Heating devices are presented in a wide range. Manufacturers offer products from different materials, in complex and simple designs. Regardless of the class and shape, radiators are needed only to transfer heat from the coolant to the room. Therefore, the simplest tubular heating radiators, made independently, will not yield to complex technical devices. If you follow the stages and technology, the structures will cope with the heating of residential, utility and utility rooms.

Advantages and disadvantages of heating registers

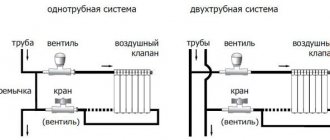

Registers in the heating system

Homemade steel or aluminum heating registers differ from standard radiators in their dimensions. They consist of several pipes with a diameter exceeding 32 mm. To organize the circulation of the coolant, the pipes are interconnected by branch pipes.

What is the reason for the popularity of these heat supply devices? Firstly, the possibility of self-production. You can make bimetallic heating registers, steel or aluminum pipes. Plastic models are much less common, since they do not have the proper performance.

Before connecting the heating registers, you should carefully study their "weak" and "strong" sides.

Benefits of using:

- Long service life... For steel and aluminum models, it can be up to 25 years. In this case, the probability of breakage will be minimal;

- Great heat dissipation... This is due to the fact that the power of the heating register exceeds this parameter for classic radiators and batteries. Associated with a large volume of coolant;

- Simple installation and operation... Since the heating registers can be correctly installed by anyone who is at least a little familiar with the rules for organizing heat supply, they can be used in buildings of all types. But most often they can be found in the heating system of large industrial, administrative and commercial premises.

But besides this, you need to take into account the possible disadvantages that a heating register from a smooth steel pipe may have:

- Large volume of coolant... This leads to its rapid cooling;

- Minimum air convection rate... Reduces the efficiency of heat supply;

- Unattractive appearance... Most often this applies to self-made structures.

Correctly calculated heat transfer of the heating register directly depends on its design. Currently, several types of these heat supply devices are used, differing not only in the used material of manufacture, but also in appearance.

The weight of the register filled with water can be very high. Therefore, you need to think in advance about a reliable system for attaching it to the wall.

Heating register types

Heating register types

Initially, you should decide on the type of construction. After all, how to calculate the heating register if its geometric parameters and the principle of coolant circulation are not known? For the manufacture of heating devices, it is recommended to use standard proven schemes.

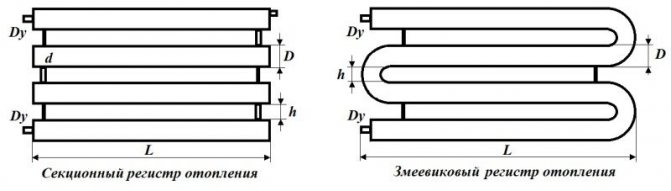

The defining parameter of choice is the required circulation rate of the coolant in the system and the degree of heat transfer from the register. Based on these requirements, you can choose two types of heating devices:

- Sectional... It consists of two or more large diameter pipes connected by pipes. The cross-section of the latter should be equal to the same parameter of the supply line.The selection of a heating register of this type is relevant for systems with forced circulation, since excessive hydraulic resistance is created in the structure when the coolant passes;

- Serpentine... They consist of one pipe that has bends. Making such homemade heating registers is problematic. To increase the circulation rate, pipes can be connected with pipes. But this is optional, as in the above models.

Since you can make a heating register with your own hands even at home - they are often made, and not purchased ready-made models. But before that, the correct calculation of the power of the heating register should be performed.

For the manufacture of registers, you can use pipes of various cross-sections - round, rectangular or square. Preference is given to the first, since for them the water friction during movement will be minimal.

Features of the

The issue of saving and rational use of heating devices in the current situation is quite relevant. It is quite simple to purchase registers today; a purchase can be made through numerous online stores or in specialized departments of supermarkets. These heating devices in most cases represent an effective design that can be used in any type of premises - residential, industrial, technical and others.

In addition, registers are widely used in heating systems for multi-apartment residential buildings. Due to the use of pipes of large diameter, even with a minimum length, it is possible to make an autonomous vertical or horizontal heating device, which, with its small dimensions, will have a high level of efficiency during heating.

There is an opinion that radiators, in comparison with registers, cope with their main task better, since they have an additional area. But registers, in the production of which smooth-bore pipes are used, have heat transfer rates that exceed those of radiators to a large extent. And additional modernization of the structure, which involves fastening to the system of metal plates, will have a positive effect on the efficiency of the register.

If you plan to install general-purpose registers, connecting thin tubes arranged in parallel with each other, as a result, a high-quality and attractive design will be formed, which in some cases is called design radiators. The manufacture of such devices is relevant for use in public buildings.

