Home »Classification of gas boilers» Principles of operation »Setting up gas boilers Proterm

Gas boilers Proterm are popular with consumers due to their reliability, European quality and reasonable price. Among floor devices, the Bear series is known, and among wall devices, the Cheetah is considered the most versatile line. Models with the letter designation MOV are equipped with an open combustion chamber, and MTV are equipped with a closed combustion chamber. Consider how to set up Proterm gas boilers.

…

- 1 Heating modes Proterm Cheetah

- 2 How does Proterm Cheetah work when connecting thermostats?

- 3 Setting up the gas boiler Proterm Medved

Heating modes Proterm Cheetah

The gas boiler Proterm Cheetah can operate in several modes:

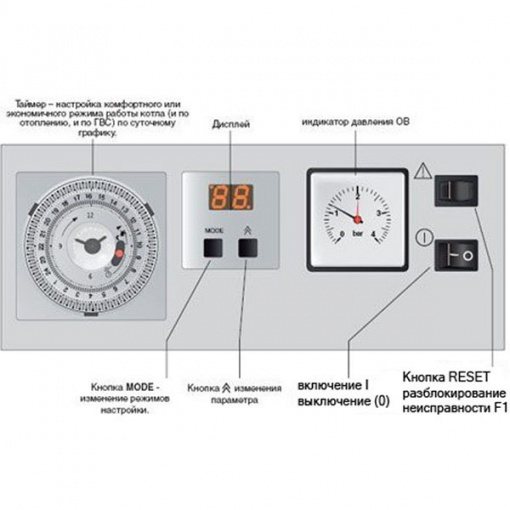

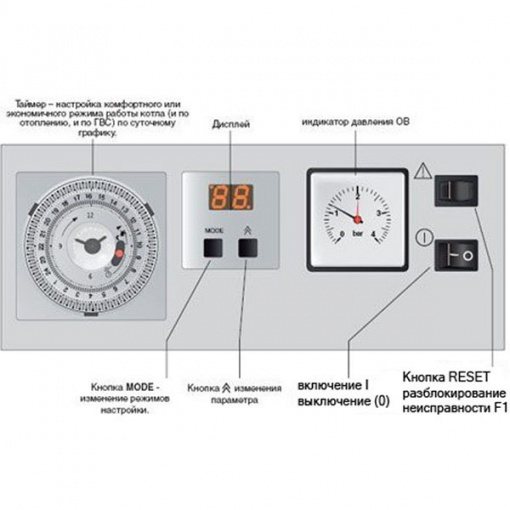

- "Heating" - press the MODE button once, and the display will show the "radiator" symbol with the current pressure value in the heating system. While in this mode, the unit works only for the production of heating, while DHW is turned off.

- "Summer" - activated by pressing MODE twice. The display will show the pressure in the heating system together with the symbol "tap with a drop of water". In this mode, the boiler operates only for hot water supply.

- "Vacation" - press the MODE button three times, and the OFF symbol appears on the screen with the pressure reading. In this mode, heating and domestic hot water does not work, but all protective functions of the device are active.

The desired heating or hot water temperature can be adjusted using the "+" and "-" buttons. The setting is carried out as follows:

- The DHW temperature is regulated as follows: after pressing the "+" or "-" button, the symbol "tap with a drop of water" and "ºC" start blinking. The required temperature value is set in the range from 38ºC to 60ºC.

- The heating temperature is also set using the "+" and "-" keys. After pressing one of them, click on the MODE button, a blinking symbol "radiator" and "ºC" appears. Then, using the "+" and "-" keys, set the optimal value of the heat carrier in the range of 38-85ºC.

The operation of the gas boiler Proterm Cheetah without thermostats is not very economical. For maximum savings, it is recommended to purchase a room thermostat.

…

documents that are relevant to this issue. Issue ...

Page 20

- Picture

- Text

18

documents that are relevant to this issue. By fulfilling the requirements listed in the standards, you can avoid such undesirable phenomena as excessive cooling of combustion products, the penetration of moisture into the masonry, fluctuations in the chimney draft, and, thereby, their negative impact on the operation of the boiler.

The combustion air enters the boiler from the room in which it is installed. Ensure that a sufficient amount of combustion air flows into the room - about 11 m

3

air for 1 m

3

natural gas.

