Mounting methods

Experts use different methods for attaching foam.

- Glue method.

This is a quick and convenient way of fastening. It is enough to choose the right adhesive and then apply it to the insulation. According to the initial state, adhesives are divided into types:

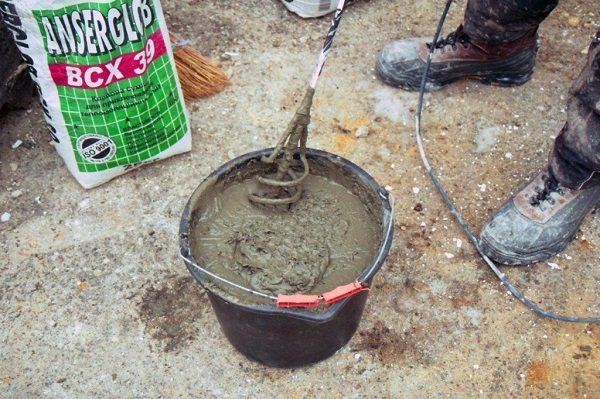

- dry mixes - bulk materials packaged in bags. They contain cement with binders. To prepare the glue, it is enough to dilute the solution according to the instructions;

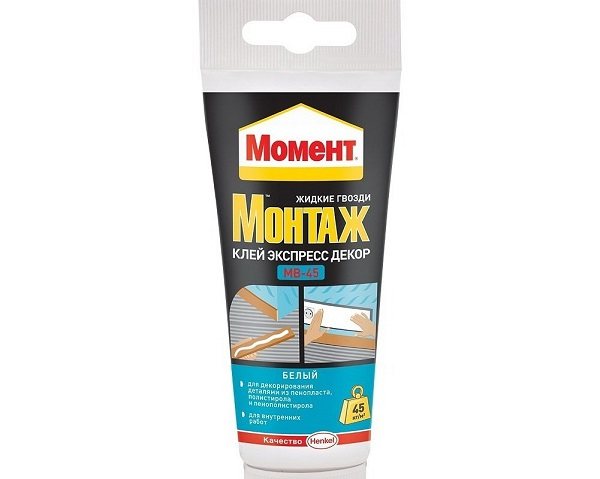

- liquid formulations are always ready to use. These include the "liquid nails" adhesive and cheap PVA glue. If PVA glues foam plastic well to metal surfaces, then "liquid nails" glue different materials, however, glue is very expensive, therefore it is used on small surfaces;

- foam - this type includes special adhesives designed for foam. First of all, these include:

- Polyurethane adhesive with good adhesion to foam. It is packaged in spray cans, therefore it is used with a special pistol.

- Adhesive - foam provides reliable adhesion to various materials. The special gun makes the glue easier to use.

- Fastening method.

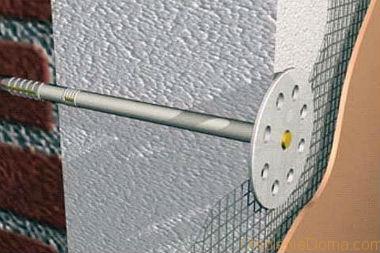

Dowels with a wide head are intended to strengthen the fastening of the slabs. They are used for external wall insulation, as well as with increased load on the heat insulator.

There are several types of dowels, but all necessarily have a sleeve, a core and a wide head. If the dowel is hollow, a nail or screw is used in the spacer zone. The plate is fastened at the corners and in the center. Compared to gluing insulation, this method is more time consuming.

- Combined method.

The simultaneous use of two methods of fixing the insulation allows you to achieve high quality styling. The adhesive composition insulates the surface from external influences, and the dowels increase the reliability of the fastening.

Video instruction:

Fastening to concrete and brick walls

Often, for the insulation of concrete and brick walls, a special crate is made, which holds the foam plastic slabs. Unfortunately, it is not always possible to install it, and besides, there are additional costs. In practice, other fastening methods are in demand.

- With an adhesive.

This method has its own peculiarities. Firstly, individual components of the adhesive can destroy the foam, and secondly, not every stickiness of the adhesive will bind the foam to concrete and brick.