In large rooms where the radiator cannot cope with heating a large volume of the room, heating registers are used - systems of parallel pipes of large cross-section. These heat exchangers are widely used in industrial and commercial buildings due to their efficiency, relative ease of installation and maintenance. It is possible to make a heating register with your own hands, but this requires accurate calculations and skills in working with a pipe bender and a welding machine.

Calculation of heating registers

Heating register operation

There are several methods for calculating the parameters of heating registers. They are distinguished by the accuracy of calculations and laboriousness. But for the organization of heat supply using steel or aluminum heating registers, it is recommended to resort to the services of professionals. An alternative option is to use special software.

However, in some cases, it is necessary to correctly calculate the heating register yourself. To do this, you can use a simplified diagram. You must first know the following parameters:

- The total area of the heated room;

- Heat transfer coefficient of the register material;

- The diameter of the pipes used for manufacturing.

For pipes with a circular cross-section, the calculation of the specific power of the heating register can be done according to the data in the table. These values are given for 1 lm. register pipes.

| Diameter, pipes, m | 25 | 32 | 40 | 57 | 76 | 89 | 110 |

| Room area, m2 | 0,5 | 0,56 | 0,69 | 0,94 | 1,19 | 1,37 | 1,66 |

However, this method of selecting the heating register has a number of significant disadvantages. The data are given for rooms where the ceiling height does not exceed 3 lm, the thermal mode of the system and the air temperature in the room are not taken into account.

For more accurate calculations, it is recommended to use the formula:

Q = P * D * L * K * Δt

Where Q - specific thermal power, W, P - number π - 3.14, D - pipe diameter, m., L - length of one section, m, TO - coefficient of thermal conductivity. For metal, this figure is 11.63 W / m2 * C, Δt - the temperature difference between the coolant and the air in the room.

Knowing these parameters, you can independently calculate the power of the heating register. Let's assume that the length of one section is 2 m and the pipe diameter is 76 mm. Δt is 60 ° C (80-20). In this case, the power of one section of the heating register from a smooth steel pipe will be equal to:

Q = 3.14 * 0.076 * 2 * 11.63 * 60 = 333 W

To calculate each subsequent section of the device, the result obtained must be multiplied by a reduction factor of 0.9.

Using this technique, ribbed heating registers cannot be calculated. Their heat transfer will be higher due to the increased area of the device.

Choosing the material of manufacture for the registers

Steel heating registers

The next parameter that must be taken into account when choosing a register is the material of its manufacture.

It is rare to find heating registers from a profile pipe - most often steel products of a circular cross-section are used for this.

Currently, several materials are used for the production of registers - metal, aluminum or bimetallic pipes.

The difference between it lies in the calculated heat transfer and service life:

- Steel heating registers from a profile pipe or round section... They are characterized by simplicity of manufacture and low cost. The disadvantage is surface rusting. When choosing, special attention should be paid to the quality of welds;

- Aluminum... They are extremely rare, since special equipment is required for welding aluminum heating registers. But on the other hand, they have the best thermal conductivity. There is virtually no heat loss;

- Bimetallic... They are made from a special type of heating pipes. They have a core made of steel. To increase the heating area, the design has copper or aluminum plate heat exchangers. All bimetallic heating registers are characterized by a small pipe diameter - up to 50 mm. Therefore, they are more often used to organize heat supply in residential buildings and small industrial and commercial premises.

The material of manufacture directly affects the calculation of the heating register. The main indicator in this case is the coefficient of thermal conductivity. Despite the fact that aluminum models have an optimal value - their high cost and laboriousness of manufacture do not allow the use of registers of this type in heating systems everywhere.

For the manufacture of ribbed heating registers, you can use accessories from steel radiators.

Instructions for self-production of registers

It is easiest to make a steel heat exchanger with your own hands, although its assembly will require skills in working with welding and grinding equipment and adherence to certain rules.

- Before installation, it is necessary to perform calculations and a drawing, which will indicate the dimensions of pipes and connecting elements, the location of fittings and connection points.The drawing will help you accurately calculate the quantity and parameters of consumables.

- The clearance between the sections is taken 1.5D or D + 0.5 cm, where D is the pipe diameter. The distance between the parallel sections of the coil register is calculated depending on the used arc element or the turning radius (R) when using a pipe bender. In the first case, the distance is equal to twice the difference between the height of the arc element (F) and the diameter: 2 (F-D). In the second case, the distance will be 2R-D. With a shorter distance, heat transfer decreases.

- Since welding and grinding equipment is used during installation, it is imperative to wear protective clothing and shoes, and protect your face with a special mask or goggles.

- For the effective operation of the register, strict parallelism of its sections is necessary; level, plumb line and building corner will help to control this parameter during work.

