Recently, in the development of German scientists - an analogue of polystyrene, which will be distinguished by environmental friendliness and one hundred percent harmlessness to people and the environment. The combination of all the advantages of the existing thermal insulator with the biological composition of the new generation material will become a breakthrough in the insulation market.

Foam selection

When choosing foam plates for insulation outside, you need to pay attention to 3 main factors:

- Thickness. For this, the climatic conditions of the region in which it is planned to carry out insulation are taken into account. For the Krasnodar Territory, foam plastic with a thickness of 40-50 mm is recommended, and for the northern regions - at least 150 mm.

- Cost. Domestic material will be much cheaper than its foreign counterpart.

- Density. Most experts recommend choosing foam plastic with a density of 15-25 points for insulation outside, which has self-extinguishing properties.

Benefits of expanded polystyrene

We found out that expanded polystyrene is resistant to environmental factors and mechanical stress. But this is just one point from a wide range of benefits:

- Effective energy saving... Due to the structure of gas-filled cells, expanded polystyrene has low vapor permeability and thermal conductivity, and has excellent thermal insulation properties. According to statistics, the thermal insulation indicators of a layer 3 cm thick are equal to 123 cm of concrete, 64 cm of brickwork, 11 cm of wood or 6 cm of mineral wool.

- Durability... Studies carried out in Germany, the homeland of expanded polystyrene, have shown that the material with which the roof was insulated back in the 50th year did not change its insulating and other properties.

- Security... The material is not a source of harmful dust and does not contain fibers. Therefore, it does not require special protective equipment (glasses, gloves) and is easy to process without causing irritation of the mucous membranes and other health problems. Even if a piece of expanded polystyrene is swallowed, there is no negative effect on health, and the material passes through the digestive tract without changes in its structure.

- Ease... The low weight of expanded polystyrene makes it the most economical and convenient material for insulation.

- Resistant to chemicals and biological influences... Expanded polystyrene is resistant to the influence of various chemicals, UF radiation and temperature changes. It is not susceptible to decomposition, washout and the development of mold. This material does not create a breeding ground for the vital activity of fungi and bacteria, and is also not assimilated by rodents and other animals.

- Eco-loyalty... Polyfoam is an environmentally friendly, non-toxic material. It does not contain astringents, does not emit formaldehyde resins, does not deplete the ozone layer and does not pollute the environment. Therefore, in addition to construction, it is used for the manufacture of toys for children, food packaging and the cultivation of greenhouse fruits. In addition, polystyrene foam is recyclable and 100% recyclable without damaging nature.

- Fire resistance... Expanded polystyrene is combustible. But if its cells are filled with carbon dioxide or other refractory components, the material does not ignite and prevents the flame from being thrown further.

- Moisture resistance... Expanded polystyrene is not affected by moisture, its absorbent and diffuse properties are practically zero, due to which it does not require additional waterproofing.

How and what is the external insulation of a wooden house, you will learn by reading this article.

And here is an article about the insulation of a wooden house with mineral wool.

About Styrofoam

No construction can do without this polymer substance, which quickly became one of the most famous and widespread materials.

Excellent thermal insulation properties make it in demand for the insulation of floors, walls and other structural elements of buildings. This heat-insulating material also attracts by its cheapness.

Despite the clear advantages of foam, it has one significant drawback - a low level of environmental friendliness. It cannot be considered absolutely harmless, because, like other foam materials, it is made from plastic, the raw material for which, as you know, is oil.

But in the near future, the market may be replenished with another innovative material that is a worthy alternative to traditional foam.

Advantages and disadvantages

Each of the methods is endowed with advantages and disadvantages.

Frameless way

The frameless installation technique implies finishing the wall with plaster. This is due to the need:

- To "refine" the appearance of the building - white sheets of polystyrene with visible dowel caps and foamed joints create the impression of unfinished construction.

- Expanded polystyrene of any brand is subject to destruction under the influence of ultraviolet radiation, an opaque "covering" material is used for protection.

- The structure of the foam does not allow it to effectively resist destructive mechanical stress.

Advantages of the method:

- The minimum number of technological operations.

- Short lead times.

- Long service life.

The advantages are slightly offset by the difficulties that may arise for a master who does not have plastering skills:

- Additional costs for skilled labor.

- Finishing must be started immediately after the installation of the insulation and finished as quickly as possible, minimizing the time spent by the foam under the sun's rays.

