What is a boiler stabilizer for?

Gas-fired boilers in modern heat supply systems are complex installations with electrical components that are susceptible to consumer quality of voltage, namely: control boards and safety automation, heating medium circulation pumps, fuel ignition systems and switching on the ventilation unit.

It is better to take the choice seriously. Photo source: rusthermo.ru

For this reason, when purchasing an expensive boiler, you need to worry in advance about the special protection of its digital cards from network violations. That is why in Russia in general, there is no question of whether a voltage stabilizer is needed for heating equipment, all consumers understand what is needed.

Russian power grids do not guarantee the consumer quality of electricity required for the proper functioning of heating systems, which is very important when using imported gas units, expensive “contents” that require strict power supply parameters.

The use of stabilizers protects expensive equipment from damage, which is also important for equipment that is under warranty.

All defects of the gas units resulting from power surges are not covered by the warranty, therefore the restoration work is paid by the owner of the unit at his own expense.

Voltage stabilizer device

The basics of the operation of such equipment must be known before choosing a voltage stabilizer for a gas boiler.

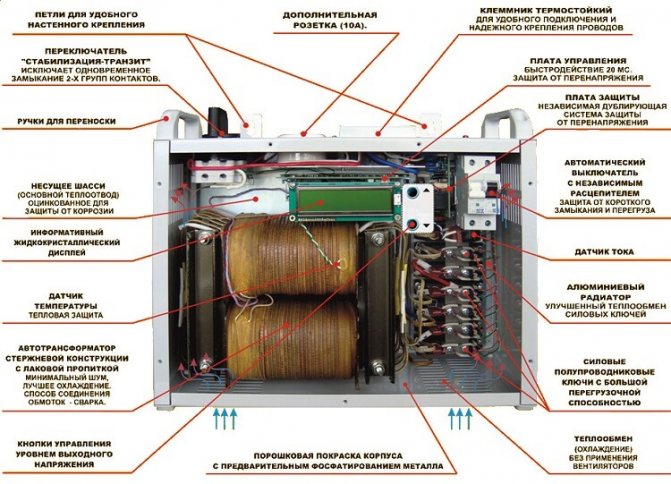

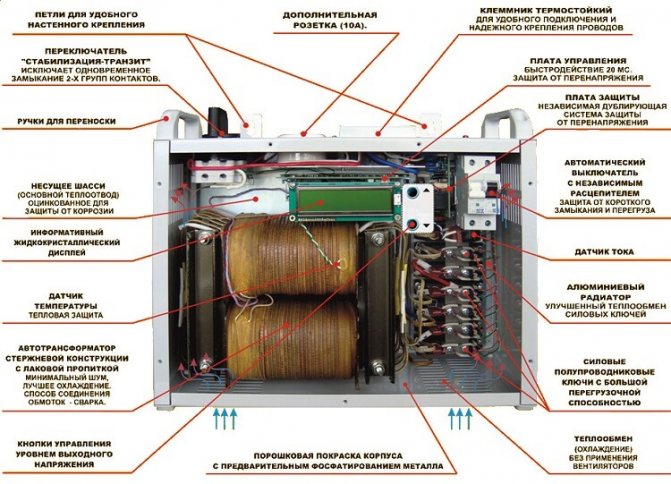

The main components of the voltage regulator

The device is made of the following structural units:

- An autotransformer with various windings, it is responsible for the compliance of the output indicators with the generally established characteristics.

- A monitoring device that determines the configuration of the incoming voltage.

- Fuses that turn off the device when the characteristics of the electrical network go beyond the permissible values.

- Control automation that changes the direction of current flow through the windings.

- Batteries that feed the device in the absence of electricity.

For relay voltage stabilizers for a gas boiler with a 10% working scale, the voltage changes around 220 V, fluctuating by 10% in different directions from the base.

This is why the stabilizer clicks when relays are frequently triggered due to poor power quality. Technologically, the effect of stabilization is obtained in various ways, depending on the modification of the device.

