Styrofoam

Polyfoam is a porous and lightweight insulation. It is made of polystyrene by foaming. It is considered one of the best (at a low cost) in relation to other thermal insulation materials. It is produced in the form of slabs of different sizes, density and thickness. It has good thermal insulation characteristics, as it consists of tightly connected sealed balls filled with air or gas.

Advantages of expanded polystyrene:

- low coefficient of thermal conductivity - 0.035 W / m · K;

- ecologically pure;

- does not allow moist air to pass through;

- able to serve for decades;

- not subject to decay;

- windproof.

Polyfoam is easy to install by one person, as it is lightweight. It is used both inside the living space - walls, ceiling, floor, and outside. They finish different surfaces with it: wood, brick, concrete and others.

It is not used as sound insulation, since it has weak sound insulating properties.

Soundproofing the apartment

Determine the cause of poor sound insulation

In the modern world, the opportunity to be in silence is a real luxury. High-quality windows can almost always protect from street noise, but getting rid of the invisible presence of neighbors is not so easy. The night crying of a child behind the wall, a loud anniversary from above, the singing of a neighbor from below, who loves to perform an aria in the shower - all these are not just sources of irritation. The inability to have quality rest in your own home can lead to chronic stress, persistent fatigue and even neurosis. Or maybe you yourself have long dreamed of a home theater, but cannot afford it because of the excessive sound permeability of the walls of the apartment?

To solve the sound problem of a high-rise building - make high-quality soundproofing. You can deal with this on your own. First, determine what type of noise is haunted. Acoustic specialists distinguish three types of noise: airborne, impact, and structural.

Airborne noise propagates through the air. Meeting an obstacle in the form of a wall, partition or ceiling on its way, the sound wave does not extinguish, but causes vibrations in the material of the obstacle. The vibrations are transmitted to air particles in the adjacent room, and we hear noise. Examples of airborne noise are a working TV, a conversation between neighbors, and a crying baby. High-quality soundproofing material dampens vibrations and helps to eliminate the problem.

Impact noise occurs when a structure is mechanically stressed. For example, when objects fall to the floor, when rearranging heavy furniture. In this case, you need to soundproof the floor and ceiling.

In case of structural noise, the sound moves through the structures of the house. Getting rid of this noise is the hardest part. If the problem is structural noise, then only complete sound insulation of all surfaces of the apartment will help.

Local sound insulation

There are especially weak points in apartments. Everyone from childhood knows the "spy way" of eavesdropping through an outlet. You may be very surprised that most often the holes for sockets between different apartments are through, and the builders do not bother to equip them not only with sound insulation, but even with an elementary partition. If this is your case, use the services of an electrician or eliminate the cause yourself, strictly observing the safety rules when working with electricity.

To do this, disconnect the power outlet, remove it, then remove the back box. Seal the hole with cement or plaster putty, and after drying, mount the rosette.

The above method allows you to eliminate one more point of noise penetration - through the junction boxes. They are usually located in walls near the ceiling and hidden under wallpaper or paint. They are fairly easy to spot by tapping on the wall. Although it is better to use the services of a professional, as there is a large number of electrical cables inside.

Risers of pipelines, heating and sewerage systems are another source of the penetration of extraneous sounds. Ideally, at the construction stage, their installation is carried out as follows: a sleeve of a larger diameter than the pipe is inserted into the ceiling. The space between the sleeve and the pipe is filled with a non-combustible sound insulating material. From above it is sealed with a special non-hardening sealant. In practice, pipes are often simply passed through the slab, and the gap is filled with ordinary cement, which cracks and crumbles over time.

To eliminate the drawback, it is necessary to clear the old cement as deeply as possible, wrap the pipe with sound-insulating material, cement the damaged section of the overlap, and seal the joint with an appropriate sealant.

The last point of local sound insulation is the elimination of deep cracks between floors and walls. To block the sound path, you can fill joints and cracks with plaster putty, cement or non-hardening sealant.

Sound insulation of surfaces

The best place to start is on the floor. Eliminate the imperfections of the overlap, eliminate irregularities and cracks. Then use dry or wet screed technology. With dry technology, a sound-insulating material is laid on the floor, and on top it is covered with chipboard or gypsum board. In wet technology, one more separating layer is used, chipboards are replaced by a concrete screed. Both options do the job well. With this technology, the rigid subfloor is not connected to the rest of the building, so the noise is not transmitted to other rooms.