The boiler is installed in a frost-protected room near the chimney. The permissible ambient temperature for the operation of the boiler is from + 3C to + 45C.

The combustion air supplied to the apparatus must be technically free of chemicals that may contain, for example, fluorine, chlorine or sulfur. Sprays, paints, solvents, cleaning agents and adhesives contain substances of a kind that can cause corrosion during operation of the appliance under unfavorable conditions, including in the chimney system. The combustion air must not contain mechanical impurities, for example: construction dust, sand, etc.

For the removal of combustion products of boilers PROTHERM 20, 30, 40, 50 KLZ, you can use the additional device "PROTHERM PT 20 (30, 40, 50) SEMITURBO" extension, which provides forced removal of combustion products.

The device makes it possible to operate cast iron boilers in cases where it is not possible to use the normal removal of combustion products into the chimney. The extension is connected to the boiler outlet to connect the chimney. The outlet of the combustion products of the extension allows the use of elements of separate chimneys from the Protherm chimney catalog for wall-mounted boilers.

The maximum flue length is 10 equivalent meters (1 equivalent meter = 1 meter straight section or one 90 ° elbow).

Warning:

When using the PROTHERM PT 20 (30, 40, 50) fan extension, the terminals of the flue gas thermostat must be bridged before the boiler is started up. In this mode of operation, the air manostat, which is included in the delivery set of the PT 20 (30-50) chimney extension, acts as a safety element. Only a specialist from a specialized organization certified by Protherm may install and operate the boiler extension.

When performing service work while the extension is connected to the power supply (even with the mains switch turned off), the safety instructions must be observed!

It is convenient to monitor the deviation from the initial water pressure in the heating system using the pressure gauge on the boiler control panel using the red arrow of the pressure gauge. If the pressure in the heating system drops, find and eliminate leaks or bleed air from the heating system or check the expansion vessel.

The expansion tank of the boiler must be adjusted depending on the parameters of the heating system - in this way, the heating system and all its elements during operation are protected from unwanted load during sudden changes in pressure.

When filling the built-in DHW boiler, it is necessary to open the cold water supply line to the boiler and the DHW outlet line from the boiler. As soon as water starts to come out of the DHW line, this will mean that the boiler is completely filled with water.

Note:

In front of the boiler (i.e. on

return line of the heating system) it is recommended to install a sump for slag from the heating system. The sump can be combined with a sump, it must have service shut-off valves.

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

Here at my grandfather, in the shed, I found an old military brochure, issued in 1976: "Instructions for packing a parachute, second edition, supplemented and revised."

Manualza! Manualza.ru

Still not with us?

How does Proterm Cheetah work when connecting thermostats?

When the gas boiler Protrem Cheetah is working without room thermostat, the heating of the premises depends on the temperature setting of the heating medium.

When connected to a gas boiler Proterm thermostat it becomes possible to set the desired heating temperature. It must be such that the unit can support it, regardless of the outside temperature. The regulator will only control heating within the selected range.

Note! In the room where the room regulator is located, the radiators cannot be equipped with thermostatic valves.

Unit Proterm with on-off regulator able to maintain the set heating temperature. The boiler will receive a signal to switch on or off depending on the temperature in the room in which the regulator is located.

When connected to a gas appliance continuous regulator the power will change smoothly to maintain the set room temperature.

The room regulator will control the room temperature and send a signal to the unit to turn off if the heat level reaches the set value or turn on if the temperature decreases.

…

The most modern and accurate is equithermal regulation... It is performed by a thermostat with an outside temperature sensor. When such a device is connected to a gas boiler, the latter will regulate the temperature of the coolant, depending on the conditions outside.

If the operation of the unit is controlled by an equithermal regulator, it is not recommended to set the maximum temperature of the coolant - this will significantly reduce the efficiency of the system.

Find out here how to make a gas boiler more economical?

Malfunctions of gas boilers Proterm and their elimination

Features of ignition of different models of gas boilers

Setting up a gas boiler Proterm Medved

The floor-standing gas boiler Proterm Medved has a simple design. There are models on sale that can only provide heating, and there are those that produce hot water. Depending on the characteristics, the Proterm Medved gas boiler is configured as follows:

- DHW temperature - press the MODE button, the lamp in the upper left corner will start blinking, and another diode will be on in the lower right. Using the button with the image of two arrows pointing upwards, set the required temperature in the boiler in the range of 40-70ºC. Confirm the selected temperature by pressing the MODE button.