Mandatory requirements for the stabilizer

Power is a basic parameter, the performance of the device depends on it. This value is taken into account when choosing a voltage stabilizer for a gas boiler.

The more electricity the boiler uses, the more stabilization power is needed. On the electrical equipment market, modifications from 0.50 to 3.50 kW are produced.

An equally important parameter for the selection of a device is the speed of response, which characterizes the response to voltage transformation.

The earlier the device detects a failure, the weaker the current curve will bend. So in inverter devices, stabilization occurs instantly in 2 stages, so the boiler is completely protected from a network failure.

When choosing a protective device, attention must be paid to the safety levels. All double-conversion protective complexes protect against short-circuit, wrong connection, polarity reversal and battery overcharging.

The main types of stabilizers

Let's discuss which voltage regulator is better for a gas boiler, because there are a lot of them on sale. First, consider the varieties:

- Relay - these devices are built on the basis of transformers with multiple windings, which are switched using high-speed relays. They do not require maintenance, but they do not have the longest service life of 3 to 5 years. During operation, they click, the output voltage changes abruptly and does not always correspond to the nominal value - the voltage compliance accuracy is within 5-8%. The response time is 50 volts per second;

- Electromechanical stabilizers are not the most common stabilizers. They are intended not so much for gas boilers as for the whole house as a whole. These devices have a low service life, are noisy during operation, have a slow response rate, and require regular maintenance. But they provide smooth adjustment of the output voltage without any steps - an excellent solution for gas boilers;

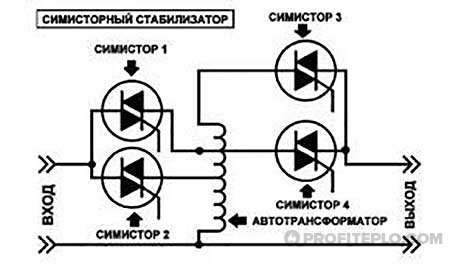

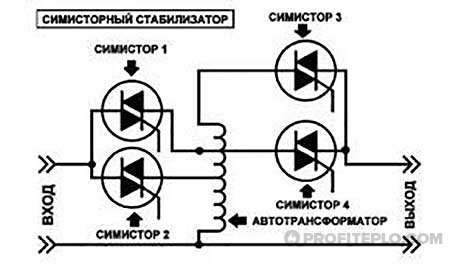

- Electronic - all the same transformers are here, only the switching of the windings is carried out by thyristors or triacs. The service life of these devices is up to 15 years, they react very quickly to changes in the input voltage, do not click or make noise, the output voltage changes in small steps (from 2 to 10 Volts);

- Hybrid - a combination of electromechanical and relay stabilization circuits, providing the ability to work in a wide range of input voltage.

An electronic voltage stabilizer for a gas boiler is the best solution, albeit the most expensive one.

Ferromagnetic stabilizers and double conversion devices are also on sale. The former are very noisy, cannot work without load, and have a high price. The latter are even more expensive, but they provide an absolutely stable voltage of 220 volts at the output - most often they are used to protect expensive electronics.

What type is suitable for the boiler

Today's electrical digital equipment market presents a large selection of protective devices, with a variety of operating principles. Before choosing a voltage stabilizer for a gas boiler, you need to understand the basics of their functioning.

Inverter

These are devices for two-system transformation. Primary when converting alternating current to direct current. Secondary - on the contrary, in connection with which another name of them appeared: inverter.

