What it is?

A dry technical definition says: an overpressure valve is an armature that automatically releases excess water when overpressure occurs.

It is a direct-acting device, since it reacts directly to the effect of the heated medium. (water or other heat carrier).

As a rule, an overpressure valve is included in the basic equipment of all compact water heaters.

Sometimes an overpressure valve is confused with a check valve. Often, both devices are housed in a single housing, which is why confusion arises. But, these devices are used for different tasks and are fundamentally different from each other.

What is it needed for?

The task of the valve is to discharge excess hot water in the working tank of the heater. The expansion of the water creates a lot of pressure that threatens the integrity of the appliance.

The valve automatically drains some water, bringing the total volume to the nominal value. This saves the heater and protects equipment and people from contact with hot water.

Excessive volumes of water are discharged through a special branch pipe connected to a drainage system or a special receiving tank.

The expediency of the procedure for draining the liquid

This procedure may be needed at any time. One of the conditions is the banal cleaning of the boiler from the accumulated dirt in the form of plaque. Also, this process may be necessary if this device is not used all year round. Another common cause of heater draining is equipment repair or replacement.

First of all, in order to carry out the process of draining the liquid from the boiler, you need read the instructions provided with the equipment at the time of purchase... It is in this booklet that the whole essence of the procedure for your model of equipment will be revealed. It is far from always possible to drain water without the help of specialists; you should be ready for such a turn. The main enemy is considered to be rust, which forms on the walls of the tank after draining the liquid. Rust can cause great and sometimes irreparable damage to the boiler.

Experts in the service of water heaters advise running cold liquid through the system for several months. This will require approximately 200 liters. The time of this process is once every 3-4 months. In some cases, the standard connection of the water heater to the network is allowed.

At a time when the device is not functioning, it is necessary to monitor the temperature in the room and, if necessary, turn on the heating. If the temperature in the room has dropped to 5 degrees with a plus sign, then there is a risk of damage to the device. There are cases when the tank even exploded due to the low temperature.

If the boiler breaks down or a leak appears, the liquid should be drained by the master. While your unit is under warranty, the drain will be free of charge, then this operation will require some payment.

Consequences of absence

When heated, the liquid increases its volume (expands) by 3%... This means that in a heater with a working volume of 10 liters, an additional 0.3 liters will appear.

If the size of the tank is not designed to accept additional volumes of water (and this happens most often), the heater body will be destroyed. Then a crack will appear, into which water will begin to go.

Most of the heaters are designed in such a way that the decrease in pressure in the working vessel is immediately compensated by the make-up from the mains. Therefore, the flow will be constant until the container is replaced or repaired..

When is it necessary to drain the water from the boiler?

Draining water from the boiler reservoir.

“I don’t use a boiler yet, which means that water is definitely not needed in it, otherwise it will stagnate” - this opinion of consumers can be encountered everywhere. But it turns out that in the case of storage heaters, everything is not so simple.

For example, if the device is under warranty service, then such actions are regarded by service representatives as third-party intervention. This means that in the event of a boiler breakdown, its owner is automatically deprived of the right to free repair or replacement.

In addition, the magnesium anode, designed to protect the internal elements of the device from corrosion, performs its functions exclusively in water. Consequently, by emptying the tank, consumers inadvertently accelerate corrosion processes.

But there are also circumstances in which experts answer in the affirmative to the question of whether it is necessary to drain the water from the boiler or not:

- lowering the temperature to values from + 5⁰C and below (if the heater is installed in an unheated house, the procedure must be performed before the onset of winter cold weather);

- self-replacement of the magnesium anode, cleaning from limescale and eliminating breakdowns after the end of the warranty period (otherwise, the water must be drained by the master from the service office).

Will the water deteriorate in the boiler?

In other situations, it is recommended to leave the boiler full, even if no one will be using it for a long time. Don't worry that the water in the tank will deteriorate. If it was initially clean, the absence of stagnant factors (air and light) will prevent the appearance of a musty smell and "bloom".

