To make heating the house cheaper, some work is carried out independently.

The filling of the system is carried out: after renovation; after draining the system for the summer; when replacing the coolant.

Each type of heating system has its own nuances, so filling can take place in different ways.

Odnoklassniki

Periodicity of coolant replacement

If in apartment buildings the coolant is drained annually, then in private ones it is not necessary. It should be assumed that the water that has already circulated seasonally in the system is prepared:

- does not contain oxygen;

- as a result of prolonged contact with internal surfaces got inertia, which became the guarantor of the preservation of the contour materials;

- all salts and chemical compounds that, when heated, turn into sediment and scale, already dropped outand the water became circulating without chemical activity.

If there is no danger of freezing the system, it can circulate one more and even two seasons. To determine the need for replacement, the coarse filter is checked - if it is relatively clean, then the water does not need to be changed.

As for antifreeze, the qualitative composition of the technology is changing every 5-7 years... However, in practice, it has been used for much longer.

Types of coolant for filling the heating circuit

Several types of heat carriers are used for heating systems.

Water

Cheap universal coolant:

- if you fill in distilled water, then there will be no scale and sediment;

- does not change properties when in contact with internal surfaces;

- safe for people;

- can spin in the system almost endlessly.

Disadvantages:

- Expands and destroys pipes when frozentherefore, in cold climates, you will have to buy antifreeze.

- Metal pipes are starting to rust.

- When using tap water, a large amount of salt crystallizes, therefore have to buy distilled water... If the water supply is poured, it is recommended to regularly clean the main units and, if possible, pipes from salt deposits. The process is time consuming and requires special reagents.

Antifreeze

Represents water solutions of ethylene glycol or propylene glycol with additives.

Photo 1. Antifreeze for heating systems from the manufacturer Termagent. Withstands temperatures up to minus 30.

- Allowed for use in heating systems only antifreeze with a composition designed for this. This liquid cannot be used anywhere else.

- Freezes at temperature from -30 ° to 60 ° C.

- Ethylene glycol antifreeze is toxic.

- Human-safe heat carrier with propylene glycol is expensive and needs to be replaced every 5 years.

- The new formulation on the market contains potassium acetate and formate. Suitable for areas with temperate climates - freezes at temperatures below -5 ° С... The cost is a more affordable option.

The correct choice of heating medium requires careful attention and consideration of certain factors:

- Sometimes the boiler operating instructions indicate the permissible types of liquid and others cannot be used. Some foreign manufacturers generally exclude the use of antifreeze - the warranty is void.

- The material from which the main units and pipes are made - the system must be made of chemically resistant pipes and assemblies... Antifreeze is incompatible with galvanized iron because it changes properties upon contact.

- Certain types of formulations do not heat up well and give off heatif they are used, the system is designed with this in mind.

- Heat carrier should not contain toxic and poisonous substances.

- Most efficient system fluid has a low viscosity.

- Some types of coolant are designed for industrial use only.

- Heat carrier cost and the permissible period of its operation.

How to pour antifreeze into a heating system with and without a pump

How to pour antifreeze into the heating system

The choice of a heat carrier for heating systems has already been discussed earlier, in this construction magazine. Its key types are water and antifreeze. Antifreeze is very rarely used in heating systems, due to its very high viscosity. Antifreeze, on the other hand, has received great use in view of its own good operating properties.

And if we talk briefly about them, then the use of antifreeze in the heating system even helps to remove deposits, secure sealing parts, etc. In general, you can read about the advantages of antifreeze for heating in the publication - which heat carrier to choose for heating.

And if you have already formed with the choice of a certain type of antifreeze, then it is time to pour it into the heating system, which can be created in several options, with and without a pump.

How to pour antifreeze into the heating system

It is immediately necessary to mention and say that pouring antifreeze into an open heating system is impractical, in view of the rapid evaporation of the heat carrier. However, if you still need to discuss the issue of how to pour antifreeze into an open-type heating system, then it is solved very simply.

To do this, the purchased antifreeze liquid is poured into the expansion tank of the heating system, which is located at the highest point, mainly in the attic.

The issue is solved in a completely different way if it is necessary to pour antifreeze into a closed-type heating system, since it is hardly possible to do without a hand pump for pumping liquid. For this, the pump for filling the heating system is connected via a ball valve to the heat exchanger of the heat supply or directly to the connection of the make-up tap.

When pumping antifreeze into the heating system, it is important to open the air vent on the outer radiator of the heat supply so that the air can leave the heating system without hindrance.