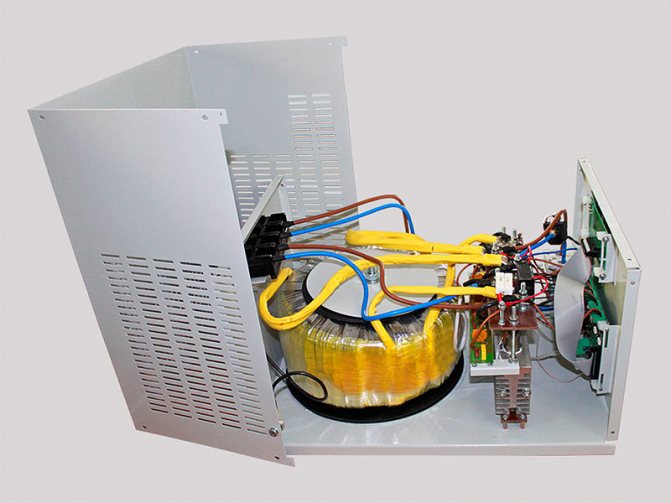

Inverter stabilizer SHTIL. Photo source: shop.ecoteco.ru

The initially unstable current from the network enters the rectifier and power corrector of the apparatus, where the filtration and stabilization processes take place. After that, energy is accumulated on the plates of a huge number of capacitors.

For stable and long-term operation of the boiler, the mains parameters with correct sinusoidal qualities are required.

This type of protection creates a perfect sine wave due to the use of an inverter. The charge from the capacitors, after the completion of the 1st stage of the conversion, is transferred to the second part of the device, where it is again transformed - inversely with stable output sinusoidal parameters.

