What is it needed for

When water heats up, it expands and increases in volume, and the pressure rises accordingly. If it exceeds the level of strength of the boiler, then it will simply explode. To prevent this from happening, a safety valve is installed. It does not allow the pressure inside the heater to rise above normal.

In addition to protecting against a possible accident, the valve performs the following functions:

- does not allow warm water to return from the tank to the water supply;

- protects against water hammer;

- if the water supply is cut off, it will not be necessary to refill the container with water.

If you think that your device will be protected by a thermostat, then you are mistaken. They control the degree of heating of the water and do not allow it to boil. However, like any other device, they can fail, with the result that the consequences will be irreversible. Therefore, it is not worth the risk.

You can read about the types of thermostats for a water heater on the page.

What can happen in the absence of boiler protection

Consider the option of lack of protection, which blocks the return flow of water supply to the tank. In this case, the water heater, even with a stable pressure in the water supply network, will not function correctly. According to the law of thermodynamics, with an increase in the temperature of water in a constant volume, its pressure will surely begin to increase. As a result, a moment may come when the water pressure begins to exceed the supply pressure. Then the discharge of hot water will begin to occur in the plumbing system or even the toilet cistern. In this situation, cold water continues to flow into the boiler, and the operating thermostat gives the command to the heating element for constant heating, thereby wasting expensive electricity.

A more critical situation may arise when the water pressure of the water supply network drops sharply. This usually happens often at night, when the relevant services perform unforeseen repairs or maintenance work, shutting off the cold water supply. In this case, a complete drain of water from the boiler leads to burnout of the heating element.

To avoid such situations, many "grief Kulibins", not realizing the complexity of the situation, put ordinary check valves in the water heater system. However, they do not understand that they are planting a "time bomb" in their homes.

After all, a water heater is a complex thermotechnical device, its automation and thermostat can also fail at the most inopportune moment. Then events can turn very sad. If the material from which the water heater tank is made is selected correctly, then boiling does not occur there, since the boiling point here shifts above the usual 100 degrees and the situation is under control. However, if the material does not correspond to the strength characteristics, then if any water tap in the apartment is accidentally opened, the internal pressure of the tank may sharply drop, the boiling point of the water will return to 100 degrees, and then an avalanche-like stream of steam appears with lightning speed, which can lead to mechanical damage to the boundaries of the tank and powerful explosion.

Output

When drawing a conclusion regarding the installation of additional protection for a water heater, the following factors must be taken into account:

- Dump excess water when it heats up, keeping the parameters of the zone of its safe pressure;

- Prevent backflow of water from the heater;

- Smooth out water hammer and pressure surges in the water supply system.

How it works and works

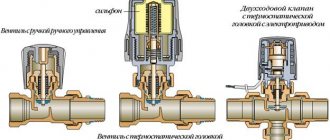

When talking about a safety valve for a water heater, it is better to use the phrase "valve system", because there are two of them in the device.