Fastening of insulation plates is carried out in a certain sequence:

- the surface is leveled, then mud and oil deposits are removed from it;

- the components of the glue are connected according to the instructions. The resulting composition should not contain water, then it will not peel off for a long time;

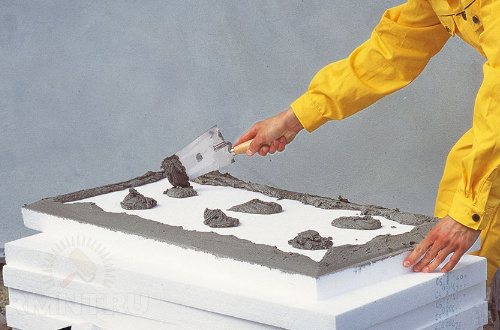

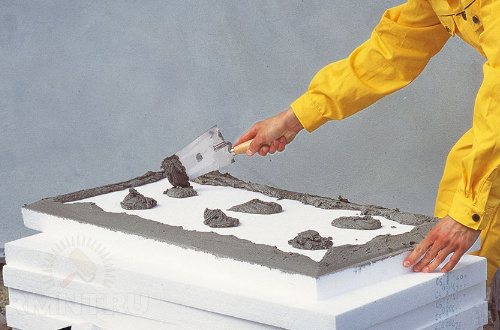

- the adhesive is laid on the plate in separate sections so that there is space for air to escape;

- the insulation is pressed and held.

- With dowels.

For fixing the slab, its center and corners are selected. Joints for better thermal insulation are treated with sealants.

Slabs in the bottom row are attached first. Deformation gaps are left between all the slabs, which ensure the stability of the coating against temperature changes in the environment.

- Using an adhesive composition "liquid nails".

The composition is characterized by high heat resistance and moisture resistance. It has features of use:

- to protect against the toxic component of the glue, you must use special gloves;

- the adhesive is applied only at separate points;

- hardening time no more than 30 minutes.

- With adhesive foam.

This method is characterized by simple installation, good adhesion to concrete and brick, and low cost.

When using foam, the surface does not need to be primed. It is enough to clean and moisten it.

The adhesive is used for processing foam or wall. After a short curing, the plates are staggered.

Linoleum

It is very convenient and reliable to fix linoleum on the concrete floor with glue. How to glue linoleum to concrete, the store managers will tell you where the flooring will be purchased. Linoleum manufacturers strongly recommend buying glue with it.

Usually, linoleum is fixed to concrete with mastic. Its advantages:

- You can choose the right quality, in accordance with the type of linoleum. The fabric base of linoleum requires the use of dispersion glue, and in the absence of a base, synthetic mastic is used.

- The compositions of all adhesives have excellent characteristics in terms of waterproofing properties, strength, and water resistance.

- Resistant to environmental influences.

In addition to their composition, mastics also differ in purpose. There is a mastic for fixing, which has increased stickiness and economical consumption, and for continuous gluing, one that should be applied to the floor in an even layer over the entire area is suitable. The thickness of the layer depends on the brand of mastic.

Fastening to a tree

Styrofoam is attached to the tree in different ways.

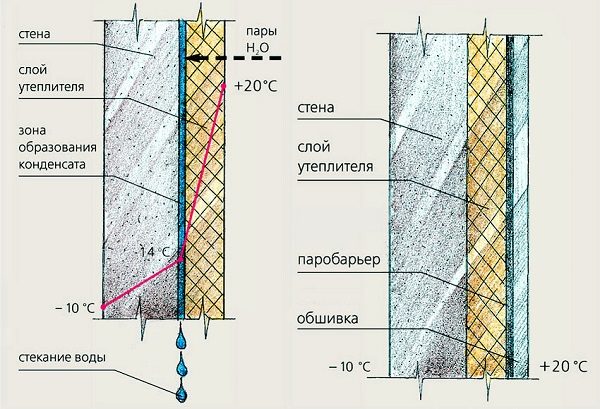

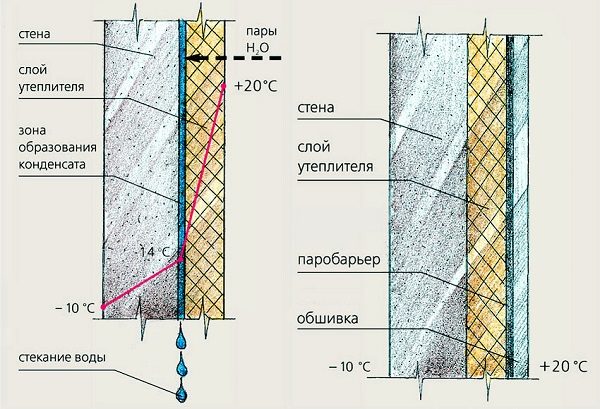

- It has long been known that wood must "breathe", otherwise rot will appear. Only due to the flow of air the tree retains its characteristics for many years.