One cannot fail to note one definite plus - there is always a reserve of liquid in a house or apartment. It can be used for technical purposes in the event of a central water supply cutoff or pump breakdown.

Advice: the most suspicious consumers can be advised to change the filling of the tank about once a quarter. To do this, you need to keep the hot tap open in the bathroom or kitchen for 10-15 minutes (you do not need to turn on the heater).

Device and principle of operation

The overpressure valve is a direct acting spring loaded valve. Its outlet is closed by a ball pressed against the hole by a spring.

When the H2O head in the heater exceeds the spring force, the ball opens the passage and releases the excess water. As soon as the pressure drops, the spring presses the ball again and closes the outlet.

There are different valve designs, where not only a ball is used as a locking mechanism, but also a wedge, a poppet element, and other parts. However, the general principle of operation is the same for all designs.

Outwardly, the valve resembles a conventional tee fitting, but a water drain handle is installed on its perpendicular outlet. The outlet is equipped with ribbed projections for connecting a tube that connects to the drainage system.

Views

There are several types of such devices.... First of all, they are divided according to the value of the limiting pressure:

- for containers up to 50 l;

- from 50 to 200 liters;

- above 200 liters.

As a rule, devices of the first and second groups are one-piece. More powerful safety valves are designed for high pressures (typically up to 7 bar).

There are models with and without a drain handle. The former are more convenient, they allow you to check the operation of the device or manually reduce the amount of water in the container.

Types and varieties

If we are talking about ordinary safety valves for a water heater, then they look almost the same, only the nuances differ. But it is these small details that are responsible for the ease of use.

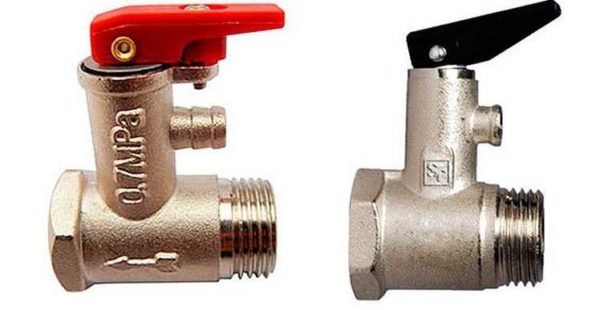

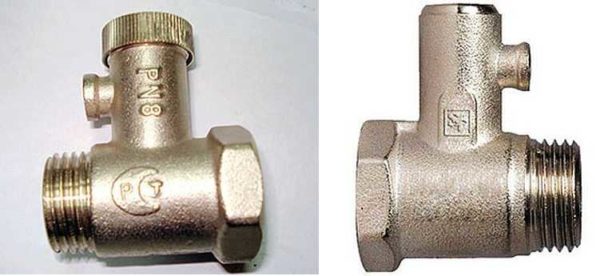

Boiler safety valve with forced pressure relief

Pictured above are two safety valves with release levers. They are needed for periodic performance checks. The lever flag is raised up. He pulls a spring along with him, freeing it to discharge water. This check should be done about once a month. You can also empty the boiler tank - raise the flag and wait for everything to drain.

The difference in the presented models is that in the model in the photo on the left, the lever is fixed with a screw. This eliminates the possibility of accidental opening and complete discharge of water.

Two more differences are striking. This is an arrow on the body, indicating the direction of movement of water, and an inscription showing what pressure the device is designed for. Seemingly minor details. But if you can figure out the direction of water movement (look in which direction the poppet valve is deployed), then it is more difficult with the nominal value. How to distinguish, for example, at 6 Bar, or at 10 Bar? Only by checks. How will sellers distinguish them? No way. By boxes. What if you put it in the wrong box? In general, it is better not to take without markings on the case. These are usually the cheapest of the Chinese designs, but the price difference isn't big enough to be worth the risk.