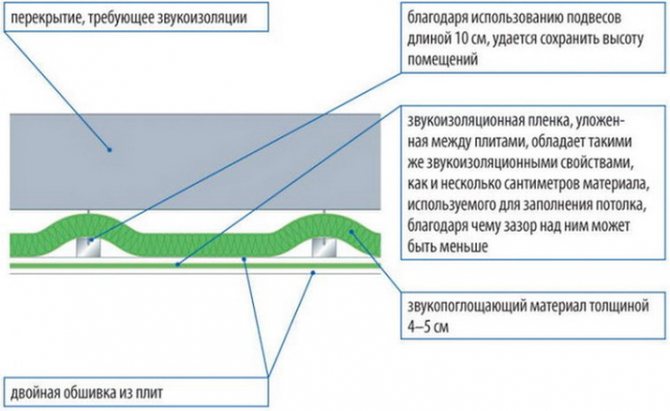

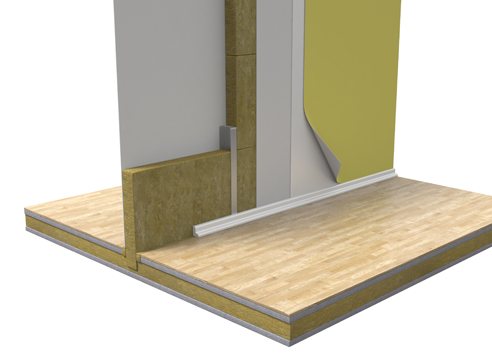

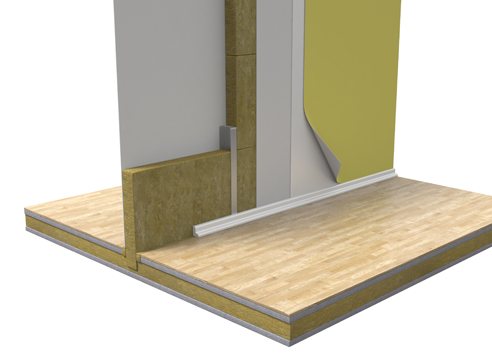

Soundproofing of walls consists of mounting a wooden or metal profile on the walls, laying soundproofing material, sealing tape and a top coat of plasterboard boards.

The ceiling is insulated in the same way. Contrary to popular belief, sound insulation can be installed not only in a suspended ceiling, but also in a stretch ceiling. In this case, the soundproofing plates are attached directly to the floor slab, and the stretch ceiling itself is an additional method of noise reduction.

Material

What material to choose as sound insulation? Often sellers offer various insulation materials for this, which not only do not cope with the additional task, but also increase the resonance. Indeed, in order to absorb sound, the material must be porous and fibrous. One of the materials that meet these requirements is stone wool. For sound insulation, special stone wool slabs are produced.

For example, the Danish company ROCKWOOL presents two products. These are ACOUSTIC BATTS and FLOR BATTS plates. The first ones are used for walls and ceilings, the second ones - for the floor, since they are able to absorb not only air, but also impact noise. They can be installed under any type of screed (wet or dry) and with any floor covering.

Material thickness

When choosing a material, you must also pay attention to the thickness. Of course, I want to make the space of the rooms as special as possible. But no matter what the sellers promise, ultra-thin slabs will not be able to cope well with sound insulation. Sound waves are designed in such a way that they can "get bogged down" only in an obstacle with a thickness of at least 50 mm. Only with such a thickness will sound insulation work in both directions: not only the neighbors will not be able to disturb you, but you will not be able to bother them either.

A 100mm slab of stone wool will do better with noise. But for a standard city apartment, such losses in space will be too noticeable. So feel free to opt for 50mm slabs. With them, each family member will receive the desired freedom of action, while peace and tranquility will reign in the apartment.

We thank ROCKWOOL for the information provided

Extruded polystyrene foam

Externally, extruded polystyrene foam is similar to conventional foam, but has a higher density and less thickness. An extruder is used in its production. Due to this, the extruded expanded polystyrene has closed cells of the same size.

Due to its high density, extrusion is used in the construction of railways and highways, as well as runways. This material has excellent strength, so it can be used not only as thermal insulation, but also as an auxiliary or supporting structure.