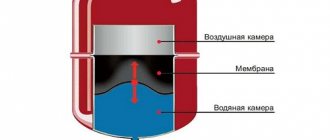

To protect the wooden wall from decay, the foam is laid with a ventilation gap. For insulation, a crate is made of wooden bars. Plates are inserted between the bars. A vapor barrier made of foil foil protects the insulation from condensation.

- Special metal nails are able to securely hold the slabs on wooden surfaces. Unfortunately, cold bridges appear at the attachment points, so a high-quality putty is required.

When instead of metal nails are used plastic fungi, then the thermal insulation of the slabs is improved.

- Fastening with adhesives is simple and reliable. The main thing is to choose the right adhesive that is resistant to changes in ambient humidity and temperature. A mortar containing cement and glue has proven itself well.

Fastening to metal

In the course of insulation work, it may be necessary to attach it to metal surfaces. There are several convenient ways.

- Familiar to everyone PVA glue is a good adhesive for metal and foam.

First of all, the burlap is impregnated with an adhesive. After that, it is glued to the metal, and insulation plates are laid on it.

- Polyurethane foam has good adhesive properties. Adhesion to metal is not very strong, but it lasts a long time.

Ceiling mount

The main condition for such an attachment is high-quality preparation of the ceiling, which includes cleaning from whitewash and dirt, as well as laying electrical wiring.

The foam is attached in one of the following ways:

The lathing or frame for the ceiling is made of wooden blocks. In order not to cut the slabs, it is recommended to form the size of the crate cells to the size of the sheets.

Inside the cells, foam is attached with glue or fungi. All gaps are sealed.

We seal the gaps with polyurethane foam

On top of the insulation, a vapor barrier film is applied, which is held on the crate.

At the final stage, plasterboard sheets are attached to the ceiling.

This method is much cheaper than the one discussed earlier. The main thing is to choose and prepare the adhesive composition correctly.

When preparing the surface of the ceiling, in addition to cleaning, it is coated with a disinfecting solution and soil. When it is not possible to completely remove the whitewash, then the entire ceiling is covered with an adhesive.

Glue is applied to the board in broken lines. Slabs are laid from the middle of the ceiling with a shift.

Dowels are used for additional fastening.

On top of the laid insulation, a reinforcing mesh is attached, which is then putty and processed.

Indoor mounting

Indoor insulation is a simple process, so it can be done on your own. In order for the fastening to be of high quality, work with foam is performed in a certain sequence.

- The surface of the walls, insulation and adhesive are being prepared. The walls must be flat, free from cracks and delamination. Styrofoam is easily cut with a hacksaw or a sharp knife. A dry mixture or glue-foam in cans is used as an adhesive.

- The finishing of windows and doors is dismantled. Subsequently, higher-quality finishing elements are installed.

- The adhesive is applied along the edges of the board, in the center and at the ends.

- Fastening plates to walls is done in one of the following ways:

- in rows - insulation with a shift is laid in rows around the entire perimeter of the room;

- pyramid - the first row is laid along the perimeter of the room, and then the corners are laid in the form of a pyramid.

- A spatula removes the layer of glue squeezed out of the joints of the plates.

- The surface of the insulation is covered with an assembly mesh, and plaster is made.

Attaching with liquid nails

Liquid nails are a special type of construction adhesive based on rubber, polymers and clay. This glue sets quickly, is very strong, moisture-proof, resistant to fungi and temperature changes.

To glue a foam board to concrete using liquid nails, you must first clean, degrease and level the surface. It differs from all previous adhesive mixtures in the application technique: not around the entire perimeter, but pointwise. In places where there are irregularities on the surface of the wall, it is applied in zigzags. As in previous cases, you need to check the evenness of the location of the slab using a measured level and correct if necessary. The glue will completely dry in a day or 12 hours, depending on the thickness of the layer and humidity.

Liquid nails will cost less than glue-foam, but differ slightly in properties.

We need the following materials and tools:

- Measured level;

- Liquid Nails;

- Styrofoam plate.