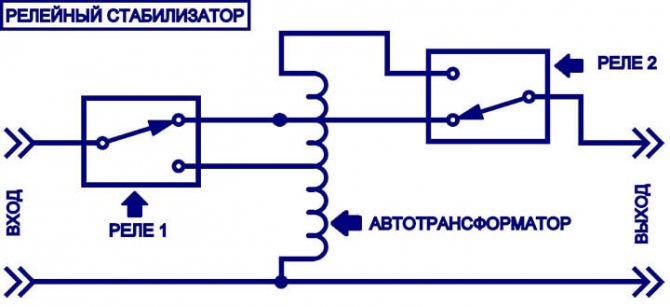

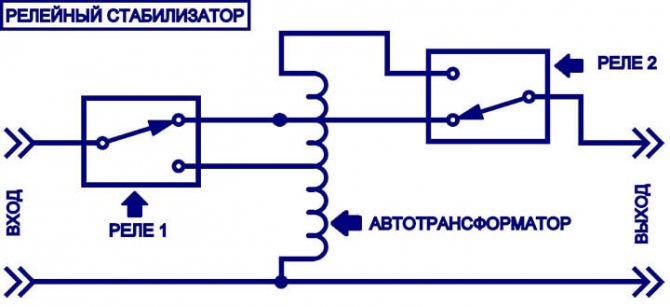

Relay

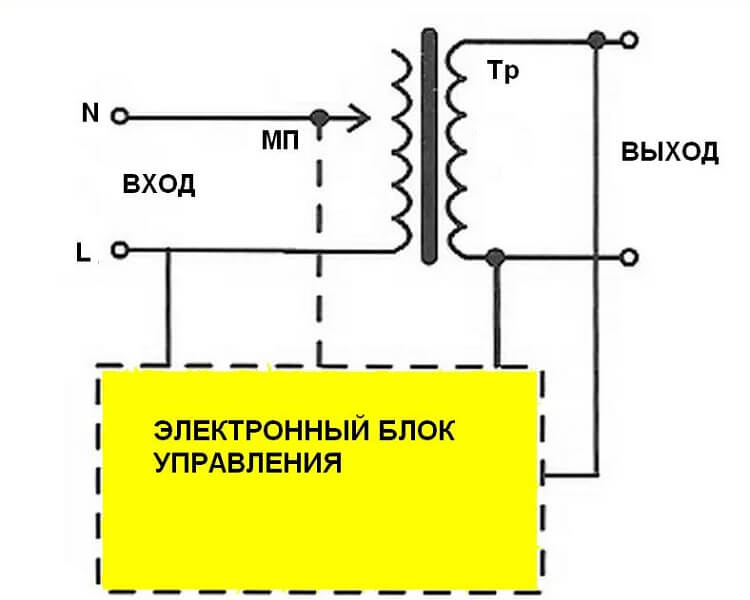

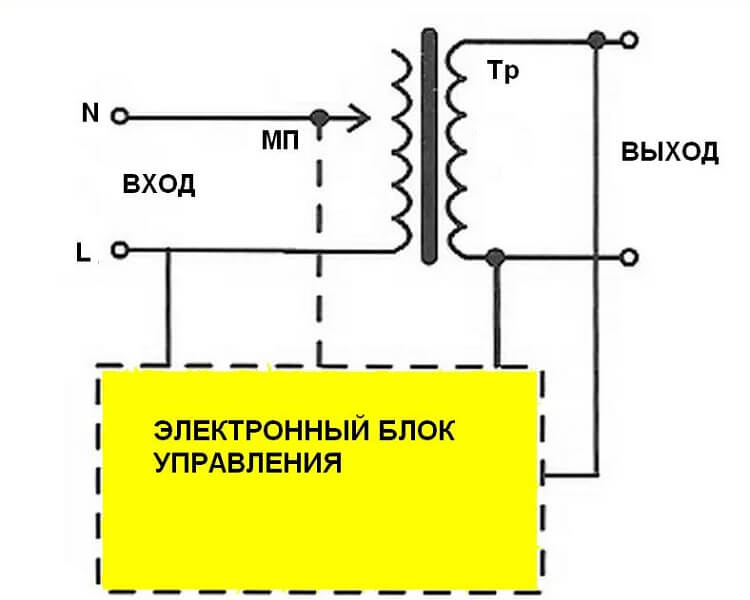

Relay devices have an automated transformer and specialized electronic circuitry that controls the transformer. They have a difference - they are relays, which is why they got their name.

With the support of this small device, a current transition is made between various windings. Initially, such 220 V voltage regulators were produced in the booster format.

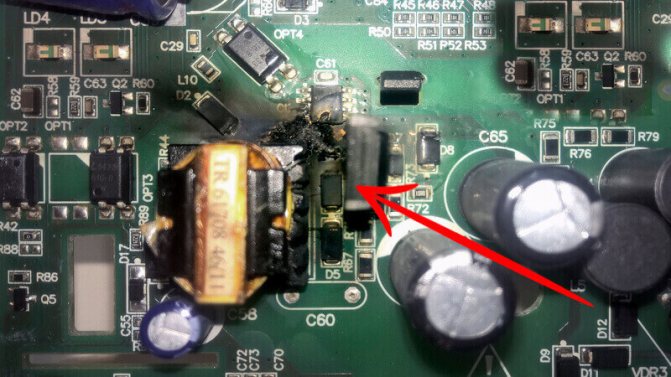

Relay stabilizer circuit

Later, changes were made to the device, which made it possible to use them both to increase and decrease the voltage.

It should be recognized that these modifications sold on the market cannot demonstrate good quality. Some manufacturers, mainly from Asia, reduce the cost of the stabilizer by using not very high-quality components, which affects the low service life of the devices.

Electronic

This type is often referred to as triacs, today they are considered the best with good technological and operating parameters. The principle of operation of the device is based on the automatic method of switching the converter with the support of digital keys - triacs, which are the primary cause of the instantaneous response of the device to all kinds of deformations of the network characteristics.

Only one drawback is the decent cost of the device. In this group of devices, the ratings are headed by the voltage stabilizer for the gas boiler Shtil.

Electromechanical

This type belongs to very simple, but super-quality devices, the method of operation is based on the sliding of the slider along the secondary winding of the drive. The slider moves the brushes, decreasing or increasing the number of turns that are energized.

Of course, the slider will not be able to move spontaneously. This is done by an electric motor or, as it is called, a servo drive.