Positive qualities of extruded polystyrene foam:

- does not absorb liquids;

- does not sit down;

- not afraid of chemicals;

- does not rot and does not overgrow with mold and fungi;

- service life - about 50 years;

- has one of the lowest thermal conductivity coefficients.

It is used for insulation of walls, ceilings, floors, foundations in private houses, apartments and industrial facilities. Also, like polystyrene, it is used only as thermal insulation.

Soundproof VEM

In 2013, a highly effective sound-insulating material was released - this is a high-density elastic membrane Soundproof VEM. In the range of materials Zvukoizol membrane is designed to increase the density of soundproofing ceilings and walls in rooms. Membrane Zvukoizol VEM is supplied in rolls and is mounted with an adhesive on a drywall sheet. The square of the roll is the same as the area of the drywall sheet. The density of the membrane is 1200 kg per m3 with a thickness of 2.5 mm. Membrane Zvukoizol VEM is analogous to materials such as Texound (Spain) Shumoblock (USA), but the price per square meter is more affordable

Polyurethane foam

Consists of two components: polyul and isocyanate. By mixing these substances on special equipment, you can get polyurethane foam of different states - from elastic to hard. Polyurethane foam has one of the best thermal conductivity coefficients, therefore it is used for heat and sound insulation of residential buildings and other objects. The consistency is similar to foam.

Related article: Cork backing for wallpaper for noise insulation

It is applied to any structure by spraying. In just a few seconds, a durable and seamless layer of thermal insulation material is obtained. It is important that all the rules for the application technology are followed. Only qualified specialists should work with this thermal insulation, using the appropriate equipment.

Positive characteristics of polyurethane foam:

- operating temperature - from −150 ° С to + 200 ° С;

- thermal conductivity coefficient 0.022-0.028 W / m · K;

- sprayed onto any surface;

- a solid and monolithic layer is formed;

- has anti-corrosion properties;

- long service life;

- environmentally friendly;

- excellent soundproofing material;

- does not require additional transportation costs, since all the components are brought by the service company.

Sale of heat and sound insulation based on stone wool in the Rockwool online store

Your region:

Unfortunately, the online store only works in Moscow, St. Petersburg and their regions.

Unfortunately, the online store only works in Moscow, St. Petersburg and their regions.

Your shopping cart is empty.

Total in the basket

| Volume: | 0 m³ |

| Square: | 0 m² |

| The weight: | 0 kg |

Request a call back *

Enter your phone number and we will call you back within a few minutes:

* The service is available from Mon-Sun.from 9:00 to 21:00

Application accepted, wait for a call!

Average processing time during business hours is 3 hours.

* - required fields

Application accepted, wait for a call!

Upon purchase of 3 packs of Acoustic Ultrathin

Upon purchase of 3 packs of Acoustic Ultrathin

Rockwool Calculator

Start calculation

Promotion for Sauna Butts

Promotion for Sauna Butts

ROKFASAD

Basalt wool

During the production process, from the molten basalt rock processed according to a special technology, mineral wool is obtained. Additives and binders are also added. Basalt slabs are used to insulate residential premises and other buildings. They are very convenient for installation, as they are easily cut with a knife. They can be given any desired shape and installed close to the structures of the house. Basalt slabs are often used as sound insulation on exterior or interior walls.

It is convenient to insulate inclined surfaces in attic buildings with mineral wool of the required thickness. Basalt wool is well suited as a device for fire protection of parts of roofs and roofs in houses with stove heating and baths.

Basalt wool properties:

- low hygroscopicity;

- high sound insulating ability;

- easy to process;

- has low deformation;

- is non-combustible material;

- has high thermal insulation qualities.

Mineral wool properties

The material, in addition to soundproofing properties, has other characteristics:

- Water vapor permeability. The property lies in the conductivity of the condensate so that it does not linger or accumulate inside. The best indicators are for stone wool. They amount to 0.35 mg / m2. x h x Pa.

- Density. Such indicators for stone wool range from 20-220 kg / m3. Depending on the density, the stiffness of the material changes. Wool with a density of 200 kg / m3 can withstand a load of up to 700 kg. The lower the density, the softer the cotton wool, therefore, it is easier to work with it on curly surfaces, in places with increased irregularities.