- Heat carrier temperature - in the heating temperature setting mode, the lamp blinks in the upper left corner. Using the button with two arrows directed upwards, set the required temperature of the heat carrier in the range of 45-85 ºC. Press the MODE button to activate the selected value.

The temperature list contains the parameter -. When it is selected, the gas boiler switches to summer mode, when the heating is turned off and the hot water supply mode is working.

When an equithermal temperature regulator is connected to the boiler, additional settings are made.

Symptoms of malfunctions of floor-standing boilers Proterm and options for their repair

_________________________________________________________________________________________

How to adjust the gas valve of the Protherm Cheetah 23 MTV boiler? Error F28 - unsuccessful first attempt at ignition. Disassembled several times a little work and got up again. It is unclear how to adjust the safety valve, it twists and sometimes unwinds. And how to install a gas flow valve? The gas valve is configured via the service menu. A pressure gauge is connected and the maximum and minimum gas pressure is set. During the operation of the boiler, the temperature of the coolant rises, and the device, using the gas valve, reduces the gas pressure on the burner (solenoid valve or stepper motor) - the flame is modulated. Decreases up to certain limits. And if these limits are not enough, then the coolant overheats, and the unit turns off due to overheating. Then it cools down and turns on again, starts to clock. Conclusion: you need to set the minimum gas pressure. As for the safety valve, the safety valve should hold 3 bars and should not drip. Why does Jaguar 24 JTV boiler give error F01? How can I fix it? Error F01 indicates an overheating malfunction. When the water temperature in the heating system exceeds 98C, the unit shuts down, and the RESET indicators and the F01 code appear on the screen at the same time. Disassemble the device, there is a button on the top right that will clear the error. Panther 30 KOV model shows F6 error. At the first start, there was a gas leak. There was cotton when the unit was ignited. What is the reason? Error F6 indicates a break in the internal flue gas sensor. It can be caused by the following reasons: Defective sensor. Incorrect electrical connection. Defective cable. In addition, a malfunction of the fan monostat may also be the cause.

Advise how to reduce the pressure on a floor-standing gas boiler Protherm 30 KLOM? And is it allowed to reduce the gas pressure? Does the unit have a regulator that adjusts the pressure of the gas mixture, or do they not need to make this adjustment? The regulator must adjust the pressure of the fuel supplied to the boiler unit. If it is too low, the burner unit does not start to ignite, if it is increased, then you can notice the separation of the torch from the wick, and the burner will go out immediately after firing up. Here are the correction operations. Preheat the boiler considerably. Open the flue gas duct fully. Turn the main burner to maximum, during this time the flame will turn blue-yellow. We close the gas fuel intake valve, which will cut off the yellow fire. Then check the operation of the boiler in various modes. The Proterm 40 KLZ boiler begins to hum and warm up thoroughly, while the check valve is leaking. What is the breakdown? If the boiler unit was connected without error, then first it is necessary to inspect the expansomat tank. A situation may occur when it is more expedient to reinstall it in a different place. In addition, adjustments are made directly to the apparatus. In particular, the circulation of the coolant is examined or the gas valve is adjusted, because its incorrect adjustment is the cause of these operating difficulties. We had a Proterm Volk 16 KSO boiler connected at home. After a year of satisfactory operation, the pressure in the system began to decrease. The expansion tank was freed from the liquid, then it was pumped up and filled with water. Everything was carried out according to the instructions, but after a short time, the pressure again weakens. No leaks were detected in the system. We tried to install a new nipple, but it does not work. Why is the boiler unable to maintain the correct pressure? How to test and adjust the expansion tank? There is no need to remove the heating medium from the heating circuit. We turn off the device. After that, disconnect the nipple located on the expansion tank. If water starts to flow, the expander needs to be replaced accordingly. When the air has flowed, the make-up valve is closed and the drain valve opens, with the help of which the coolant is drained from the unit. When the water stops flowing, a pump with a pressure gauge is connected to the nipple and the pressure indicated in the instructions is pumped in. Perform the operation two to three times, as a little fluid is regularly poured out during pumping, as a result of which the pressure drops. It is necessary to pump up until the decrease in pressure and water leakage stop. Next, twist the cap, turn on the taps and feed the system with the coolant. We turn on the unit and, when using an air vent, remove excess air from the system.