How to fill the heating system with antifreeze without a pump

It is possible to pour antifreeze into a closed-type heating system without a pump, but in time this is a rather long process, for the implementation of which it will be necessary to fill in the heat carrier through again, the highest point in the heating system. This can be done using the installed air vent or relief valve, for example, if it is placed on top.

Before pouring antifreeze into the heating system, make sure of the following:

- Shut-off valves must be open, and those that are installed on the boiler, on the contrary, are closed;

- Before injecting antifreeze, it must be diluted according to the manufacturer's instructions;

- First of all, it is necessary to open the air release device to release the air;

- Close the tap on the expansion tank.

As soon as a significant part of the antifreeze is poured into the heating system, the air vents should be closed and continue pumping antifreeze further. It is possible to observe the generated pressure in the heating system using a device for determining the pressure value supplied to the boiler.

It is still recommended to use for filling closed heating systems with antifreeze, at least a hand pump designed specifically for these purposes.

Preparatory work before injection of thermal fluid

Before filling the heating system, preparatory work must be done.

Crimping

Pressure testing is a serious part of the commissioning work that is carried out before the first start-up of the system, as well as before each heating season. This is the name of the hydrodynamic testing of the system. in conditions that exceed the subsequent real load in complexity. This is a check for the strength of the pipeline, all connections and nodes, as well as points of entry and exit into the building, underfloor heating systems, equipment and boiler rooms.

The principles of the conduct are regulated by SNiP:

- The temperature in the building should be above 0 ° C.

- Selection of pressure test should not exceed the limit valuesspecified by the manufacturer.

- The value of the crimping pressure must exceed the operating pressure. by 50%.

- In private homes, the crimping pressure is on average in the range 2-6 atm.

- Systems in old houses are tested with underestimated values, cast iron radiators also set a limit to the maximum value - no more than 6 atm.

- When selecting the optimal value of the pressure test it is important to use technical documentation for pipes and equipment, it follows from the admissible maximum for the weakest link in the system.

- Testing with water, even if antifreeze is poured into the system, pressure testing with the working solution is done secondarily.

Parameter control

Competent pressure testing is carried out only by a specialist with the appropriate knowledge and experience. Parameter check and control requires special equipment.

Recommended parameters:

- above workers one and a half times, not less than 0.6 MPa.

- not new networks are tested under pressure 1.25 higher than workers, not lower than 0.2 MPa.

- in private houses up to three floors heating works under pressure no more than 2 atm.

- in multi-apartment five-storey buildings 2-6 atm

- in buildings with more storeys 8 - 7-10 atm.

These values are amended on site based on the condition of the system components..

In private houses, fittings, radiators, etc. are often in better condition than in apartment buildings.

According to the rules, in apartment buildings, such work can be carried out every 5-7 years.

Choice of energy carrier and heating system

If you do not take into account the cost of energy carriers, but approach from the point of view of independent heating, then electricity will surely take the first place. It is more convenient in operation than any hydrocarbons, and if there is a multi-tariff meter in a private house, then the price becomes acceptable

An important advantage of electricity is that it is not necessary to install hot water heating in order to use it.

Advice. An excellent solution for the southern regions is an inverter air conditioner or a split system with heating mode. It is capable of operating down to -15 ° C in winter and producing 3 kW of heat for each kW of electricity consumed.

Combustion of other types of fuel implies the presence of a single heat source - a boiler or stove. And from them, heat dissipates through the rooms through water (heat carrier) or heated air. It is difficult to carry out traditional water (previously they said - steam) heating yourself, since you need to correctly calculate pipes, radiators and select shut-off and control valves. The same is with the distribution of air - air ducts and fans are needed, taken by calculation. All of these systems are expensive.

An exception can be considered gas convectors, which are placed against the outer walls of rooms and directly heat the air of each room. There is no particular difficulty in installing them with your own hands; usually, the installation process is well covered in the product documentation. The only problem is the connection of the convectors to the gas main; it can only be carried out by specialists from a licensed company with all permits.

In a small one-story house there is an opportunity to independently put a steel wood-burning stove, it will be enough to heat 2-3 rooms. True, you will have to mount a chimney with good natural draft. Such solutions are good for summer cottages or country houses with periodic residence of the owners.

It turns out that the most affordable option for self-realization is heating a wooden or stone house with electricity, which will be discussed below.

Filling the heating system

The filling methods for open and closed heating systems differ.