How to glue foam slabs

To increase the efficiency of insulation, it is enough to glue the plates together. In this case, the correct choice of glue is of great importance. It should not contain components that destroy the foam. These include:

- solvents containing acetone;

- gas and oil products;

- alcohol solutions.

Experts recommend using polyurethane glue, PVA and liquid nails adhesive for gluing foam.

Of course, it is impossible to unequivocally answer the question of how best to fix the foam. Much depends on the nature of the surface and the operating conditions of the insulation.

Only adherence to the technology of fixing foam, they allow high-quality insulation of walls.

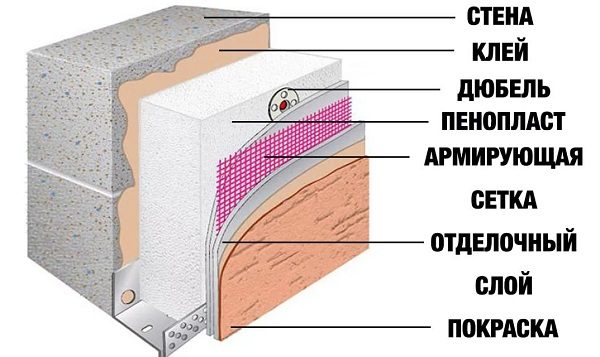

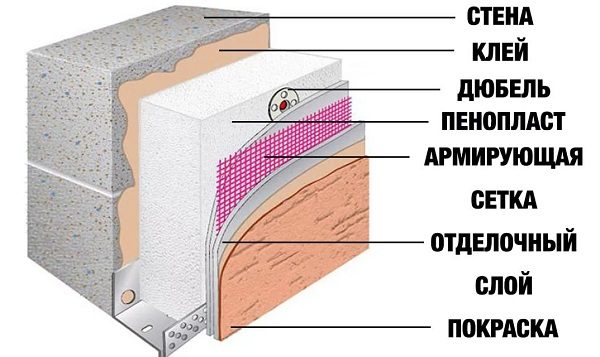

Concrete structures are strong and durable, but they have high thermal conductivity. For the insulation of concrete structures, expanded polystyrene sheets are widely used. Low thermal conductivity, light weight, moisture and fire resistance of this material create high-quality insulation. Installation of expanded polystyrene without the construction of the lathing is a solution that reduces labor costs and saves time.

Proper preparation of the base for fixing the insulation will help save time and resources, as well as create a strong and safe structure.

Walling

The availability on the market of a variety of and highly reliable adhesives contributes to the development of new technologies in construction. The construction of pre-fabricated houses from gas blocks on glue allows to reduce the construction time and the cost of materials for the preparation of the solution.

The question of how to glue concrete to concrete is not a big problem. The proposals of the manufacturers of numerous adhesives with excellent waterproofing properties allow you to make the right choice. The use of glue helps to avoid the appearance of "cold bridges". And this in the future saves home owners heating costs up to 30%.

In order to answer the question of how to glue concrete to concrete, climatic conditions should be taken into account. According to their characteristics, adhesive mixtures can withstand a fairly low temperature, but some of them are used only for the construction of internal walls.

Another definite plus when using glue is the aesthetic appearance of the wall. After its construction from gas blocks, no additional finishing is required, the seams are almost invisible.

Epoxy-based adhesives are not afraid of aggressive environments, moisture and other adverse conditions. When building production halls with similar characteristics, the question of how to glue concrete to concrete can be resolved quickly.

A few important tips before starting installation

Preliminary preparation of a concrete base includes the following steps:

- clean the surface from any dirt;

- to embroider and plaster large defects in the base;

- prime the entire surface.

Each step of the pre-installation preparation step is essential to ensure optimal adhesion, regardless of the way the polystyrene is fixed.

The choice of a method for fixing polystyrene foam sheets on concrete involves an analysis of the state of the surface. Methods also differ in the speed of work and the amount of required costs.

Methods for attaching foam to concrete

Using dry mixes

Dry building mixtures are considered a practical choice when installing expanded polystyrene foam on the facade of a building, or on the surface of a large indoor area. For outdoor use, cement-based compositions are used, and for internal works, gypsum-based compositions. The mixtures are supplied in paper bags, to prepare the solution, the powder is diluted with water in the proportions indicated in the instructions.

Advantages of bonding foam with dry mixes:

- durability and strength of adhesion to the base;

- moisture resistance and frost resistance;

- low cost;

- the ability to adjust the position of the sheet within 20 minutes after applying the adhesive;

- correction of small irregularities with an adhesive mixture.

