When there is a desire to make the home cozier and warmer, modern technologies are used, because it is economical and rational. When choosing a home heating system, many factors should be taken into account so that it lasts a long time and does not break. One of the most economical is a warm floor.

There are three main types of them:

- convection radiator room;

- underfloor heating installations;

- combining two systems - when a radiator is used as the main heating, and panel structures are used as additional heating.

Direct floor heating is possible in several ways:

- water system;

- electric.

Varieties of underfloor heating under laminate

Laminate has recently become a very popular flooring used for decorating rooms, corridors and kitchens. To save the family budget, many families decide to install underfloor heating without additional screed under the laminate.

In this case, they have a question: what system can be used under the laminate. The answer will be ambiguous, since there are many types of laminate, under which both electric and water heat-insulated floors can be laid. What is the difference between them?

We recommend: Wood foam: an innovation in the construction market

How to choose a heating mat?

The choice of the mat is influenced by the area of the room, the required level of heating, the type of floor covering and the heat loss of the room.

1. Heating intensity For colder rooms, and also if you want to achieve a higher floor temperature, you need to take a more powerful kit. So, a system with a capacity of 150 W / m2 warms up tiles up to + 24 ° С - + 27 ° С, with a power of 165 W / m2 - up to + 26 ° С - + 28 ° С. As a rule, + 27 ° C is more than enough for a comfortable temperature underfoot.

Underfloor heating installation - mat without screed.

2. Coating Laminate, linoleum, carpet, parquet because of their poor thermal conductivity and sensitivity to high temperatures are not the most popular options for heating. If a cable system is nevertheless placed under them, it must have a reduced power - no more than 100 W / m2, and the coating itself must warm up to no more than + 26 ° С. The thickness of the tile adhesive is 1-2 cm. There are no such restrictions for tiles and porcelain stoneware.

3. Area One of the main advantages of mats is that they are sold in ready-made kits designed for a certain area. You just have to choose a set of the required power and measure the area of the room (excluding the areas occupied by furniture). The mesh can be placed in any position, if necessary, cut (without damaging the cable). Based on these criteria, you can choose a suitable set of underfloor heating.

On our website you can buy a warm floor - mat from the Energy company. The offered sets Energy Mat and Energy Light Plus have a power of 165 W / m2 and 150 W / m2, respectively. These models are used with coatings with high thermal conductivity (porcelain stoneware, tiles).

megaobogrev.ru

Water heat-insulated floor and laminate

Such a system will be relevant for a private house where a boiler serves for heating, or for an apartment with a small area in the presence of a gas water heater.

Since the installation does not require special skills, it can be assembled by any craftsman. Another advantage is the ability to lay on any surface, even wood. In addition, the absence of an additional screed does not hide the height of the ceilings.

For installation of a water-heated floor under a laminate without a screed, special systems with the so-called "dry" installation are used.So that the pipes are not damaged during operation, they are laid on special mats with grooves. As a rule, sheets of polystyrene, OSB or fiberboard are used for the manufacture of mats.

Since water systems have poor heat transfer, it is recommended to additionally lay metal sheets on them, which will increase heat transfer to the laminate.

The warm water floor should be laid on a flat subfloor. First, the mats are mounted by fixing the spikes in the grooves, then pipes are laid along the grooves. Next, a connection is made to a boiler or column.

To be sure, check the structure for functionality before installing the laminate. If everything works well and there are no leaks, you can start installing the laminate.

Since the mats, regardless of the material, have a weak heat transfer, this allows you to save on thermal insulation.

System calculation

- If an underfloor heating is planned as the main source of heat, the recommended heat transfer of the system is 150 watts per square meter, for the lower floor - 180. And the underfloor heating itself must occupy at least 70 percent of the total area.

- If this is additional heating (plus radiators, convectors, etc.), the system power of 110-130 watts is sufficient.

- From the total length of the cable (area of mats, films, etc.), you must immediately subtract the areas occupied by furniture and other massive objects.

- The distance of the cable to the walls, furniture is at least five centimeters, to the risers of the water heating system - at least ten.

- The formula for calculating the pitch between the turns: H = S * 100 / L (S is the area of the heated floor, L is the length of the cable).

- The formula for calculating the length of the cable: L = S * Ps / Pk (Pk is the specific rated power of the cable per running meter, Ps is the required specific power per square meter). To the resulting figure, you need to add a piece to connect to the thermostat.

Characteristics of cables depending on the current and power of the system

- copper, with a cross section of 2 by 1 mm: maximum current 16 amperes, system power 3.5 kilowatts;

- copper 2 at 1.5: 19 amps, 4.1 kW;

- copper 2 by 2.5: 27 and 5.9;

- aluminum 2 by 2.5: 20 and 4.4;

- aluminum 2 by 4: 21 and 4.5.