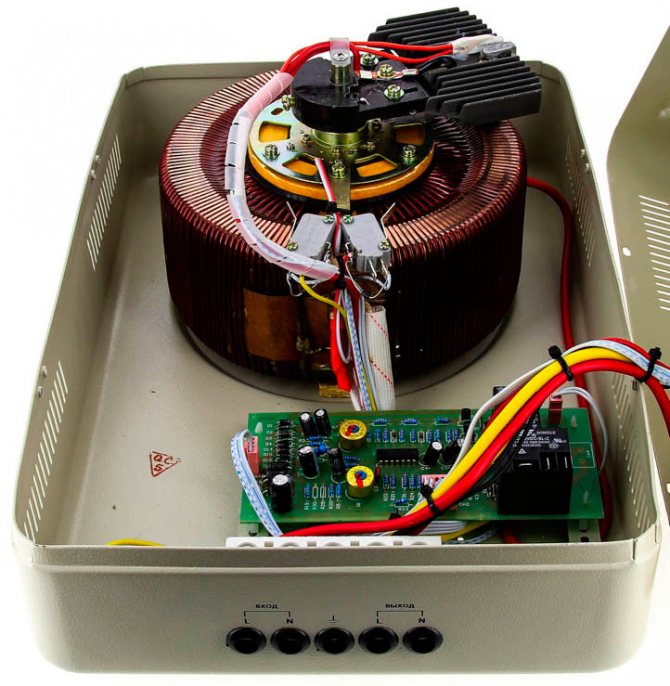

Electromechanical stabilizer

The engine is directly under the control of the processor, which controls the stress strain. When the network characteristics change, the microprocessor will send a signal to the electric motor, which starts and initiates the direction of the slider along the windings, in one direction or the opposite direction, on the basis of which the network parameters have decreased or increased.

Types of stabilizers for gas boilers

The modern electronic equipment market today offers a wide selection of voltage stabilizers. They are divided into several groups, which are based on different principles of device operation. Hence the different degree of safety of the boiler automation unit.

Electromechanical (servo)

They are the simplest, but most reliable devices, the principle of which is based on the movement of the slider along the turns of the secondary winding of the electric drive. The slider moves the brushes, reducing or increasing the number of energized turns.

Of course, the slider cannot move on its own. This is done by an electric motor or, as it is called, a servo drive, directly connected to the slider. The engine is controlled by a microprocessor that reacts to voltage changes in the network. It turns out like this: as soon as the voltage in the network has changed, the controller (also known as a microprocessor) signals the engine. The latter turns on and begins to move the slider along the windings of the transformer in one direction or the opposite direction, depending on whether the voltage in the network has decreased or increased.

Reliable servo-driven stabilizer for gas boiler

Manufacturers of different brands offer the principle of moving the slider using different technologies. For example, one of the most effective ways is to move the servo itself with a slider along the guides made of copper. They are circular in cross section and are located along the transformer coil.

Speaking about the advantages of this type, it should be noted:

- smooth adjustment;

- high accuracy of voltage setting;

- the device can withstand large overloads for a long time;

- when overloaded, its work will always be stable.

As for the disadvantages of electromechanical stabilizers, they include a short service life, not exceeding 1 year. After that, the device must be taken to a service center to replace worn brushes and check other parts. During operation, the unit makes noise and heats up. Therefore, manufacturers recommend treating it as equipment from the fire hazard category.

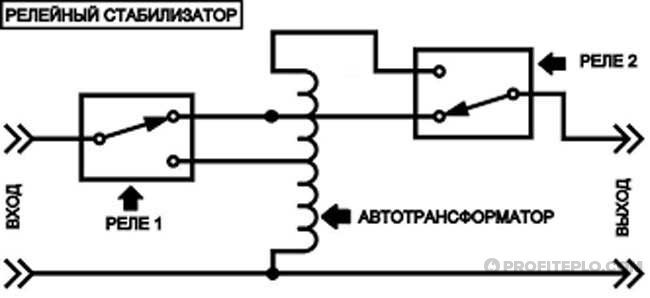

Relay

Like most voltage stabilizers, relay ones have an automatic transformer and a special electronic type circuit that controls the transformer. But they also have a distinctive detail - this is a relay, hence, in principle, their name. This small device switches between different transformer windings.

Initially, such 220 V voltage stabilizers were used as boost voltage regulators. That is, they were installed in an electrical network, in which the voltage was usually below the nominal. But over time, changes were made to the design, which made it possible to use them for lowering the voltage.