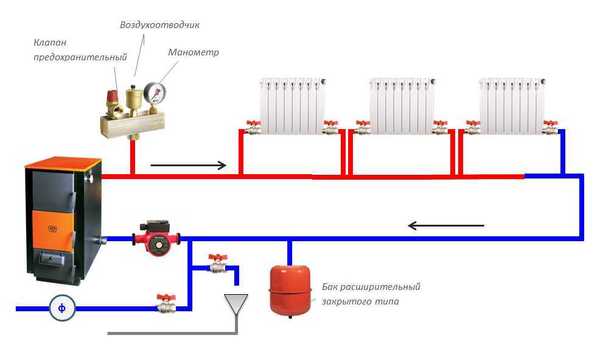

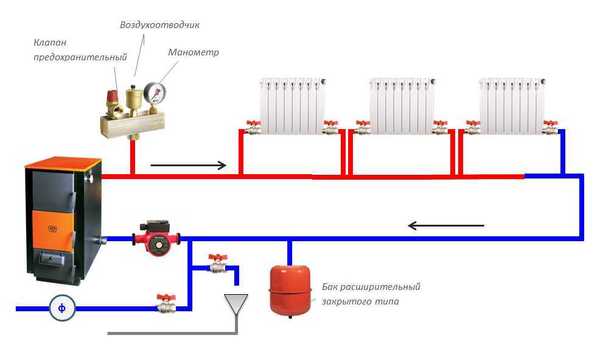

How to pour into a closed

The closed system is equipped with sealed expansion tank, which is set arbitrarily.

Attention! It is not recommended to use the upper tier of the system for filling the coolant. In this case, air comes out through the coolant layer, saturating it. When heated along the entire circuit air locks are formed.

The best option is to supply the coolant through the bottom valve:

- from the water supply;

- from a tank, a well with a pump.

Photo 2. Scheme of a closed heating system. A sealed expansion tank and a pump are mounted in it.

The process itself is carried out at the beginning of the heating season or after renovation work.

High quality antifreeze can be overfilled every 5-6 years.

If the liquid is supplied not from the water supply, then a pump will be needed. The source is a well or tank. Filling process:

- It is better to fill the system with two people.then it will be easier to control the pressure.

- The heating medium is being pumped with the heat source turned off.

- All shut-off valves open, remains closed only drain.

- Radiators also overlapexcept for the most distant ones in each branch.

- The coolant supply is connected: the circuit, boiler and tank are filled.

- From the beginning of the process, the air outlet is monitored: it must exit through the safety group valve and the drain at the top of the line.

Important! It is recommended to set the security group for a system with any type of boiler and type of fuel.

- The radiators are opened, starting from the first from the boiler. The taps are opened, the air is vented through the Mayevsky cock, after filling the radiator is closed again. This process is repeated with all branch radiators.

- When the batteries are full trapped air is released from the circulation pump.

- Then the heat source is activated and at the same time the pump is turned on.... The system is being pumped - without radiators.

- When the pipes are hot enough, taps on each battery open. In this case, it is necessary to once again check the air outlet from each.

- If done correctly, the pressure stabilizes and is no more than 2 bar.

- The process is repeated for each branch., in the last turn, the coolant is poured into the warm floor.

If the heating is designed with a manifold, then branches are filled in separately, the air is discharged through the manifold valves.

Attention! In the case of a branched structure, pumping and heating of the system is carried out only after filling in all parts.

The process takes a lot of time and requires care. If the main points are missed, air may remain in the system, which will subsequently create problems in the operation of the heating.

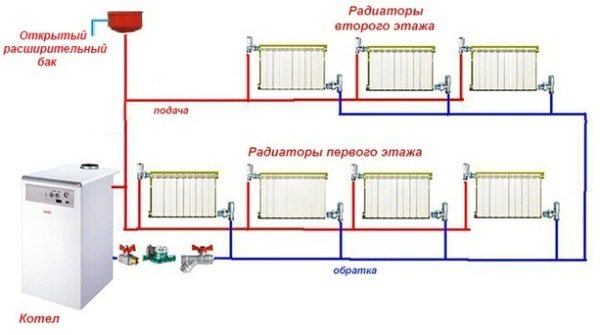

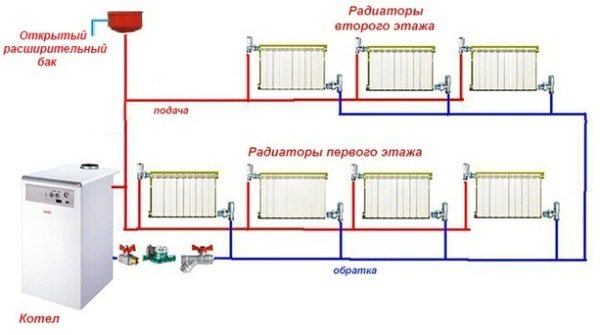

How to upload to the open

It is an open container with a lid, which is also a convenient entrance for water to enter the system. It is filled with a regular bucket or a pump is connected. The difference in filling lies in the pressure in the circuit: it is equal to the usual atmospheric. The coolant is in contact with the environment - an expansion tank is installed at the highest point of the circuit.