Electric underfloor heating: laminate compatibility

Electric underfloor heating as an alternative to water is suitable for rooms where it is not possible to connect the latter option.

We recommend: Types and characteristics of heating radiators

The electric floor is divided into two types:

- infrared film;

- cable.

Benefits of infrared electric floor

Infrared radiation of a warm floor is equated to heating by the sun's rays and the heat of a living organism.

It is considered the most economical, as it consumes the minimum amount of electricity in comparison with other electric heaters.

Installation is very simple, you just need to follow the instructions.

This system does not require a lot of time to warm up, like a water system.

Infrared rays heat objects and do not dry the air like radiators. All the heat goes from bottom to top, and not vice versa, which is much more comfortable.

IMPORTANT! Under any electric floor, it is laid under a laminate without a screed or under any other covering with a screed, it is imperative to use a polystyrene backing, cork or other substrates recommended by the manufacturer of the warm floor.

Specialists of hardware stores will help you choose the right substrate.

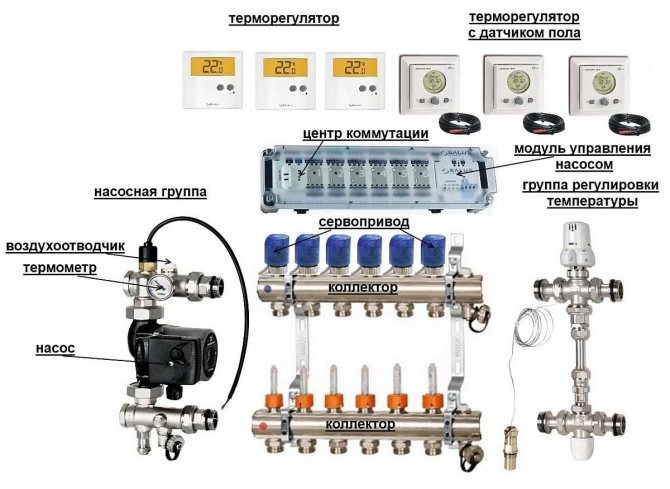

Underfloor heating system with water

This system pleases with insignificant costs in comparison with the electric one. It is better to install a structure using water in conjunction with a radiator in order to increase the heating rate of the building. The coolant in this case is antifreeze or water. The pipes are installed under the floor unit and filled with concrete screed.If you do the installation without concrete, such a system will be weak in terms of thermal conductivity.

Boilers are used in different designs, it can be either a solid fuel or an induction boiler. The latter is the most economical in use, since heating occurs without temperature loss. A characteristic feature of underfloor heating with water is that the pipes must comply with the standards. Only pipes made of plastic meet the necessary conditions. The period of operation is quite long, about 50 years, which is suitable for use in residential buildings.

Water type

If you mount this system on a wooden base, you can use the air thermal insulation technique. In the use of heat and sound insulation filling, heat will be well retained. After that, a thin layer of plywood or OSB is mounted. The next element will be the one that distributes heat and directs it in the required direction - this is aluminum foil.

Important! It is necessary to provide for the waterproofing of the system. To make the structure safe when installed on a wooden floor, it is recommended to use a corrugated metal pipe. It is resistant to minor deformations and will compensate for inaccuracies during installation.

Step-by-step instructions for installing an electric infrared floor heating

Before installation, remove the old floor covering; if necessary, level the subfloor with a self-leveling mixture.

Lay the backing, securing the strips together with tape.

Next, sheets of underfloor heating are laid, which must be cut in places where there is no heating element.

For convenience, the strips of film can be fastened together with tape.

Next, you need to connect the system - the ends of the copper element are fixed to each other with special clamps.

Then they connect the wires to the terminals as indicated in the diagram, they must be insulated.

So that the joints of the wires do not interfere with the laying of the laminate, a cut is made in the thermal insulation, and the wires are laid there.

Recommended: Modern flooring materials

At the last stage, the thermostat is installed and the floor is connected to it.

That's it, you can start laying the laminate.

Installation process

The beginning of the installation of a warm floor without a screed is associated with the installation of all the main components - a thermostat and a temperature sensor. The thermostat is fixed in a specially prepared hole on the wall at a distance of at least 30 cm from the base of the floor.

In shape and size, it is not much different from a classic outlet. This device will be necessary to control the temperature level in the room, as well as to set certain parameters and time frames. Connection is made to a separately prepared socket. Electric wires are connected to it directly from the meter. Installation is best done according to the manufacturer's attached diagram.