Also pay attention to the shape of the water outlet. The model on the left has a long, non-linear choke. The hose will fit quite easily on it and there will be enough length to install the clamp. The shape of the fitting on the model on the right is different - with an extension towards the end, but more importantly, the fitting is short. You can still pull the hose on it, but the clamp is questionable. Unless crimp with wire ...

Related article: Pattern of numbers for cross stitching: metrics how to embroider, small roman, beautiful font, like a calculator

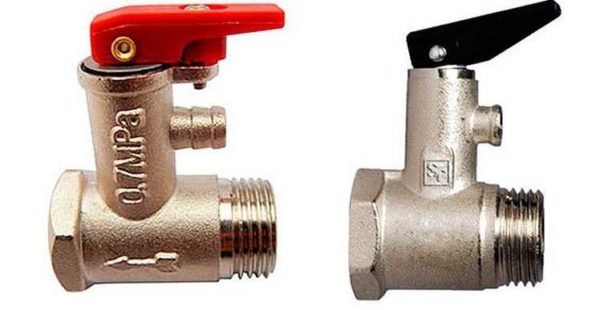

The next photo shows safety valves without a forced pressure relief flag. The one on the left has a screw cap at the top. This is a serviced model. If necessary, you can unscrew the lid, remove clogging, scale and other dirt.

Safety valves - serviceable and not

The model on the right is the worst of the options. No indications, forced reset, or maintenance. These are usually the cheapest ones available, but this is their only advantage.

All of the above models are suitable for water heaters up to 50-60 liters. Other models are available for larger boilers, many of which have additional devices built in. This is usually a ball valve and / or a pressure gauge to control pressure.

For boilers up to 200 liters

The water discharge connection here has a standard thread, so there will be no problems with the reliability of the fastening. Such devices already have a rather high price, but their quality and reliability are much higher.

With pressure gauge and original

Not everyone likes these devices in appearance. For those who attach great importance to aesthetics, very attractive devices are produced. Their price, however, is comparable to the price of an expensive water heater, but beautiful.

How to choose a boiler model?

If the heater is equipped with a safety valve as standard, the same model must be purchased for replacement. However, sometimes situations arise when it is necessary to install the device on an old boiler model that is not equipped with such protection.

In such cases, it is customary to be guided by the color of the drain handle:

- red - the model is designed for a maximum pressure of 0.6 MPa;

- black color - 0.7 MPa;

- blue color - 0.8 MPa.

The boiler parameters can be found in the instructions. Sometimes the ultimate pressure is indicated on a special plate or paper sticker installed on the body of the device.

It is necessary to choose a device in exact accordance with the forthcoming load.... If it is designed for less pressure, the water will constantly drain. If the rating of the valve is much higher than the operating value, the device will not work in case of overload, creating a danger to the heater.

How to choose and install

Select the safety valve for the water heater according to the pressure for which the unit is designed. This figure is in the passport. Also, the choice is influenced by the volume of the tank. They produce devices with a response limit of 6, 7, 8, 10 bar. Basically, all units are designed for such pressure. So everything is simple here.

Installation is simple: linseed tow or fum tape is wound on the thread, after which the valve is screwed onto the branch pipe. It is twisted all the way by hand, then another one or two turns with the help of keys. It is much more important to choose the right place for its installation. When installing the water heater, this valve is installed directly on the cold water inlet.

Related article: Finishing window slopes with sandwich panels - the final stage of installation