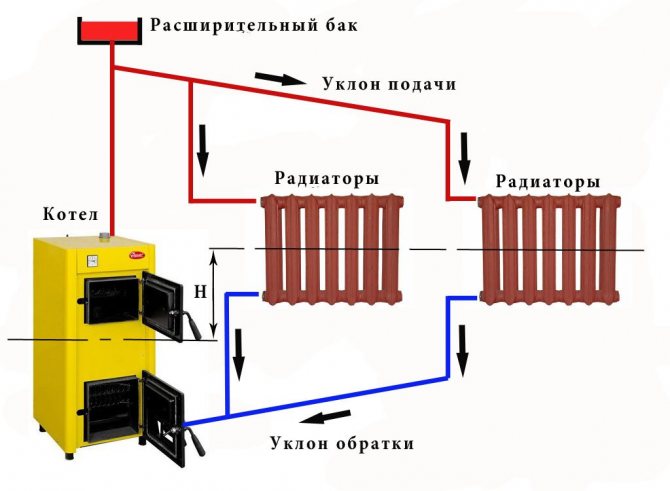

Photo 3. Scheme of an open heating system in a two-story building. The circuit is filled with a coolant through a special reservoir.

Filling process:

- If a pump is used, then you need a large container for feeding in certain volumes.

- Water is poured gradually, intermittently - so the air will be able to escape. If the pump is turned on, the pressure in the circuit should not exceed two atmospheres. The water is stopped when the expansion tank itself begins to fill.

- Further, air is released from all radiators and system components. For this, Mayevsky's valves or taps are opened until the liquid appears.

- Then water is added to the system. Most of the air is removed by itself through the expansion tank, after starting the heat source, this process is intensified. In an open system, the problem of air locks is not as acute as in a closed one.

Evaporation occurs from an open tank, therefore from time to time you will have to top up the water.

The contour is filled from belowif there is a corresponding connector.

How to pour water into the heating system through the expansion tank, that is, from above

Thus, if you have an open system, then we take a bucket or a hose, go up with it to the attic or to where the expansion tank is, remove the lid from it, insert a large watering can into the neck of the tank, or put the end of the hose directly into the tank. After that we fill in water. Our tank should have a device, usually a simple transparent tube that shows the water level in the tank. We need to know when to stop! In addition, at the very top of the tank, there must be an outlet for excess water. Roughly speaking, this is a branch pipe to which a hose is connected to the sewer.

Water, in theory, should drain down the pipes and fill the system. But this is only in theory. The fact is that water, going down, forms bubbles. Water compresses the air at the bottom of the system. The air needs to come out. The air should come out, again, up. Through the same pipes through which water is poured. And this is the big problem. While water moves down the pipes, air cannot move up the same pipes. This means that we cannot fill in constantly, in principle. We can pour water and then wait. First, wait for the bubbles to go. Then wait for them to stop walking. And only after that we can pour a new portion of water into the tank. Thus, we fill, as it seems to us, the complete system. At least there is water in the tank and does not go anywhere. But believe me, it's too early to turn on the heating! We need to go to each radiator and bleed air from each. Each radiator is a kind of air trap. He just has nowhere to leave the radiator! In this case, we need to make sure that the water does not completely leave the tank. After all, if it leaves there, then empty pipes are formed, which means that when water is poured into them, new air cavities, bubbles are formed, which will have to come out.

So, we go down to the radiators. Do we have air release devices on the radiators? If there is, then it is good, if not, then everything becomes very complicated and the issue of pouring in heating acquires the status of not a big, but a very big problem. We need to spin something to drain the water and, quite possibly, this will not be enough to release air from the radiators. But let's not talk about sad things! We will assume that we have on each radiator the so-called Mayevsky taps, or air release valves. We turn them off one by one and release the air until water flows. As already indicated, do not forget to add water to the expansion tank.

After the air has been deflated from all the radiators, you can already try to start the boiler. If at the same time the boiler heats up, and the pipes do not heat up, then we can only wait. How many? Maybe a day. Maybe a week. And during this week, there may be times when we, like, wake up at night and hear how a bubble inside our heating suddenly begins to move upward with a characteristic gurgling sound.Here they are - the delights of an open heating system!