Frame version of insulation

The method consists in preliminary installation on the walls of the building of the frame, between the logs of which a heater is installed. The finishing is fixed in the crate.

Wireframe method:

- Suitable for use with foam with a density of 15 kg / m3.

- Saves building materials for fastening the battens.

- Available for beginners and inexperienced craftsmen.

- The outer finish and waterproofing layer reliably protects the thermal insulation from mechanical damage and weather.

Picture. Warming by the frame method.

Main disadvantages

Flammability. When answering the question whether it is possible to insulate a wooden house with polystyrene foam, the most important argument against is that it, like wood, burns well.

Releases dangerous toxins on fire. Therefore, choosing this method of insulation, it is imperative to carry out fire-retardant processing of wooden structures, choose fire-safe facing materials, and comply with fire safety requirements.

At high temperatures (over 70 degrees), polystyrene loses its structural properties, therefore it is better to use it for external insulation, away from heating radiators and other heating devices.

The disadvantages of this type of insulation include insufficiently high vapor permeability, which can lead to dampness and decay of logs. This applies to damp rooms (saunas where the use of expanded polystyrene is not recommended). In other cases, the problem is solved by organizing ventilation.

It is worth remembering that polystyrene is afraid of chemicals such as gasoline, acetone, etc.and therefore it is necessary to insulate garages, sheds in which paint is stored with them with the implementation of all necessary precautions.

Description of wood foam production

German scientists have invented a cellular material similar in structure, for the manufacture of which natural wood is used. This novelty has the necessary environmental friendliness, which is absent in conventional foam. Woody foam, if you can call it that, will be a profitable replacement for the traditional one.

Recommended: Modern flooring materials

The technology for the production of wood foam is not a particularly complex process. The wood used for its manufacture is thoroughly chopped.

As a result, a viscous mass is obtained, consisting of the smallest particles. This suspension is foamed using a special gas. The mass processed in a similar way gradually solidifies, which is carried out due to the natural substances contained in the wood.

The end product of this process is cured wood foam, which is particularly lightweight. Based on the characteristics of further use, this substance can be used to create both thick solid plates and thin flexible sheets. Finished products are easy to saw and cut.

Description of insulation processes

Each of the above methods of warming is carried out according to an individual method.

Frameless thermal insulation algorithm

The method involves fixing the insulation directly to the wall of the house and subsequent finishing.

Sequencing:

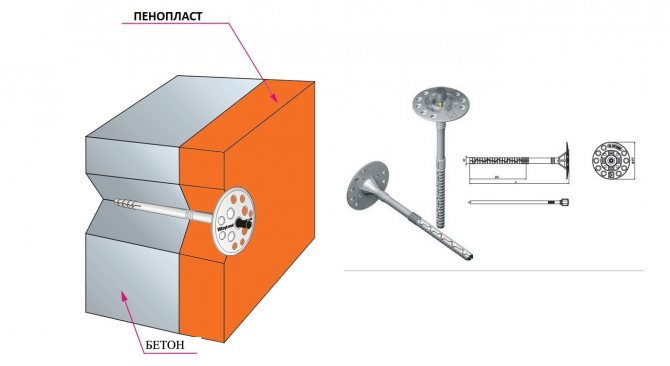

- Calculation and purchase of polystyrene and fasteners. It is not difficult to calculate the amount of insulation required. The perimeter of the task is multiplied by the height of the walls and the area of the window and door openings is subtracted. Dividing 100 by the selected sheet thickness in cm, you get the area that 1 m3 of material can cover. 5-10% is added to the result obtained in case of unforeseen situations. For fixing the foam, dowels with disc heads are purchased. To fix one sheet with dimensions of 1x1 m, you will need 5-6 hardware.

- To seal the seams, buy glue foam or polyurethane foam. For application, you will need a special gun. It should be noted that glue-foam is more expensive, but it is better suited for sealing joints, since it expands less after application, without deforming the insulation sheets.

Excess foam that needs to be removed

Important! Be sure to purchase a polyurethane foam cleaner - other means to wash the tool, hands and clothes will not work.

- Prepare the surface of the walls for insulation. Work is best done in summer when the walls are best dry. Beams, logs, boards are cleaned of dirt, old paint is scraped off. The gaps in the walls made of logs and beams are sealed with tow or caulked. The surface is treated with an antiseptic to prevent the appearance of fungus, mold, and destruction of wood pests. The damaged parts of the walls are restored by removing the damage. Finish the work with a double application of a fire retardant (fire retardant impregnation). The walls are dried.