Installation example

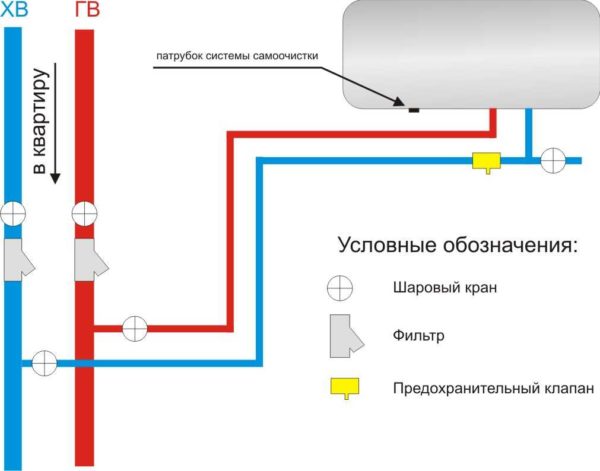

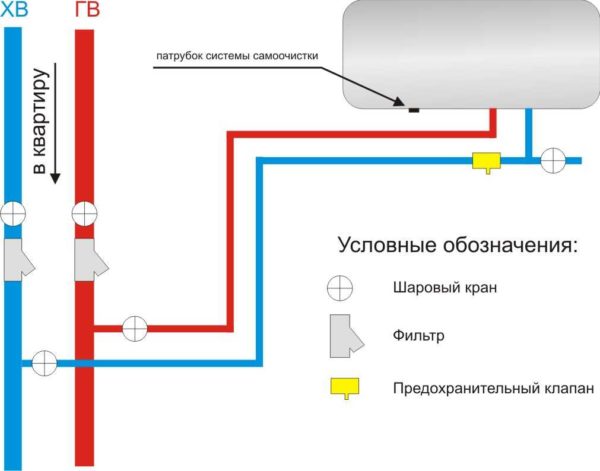

Further, there may also be a check valve, which is also called a stop valve. But this is already a reassurance - the same device is available in the safety one, and even often after the water meter at the inlet. The installation diagram is shown below. This is one of the normal options.

Boiler safety valve installation diagram

The diagram has a ball valve. It is necessary to empty the tank before storage for the winter (in summer cottages) or before dismantling for maintenance and repair. But more often they put it on a tee, which is screwed directly onto the inlet pipe of the water heater. A safety valve is screwed onto the tee from below, and a ball valve is placed in the side outlet.

Installing the safety valve after the tee

Actually, these are all normal options.

Step-by-step installation instructions

An overpressure valve is installed on the cold water supply line to the water heater. There should not be any additional devices or shut-off valves between the boiler and the device.

On the body of the device, an arrow shows the direction of the water to eliminate installation errors.

Tools and materials

To install, you will need:

- FUM tape or sanitary flax;

- transparent tube to the outlet;

- gas wrench (small).

Winding is needed to seal threaded connections. It is necessary to use the gas wrench carefully so as not to rip off the thread or tear off the pipe on the boiler.

The transparent tube is pulled over the outlet and the other end is placed in the sewer.... The tube does not have to be transparent, but it is more convenient to control the drainage process if you can see the mode of dumping excess water.

Installation process

Before starting the installation, it is necessary to disconnect the power supply from the boiler, drain the water and turn off the supply valve.

The valve assembly is usually screwed directly onto the heater make-up connection.... Plumbing tape or FUM tape is applied to the threaded connections, after which the valve body is screwed on.

The outlet must point downwards. Then the flexible supply hose is screwed on and the water drain tube is stretched.

To test the performance of the protection, pour water and turn on the heating. When the device reaches the nominal mode, the drain handle is set to the vertical position. If water has flowed from the pipe (it can be seen through the transparent walls of the pipe), then the installation is done correctly.

Draining

Next, proceed directly to the drain. How quickly the operation will take place depends on how the device is connected (strapped).

Connection is simple

Loosen the nut on the cold water supply pipe.

The simplest of the options for connecting the boiler does not imply the presence of any devices to facilitate the task of draining.Here, most likely, you will need tools - an adjustable or wrench (the number of the latter is selected independently), a hose of a suitable diameter.

So, there are two pipes available, connected to the nozzles on the body. Cold water enters the tank one by one, hot water comes out on the other, they are easy to distinguish by the color of the gaskets at the point of connection to the boiler body (blue and cold, respectively). A check valve must be installed on the first (cold) pipe - it passes the liquid towards the tank and does not allow it to flow back.