- Thermal conductivity. According to the norms, this value should correspond to the value of 0.45 W / mx K.

Mineral wool is a non-combustible material. When heated, no corrosive substances are emitted. Withstands temperatures up to 700 degrees without any consequences.

Bung

Environmentally friendly wood material made from oak bark and having a porous structure. All cells are filled with inert gas. Differs in positive qualities in sound and heat insulation when used in residential premises. Not used outside.

Technical cork materials provide excellent sound insulation. It can be classified into three application groups:

- Agglomerate panels are made from crushed cork oak bark followed by steam treatment and then pressed. Since the bark contains the suberin adhesive, unnatural additives are not required. Two types of panels are made: white - from the bark taken from tree branches, and black - from the trunk bark.

- Natural cork - used for decorating rooms. The panels are additionally coated with wax, after which they will not be able to absorb moisture and odors.

- Cork granules - used to insulate frame structures.

Related article: Do-it-yourself thin soundproofing of walls in an apartment

Technical cork is produced in three forms: sheet, roll, in the form of mats.

Roll insulation is most often used as a backing for wallpaper. It can be with or without antibacterial and refractory impregnation. It is produced in lengths of 10 m and a width of 30 cm to 100 cm. For fixing on the surface of the walls, special glue is used.

Cork in the form of mats and sheets is used to insulate floors, walls and ceilings indoors.Also well suited for sound insulation from the inside of the roof, the covering of which is made of metal or profiled sheet.

Plugs of cork:

- low thermal conductivity - 0.042 W / mK,

- it is resistant to deformation;

- good sound insulating performance - reduces noise by 17 dB;

- excellent antistatic properties;

- environmentally friendly;

- durable;

- natural material.

Working with a cork sheet does not require additional physical efforts, since it is easily cut to the size of the shape and is easy to install.

In rooms with high humidity, the cork coating must be protected with waterproofing materials.

Varieties of materials

According to GOST, mineral wool is divided into 3 types:

- Glass wool. This material, made of glass, is characterized by strength and resilience. The length of the fibers ranges from 15-50 mm, and the thickness is 5-15 microns. Work is carried out in respirators so that glass dust does not enter the lungs. Due to the fragility of the fibers, this type is not laid in residential premises. Available in rolls.

- Stone wool. Has a cellular structure. It is made in the form of canvases. It is used as sound insulation on various surfaces.

- Slag wool. It is considered the cheapest type of mineral wool. It is rarely used in construction, because it can sinter when overheated.

Heat and sound insulation panel manufacturers

On the market of heat and sound insulating materials, cork insulation is represented by the Portuguese company Amorim Group.

The most popular brands of basalt wool are:

- TechnoNicol;

- Paroc;

- Isover;

- Linerock;

- Rockwool.

Well-known trade brands of expanded polystyrene are Penoplex, URSA and TechnoNicol. Knauf is the most popular foam manufacturer.

What materials provide better sound insulation?

The most important and widespread material in our life, which has a fair amount of noise-absorbing properties, is polystyrene. Please note that even the headphones used in shooting ranges during blasting operations are made of foam. That is, in the plastic case, behind the protective casing, there is an insert made of dense foam. Thus, I would put the foam in the first place in this standings. But the disadvantage of foam is the high flammability of this material.

Its additional advantages include the convenience of work. The foam is usually supplied in large panels, in the form of sheets of various thicknesses. When we were a large construction site in the country, at the dawn of the eighties, we all had communication with this material, and could study both its buoyancy and noise-insulating properties.

The second most popular material is foam rubber, which, in one way or another, is always present in the life of each of us. We must start at least with the fact that most home furniture is made with foam rubber. Furniture is also a good sound absorber, and therefore an echo appears in an empty room.

Foam rubber is made mainly in white, but there is also black, mainly used for technical work, as well as in other colors (multi-colored - for handicrafts). It is sold in rolls or sheets, and can also have different thicknesses. Moreover, it can also be of different density.

Applying for example for upholstery of doors, in addition to heat saving, noise absorption was also achieved.

