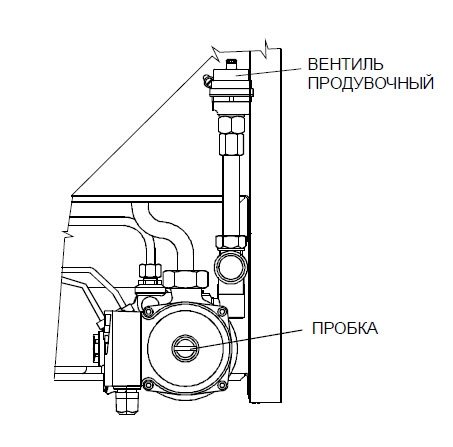

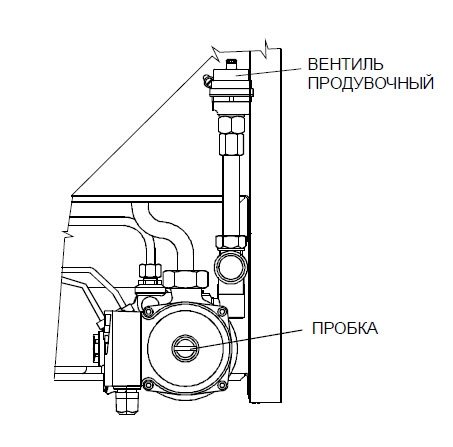

How to prepare a circulation pump for starting a gas boiler

Before turning on the gas boiler, air must be removed from the system. First of all, it is necessary to remove the air from the pump. There is a purge valve at the top and a plug on the side. First you need to unscrew the valve of the heating system. After that, air can be removed from the pump.

The boiler circulation pump has the following modes: start, operation and run. After turning off the gas boiler, the pump runs and removes heat from the combustion chamber. This prevents temperature peaks and increases the service life of the boiler heat exchanger.

Regardless of the type of gas boiler (single-circuit or double-circuit), the circulation pump has a positive effect on the operation of the entire heating system. The pump in a wall-mounted gas boiler is especially important.

The nuances of installing heating systems

With an open combustion chamber for the boiler, it is necessary to equip a chimney

For gas-powered equipment, a project for its installation is necessarily made. If there is a certain freedom in choosing the place of fixing the boiler, you can indicate some points that will help more correct operation of the device.

It is advisable to mount flow heaters closer to the place where the water intake will be.

If there are two coolant return taps, the distance from the heater should be minimal to the valve from which water is more often taken.

Installation nuances

When installing the heating on a turnkey basis, the master plumber installs a circulation pump with a wet rotor. Such a device does not create much noise, its rotor rotates without lubrication.A heat carrier is used here as a coolant and lubricant. When installing pumping equipment, you need to take into account the following nuances:

- The shaft of the pressure generating device is positioned horizontally in relation to the floor plane.

- Install in such a way that the direction of the water coincides with the arrow on the device body.

- Install the device with the terminal box facing up to prevent water from entering the electronics.

Important! Experts recommend installing the pump on the return pipe of the heating system of a one-story or multi-story residential building. Despite the fact that such equipment is designed to work in hot water with a temperature of up to 110 degrees, a warmer liquid on the return pipeline will only extend the service life.

The installation of the unit is carried out only after the water has been drained from the system. In the event of a power outage, the pump will not be able to pump the coolant, therefore it is connected through the bypass, a mesh filter is installed in front of the inlet pipe to prevent scale and debris from entering the impeller. In addition, shut-off valves are provided at the inlet and outlet of the device for possible replacement and repair of the device.

As we can see, the installation of a circulation pump requires certain skills, therefore, the installation of this equipment should be carried out by a professional. To order the service, you can leave a request on the website or call the number

Source: master-santekhnik.ru

Top manufacturers of double-circuit and single-circuit systems

The most popular and popular boilers on the market are Italian, Korean, German and Russian devices.

- Bosh is a line of German devices with heat exchangers made of copper pipes with a sputtered anti-corrosion coating. Equipped with advanced electronics and security systems. The service life reaches two decades.

- Viessmann - German boilers with efficiency reaching 93%.

- Beretta - gas heaters of the Italian manufacturer for high power. The devices proved to be excellent in work under severe winter conditions.

- Baxi - heating systems with a quiet atmospheric burner. There are products for any capacity.

- Olympia is a Korean-made double-circuit gas boiler with an automatic weather adjustment system.

- JSC "Borinskoye" ISHMA BSK - boilers from a reliable series of domestic manufacturers with a built-in pump for circulating liquid.

When choosing boiler equipment, you should take a closer look at domestic products and devices of German production. The main arguments are the simplicity of the equipment in service, the reliability of the structural elements and durability.

Why do I need a hydraulic arrow

If several pumps are installed in the heating system of a summer house or cottage, a hydraulic separator or a hydraulic arrow must be included in the circuit. The specified device can be operated together with a single-circuit diesel boiler or solid fuel unit. In the latter case, the device regulates the supply of the coolant in different phases (fuel ignition, combustion phase and attenuation). Installing a hydraulic arrow allows you to balance the operation of the heating system. The main tasks of the hydraulic separator are:

- Automatic removal of accumulated air;

- Capturing dirt from coolant streams.

Important! The hydraulic arrow in heating allows you to balance the operation of the system, protects it from airborne air, and prevents the accumulation of dirt in the pipelines. Such a device must be installed without fail in the presence of several booster units.

How to calculate the power of an electric boiler

Choosing a suitable option for an electric boiler with a pump and an expansion tank, first of all, they are guided by its power. It must be such that all heat losses of the heating system are fully compensated.In addition, the boiler is responsible for an uninterrupted supply of hot water.

Before choosing a suitable model of a heating device, it is necessary to make a detailed heat engineering calculation. It takes into account not only the total area of the heated rooms, but also the condition of the walls, floor and ceiling, the quality of insulation, the presence of modern windows and doors. To calculate a boiler for heating a private cottage, it is allowed to use a simplified scheme. Using the instructions below, you can independently determine the required parameters of the device.

To do this, you need the following formula:

W = S x Wsp / 10m2, where:

- W is the required heating power (kW).

- S is the total area of all heated rooms (m2).

- Wud - power density per 10 m2.

Wwood in different regions has a different value. In areas with a harsh climate, this parameter ranges from 1.2-2. In the central zone of Russia, Wud corresponds to 1; in the southern regions, values of 0.7 - 0.8 are used.