Tell me, why does the Gepard 23 MTV boiler give error F75? It often turns off for me, the F75 error is on. How to fix it? Error F75 appears after 5 times starting the pump, when a pressure increase of more than 50 MBar is not detected. The first step is probably to check the system for leaks. Suddenly, somewhere flows and there is simply no pressure (or rather atmospheric pressure). If everything is in order, then the faulty sensor is most likely to blame. We installed a Proterm 23 MTV boiler. Almost immediately, an error with the code F62 began to appear. Sometimes 1-3 times a day. Sometimes once every 2-3 days. After rebooting, the device starts up. Winter is coming, what to do? How can I reset the error? Error code F62 means gas valve is closed. These heating models really have a very stuck gas valve. It is possible that the valve is working properly but is incorrectly installed. Maybe something prevents him from working normally and does not allow the gas to be shut off in time. You just most likely need to lubricate the gas valve so that it does not stick during operation and does not cause this malfunction anymore.What caused the device to click in the temperature set mode? Suppose a gas burner device is ignited, the temperature rises, then strange metal knocks are heard. However, if you take out the screws securing the front panel, in this case there is no clatter. What happened? From time to time, the apparatus begins to crackle, rattle and crackle, most often after the main gas burner is turned off. An important reason for this malfunction is the uneven heating of the heat exchanger surfaces due to clogging or calcium deposits. You urgently need to clean the boiler. On the gas boiler Bear 60 PLO, it is not possible to start. The gas burner device is in working mode, if you hold the power button. But the device fades out if only the key is released. What is the cause of the breakdown? The problem is most likely in a defect in the thermoelement or in the gas valve. Alternatively, a supply pipeline. gas pressure may be low or control board voltage is very low. The flame began to smoke significantly and the gas burner device burns all the time, does not go out. The temperature above the set temperature cannot rise, and at the same time the flame will burn. There is a lot of soot on the parts of the unit. The gas service says it's a lack of traction. What can be done? Most likely, the air flow has decreased. It is imperative to carry out maintenance. Dismantle the gas burner block, clean and wash the burner and jets. The heat exchanger must be cleaned from the outside.

Panther of the 17th series. After firing up, the piezo turns on again for a few seconds. Periodically (1-2 times a day) it turns off due to a malfunction with code F1. Why does the device give this error? It is possible that the draft in the chimney is noticeably higher than the recommended 3-5 Pa. In this case, the flame of the pilot burner bends up and the flame control electrode is at the edge of the pilot flame, as a result, when the flame oscillates, a false signal about extinguishing is transmitted and the ignition unit shuts off the gas supply and starts re-ignition. This is corrected by correcting the position of the flame control electrode, its tip is slightly bent up. Most likely the reason is this, since in case of problems with traction, ignition will not occur and the device will unambiguously indicate an error F1. The gas boiler does not turn on due to error F83. A familiar master connected some kind of sensor directly, but the error still persisted. What's the matter? Error code F83 indicates that there is no heating medium in the system, since its temperature does not rise when the burner is running. The pressure drops below 0.3 bar. One of the reasons is the airing of the heating system. It is also possible that the temperature sensors fail, which send an erroneous signal to the board. Why does the Panther 25 KTO boiler make a lot of noise when the burner is turned on at maximum? What would you advise in this case? If the increase in noise is related to the operation of the burner, then it is most likely due to a faulty gas valve or bypass. Also, when the load increases, the gas meter may work loudly. The heating system can also produce significant noise: air-conditioned piping and radiators, poorly installed shut-off valves. In the unit itself, a heat exchanger clogged with scale, an unlubricated fan bearing, a circulation pump at increased pressure often make noise. Discovered a startup problem recently. For some unknown reason, the main burner cannot ignite, but there is a fire on the ignition device. I just can't figure out what could have happened? Apparently, the ignition unit is faulty. We advise you to check the device and clean the ignition block. At home we use the Proterm Grizzly boiler. About three days ago he had a problem. It goes out as soon as the wind blows on the igniter. I replaced the thermocouple twice, but it did not help in any way.What reason? When the main burner starts to work, this causes a decrease in the gas supply to the ignition device, which means that the automation unit starts up. You must add fuel flow to the igniter. This can happen intermittently due to low pressure in the heating system. There may also be a lack of draft of the chimney if it is designed with errors. What is the problem if the Protherm Bear 40 KLZ boiler does not start and the error code F75 is displayed? The pressure keeps normally, there are no leaks. I tried to turn it off from the mains, but the accident does not go away. Tell me what is the reason? This situation usually occurs when the liquid pressure in the heating circuit is low. In this case, it is required to check the pressure switch. Probably the problem is with him.