- Using a building level and a plumb line, horizontal and vertical markings are applied for the first row of insulation. If the first row will be suspended by weight, a support bar is attached to the wall.

Styrofoam installation

There are 2 main ways of insulating a wooden house with foam:

- using crate;

- landing on glue.

Fastening of expanded polystyrene plates with crate

When insulating a wooden house with foam outside, the technology of creating ventilated facades has proven itself well.

The main stages of work:

- To create the lathing, vertically arranged boards are stuffed onto the insulated wall. To calculate the distance between them, you need to add the thickness of the rail to the width of the foam and reduce the resulting bag by 5 mm.

- A vapor barrier film (vapor barrier) is attached on top of the boards with a stapler.

- Rails are stuffed onto the vapor barrier with the help of nails. The distance between the slats should be slightly less than the width of the insulation.

- Expanded polystyrene plates are tightly installed between the slats.

- To seal the foam, use dowels in the form of a fungus. They are screwed in five places. The slots should be blown out with polyurethane foam, and after it dries, lay a diffusion membrane. It is she who removes excess moisture from the house. The smooth side of the membrane is attached to the wall to ensure proper air circulation. The joints are glued with any available adhesive tape.

- Finishing stage - exterior decoration. Most often, thin-layer plaster, siding or lining are used as materials. Their use makes it possible to increase the fire resistance of the walls.

Landing on glue

Foam insulation from the outside by gluing is carried out without creating a frame, the plates are attached to the walls themselves. The disadvantage of this method is the need to hide the joints of the plates and the caps of the dowels under the putty. Plus ─ no need to waste time creating the crate.

Installation procedure:

- For people without experience, it is better to start work on foam insulation from the less visible side of the house. First, stir the glue and leave for 5 minutes, then mix it again. For greater savings, cement mortar is used as the material for fastening. A starting profile is attached to the prepared wall in a horizontal position.

- Using a spatula, glue is applied in a thin strip along the entire perimeter of the slab, and then pointwise in several places in the center. After that, they are firmly pressed against the wall, checking the evenness with the help of a building level.

- If necessary, align with light pats of the hand or using other available means.

- The rows of expanded polystyrene should be laid horizontally, starting from the bottom, in a checkerboard pattern. Slabs are cut with a knife. Openings around windows and doors are lined with a layer of non-combustible insulation. It is advisable to cover the formed cracks with glue.

- After the glue has completely dried, which usually happens after 1-2 days, the insulation plates need to be fixed. To do this, use dowels, fungi. The corners also need to be strengthened by placing the perforated corner on the glue. There is no time to waste time with finishing work, because the foam loses its properties in the sun. Before starting work, the gaps between the plates are foamed. Polyurethane foam is chosen without toluene, because it is dangerous for the foam. The reinforcement mesh is glued to the wall with a small margin. The same is done with the next section.

- The surface is rubbed with sandpaper after 2-3 days, when the glue is dry, then finishing is carried out.

As you can see, foam as a heater for a wooden house outside has its pros and cons.

How to fix polystyrene foam to wooden walls at home

Insulation of the facade of a wooden house is carried out using frame technology. It is a construction of a frame in which the insulation is placed. All work is done in stages.

An example of a frame system for house insulation

Styrofoam properties

This material has long been used in construction and this is due to the peculiarity of its production, which gives it certain properties.

The foam is based on granules treated with dry steam and 98% air. This provides the material with low thermal conductivity and low weight. Porosity gives the foam another property - sound insulation, which is higher, the thicker its sheet.

Thermal insulation of a wooden house with foam outside (video shows in detail how this is done) protects it additionally from moisture, since the absorption of water by it is less than 1% with constant contact with it during the day. In this property, polystyrene is superior to the popular mineral wool, which is also often used to insulate external walls.

This material is not afraid of temperature changes, and it easily tolerates an increase in it to +90 degrees and a decrease to -30. The composition of the foam leaves no chance for the reproduction of insects and microorganisms, therefore it is often laid on external walls that are subject to biological or chemical influences.

With all its hygroscopic and heat-insulating properties, this material has 2 significant drawbacks, which can be reduced to almost zero with the help of special means. It is fragile and highly flammable. Choosing it as a heater for a wooden house, you need to think about how to secure the building.