What does a relay stabilizer look like from the inside

The advantages of this type of stabilizer include

:

- small dimensions;

- a fairly decent range of stabilization of the input voltage (for example, the range of Resant brand stabilizers is 140-270 V with a rated power of 80%);

- overload can be 10% more, and its duration is 4 seconds;

- the same Resant devices can operate in the temperature range from -20 ° С to + 40 ° С;

- relay stabilizers work almost silently;

- the service life is not less than 10 years, provided that high-quality relays are used.

Unfortunately, not all relay models on the market can boast of high quality. Many manufacturers, especially Asian ones, are trying to reduce the cost of the device by using parts of not very high quality. Hence the reduction in service life.

Relay stabilizer circuit

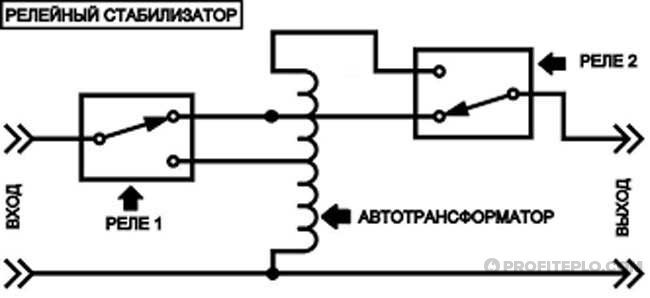

Electronic (thyristor)

They are more often called triac, and today they are the best with high technical and operational characteristics. The principle of operation of the device is based on the technology of switching an automatic transformer using electronic keys (triacs). It is they who are the reason for the rapid response of the device, which reacts to any changes in the voltage in the network.

Shtil high-tech triac stabilizer

Hence the positive characteristics of the device.

- The response time is 10-20 ms.

- The accuracy of the output voltage does not exceed 2.5%.

- The range of voltage surges (for example, for Resant - 120-280 V).

- The maximum error of the output voltage is 0.5% of the nominal.

- The service life is practically unlimited.

- The work is silent.

- If one electronic key fails, the device continues to operate normally.

The only drawback is the high price of the equipment.

Triac regulator circuit

How to choose the power of the stabilizer

The protective device must have good power in order to ensure the performance of absolutely all elements connected to the boiler unit: the unit control unit, the coolant circulation pump and the fan.

Therefore, first of all, it is necessary to clarify how many nodes for the consumption of electric current will be connected through the stabilizer.

Power data are registered in the passports. In addition, it must be taken into account that current consumers, for example, such as a pump, have increased starting power characteristics. Therefore, the calculated value needs to be increased by 1.3.

The best voltage stabilizers for gas boilers

Not all companies manufacture devices of several varieties at the same time. Usually companies focus on one type of development. The choice of protection for the boiler unit is significantly determined by the parameters of the regional network and the load of the switched-on boiler units.

Installing the stabilizer in the circuit: Photo source: fenixled.ru

You can make up the characteristics of a decent device:

- The smallest power is 1000 VA.

- Built-in protection against overheating of contacts and short circuit.

- Input voltage range 90-290 V, absolutely non-critical to the load.

- Output perfect sine wave.

- The low voltage pickup level is higher than the normal value on the district power grid.

- Autostart with the suspension of the process, upon completion of the protection operation.

- The presence of a grounding terminal.

- The speed of voltage regulation is no more than 20 ms, with a processing accuracy of 2-3%.

According to this list of parameters, the rating of voltage stabilizers:

- Cool stabilizer 220v relay type for gas boiler Baxi - LogicPower LPT-1000RV, the price as of December 1, 2019 - 2180 rubles.

- Relay stabilizer Warm unit TEPLOCOM ST-222/500, price as of 1.12.2019 - 2970 rubles.

- Best Servo Motor Stabilizer - Resanta ACH1000 / 1-EM, price as of 1.12.2019 - 3120 rubles.

- Excellent thyristor device - voltage stabilizer Calm for gas boilers R 1200SPT, price as of December 1, 2019 - 13,070 rubles.