Model Leopard 24. Why does the error code F7? I checked the sensors, the board - there are no external defects. What could be? Error F7 is a failure of the control board. This code indicates a malfunction in the connection between the display and the board. Check the following: Try restarting the instrument. Ring the board-display circuit for an open or short. Phase is reversed with zero, swap the plug. The pressure in the coolant system has dropped below the permissible minimum. Top up the system to the 1-2 bar mark. Gas boiler Proterm Cheetah does not turn on. They cut off the gas due to repairs. After turning on the gas, the device did not start by itself. Launched it manually, it works fine. Is that how it should be? If no one is at home can everything freeze? How is this problem solved? Usually restart occurs automatically after a power outage. In the case of a temporary lack of gas, the gas valve is triggered, since the device does not see the flame and considers that the gas pressure is insufficient, but it simply is not in the system, as in your case. Look at the instructions on how to set up the gas valve, it should tell you what to do so that the unit will restart itself. The gas valve may be defective or not working properly. Still. The boiler has a reset button on the panel (which burns when there is no flame), and there is an emergency thermostat (a button in a recess under the lid). Try to press it - it will take the board out of the accident. In operation, the Panther KTO 25 is single-circuit with a connected boiler. The burner burns constantly without switching off, while the display shows the set temperature of 54 degrees. Then the unit began to turn off completely, giving out the F29 error, after a restart (reset) it turns on and works again without interruption. What could be the malfunction? About error F29 - it looks like the valve is stuck. A gas valve setting is required. And the chimney would not hurt to check that the boiler is atmospheric. If this does not work, then most likely there was a jump in gas pressure and the gas valve failed. The solution to the problem is to replace the gas block. Proterm Lynx 23 BTVE. I turn it on, the fan starts, then the pump, then the gas valve clicks, the piezo ignition is triggered, then the gas on the burner flares up and immediately goes out. The piezo immediately stops talking, the red light flashes. I changed the polarity on the stabilizer and tried it without a stabilizer - nothing changes. Then he cleaned the ignition ionizers, the piezo, pressed the button on the temperature sensor. Gas is supplied, judging by the meter, the temperature in the room where the device is located is positive +15, outside -3. Pressure 1.5 Bar. What is the malfunction? First, try cleaning the ignition and ionization electrodes, the device should work. Why does our boiler stop turning off after it reaches the required temperature? Heating occurs up to 89 degrees, after which it goes into an accident. After performing a reboot, the situation follows again. Presumably, the board is out of order, the thermal sensor is broken, the protection sensor button is broken. It cannot be ruled out that there was a violation of the automatic controls.In October of that year, I commissioned the Medved 20 PLO floor boiler. After about five months, there was a problem. I am trying to set the temperature cycle, but it does not hold it. Please tell me why the temperature does not hold? Apparently, the automation has malfunctioned, and if the temperature rises by 62 degrees, the nozzles stop working. It is required to configure the automation for the correct execution of functions. Another reason may be that the selected inappropriate power of the device is proportional to the areas that need to be heated. Why did the Proterm TLO 30 boiler not turn on? At the same time, it often gives an error F3. How can I fix this? This malfunction is usually issued due to some problems with the thermostat, temperature sensor, and in addition, in case of malfunctions in the main circulation circuit. Apparently, there is overheating of the liquid in the heat exchanger. If the temperature sensor and thermostat are OK, then the problem is with the control board. You must replace it.