The sophisticated design of the floor cushion also provides good additional sound insulation. In other words, the floor is obtained as a layer cake, where the base of the floor is a slab, then there is a screed made of vetonite, then there is a special noise-absorbing gasket, a layer of thick chipboard plywood is laid even higher, which itself is a good sound insulator, and then a porous base is laid and the coating itself, whether it is linoleum, again on a soft or fibrous basis, or a laminate. Thus, the floor, which was previously completely sound-permeable, acquired powerful properties overnight, and became both warmer and less noisy.

For maximum effect, all non-load bearing walls are separated from the ceiling by creating an opening.Special rubber-based materials, made of dense rubberized or hard rubber, naturally non-combustible in composition, are introduced into this lumen. Thus, the effect is achieved that the sounds descending from the ceiling along the walls can no longer do this as before, because there is no solid joint, which means there is no rigid transmission of vibrations and sound waves.

There are even rubberized dowels on sale, thanks to which a screw screwed into the walls does not transmit sound from the wall to the wall as well. But this is a specialized tool, and you can rarely find it on placers in stores.

There are options for felt coverings that use voids and niches. Ready-made pressed felt slabs, voids and niches are placed against the wall that we want to soundproof. Thus, the effect is achieved in which the sound remains inside this panel, that is, inside the niche space.

Of course, the use of any kind of additional ceilings adds a plus to sound insulation. Ceilings can be either suspended or suspended. Additional ceilings can be made of plasterboard, and special wool with good sound-absorbing properties can be placed inside. You can also place foam panels on the ceiling, which are now sold in all hardware stores, in a large assortment. That is, such slabs have a pattern, pattern, ornamentation.

In addition to panels, there are other ceiling space decor items on sale. These are columns, arches, cornices and corners. Everything is made of polystyrene and is easily glued to the wall during installation and repair.

By itself, the glue has the same ability as any silicone or rubberized sealant, and absorbs sounds to some extent.

Summarizing all that has been said, one thing can be said that it will not work to achieve the effect of noise isolation with one or several actions. You will need to perform a full range of all necessary actions and work, using a large number of materials, including non-standard ones. Under non-standard materials here it is necessary to understand purely specific materials that are used exclusively to achieve soundproofing of the room. Therefore, those performers who will carry out and implement the task must have the appropriate experience and understanding of carrying out such work, otherwise the effect may be only partial.

Installation of mineral wool on the walls

The procedure for soundproofing walls with basalt wool:

- A frame is made of wooden beams on the wall. The distance between the vertical posts is made 2 cm less than the width of the insulation.

- Basalt wool slabs are laid.

- Planks are attached to the wooden frame in a horizontal position - for mounting the gypsum board.

- Plasterboard sheets are installed. Screwed to horizontal crossbars with self-tapping screws.

Expanded polystyrene plates are installed in a different way - they are attached to the walls or ceiling with glue and special plastic dowels-nails.

Heat and sound insulation for external walls

Most experts say with confidence that it is the outer insulation that performs much better heat and noise insulation. One cannot but agree here, since it is much easier to install a barrier to freeze the walls than to deal with such freezing inside the building.

In addition, by using insulating covers outside, the usable indoor space will not be reduced by the insulating layer, which often requires a decent number of centimeters.

For high-quality heat and sound insulation outside, a clear installation is required, carried out taking into account a sequential algorithm of actions:

- First of all, it is necessary to substantially prepare the elements where the insulating layer will be mounted. For insulating materials requiring the presence of a frame, a vapor barrier will first need to be made. This point is very important, especially when insulating the coating with mineral or other wool. It is very important to protect the thermal insulation layer from possible moisture penetration. Otherwise, the properties of the insulating materials will be significantly lower than expected. If an adhesive is used as an attachment, then the walls first need high-quality drying. To perform such work, it is better to choose the summer time period. It is very difficult to achieve the desired effect in the spring, winter or autumn period.

- The insulation coating, in the case of outdoor use, is fixed in the same way as indoors. Here, for its installation, you can use both adhesives and other fasteners. After the installation work on heat and sound insulation is completed, the outer walls are sheathed with special materials for facade work.

Unfortunately, this method of insulation is not always available for apartment residents, which is why heat and noise insulation is performed here only indoors.

Insulation of the house outside

Features of thermal insulation in the apartment and tips for choosing

Only environmentally friendly heat-insulating materials should be used in houses and apartments. Cheap basalt wool will contain hazardous phenol formaldehydes. During the heating of the insulation, they begin to turn into volatile compounds that are harmful to human health.