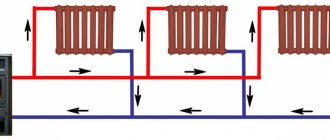

Pipe slope

In order for the air to escape from the heating system on its own, all pipes must have a slope. Slope towards the expansion tank. The bubbles should rise upward. They will also gradually rise along gentle pipes. It is only necessary that the pipes have a slope in the right direction and there are no hollows and loops. It is quite possible to lay the pipes so that air will collect in them, which will never come out of them, which means that there will never be circulation in the system. Moreover, most often in the entire system, or in the entire branch.

But the slope of the pipes is important not only for an open heating system! Unfortunately, other articles about heating are written in such a way that it begins to seem that in a closed system, the slope of the pipes is unimportant and unnecessary. This is not true! The slope of the pipes in the heating system is always needed. Where should the bias be in a closed system? There is also no open expansion tank at the highest point!

The slope of pipes in a closed heating system should be exactly the same as in an open one. Ideally, the pipes should rise steeply from the boiler to the highest point, and then smoothly descend to the last, farthest radiator. A vent valve should be installed at the highest point. When draining water from the heating system, water should not stagnate in any of its places. It should pour out completely, and by gravity. And this is also due to the slopes of the pipes.

How to add water to a heating structure

In a closed and open heating structure, the coolant is added in different ways.

Closed

The system must be kept at a constant pressure, which depends on the total volume of the coolant in the circuit.

During operation, the amount of fluid decreases, so you should regularly recharge the circuit through special make-up valveslocated at the point of lowest pressure - in front of the pump.

Photo 4. Make-up valve for the heating system. With it, you can top up the coolant with a closed heating circuit.

Openly

In an open system, the problem of coolant leakage is more relevant - the evaporation of hot water from the tank requires constant monitoring and replenishment of the system.

The liquid is simply poured into the tank.

Types of pumps for pumping liquid

Filling an open system is not a problem in terms of equipment - a simple bucket is sufficient. To speed up the process and more convenience, it is used a hand pump or a device powered by electricity.

A closed system, on the other hand, only filled with pump, the coolant is supplied under pressure.

Any pumps are suitable for these purposes., specialized - no for pumping antifreeze into the heating system.

Vibrating

Vibratory submersible pumps are completely in the liquid. This is how the popular works "Kid"which is used in wells and boreholes. This device is quite suitable for pressurization up to 4 atm... It is also useful for the system that this pump is equipped with filters.

Drainage

This is also a submersible device, but there is a difference from the previous type of devices: the unit skips inclusions, the maximum size is indicated in the data sheet.

Using such a device, measures are taken to prevent foreign particles from entering the system.

Selecting a container for the pumped liquid, another feature of this type of device is taken into account: a float mechanism that turns off the unit if there is little liquid left.

Self-priming centrifugal

These pumps work while staying on the surface - the hose is immersed in the liquid. Due to their high power, they are used for filling the system and for crimping.

Manual piston

A convenient economical unit with a reservoir, equipped with a pressure gauge, which allows you to control the pressure. Requires significant physical effort.

How to pump the coolant from below

Considering various options and prices, many owners of private suburban buildings stop at the bottom filling of the heating system with coolant. To do this, we take a plastic barrel with a volume of 200 liters, fill it with low temperature water and lower the pumping device, for example, a baby pump. Connect the hose coming out of the device to the point of entry into the return line and open the tap.

Correct installation of the unit is required during work. The upper branch pipe must be constantly in the liquid, which will prevent airing of the circuit. When the level of antifreeze decreases, turn off the pump and top up the coolant.

Important! We fill the closed-type heating system with Mayevsky's taps open. Containers for collecting liquid are placed under each of the air vents. When the water starts to show through, the taps are closed.

When pumping fluid, you need to monitor the pressure on the pressure gauge. After reaching the required parameters, we open the air vents, which will lead to a decrease in the pressure. We pump up the liquid several times until the air is completely out of the system. We finish the work by checking the tightness of the circuit.

For some users, the process of filling the system with coolant may seem too complicated. If you need help in this matter, contact this number

Coolant drain technology

- To drain, you need a hose that connects to the boiler nozzle. The other end is located in the sewer or in a separate container.

- The boiler shuts down.

- The hose is connected to the return valvelocated under the boiler (if it is not there, then the location is indicated in the technical passport).

- The valve opens, and the liquid is drained, then closed again.

- After that, the system is filled with air., for this, Mayevsky's taps are opened at the highest point of the contour. Then they drain again.

- Now they start the air again, but this time they open all the available Mayevsky taps. The liquid is drained again.

- Finally, the hose is reconnected from the return valve to the supply valve.... In this case, the hose is placed as low as possible in relation to the tap.

Important! It is impossible to drain the underfloor heating system in this way, to drain this branch you will need a special compressor.