Disadvantages of using dry mixes:

- impossibility of installation at temperatures below 0 С;

- ready-made glue must be used within two hours;

- the possibility of an error in proportions when mixing the adhesive mixture;

- the composition completely hardens within three days;

- additional tools are required (mixing container, drill with attachment, spatula for application).

Expanded polystyrene is not a hygroscopic material, therefore it is necessary to make sure that the dry mixture is completely mixed and homogeneous. Free water in the mixture can cause the polystyrene board to soon pull away from the surface.

Depending on the quality of the substrate, you can use one of the methods for applying the adhesive mixture:

- Solid... Suitable for the most even surface, differences of no more than 3 mm are allowed. The glue is applied in an even layer over the entire sheet of insulation using a notched trowel, and then applied to the concrete base.

- Cavity... Allowed for bases with differences of no more than 5 mm.The glue is applied in a thin strip along the perimeter of the sheet, about two centimeters away from the edge. Then it is also distributed in the center of the foam. This method will get rid of air congestion under the insulation.

- Beacon... They are used for unevenness of the base up to 15 mm. The glue is applied in discontinuous stripes around the perimeter of the sheet, leaving a gap of two centimeters. The height of the strip should also be two centimeters. The same "beacons" are placed in the center of the sheet.

Adhesive or foam for expanded polystyrene

Foam glue for styrofoam. You can glue polystyrene foam on a flat concrete surface with a special foam glue. This takes a little time. This method is relatively inexpensive. At the same time, the material can also be glued onto ordinary polyurethane foam. However, this will increase the work time, since it will be necessary to press the plates against the surface with effort for a long time.

If this is not done, due to the increased volume of foam, the sheets will swell and rise above the surface, and the seams will disperse. Before using the glue-foam, make sure that the contents of the tube are intended for foam (and not for foam concrete) and find out the conditions of use. The use of special foam is possible even without priming, it is enough to clean the concrete surface from dirt and moisten it for better adhesion.

The advantages of this composition are:

- acceptable adhesion;

- the ability to glue slabs at low temperatures inside and outside buildings;

- lack of odors;

- moisture resistance;

- the ability to take long breaks in the installation;

- frost resistance;

- no shrinkage;

- biological resistance;

- safety (fire, chemical);

- ease of use.

You should also be careful not to get the composition on the mucous membrane of the eye. The special foam is filled into standard cylinders filled with a polyurethane compound. Before use, it is installed in the assembly "gun", which regulates the release of the substance. The can is pre-shaken, it can be warmed up in warm water. The temperature of the cylinder is approximately plus 20 degrees.

Foam can be placed on concrete or foam, covering at least 40% of the area under the sheet. Drawings of its application - stripes along the perimeter of the slabs or in a checkerboard pattern (with indents from the edges), in the center it is squeezed out in a zigzag manner (necessary when the surface is not even enough). Then a little time is given to soak the mixture into the surface to improve adhesion. Foam that has come out is removed. With this composition, the seams between the sheets of material are foamed.

When insulating with expanded polystyrene with your own hands, the question arises of how to fix the material to the wall. Glue or foam is not suitable for tiles, since it does not guarantee the proper attachment of the insulation to concrete or brick for a sufficiently long time. Professionals recommend that in order to glue the PPP and the wall, use only a special adhesive, such as glue or foam for expanded polystyrene.

Typically, the glue or foam for attaching the PPP and sticking it to the wall is a dry mix. Before use, this mixture is diluted in warm water at room temperature in accordance with the instructions and kneaded to a uniform consistency.

Glue or foam for extruded polystyrene foam have their own specificity of use, which significantly distinguishes them from adhesives for other materials. So glue or foam for expanded polystyrene is not applied directly when you need to attach the material, but in advance.About an hour before you need to fix the EPS, the glue or foam is applied to the wall surface in a uniform layer. Also, glue or foam is applied to pre-prepared sheets of extruded polystyrene foam.

How to glue foam to concrete

Foam glue is the most modern solution.

Usually, when they ask themselves how to glue the foam to concrete, we are talking about the insulation of walls or foundations, that is, any vertical structures.When laying polystyrene on a horizontal surface under the screed, the thermal insulation does not need to be fixed.

Options for how to glue foam to concrete:

- glue foam;

- dry mixes;

- liquid Nails.