Insulation made of expanded polystyrene is best used for insulating floors (filling with a screed), balconies, loggias, since it is highly flammable. When the foam burns, it emits toxic fumes that cause poisoning. Also, expanded polystyrene does not allow moisture to pass through, therefore, in houses or apartments with poor ventilation, the microclimate will worsen.

Soundproofing materials

Sound insulators such as mineral wool, ecowool, coke fiber, felt and some roll types are fixed on the base between the strips of the supporting frame. The membrane insulation can be glued directly to the ceiling surface. The same goes for self-adhesive soundproofing for the ceiling and foam foam. Consider the characteristics, pros and cons of the most common sound insulators.

Acoustic foam rubber

This is the most inexpensive noise isolator. Foam soundproofing is lightweight, so it can be easily glued to silicone or double-sided tape. The minimum slab thickness is 2.5 cm, and the maximum thickness is 10 cm. One side of the acoustic slabs is embossed. All slabs are classified according to the type of sound waves they dampen. The surface relief depends on this. Foam rubber can be used both independently and together with other materials.

The advantages of foam rubber include its elasticity and flexibility, simplicity and speed of installation, and an increased sound absorption coefficient.

The disadvantages of the material are as follows:

- foam rubber burns, smokes and melts in case of fire;

- the material collapses when heated and under the influence of ultraviolet radiation;

- deteriorates with mechanical stress.

Styrofoam and expanded polystyrene

Extruded polystyrene foam and polystyrene foam are made from foamed plastic. The materials protect the room well from noise and heat loss. In modern houses, sound insulation of the ceiling with Technonikol foam is used, because it is inexpensive, easy to install and has a high sound absorption coefficient. The panels are glued on liquid nails.

Important! The sound absorption coefficient of polystyrene foam plates is 0.4-1, depending on the frequency of sound waves.

- The material can be used in high humidity conditions. It is not spoiled by microorganisms.

- Ease of installation and processing, as well as durability and resistance to temperature extremes are additional advantages of foam.

- High sound absorption coefficient and low thermal conductivity.

- Reasonable price and light weight.

However, polystyrene and expanded polystyrene have significant disadvantages, due to which its use in housing is increasingly being abandoned. Foamed plastics burn well and emit harmful substances with smoke. They do not allow air to flow to the base. When heated, the foam will release toxic compounds. Low mechanical strength of the surface is also a disadvantage.

Design solutions for warmth and silence

The design of entrance doors with sound insulation and thermal insulation assumes the use of various technical solutions. A decrease in the level of heat loss and the volume of sounds is provided mainly by filling the door leaf and ensuring the density of the porch.

Filling the canvas

The canvas is the largest structural element. In the closed position, it is this that is responsible for conserving heat. If wooden parts by themselves retain heat well, then metal is characterized by a very high thermal conductivity, and sound passes through the steel sheet. To compensate for these shortcomings of the metal, it is densely filled with such materials:

- Polyurethane foam. A porous polymer material that retains heat well. It is used not only for warming the canvas, but also for thermal insulation of door slopes under the finish.

- Mineral wool. Heat insulator, consisting of mineral (most often basalt) fibers. The structure provides a decrease in the thermal conductivity of the canvas and reduces the intensity of noise.

- Aerated concrete. It is inferior to common heaters in terms of resistance to heat transfer, but it provides the canvas with additional strength.

- Vibroplast. A material that effectively dampens sound vibrations, reducing the volume of external noise.

Clamp and seal

In addition to heat transfer through the canvas, blowing at the place of pressure can also become a source of heat loss. The tight abutment of the door leaf to the door frame is ensured by the joint operation of hinges, locks, as well as additional elements, for example, eccentrics.

In the place of pressing the leaf against the door frame, one or more sealing contours are fixed on it. In the closed position of the sash, the sound-proof seal for the door leaf completely bridges the gap, preventing the penetration of drafts, loud sounds or foreign odors inside.

Installation

High-quality installation also plays an important role in protection against heat loss and noise.

The structure must be installed as securely as possible so that the slightest vibrations are excluded. Hinges and other elements should be adjusted to ensure effective clamping.

In addition, the junction of the door frame to the opening and door slopes (inside and outside) must be insulated using polyurethane foam, expanded polystyrene, polystyrene and similar materials.