The floor-standing 2-circuit boiler Protherm 40 KLOM starts up for a short time, but then it is blocked with an F1 error. So he started working after a recent power outage. How to deal with this problem? For devices of this model, error F1 is often associated with overheating of the thermostat, and it is eliminated by restarting via the STB button. It is also possible to change the polarity in the network due to electrical work, which is critical for phase-dependent models. Another error means that the gas supply to the gas valve is cut off due to loss of flame. This loss is signaled by the ionisation electrode, which could become clogged. In the worst case, the main board has failed due to a sharp increase in voltage, which happens when the unit is connected to the network without a stabilizer or UPS. The boiler is two years old. The first problem is that when hot water is turned on, it is not forcibly turned off, the heating circuit and hot water are not there until it turns off when the heating operating temperature is reached. The second problem is that the electricity is periodically cut off. The device goes out, when power is supplied, it always starts itself. The last time it did not start and gave an error code F84. The pressure in the cooled system is 1.4 bar. I pressed the reset button, it started right away. What could be the problem? Error code F84 can mean a constant temperature difference between the flow and return sensor (NTC2, NTC5). Cause: Temperature, flow and return sensor inverted or disconnected. Faulty temperature sensor - Check the temperature sensor connector. Check sensor (replace if necessary). Regarding the activation of the heating circuit - it is possible that the settings have priority for the heating circuit - check this. Why does the gas boiler Proterm Cheetah 23, when turned on, immediately give an error F29. He removed the cover, the electrodes are clean, the phase-zero is in place. Gas and water pressure is normal. Dismantled the gas valve - clean, rang the valve coil - working. When the device is turned on, there is no spark on the electrodes. What could be? And when should the exhaust fan turn on? Error F29 - The flame goes out during operation and subsequent ignition attempts are unsuccessful. Gas supply interruptions, improper grounding of the appliance. It is necessary to disassemble the gas valve and clean it properly. Most likely it's all about the stock that regulates the gas supply. If microparticles get into it, then it does not open. Clean it, although it may look clean and grease it - the boiler should work. The fan should turn on, and then the unit ignites. Someone please help to solve the problem with the chimney? Soon the second day, as the return thrust is observed, while the smoke passes immediately to the kitchen. I made the chimney myself. It consists of a metal tube. It looks like there is an inaccuracy somewhere. The main factor may be an incorrectly executed chimney design. Sometimes there is contamination of the pipe with combustion products, which greatly weakens its capabilities.It is also required to control the ventilation openings in the house. Please tell us how you can check the 3-way valve? I think this component does a poor job of opening. The distant radiators do not pump for heating, and in the DHW mode, the pipe for heating supply under the boiler is heated. That's right, it is necessary to check the 3-way valve for acidification of its stem in an intermediate position. In turn, we advise you to check your heating system.

When the DHW tap is fully opened, the unit begins to wheeze and vibrate as the water flow decreases, the noise decreases. What could it be? This usually indicates a clogged heat exchanger with prolonged use, the heat exchanger is failing. Over time, it becomes clogged with dirt and scale. This creates such noises, and when the scale heats up, it emits air bubbles that hum and wheeze - you need to wash it unambiguously. Both heat exchangers should be flushed - both heating and DHW. Everything should work fine after flushing. Proterm 40 klz. Summer. The DHW temperature is set to 50 degrees, but the device heats up to overheating and the F3. Replaced the NTC sensor. No result. What is the reason? Surely the pump rotor has soured. The pump has a plug - a plug, unscrew it, in the vacant hole you can see the end of the rotor with a slot for a screwdriver. Turn the rotor by hand with a screwdriver until it starts to rotate freely. Start the unit. If the pump sour, as a result of overheating, and then an error. It is necessary to remove the cover from the boiler. The reset button is located directly on the sensor body, almost at the very top on the left side. If everything is in order with the heating pump, then you should check the condition of the heating filter and check the heat exchanger of heating water. The reason is the same, that is, clogging of the working elements. And your symptoms - after cooling down, the error is reset itself. Very often, electronics fail precisely because of unstable voltage or because of a sudden power outage. For many, this problem disappeared after installing the stabilizer. What causes the Proterm Jaguar boiler to give error F04? It turns on, then it does not turn on. This has happened many times. It stands a little and lights up again. Error F04 is eliminated by replacing the DHW temperature sensor. This code is an ionization problem. We'll have to repair the board and check the optocoupler and other details. The unit operates for about two to three minutes, then the gas burner goes out, and error F36 comes out. It lights up for about a minute, the gas burner turns on again for ignition, and the device works normally for another three to four minutes, and so on many times. This failure, judging by the manual, means that the draft sensor is triggered, but the chimney is free of contamination, flue gases are discharged normally. Can't figure out what the problem is? In your case, the probable reasons affecting the lack of traction are: a breakdown of the traction sensor. There is no contact between the control board and the traction sensor. The presence of condensation, as well as incorrect connection of the pipes to the pneumatic relay. Fan problem. Most likely, it runs at low revs. The Protherm 30 TLO boiler buzzed during the switch-on period, and now it rumbles even more loudly. At first, the sound quickly disappeared, but now it is heard longer. occurred for a short time, observed such a problem? The formation of excess noise can be explained by the presence of scale inside the body of the heat exchanger, which heats up not equally due to the different wall thicknesses. The more dirty the heat exchanger is, the louder the unit makes the noise, and the heat transfer decreases. I have this model installed. Today, at start-up, the wick ignites for a few seconds, the main burner does not take fire, and the apparatus begins to extinguish. How is it possible to fix the breakdown? Probably, the ignition mechanism is out of order or there is a problem with the burner. Just in case, check if the phasing is not lost when connecting to electricity.The gas boiler Proterm Medved 50 KLOM was put into operation. In the last week, the error code F1 (ignition) flashes almost daily. After rebooting with the reset key, the device occasionally starts up without problems, but this is quite rare. Just yesterday I dismantled the air cap and it started to work better. What is the problem? If it starts to give an error in traction, it is imperative to open the safety covers. This will help draw in air from the room. Then check the chimney for the presence of ice and remove it if necessary. If the accident is related to combustion, it is necessary to find out if there is a gas supply to the room.