Glue-foam is similar to regular polyurethane foam, this is where their similarity ends. This compound was specially developed for gluing polystyrene foam boards to any kind of surface. The expansion ratio of the foam is very low, so the thermal insulation hardly pushes out. Glue foam can also be used to fill seams. Available in 750 ml cylinders. TechnoNIKOL costs 300 rubles, Cerezit - 600 rubles. The balloon is enough for 10 square meters.

The universal construction adhesive is also suitable for the installation of polystyrene foam. It comes in the form of a powder in bags. 25 kg costs about 550 rubles. To prepare the composition for work, you just need to add water to it and mix thoroughly. Consumption 4.5-5 kg per 1 sq. M.

Almost everything can be glued with liquid nails, foam is no exception. Often used only in small areas. Let's say you need to glue a sheet of polystyrene, and there is nothing but liquid nails at hand. A tube of the Moment 400 grams costs 200 rubles.

During the season, you will spend less money on heating a cottage with gas than on heating with any other type of energy source.

Read about how to make cheap heating of a private house with your own hands in this article.

How to properly prepare the walls before gluing the styrofoam

Let's pay attention to the walls of your house, which you decided to insulate. Of course, in view of the fact that the foam is even and dense, in order for it to adhere well to the walls, they must be properly prepared.

First of all, it is advisable to plaster the walls. In the event that your house is composed of gas silicate blocks and the master has completed the masonry evenly, then plastering the walls is not necessary. However, in this case, it is necessary to cover up all the joints of the blocks.

In the event that the walls are not even, then they must be leveled. you can level the walls both with the use of lighthouses and without them.

The lighthouses are exposed to the solution and leveled with a bubble level. This will create a level surface with the correct vertical level.

The last step before you glue the styrofoam to the walls is the primer. It is imperative to use a primer! You should not save on primers, as it creates good adhesion, which contributes to the fact that the foam will adhere confidently to the walls and will not fall off.

How to glue styrofoam to concrete

Any adhesive is best used in tandem with dowels and fungi.

Now let's look at the procedure itself, how to glue foam to concrete for each material separately. Let's start with foam glue - this is the most convenient adhesive. To apply it, you need a gun for polyurethane foam.

A polyurethane two-component composition is applied to the thermal insulation, first along the perimeter, and then in parallel lines with a step of 20 cm. The diameter of the sausage should be no more than 3 cm. After that, the insulation should be pressed to the working surface and held for at least a few minutes. Then the seams are foamed. The film on the glue-foam is formed within 10 minutes, fully cured after 2 hours. You need to work at positive temperatures. If the foam is glued to the facade at a height above 2 floors, then it is imperative to additionally fasten the sheets with dowels.

Regardless of what you decide to glue the foam to the concrete on the ceiling or walls, the sheets of insulation must be additionally fastened with dowels with fungi.

The method of applying construction adhesive depends on the quality of the preparatory work. So, if the wall is even, then the composition is applied with a notched trowel. If the working surface is uneven, then the glue should be applied with cakes around the perimeter of the sheet.In this case, the height of the cake will be about three centimeters. Specifications:

- suitability for work within 20 minutes after adding water;

- complete hardening in 7 days;

- installation at a temperature of 5-30 degrees;

- operating mode from -30 to +80.

Suitable for indoor and outdoor use. For insulation of walls and ceilings, it is ineffective without fungal dowels. It can be used as a finishing layer when insulating using the wet facade technique. In this case, it is necessary to do reinforcement with fiberglass mesh, otherwise the facade will crack.

Liquid nails are available in tubes and flasks. To work with flasks, you need a special pistol. Adhesives are available in white and gray. Freezes completely in 15 minutes. Hardened liquid nails can be painted with any paints.

A two-pipe sealed heating system of a one-story house can be vertical and horizontal. It is also possible to combine the two schemes.

Here you can find out what inverter heating of a private house is and how profitable it is.

How to glue penoplex

So how to glue penoplex to concrete? There are several options:

- The special glue is mixed in strict accordance with the instructions; is applied to the foam board in strips to prevent the formation of an airlock, then the board is fixed, and excess glue is removed.

- "Liquid Nails". Toxicity requires work in protective ammunition, this glue has high moisture and heat resistance. It hardens within half an hour.

- Special material - glue-foam. Inexpensive high-quality material, very easy to use, allows you to seal the gaps between the plates during installation.