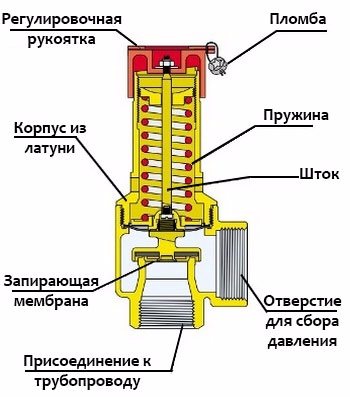

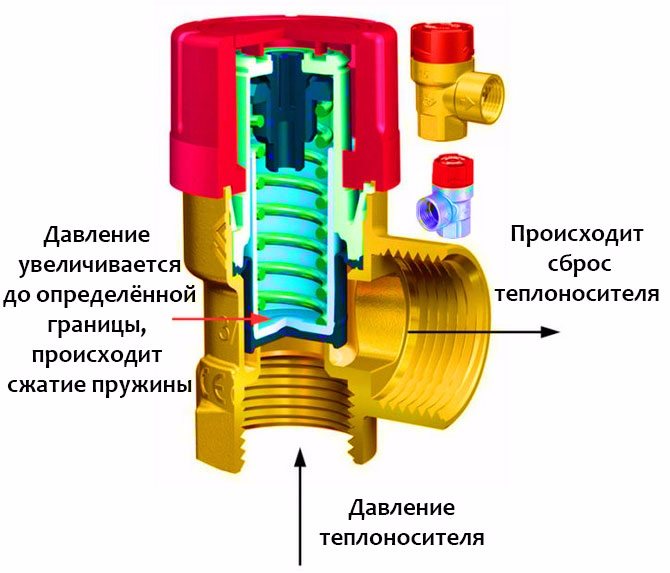

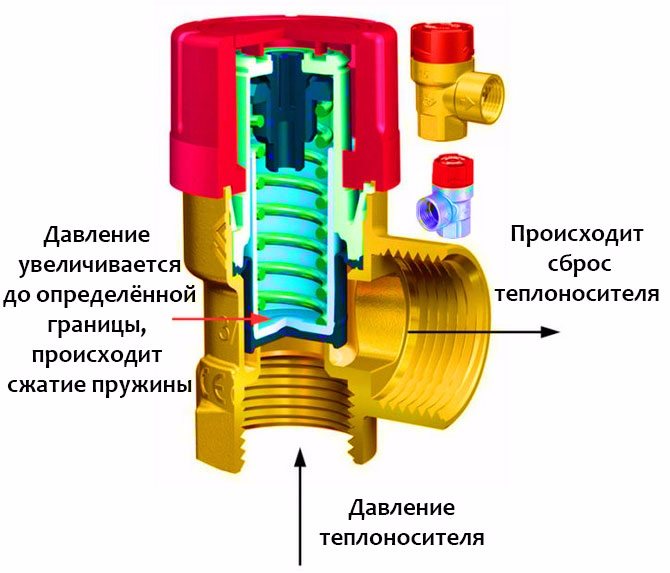

Boiler safety valve device

They are located in a brass or nickel-plated case. A non-return valve is installed at the bottom of the body, which, at the moment of decreasing the pressure in the system, prevents the outflow of water from the water heater. In the perpendicular branch there is a second valve, due to which, at the moment of pressure increase, part of the water is released through the nozzle.

How the safety valve works

Principle of operation:

- As long as the pressure is normal, the valve is closed and does not allow the liquid to flow out, as soon as it becomes equal to the pressure in the water supply, the spring presses the plate against the protrusions of the body and blocks the flow of water.

- When heating is turned on, the temperature of the water gradually increases, along with it, the pressure rises.

- As soon as the pressure exceeds the spring force, an outlet opens to the fitting, through which excess water is drained. When the pressure returns to normal, the spring closes the passage and the flow of water stops.

Based on the principle of operation, it becomes clear that water from the nozzle will constantly drip. To drain the draining liquid, a tube of the appropriate diameter must be put on the branch pipe and secured with a clamp. The pressure required for the normal operation of the water heater is 6-10 bar.

The tube on the fitting must be transparent so that you can control the process of the device functioning.

What is a safety valve for?

To figure out why a valve is installed on a water heater, it is worth recalling the school curriculum. According to the law of physics, water expands when heated. The liquid is inside a sealed container. If there is no parsing of water, the pressure rises and the tank can burst. A safety valve for the boiler, which releases excess liquid from the container, will help prevent an accident.

On the forums, you can find information where it is advised simply not to install a check valve. Then the installation of the overpressure relief valve does not need to be done. In their opinion, when an excess of pressure appears, part of the water will go back into the pipeline. Part of the advice is correct, but the system will work as long as the water supply is stable. The fallacy of this advice lies in three reasons:

- there are no stably working water pipelines without breakdowns;

- without a check valve, all the water from the tank will go into the empty pipeline;

- the bare heating element will heat the air inside the empty container.

Now let's look at the end result of the problem. In the event of a water supply failure, the pipes remain empty. There is no check valve on the inlet pipe, and water from the storage tank flows freely into the system. The thermostat will turn on the heating element when the temperature drops. Without water, the heater will simply burn out, but this is only half the problem.

There is another danger. The heating element is heated, and water appears in the water supply system. A large amount of steam and excess pressure are suddenly formed inside the tank, which does not have time to bleed back into the pipeline. The tank is guaranteed to burst in several places. Boiling water will pour into the apartment. For this reason, it is better not to be smart, but simply install a relief valve for water.

Views

Conventional safety valves are similar in appearance and differ only in small details, but they are responsible for the practicality of use.

The figure shows two safety valves with release levers. They allow you to check (need to be carried out monthly) the operability of the device.

Boiler safety valves with forced pressure relief

The difference between the two presented modifications is that in the sample in the photo on the left, the lever is fastened with a screw, thereby eliminating the possibility of accidental opening or complete discharge of water.

Another discrepancy: the shape of the fitting. The sample on the left has an oblong, nonlinear fitting. It is easy to put on a hose and is long enough to install the clamp. But the fitting on the right model is short, with an extension towards the end. It will be very difficult to pull the clamp on such an instance.

The following illustration shows a relief valve without a positive pressure relief flag. The model on the upper left has a screw cap. If necessary, it can be unscrewed and cleaned of all kinds of blockages.

Safety valve without forced pressure relief

The sample on the right is the worst of the options because it cannot be serviced. The only plus of these models is the low price.

The above models are suitable for water heaters with a volume of 50-60 liters. For larger boilers, other models are suitable with built-in accessories: a ball valve or a pressure gauge that controls the pressure.

Safety valve for large boilers

In such devices, a water discharge connection with a standard thread, therefore, the fastening is strong. Such models are of high quality and reliability, and therefore are not cheap.

How to choose

When choosing a safety valve for a water heater, pay attention to the following components:

- the temperature for which it is designed;

- threaded connections (usually half an inch);

- pressure;

- whether the design provides a handle for forced draining.

When purchasing a relief valve, be sure to check its pressure, because this is one of the most important indicators. If you buy a device with a smaller size, you will constantly have to face the problem of water leakage. If with more, then it may be useless and will not protect the container from an explosion.