Installed a wall-mounted double-circuit boiler Jaguar JTV 24. Connected. The device turns on, after a minute it shows the F01 error and stops working. Let the air down. No changes. What's the matter? When the water temperature in the heating system exceeds 98C, the device turns off, and indicators of a return to its original state appear on the monitor at the same time. Check the pressure in the system, the instructions for this model indicate that at a pressure above 2.5 bar, the unit will not work. Perhaps this is the reason. The device decided that it had been reached and therefore switched on the protection. Therefore, you need to press the red button under the plastic cover to reset the overheating protection - it should work. We use the same boiler. The device instantly raises the temperature above 98 degrees, but then gets up with an error. Later, after it has cooled down, it can turn on on its own. What is the reason? Overheating stop indicates a violation of the circulation process. First, you need to pay attention to the faucets of the heating radiators. They must be left open. Next, an inspection is carried out for clogging of the dirt filter, and you should also make sure that the heat exchanger does not contain scale.

_________________________________________________________________________________________

_________________________________________________________________________________________

- How to troubleshoot and malfunctions on the Juncker boiler

- How to troubleshoot basic problems on boilers Buderus Logano G334

- Errors and malfunctions of Rinnai boilers

- Recommendations for the repair of boilers Buderus Logano G124 / 125

- Possible breakdowns during the operation of the Beretta gas water heater

- How to correctly adjust and repair the Electrolux gas column

- Tips for adjusting and repairing gas water heaters Gorenje

- Values of error codes for boilers Immergaz

- Problems in Junkers gas water heaters - Recommendations for repair and maintenance

- How to identify and eliminate malfunctions in the Ladogaz gas column

- Recommendations for the operation, repair and settings of the Mohr gas column

- We repair the Zota Carbon boiler - Types of faults and options for their elimination

- Repair of the Zota Master boiler - What can be malfunctions and actions to eliminate them

- Celtic boiler error codes decoding

- Repair of the Buderus Logano G221 boiler - Types of malfunctions and methods of their elimination

- Causes of irregularities in the operation of Buderus Logano S131 boilers and how to repair them

- Questions on troubleshooting storage water heaters

- How to troubleshoot storage boilers operation

- Electric water heater malfunctions and tips for their elimination

- Electric boiler malfunctions and repair recommendations

- Boiler error codes Hermann Habitat

- Tips for eliminating basic problems in storage water heaters

- Help in troubleshooting storage boilers operation

- Possible malfunctions and breakdowns during the operation of gas water heaters

- How to repair a gas water heater in the event of a malfunction

- Ways to eliminate malfunctions and breakdowns on gas water heaters

- Errors of gas boilers Proterm Cheetah

- Elimination of breakdowns and malfunctions during the operation of gas water heaters

- Causes of malfunctions and repair of gas water heaters

- Repair of gas water heaters in case of malfunctions in operation

- Hermann boilers - Methods for eliminating errors and malfunctions

- Elimination of errors and malfunctions during the operation of Arderia boilers

- Boiler error codes Ariston Egis