Its cost and low weight also play an important role when choosing a material for external wall insulation.although low vapor permeability can cause breathable wooden walls to be constantly damp, leading to gradual rotting. This drawback can be easily removed by installing ventilation.

Thermal insulation of a wooden house outside with penoplex

Often, wooden houses have good thermal insulation properties. therefore external insulation of a wooden house with expanded polystyrene is necessary only if:

- during long-term operation, the tree began to leak air;

- there was a violation of the caulked layer;

- blowing takes place with poor joints;

- moisture evaporated from the tree, and the logs began to crack.

If you are not sure that you can competently insulate the house with your own hands, it is better to seek help from specialists.

Thermal insulation of a wooden house with expanded polystyrene takes place in four stages:

- Surface preparation.

- Installation of a vapor barrier.

- Insulation laying.

- Finishing work.

Training

Wood is a rather whimsical material. Therefore, before starting the installation of insulation, you need to properly prepare the surface.

Surface preparation for laying heat-insulating material consists in:

- Removing old paint.

- Drying the walls.

- Checking the joints between the beams / logs.

- Re-caulking the walls (if necessary).

- Potting up potholes.

- Sawing off protruding parts.

- Processing and impregnation of wood with special substances.

Preparing the walls

Before starting work, you need to make sure that the walls are ready for this:

- At first, the wood must be dry enoughtherefore the best time to work is on warm or hot days in the absence of humidity in the air.

- Secondly, cleaning of the wall surface is required, for example, removing old paint or any kind of insulation. They can also be covered with moss or dirty, all this should be removed before starting work. If there are gaps between the bars, then they need to be blown out with polyurethane foam.

- Thirdly, the entire surface of the walls should be treated with an antifungal agent, even if there is no fungus on them. This will save the insulated walls from its reproduction if any spores remain on them.

Having completed this preparation, you can take up the foam. Insulating walls outside a wooden house also requires some work.

Application area

Taking into account the previously mentioned disadvantages, it is possible to choose the use of foam without damage to the building. It is better to insulate wooden buildings with polystyrene (if required) from the inside than from the outside. This will protect the material from destruction, and the building from defrosting. It is more reasonable to use a vapor-proof material in stone buildings (brick, concrete), but if absolutely necessary, you can also insulate wood.

Stone and block buildings can and should be insulated from the outside. But it is not recommended to insulate wooden houses from the outside with foam plastic.

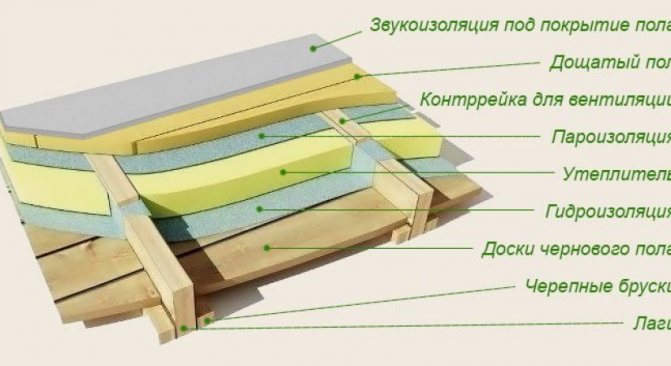

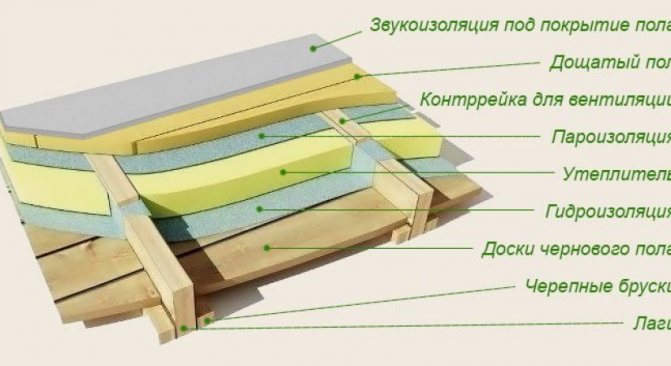

Insulation of floors

When used from the inside, the main area of application is the ceiling. Laying into the floor structure is also possible. But when carrying out work, the strength of the material should be taken into account.

- The first use case is common for concrete slabs. In this case, the insulation is placed under the cement-sand screed. To prevent the foam from perforating, the screed is made reinforced with a thickness of about 50 mm. For reinforcement, special meshes with reinforcement with a diameter of 3 to 6 mm are used.

