Previously, when a stove served as a heating system, there were no problems how to get rid of soot. And such a profession as a chimney sweep was held in high esteem. Now many people use boilers as a heating system. But in order to ensure uninterrupted operation, you need to observe simple conditions and clean them in time, as well as carry out a preventive inspection of the equipment.

Causes and consequences of clogging

To answer this question, you need to know which boiler is in the house: volatile or mechanical.

Volatile are divided in turn into:

- processing gas;

- electrical installations;

- solid fuel and liquid fuel equipment;

- combined models.

Volatile boilers can be shut down for a number of reasons:

- power line surges and surges

- lack of electricity

- failure of factory settings.

Often used in homes: AOGV, Zhukovsky boiler, gas "Ochag", Lemax, Signal, Conord.

How to clean a chimney pipe in a private house: a detailed analysis of cleaning methods, tips, prices. Do-it-yourself furnace for working out: drawing, work diagram. Read here.

Connection to the city water supply network: documents, prices:

https://klimatlab.com/vodosnabzhenie/vodoprovod/podklyuchenie-k-gorodskoj-seti-v-chastnom-dome.html

Mechanical can work intermittently due to the ingress of wind flow into the chimney. In addition, the flame may go out due to insufficient oxygen. You should pay attention to the hood (it is not always present in cheaper models).

If the chimney is dirty, modern devices have an alert system that will notify you of problems and the need for cleaning.

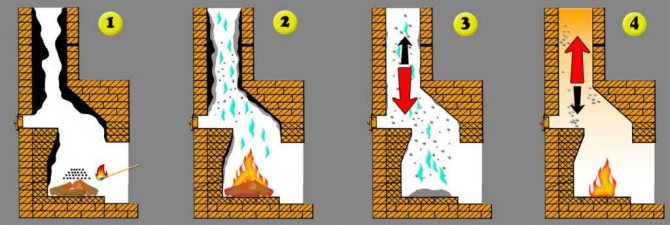

The causes of combustion products and how to remove them

By-products that appear during the incineration process are:

The reasons for the appearance of these substances are in some important points:

- there is not enough oxygen for the combustion process;

- extremely low combustion temperature.

Important! Do not forget that the chimney is an integral part of the home heating system and, like the boiler, requires periodic cleaning. You will find detailed information on how to carry out this procedure in our article "Chimney Cleaning".

Factors that influence the appearance of the resin:

- the fuel you are using is of poor quality;

- the moisture level of the fuel material is very high;

- the temperature at which the boiler operates is low enough;

- you are loading too much fuel into the furnace.

Cleaning methods

Cleaning is done in two ways: mechanical and chemical

Mechanical cleaning

The cleaning method is imperfect and involves mechanical action. The soot should be carefully removed so as not to damage the inner surface of the boiler and parts, which can lead to metal corrosion in the future. Often the tools come with the boiler - these are brushes, brushes and scrapers. It is also possible to use air cleaning when warm air is supplied under pressure.

Dry cleaning

It is recommended to apply means for cleaning parts in PPE (personal protective equipment), usually rubber-based gloves are used, so it will turn out to protect the skin from interaction with harmful substances. Chemicals clean not only the soot, but also the metal, which in the future can lead to its destruction. This method is best used on light dirt and small areas of pollution.

Hydrodynamic cleaning

Hydrodynamic cleaning or how to clean a diesel boiler from soot.

It is used in boilers with a small thickness of contamination, as well as when speed of execution is required. The equipment for such flushing consists of:

- pump and

- containers with waterwhich is supplied under high pressure.

Thanks to such cleaning, soot and soot are removed quite quickly, but this method is applicable only to specialists, it is not recommended at home.

Booster cleaning

The procedure for flushing the heat exchanger with a booster (for example, cleaning the Zhukovsky boiler from soot):

- First you need to disconnect the pipes from the heating system.

- Then connect to one of them to the booster hose in order to supply the reagent.

- We connect the second pipe to the second end of the hose. The spent reagent will be discharged through it. Thus, the system is closed and the reagent will circulate through the pipes.

- After cleaning, the solution must be drained from the tube.

- Flush the heat exchanger itself with sufficient water.

Booster is an apparatus for chemical cleaning. Thanks to it, the reagents circulate autonomously.

During such cleaning, it is recommended to change the reagent several times, since the old one gradually decreases its properties. This method is most often carried out by specialists.

How to clean the resin from the boiler?

It is recommended to clean the boiler in unnecessary clothes - resin can get on the thing and ruin it

In total, there are 4 main methods of cleaning the boiler from tar:

- mechanical;

- chemical;

- steam;

- "Soft blasting".

Mechanical cleaning is carried out manually, and with the other three methods, it is necessary to use special solutions, substances or aggregates.

Experts recommend to carry out the procedure regularly: once a month if you use high quality fuel, and every 2-3 weeks if you use low quality material.