We must not forget about installing a thermal sensor. Everything is carried out as follows: wires are drawn from the thermostat to a closer section of the IR underfloor heating, where they are glued to the graphite section with adhesive tape.

Further, the thermal film of the warm floor is unfolded over the surface without air layers. It should fit securely.

After that, places are selected where the insulation is removed from the film - they are cleaned with special sharp knives at a distance of 5-10 mm from the near edge. After connecting all sections of the film with wires, they are processed with bitumen insulation, which is supplied with the underfloor heating system without pouring the screed.

When all these steps have been completed, you can test the system. The thermostat is connected to the mains and brought into working condition.If there are no problems with operability, a polyethylene film is laid on top of the infrared film for further installation of the floor covering.

Polystyrene flooring

By weight, polystyrene systems are much lighter. The thickness of the product can vary from 15 mm to 70 mm, depending on the manufacturer. You can also select the pipe pitch: 120 or 300 mm.

Polystyrene plates, in addition to laying pipes without a screed, play a role in thermal insulation.

The boards are installed on a clean and level base. If additional thermal insulation is needed, then spread it first. Plates differ in shape, for example, swivel or simple. Thanks to this, you can choose any pipe laying scheme. When polystyrene or wooden modules are laid, heat-distribution metallized plates are laid on top of them. They are equipped with special grooves for fastening pipes.

The use of underfloor heating technology without screed requires the installation of a damper tape. Thanks to it, there will be no cracks near the wall and floor. Also, this tape should separate several contours that are located in the same room.

Video of installation of a dry underfloor heating:

teplapol.ru

Wooden flooring system

Wooden structures are in great demand. This material is easy to obtain and the system can be assembled by yourself.

There are ready-made modular wooden floors. They consist of chipboard or OSB. They have channels for heating pipes. The module width is standard - 130, 180 and 280 mm. They are fastened together with a special lock.

There are also shell boards. In this case, the wood is well dried and processed. Depending on the company, their sizes may differ, for example, 21 × 120 or 18 × 120. The choice of the block is based on the required laying step. These blocks are mounted on logs. The assembly is carried out so that a given pattern of pipe laying, a snail, a snake, and so on, can be repeated.

Self-production of the base

If it is not possible to use a ready-made solution for installing heating in a private house, then for laying a warm floor using water or antifreeze as a heat carrier, you can use polystyrene foam plates, having previously cut grooves in them, for laying pipes. And to evenly distribute heat over the entire floor area, on top of expanded polystyrene, lay out ordinary foil and only after that install the pipes. Such a scheme will save a little financially, but will require more time and physical costs.

You can cut grooves in extruded polystyrene foam using a "grinder". This will greatly facilitate and speed up the process.

Instead of foam, you can use any available, sheet insulation, for example, it can be extruded polystyrene foam from the Penoplex company. If the room allows, then a layer of insulation and more than three centimeters can be used, this will reduce heat loss and make the system much more efficient.

An electric or gas boiler can be used as a heating element in a similar design, and in the presence of central heating, a water supply master will be able to connect the system to and from it without any problems. But it is worth remembering that in Moscow, utilities, it is forbidden to connect such systems to the central hot water supply line, since this leads to a large amount of heat loss in the hot water supply main line. Simply put, if all residents of an apartment building install water heating, then there will not be enough thermal energy for everyone.

On top of the system, any class of laminate can be laid, there is no need to look for a waterproof one, since this is not a matter of principle, but it is better to use a finishing material that has a 33rd class, since it is quite durable and easily tolerates changes in temperature conditions.In a private home, such a laminate can last more than 15 years.

It should be noted that the material intended for laying on top of a warm floor has a special marking on the packaging.

Advantages and disadvantages of screed cable systems

When installing floors in new houses, when it is possible to fully perform all the necessary work on the installation of the subfloor, a layer of thermal insulation and a high-quality screed of the required thickness, the best solution is to install a cable underfloor heating. A sufficiently thick floor screed reliably protects the installed cable and allows the use of any finishing materials. The advantages of this electric heating or heating system are:

- the ability to purchase an inexpensive cable;

- uniform heating of the floor surface;

- reliability and fire safety;

- high thermal efficiency.

A prerequisite for the installation of a heating cable is the uniformity and high quality of the screed, as well as the execution of finishing work and the trial switching on of the system after the concrete has been set with sufficient strength. There are cases when the screed cracked and damaged the cable a few months after the completion of the repair. That is why porcelain stoneware and heavy ceramic floor tiles should be installed no earlier than a few weeks after installing the cable and pouring the top layer of the finished floor.