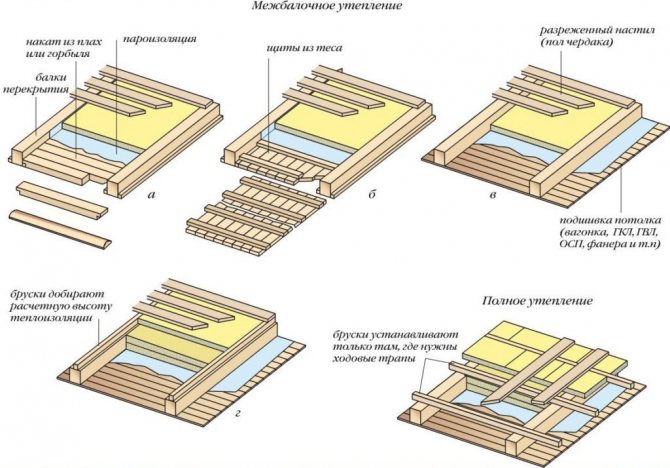

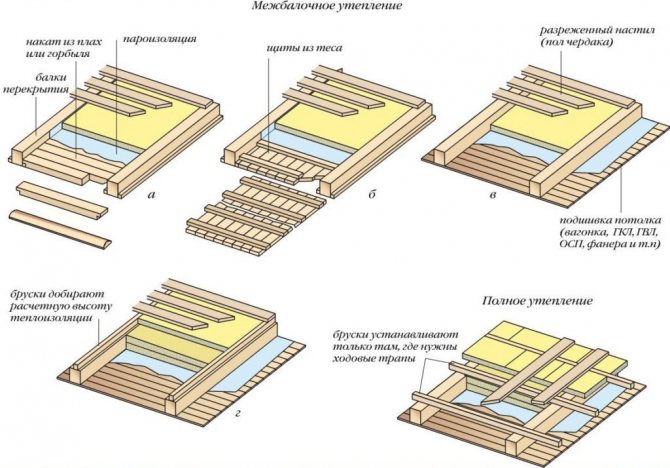

- The second option is applicable for buildings with timber and concrete floors. In the first case, the insulation is placed in the ceiling or floor between the beams. In the second case, you will have to make a wooden frame, between the lags of which foam is mounted. In this case, the overlap pie increases, eating up the useful height of the rooms.

You can also fix foam on the ceiling in two ways. With or without frame. The choice of method depends on what material the ceiling is made of and technical capabilities.

Ceiling insulation with foam

When insulating the ceiling, it is worth remembering about waterproofing and vapor barrier. Polystyrene balls are not afraid of water, but moisture can accumulate between them. Manufacturers are usually silent about this property. In this case, the ceiling should contain the following layers (they are listed from bottom to top, from the side of a warm room):

- the material with which the ceiling is sheathed;

- vapor barrier required to protect the insulation;

- insulation;

- floor structure;

- waterproofing (sometimes mounted over the floor);

- floor of the next floor.

Insulation of the ceiling of the house (attic floor)

If it is necessary to insulate the floor, the vapor barrier is also laid at the bottom, and the waterproofing at the top. It is important to remember that the first is always located on the warm air side, and the second on the cold air side.

Wall insulation

Also, foam is actively used for thermal insulation of the walls of houses from the inside. In this case, steam and water protection is also required. When performing interior decoration, it is worth leaving a small gap between it and the heat insulator to eliminate the accumulated steam.

But it's important to remember that styrofoam is not the best option for walls. It has extremely low air permeability, so it can create a greenhouse effect in the room. In this case, you will have to take care of the device for additional forced ventilation (which is expensive).

Based on the foregoing, it can be summarized: Styrofoam is an inexpensive material to protect a home, with an impressive list of disadvantages. It is wiser to use it for floors than for walls. If possible, it is better to use vapor-permeable mineral wool in a wooden building.

Tips from experts

If only one wall begins to freeze, it is still worthwhile to carry out insulation around the perimeter.

It is better to insulate windows and doors immediately after their installation, and walls - after 1-2 years.

It does not hurt to leave ventilation gaps between the foam and the wall. They should be small. When building a house, it is better to immediately think over the ventilation system.

You should not dwell only on wall insulation, since a significant share of heat can escape into the atmosphere through the ceiling and floor.