Mechanical cleaning

To make the resin easier to move away from the walls of the boiler, some heat it with a gas burner

The essence of the method is to clean the boiler from the accumulated resin using tools suitable for this purpose. This could be:

- poker;

- shoulder blades;

- metal brushes;

- brushes;

- scrapers.

Mechanical cleaning begins only after the unit has cooled down.

The cleaning process itself is carried out according to the following scheme:

- The boiler is heated, then allowed to cool to an acceptable temperature.

- Using the above tools, remove the accumulated resin from the walls.

- After finishing cleaning, turn on the boiler again so that all resin residues are burned out.

Dry cleaning

Wear heavy gloves when handling chemicals

Cleaning the boiler in this way involves the use of special chemicals. In this case, the procedure itself can be carried out according to two different schemes:

- The chemical agent is poured onto the fuel as it burns. The substance reacts with the resin, destroys it and removes it through the chimney.

- The reagent is used to treat boiler walls contaminated with resin. Acidic solvents quickly destroy plaque, effectively cleaning the entire surface of the unit.

For dry cleaning of the boiler, adipic or sulfamic acid is often used.

Steam cleaning

When working with the steam generator, it is necessary to observe safety precautions so as not to burn yourself

The contaminated boiler surface is treated with a steam generator. During this cleaning process, the unit also undergoes disinfection.

"Soft blasting"

It is convenient to work with equipment for soft blasting, since the products used do not contain substances hazardous to humans.

This is an American method of cleaning the boiler from resin using a special apparatus. With the help of such a device, a specific solution containing chalk and baking soda or other abrasives is applied to the contaminated walls.

The soft blasting technique is also used in car services, when cleaning premises after fires, for cleaning monuments and building facades.

Time to clean the heat exchanger

When it is necessary to flush the heat exchanger of a gas boiler is a frequent question. There are a number of signs by which you can be sure that the time has come.

Some of the main ones:

- permanently on gas burner;

- the circulation pump has become noisier, which means it is overloaded;

- heating radiators began to heat up longer in time;

- gas consumption increases;

- the water pressure has become weaker (the first sign for flushing a double-circuit boiler).

In addition to cleaning the chimney, the boiler is also cleaned from soot. If the work of the chimney is difficult, then in some cases it turns off, but when it is clogged with soot, this does not happen. Combustion products are released into the air, and the owners breathe them.

It is recommended to clean the boilers once a year, especially if there is a year-round operation.

How often should the heating devices be cleaned?

In order for your unit to constantly work at optimal modes, to give out the necessary power, the boiler should be cleaned regularly. Using normal and quality fuel, you can do this activity once a month.

On a note: when using low quality fuel raw materials, the boiler should be cleaned more often, once every two, every three weeks. If the operating parameters deteriorate, an unscheduled cleaning of the equipment can be carried out.

To prevent severe clogging, it is necessary to regularly inspect the solid fuel boiler. When different types of fuel are used, the device operates at low temperatures, the unit will have to be cleaned once a week.

Dismantling and removal of soot from the inner surface of the boiler

In order to clean the entire system at home, you will need the following tools:

- screwdriver;

- metal brushes (soft and for metal);

- brush;

- open-end wrenches;

- rags or any cotton cloth.

Stages of work:

- Shut off the gas.

- Remove the boiler door and disconnect the wire leading to the piezoelectric element.

- Unscrew the thermocouple, ignition electrode and pilot tube one after the other.

- Replace with a new gasket under the pilot burner.

- Remove the nozzle, copper pipe, burner.

- Carefully take out the thermometer sleeve and then remove the boiler lid together with the insulating sheet.

- Disconnect the terminals from the traction sensor and take out the gas duct.

Before cleaning, turn off the gas supply, wait until the structures have completely cooled down and only then disassemble.

After removing all the parts, you need to:

- clean with a brush and metal brushes.

- The channels should be cleaned with a vacuum cleaner.

- Particular attention should be paid to the burner, as the inner channel can be easily damaged, it must be wiped carefully.

Wood-fired boilers are often used for heating in homes. And only a few people think about what kind of firewood should be chosen for kindling. Usually they use whatever they have. Resin firewood is especially harmful to chimneys. It settles on the walls of the boiler and the chimney pipe. Mechanical cleaning is required. In this case, the chimney must be cleaned of tar and soot residues from the roof, so it will be easier to remove the combustion residues from the inside. Observe safety measures!

What should be the regularity of cleaning processes?

The interval between the cleaning processes of wood, pyrolysis or pellet boilers depends, first of all, on high-quality fuel material:

- if you use high quality fuel, the boiler unit must be cleaned approximately once a month;

- in the event that you use fuel of poor quality, as well as with a high level of humidity, cleaning should take place once every 15–20 days.

Important! Despite the above terms, you should always monitor the operation of your unit, and if there is a violation of the working rhythm, you can clean the solid fuel heating boiler from resin outside the schedule.