In order to drain the water from the boiler, you must do the following:

- unscrew the nut at the junction of the cold water supply pipe and the branch pipe on the heater body (a little water will flow out, you must substitute a basin in advance);

- put a flexible hose of a suitable diameter on the nozzle (sometimes a hose from the shower fits along the thread) and direct it to the sewer - to the toilet or bath;

- unscrew the nut at the junction of the hot water outlet pipe - air will enter the branch pipe, a characteristic gurgling will be heard, and the liquid will begin to flow down the hose.

Tip: how to drain the boiler with this connection method is available and shown in the video at the end of the article.

How to do without dismantling pipes?

In the above described way, the water from the boiler can be drained quickly enough, but there is one problem - you will need to tinker with loosening and tightening the nuts. For those who do not like (do not know how) to do this, you can try to release the liquid through the check valve.

It is necessary to raise the flag on it to a vertical position, and place a bucket under the outlet. When it becomes necessary to empty the container, it is lowered again and the liquid stops flowing.

Important: if the shut-off valve does not have a valve, it will not be possible to do without dismantling the connection.

It remains to solve the problem with the hot water outlet pipe. In order not to unscrew it, you can try to blow air through the nearest mixer. To do this, it is recommended to put a small hose on the gander and blow into it with force. In this case, the hot tap must be open.

Important: This method has a couple of disadvantages. Firstly, the opening of the check valve is much smaller than the diameter of the pipe, and therefore the water in any case will drain much longer than through the tee tap. Secondly, it is possible to blow air into the system through the mixer only if it is located near the boiler, and the hot water supply pipes are not of a complex configuration.

Connection with quick drain fittings

Quick drain of water from the boiler.

The question of how to quickly drain the water from the boiler is not concerned with those consumers whose boiler was connected in a complex way - with the installation of special tee valves. They are installed on pipes, right at the outlet of the boiler (in cold water, be sure to above the check valve).

In this case, after carrying out preparatory measures, they act according to a simplified scheme:

- a flexible hose is put on the outlet of the tee on the cold water supply pipe, lowered into the toilet or bath;

- start the air through the hot water pipe (open the tap);

- turn the faucet on the cold water supply pipe to a horizontal position;

- drain the liquid until the stream runs out.

Important: often the outlet of the tee on the hot water pipe is immediately (when a water heater is connected) connected to the sewer. This installation method is undoubtedly convenient - there is no need to pull and remove the hose every time. However, with this option, it is solely by ear to determine whether the water has drained from the boiler.

Malfunctions: their causes and elimination

There are two types of malfunctions:

- Continuous leakage from the outlet. This indicates overpressure in the water supply system. The problem is solved by installing a gearbox.

- No release of excess water at high pressure in the tank.This means that the valve is damaged or has a higher pressure rating. In any case, the device must be replaced by choosing a suitable model at par.

It is necessary to periodically check the functionality of the device. Replacing it will be much cheaper than repairing or buying a new boiler.

What to do if it flows from the safety valve from the water heater, the video will tell you:

Pouring water from the boiler through the drain cock

This is how the most far-sighted people free the water heater from water. Knowing about the inevitability of this process, they pre-install a drain valve in the boiler connection diagram to the water supply. The tap is mounted on the cold water supply directly at the boiler inlet. It is clear that one more tap is needed before the drain tap, which will shut off the water supply to the boiler. Otherwise, an attempt to drain the water from the "ariston" will turn the apartment into a pool, where the riser will work to fill it. A piece of hose is put on the tap, through which the water can simply be drained to the right place without spilling a drop. And an important detail. The hot water pipe of the boiler must be in communication with ambient air. To do this, it is enough, for example, to turn the hot water valve on the mixer in the bathroom. Without this, the vacuum inside the boiler will prevent you from quickly and easily getting rid of the water. This rule applies to any method of removing water from the boiler.