You will also need to install a water filter, which will protect the water heater.

Installation

Before starting the installation of the safety valve for the water heater, be sure to drain the water from the device and turn it off.

The location of the device is the inlet of cold water to the boiler. The installation process is quite simple: with a key for 3-4 turns using seals, the second threaded end of the valve is connected to the cold water supply system.

Be sure to check the direction of the incoming water - it is marked with an arrow on the valve body.

If the water pressure constantly jumps and often exceeds the norm, then you must first install a water reducer.

Water leaks from the valve from time to time. This is an absolutely normal phenomenon, which indicates the normal operation of the boiler, but not everyone likes it. In this case, the drainage pipe must be connected to the sewer system by means of a flexible transparent hose, which will allow you to control the device's performance.

Installed safety valve on the water heater

Some people in the street do not want the valve to be visible and place it away from the water heater. Such manipulations are quite applicable, but subject to two important conditions:

- shut-off devices must not be installed at the distance between the valve and the boiler inlet;

- a long vertical section of the water supply will by itself increase the pressure on the valve and unnecessary leakage may occur.

The distance between the valve and the boiler should be no more than 2 m.

Valve performance check

The first way: it can be determined visually. It is enough to turn on the water heater. Working product - water starts dripping.For convenience, a hose with a transparent surface is mounted on the drain outlet. Its end is discharged into the sewer or a nearby dish.

Second way: using a lever. With its help, the forced draining of water is carried out. This method is useful if the entrance hole is clogged with various particles of debris, rust. Hand draining a small amount of water at regular intervals will ensure that the valve is functional.

How to choose the right product

The purchase of a safety valve is made taking into account some parameters:

- what temperature the product is triggered;

- thread size;

- preset pressure for the valve. If the parameter is not indicated on the case, then you need to ask the seller. A purchased product with a higher pressure value will lead to an explosive situation;

- the presence of a forced drain handle on the product.

From a large number of designs, experts advise choosing a product with a spring. It is distinguished by its reliability. Such a mechanism is capable of withstanding fluid pressure.

It is recommended to opt for a product of low or full lift in terms of its throughput. The open type safety valve is selected if excess water is discharged into the atmosphere. If in a special hose, then preference is given to the closed type of valve.

Installing the product

Modern models of boilers on sale come with a safety valve mounted in them.

If the product is missing, it is recommended to put it back in place:

- The water heater is disconnected from the network.

- Liquid is drained from it. It shouldn't be in the boiler.

- A valve is installed on the cold water pipeline. For work, you need to prepare a key, a FUM tape.

- The correctness of the installation is checked: the water flow must coincide with the arrow on the wall of the structure.

Recommendations for use

Do not install locking mechanisms between the safety valve and the inlet to the storage water heater.

The valve is fixed at a distance not exceeding 2 meters from the boiler entrance.

Why is tap water dripping

Dripping water signals a malfunction of the part, but even if water drips under high pressure, do not panic in advance. This can be triggered by several reasons:

- spring stiffness is poorly adjusted;

- the pressure in the pipeline exceeds the norm.

In the first case, a malfunction could arise due to the fact that the installation was carried out by non-professionals. Many check valves are manufactured with the ability to change the factory settings for the spring rate. A specialist should adjust the stiffness. If the settings have not changed, then most likely the spring has weakened, in this case, it is advisable to replace it with a new one.

If the cause of the breakdown lies in the increased pressure in the pipeline, then before installing the safety valve, it is recommended to install a pressure reducing valve.

If there is excessive pressure in the pipeline, you can install a pressure reducing valve at the entrance to the apartment, so you will protect all devices in your home at once.

You will spend very little money on the purchase of a safety valve, and you will get the safety and long service life of the water heater.

How to check if it works?

You can check the serviceability by turning on the water heater (do not open the hot water tap at the same time) and wait for the water to fully heat up to the maximum possible temperature. After a while, excess water should drip from the safety protection mechanism.

The valve will not work if:

- the hot water supply tap is faulty (the pressure will be released through it);

- the thermostat is set at 30-40⁰ С (the water will not warm up to such an extent that the pressure inside the tank reaches the permissible level);

- the operating pressure of the safety valve is high, does not correspond to the capacity of the water heating equipment (the maximum permissible pressure in the storage tank will not be sufficient to trigger the safety valve mechanism. It can have dangerous consequences).

Water from the valve device must be drained periodically. If this does not happen and all of the above cases are excluded, the fuse itself is faulty. It must be replaced with a new one, after checking its performance.

The safety mechanism must be installed on the water heating equipment to ensure long, trouble-free, safe operation of the device. You should choose the option most suitable for all design and functional parameters, otherwise its activities will be ineffective, and even dangerous. In this case, it is necessary to periodically check its serviceability, approximately once a month. If a malfunction is found, replace the inoperative valve with a new one.

It is very dangerous to improve it independently, to replace it with a check valve mechanism. This will lead to unpleasant consequences, due to which, it is likely that you will have to replace the purchased water heater with a new one.