Criteria for choosing a stabilizing device for a heating boiler

To choose the best stabilizer for a gas boiler, you need to know its main characteristics. All devices designed to stabilize the mains voltage, have the following main parameters:

- Power;

- Response speed;

- Output voltage accuracy;

- Input voltage range.

In addition to these parameters, the cost of the device, its reliability and additional factors such as noise and heat may be important for a potential user.

- All stabilizers have built-in protection against overload, short circuit and disconnect the load when the input voltage is significantly exceeded. The power of the stabilizer is determined by the power of the gas boiler, and if the heating system is equipped with a circulation pump, then by the power of the pump;

- The response speed determines how quickly the regulator responds to the changed input voltage. In this sense, a device with a servo motor is the slowest, followed by a relay stabilizer. Electronic devices carry out almost instantaneous voltage switching so that the risk of failure of gas equipment in this case is minimal;

- Foreign-made gas boilers, as a rule, are designed for small fluctuations in the supply network. This value is indicated in the passport for the device and can be decisive when choosing a voltage stabilizer;

- The highest accuracy is provided by inverter and servo stabilizers. In relay and thyristor devices, the output voltage levels are switched in steps at certain intervals, which ensures an installation accuracy of about 5-6%. In most cases, this accuracy is sufficient for the normal operation of the control system and automation of the gas boiler;

- An important parameter of any stabilizer is the permissible input voltage range. Depending on the design, stabilizing devices can only maintain a constant output voltage at certain input voltage limits;

- Usually stabilizers work successfully with an input voltage of 140-150 to 240-260 volts. This parameter is indicated in the product passport and may differ slightly. If the mains voltage deviates significantly from the permissible, the electronic fuse will disconnect the consumer (load) from the electrical circuit. After normalization of the input voltage, the load is automatically connected to the stabilizer;

- In terms of cost, stabilizers of different design can vary significantly. Powerful thyristor or inverter stabilizers are several times more expensive than relay ones, but this pays off with their high reliability and complete absence of noise during operation;

- For the convenience of users, most models of stabilizers are equipped with LED indicators of operating modes and a display where some digital parameters are indicated.

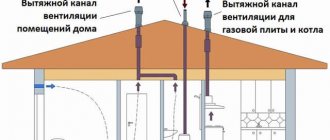

How to connect

The stabilizer manufacturers clearly state in the instructions how to turn on the device. First of all, you need to prepare the workplace, which must be dry. Further, the installation is carried out in such a way that there is an unobstructed approach to the apparatus.

At the same time it must be taken into account that the regulator is air-cooled For this reason, a lot of free space in front of it will be required. Therefore, it is forbidden to place it in a sideboard or drawer. And the last limitation, the installation is placed away from fire hazardous building materials.

The monophase device is connected via a standard socket. The plug with the adjusted mains values is connected to the socket on the boiler body.

Based on the above, it can be argued that a stabilizer is needed for the gas boiler to function correctly and not be damaged from failures in power grids.

The specific conditions of power supply and the power of the protected equipment will determine which voltage stabilizer will better cope with its tasks.

Rules for connecting stabilizers for a gas boiler

Manufacturers clearly stipulate how to properly install and connect the stabilizer. First, the installation site must be dry. Secondly, the installation is carried out so that the device has free access. It should be borne in mind that the stabilizer itself is cooled by the ambient air. Therefore, there should be a lot of free space. This means that it is forbidden to install it in a cabinet or drawer. Thirdly, the installation should be carried out away from the place of storage of fire hazardous materials.

Making the right choice of stabilizer

The single-phase device is connected to a regular outlet. There are no requirements for this position. The plug with the output voltage is connected to the socket, which is located on the body of the gas boiler, or rather, on its control unit.

Summing up all of the above, it should be noted that the question of whether a stabilizer is needed for a gas heating boiler of a volatile type is no longer worth it. The device is necessary for the heating equipment to work correctly. After all, everyone knows what voltage surges are present in domestic electrical networks.

The most important thing is, taking into account its technical characteristics, to choose the right brand of the desired device. Therefore, choose exactly according to them and do not think what kind of stabilizer you need, what brand and type.