- At the upper point of the register, the most distant from the supply pipe, an air vent is installed, which allows you to get rid of air locks in the circuit. When installing a parallel heat exchanger with collectors, air vents are installed at the top of each collector.

- Stands and brackets are required to secure the register. The more massive the structure, the more fasteners will be required.

| low heat transfer, | |

| Galvanized steel | low cost, |

| low heat transfer, | |

| Stainless steel | not susceptible to corrosion, |

| low heat dissipation, | |

| Copper | high heat transfer, |

| high price, | |

| Aluminum | high heat transfer, |

| high price, | |

| Cast iron | high heat transfer, |

| heavy weight, |

Making registers for heating with your own hands

Heating register production

One of the advantages of using registers in heating systems is the possibility of their own production. For this, steel pipes of circular cross-section are most often used. Despite the fact that the heat transfer rate of the heating register in this case will not be ideal, the manufacturing process does not require special skills.

For self-production of this heating element, you will need a pipe with a diameter of 40 to 70 mm. A larger cross-sectional value will lead to significant heat losses during the circulation of the coolant. You can make a heating register with your own hands according to the following work scheme:

- Calculation of the optimal parameters of the heating device - the diameter of the pipe, the total length of the section.

- Drawing up a drawing to calculate the optimal amount of material.

- Do-it-yourself work on the manufacture of a heating register.

- Checking the structure for leaks.

Steel pipe plugs

To accomplish this task, you will need a steel pipe designed to form the main registers and a line with a smaller diameter. With its help, the registers will be connected to each other and the heating system. You will also need special pipe end caps.

At the first stage, it is necessary to cut the pipes to the required length with the help of a grinder. It is not recommended to use a welding machine for this, since an overlap will form at the ends of the heating register from a round pipe. Then holes are made for connecting the branch pipes. The nozzles are welded with a welding machine and end caps are mounted. To ensure the safety of the operation of a home-made heating register, it is necessary to install an air vent and a drain valve. They are mounted in the upper part of the structure, but on the opposite side relative to the heating connection point.

Heating register with heating element

In some cases, the modernization of the traditional scheme of the steel or bimetallic heating register is carried out. It consists in installing an electric heating element.

So you can make an autonomous heat source, which will not depend on the operation of hot water heating.In the event of an accident or technical work, a self-made heating register will generate heat using a heating element. But for this, shut-off valves should be installed during installation so that the coolant circulates only inside the heater.

During the selection of the scheme and the manufacture of the heating register, the thickness of the pipe does not matter. The difference in diameters between it and the supply line determines the complete absence of water hammer in the structure.

Calculation

Now let's figure out how to calculate the heating registers.

Before buying or making a register with your own hands, take note of the pipe diameter. Masters are advised to consider devices for the home with a diameter of 3 to 4 centimeters, but not more than 8 centimeters. The main reason lies in the inability of the heating boiler to issue such a volume of coolant, which would be sufficient for optimal heating of large surfaces.

When calculating registers from smooth pipes for heating, it is worth taking note of the length of one edge of the register and the heat output for each 1 meter.

The register is 1 meter long with a cross-section of 6 centimeters from the inside, capable of heating a room of about 1 m². This is how the heating registers are calculated by the area of the room.

After calculating the edges, rounding is done up. In some cases, the data obtained can be increased by 20-50%. Such cases include the following.

- a considerable number of window openings and doors in the room;

- small wall thickness;

- poor thermal insulation of premises;

Installation of registers in the heating system

Heating registers in the production area

Correct installation of heating registers can be carried out in two ways - on threaded connections or using a welding machine. It all depends on the total weight of the structure, its dimensions and the parameters of the heat supply system.

In general, experts recommend following the same rules as when installing radiators. The difference lies only in the size of the structure. If it is necessary to connect the heating register to the gravitational system, the required slope indicator must be observed. The heat supply device should be tilted towards the direction of movement of the heat carrier. There are no such requirements for systems with natural circulation.

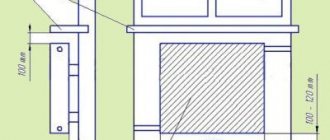

For the correct installation of heating registers, the following rules must be followed:

- Compliance with the minimum distances from the wall and window structures. It must be at least 20 cm. This is necessary for carrying out technical or repair measures;

- For the threaded connection of the heating register, only paranite linings or sanitary flax are used;

- All heating registers made of profile or steel pipes must be painted. This is necessary to prevent the appearance of rust on their surface.

Despite the fact that the heat transfer rate of the heating register will decrease, the period of the maintenance-free service of the structure will significantly increase.

Installation is recommended outside the heating season. After a trial run of the heating system, you can compare the calculated power of the register with the actual one and, if necessary, make operational changes to the design.