Recommended for viewing:

Returning to the question of the possibility of insulating a wooden house with foam, we can conclude that this is quite acceptable. The main thing is to do all the work correctly, in compliance with fire safety requirements.

Technology options

When the facade of a wooden house is insulated, you can live in it in the winter.

When choosing a technology for insulating a wooden facade, it is necessary to take into account the degree of its wear, the properties of the elements of the thermal insulation system, and the features of the area.

The first stage of work is the same for all methods - preparation of the foundation.

Most of the problems arising during the operation of a thermal insulation system are caused by negligence in this stage of construction work.

Foam insulation of a wooden house: wonderful myths and harsh reality

The most frequently asked question about insulation is whether it is possible to insulate a wooden house with polystyrene outside? In order to correctly answer it, you need to go a little deeper into the jungle of thermal physics.

A little about fire safety

Insulation of a wooden house with foam outside is warned to do on the basis of fire safety: the first polystyrene foam burned, while emitting poisonous smoke. However, the production of materials for thermal insulation of facades has now been established (they have the letter F in the marking), capable of self-extinguishing within 1 second. Therefore, fears about the fire hazard have become unfounded.

It's all about vapor permeability

So that the wood of the walls does not rot after insulation, it is required that the "dew point" - the point where water vapor turns into water, does not fall on the surface or body of a wooden wall. If this happens, the tree will rot. That is, after calculating with the help of a calculator, the walls of a house in the suburbs with a structure:

- A beam of pine or spruce wood, across the grain - 250 mm.

- Insulation - polystyrene concrete slab PPS FG15–80 mm.

- Moisture-windproof membrane - 0.1 mm.

- The air gap is 40 mm.

- Facing with planks (like a ventilation facade).

We get that the wall meets all the heat engineering requirements, and it does not have the conditions for the formation of condensation. No condensation - no decay, which means that insulation with expanded polystyrene followed by finishing with a plank or clapboard, walls of such a structure is possible.

The second option: we have a house in the Moscow region made of logs Ø 250 mm, insulated according to the plaster system:

- Pine or spruce log, working thickness - 150 mm.

- Air closed layer (due to rounding of the log) —50 mm.

- Insulation - polystyrene concrete PPS F 20-50 mm.

- Finishing layer - mineral plaster - 8 mm.

In this case, there is 100% moisture inside the structure and wall decay is inevitable. This can be prevented only by increasing the thickness of the insulation.

As can be seen from these calculation examples, external insulation of a wooden house with expanded polystyrene is possible, however, it requires a balanced approach, and a thickness of 50 mm for a log frame Ø 250 mm with a working thickness of 150 mm is clearly not enough if you want your house to stand more 5-8 years old. A person who claims the opposite is a myth-maker.

In terms of functionality, foam insulation works better when subsequently cladding with a ventilated façade rather than with plastering systems. This is due to the fact that the layers of materials, as they approach the outside air, should have greater vapor permeability.

The vapor permeability of moisture - windproof membranes is higher than the adhesive and finishing layers of plaster materials, and the air gap and cladding give 100% water vapor release.

Stages of work on foam insulation with your own hands

Before starting work, the walls of the house from a bar must be treated with antiseptic compounds.

- To equip a ventilated facade, it is necessary to make a vertical crate. To do this, wooden boards are nailed to the walls so that the insulation lies as tightly as possible, the distance between them is 5-8 mm less than the width of the plates.

- On top of the lathing, a vapor barrier film is fixed with a stapler.

- Counter-lattice slats are stuffed onto the vapor barrier, which serves to create a ventilation gap between the wall and the insulation.

- Styrofoam is laid between the racks, which should fit snugly to the rails. The gaps between the plates must be blown out with polyurethane foam.

- A diffuse membrane is laid on top of the insulation. The smooth side of the material should face the wall. The membrane ensures good air circulation and the removal of excess moisture from the house.

- The joints between the canvases are glued with adhesive tape.

- The last stage is facing with decorative material.As a finish, you can use siding, facade panels, lining, etc.

With external insulation of a log house with foam, which, due to the natural roundness of the logs, has uneven walls, a two-layer crate is made. To do this, first install vertical racks, and then after laying thermal insulation plates in them, they are additionally fixed with horizontal guides. This fastening provides a tighter fit of the insulation and makes the structure even more reliable.

With thermal insulation of a log house, there is no need to equip a counter-lattice, since a natural air gap is created between the logs and the insulation.