The device of boilers Vilant

Electrical diagram

Consider the design of the Vilant boiler using pictures and diagrams from the installation manual. For correct setup during installation and troubleshooting, a circuit diagram is required. It shows exactly where all the nodes of the device are connected to the electrical control board.

The wiring diagram for a specific model of a gas heater may differ slightly from the standard one. To make repairs and adjust a specific model, you need to use the instruction manual that comes with each device.

Hydraulic circuit

On the hydraulic diagram of the boiler operation, all the nodes that pass the liquid during the heating process are indicated. Below there are five pipes, two for hot water supply and heating and one for supplying gas.

The cooled heat carrier from the heating system enters the rightmost branch pipe. The liquid passes through a three-way valve, a circulation pump and enters the primary heat exchanger. There it heats up and goes out through the filter from the leftmost branch pipe into the heating system. If hot water priority is set, then it passes through the secondary heat exchanger, while heating the water for domestic use. A three-way valve controls the flow direction of the heating medium.

Cold clean water enters the second pipe on the right side, goes to the secondary heat exchanger and from there, the already heated one goes into the second pipe from the left.

Installing a gas boiler Vaillant

The main condition for ensuring the correct and stable operation of the boiler is the correct choice of premises. If the installation is not in a kitchen or other living room, frost protection must be provided.

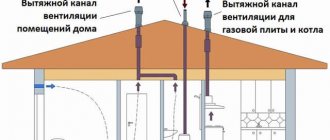

In parallel, it is necessary to organize high-quality ventilation and install grounding, without which the unit will not be able to work. During installation, the established gaps and distances from the nearest walls or window openings must be observed.

The connection of the pipelines must be done carefully so as not to confuse them with each other.... All gas connections are checked for leaks using a soap solution.

Features of one and two-circuit models

Single-circuit wall-hung boilers such as the Vaillant Turbotec plus VU are distinguished by their simple design and compactness. Their main disadvantage is that they do not provide the user with hot water supply. In order to use it to heat running water, you will have to additionally purchase and install an indirect heating boiler.

Vaillant Turbotec plus VU boilers

Dual circuit models such as the Vaillant 240 are equipped with a thin-walled steel secondary heat exchanger to transfer heat from the heating medium to the running water.

Also available are two-circuit devices with a built-in boiler. They are large in size. The water tank is located at the bottom of the case. This is how Vilant models such as AtmoCompact and AtmoVit Combi are arranged. Let's take a look at how a typical two-circuit boiler works.

Principle of operation

Consider the principle of operation of Vilant gas boilers. They are designed for space heating and domestic hot water heating. They are connected to a heating system with radiators located throughout the house. When the coolant inside cools down to a certain temperature, the thermostat is triggered. It sends a signal to the control board.

From there, a signal goes to turn on the circulation pump, open the gas valve and supply electricity to the ignition electrodes.Gas begins to burn in the burner, above which the main tubular heat exchanger is located. In it, heat is transferred from the combustion of the gas to the coolant in the tubes.

When the water in the heating system heats up to the temperature set in the settings, the thermostat is triggered again and the boiler stops working. When the hot water tap is turned on, a three-way valve is triggered, which directs the heated coolant to the secondary heat exchanger. There, through the thin walls, heat is transferred to the tap liquid.

In some series, for example, Vailllant Turbo, it is possible to connect an external room thermostat. In this case, you can adjust the heating to the desired room temperature.

Vailllant Turbo boilers

Condensing models such as Vilant ecoTEC have a specially designed heat exchanger that allows additional use of the heat of the volatile combustion products during their condensation.

VR 920 data transfer unit

The question of remote control of the boiler and the temperature in the house arises not only in the case when the house or dacha is unattended most of the time, but also in any house of permanent residence. Since the information about the main parameters of your boiler and its operation mode in your phone, it simplifies the control over the equipment and saves energy resources if the remote control device operates in the thermostat mode.

A feature of most Protherm and Vaillant boilers is the presence of a digital eBus bus, connecting to which makes it possible to receive more information about the operation of the boiler. Vaillant offers the VR 920 Communication Unit, which allows remote access to the control of the heating, cooling and ventilation system. This unit only works when used with the multiMATIC VRC 700 / x system controller. As a result, the cost of a remote monitoring and control system is comparable to the cost of a mid-range boiler.

Therefore, at most objects and on sale, our company uses already proven and easy-to-use thermostats and controllers from Microline - Zont and others.

Scope of use and technical characteristics

Vailant gas boilers are designed for heating domestic and industrial premises. Depending on the model, they have a different power range. From small appliances like the 4 kW Eco Compact to higher power devices like the Eco Craft VKK 294 kW. Also, if necessary, a number of models can be connected in a cascade to fold the generated heat energy.

Both wall-mounted and floor-standing devices are available. Depending on the type of combustion chamber, atmospheric and turbocharged series are produced. For example, Vilant T3 and T4, where T3 is equipped with atmospheric, and T4 is equipped with a closed combustion chamber. The heat exchanger is made of copper, stainless steel or cast iron.

All devices are equipped with modern protection devices: from freezing, overheating, extinguishing the flame and lack of draft. Individual devices can operate on both natural and liquefied gas. All boilers have an electronic control system and automatic ignition. Modulating burners allow you to smoothly change the required intensity of work.

General characteristics and principles of work

To make a competent decision on the purchase of a certain standard size of such complex household appliances as a gas boiler, it is necessary to be guided by the following principles.

- Where the equipment will be installed. The Vaillant brand produces both floor-standing and wall-mounted units. The first ones are in great demand, since they do not require any special room for their installation, they are compact and are distinguished by great ease of use.At the same time, if there is a technical room in individual houses with a significant heated area (more than 300-400 m2), the installation of floor-standing gas boilers is quite the best option.

- It is supposed to remove the flue gases generated during the operation of the unit. Where the arrangement of a special chimney can be carried out even at the stage of building a house, it is possible to install a Vaillant gas boiler according to the instructions with natural exhaust of flue gases due to the difference in density. At the same time, in apartment buildings, it is more expedient to install turbocharged, closed boilers, the removal of combustion products from which is forced by means of a specially mounted fan.

- Providing the greatest cost-effectiveness. The Vilant company supplies a fundamentally new line of gas condensing boilers, where the so-called modulating burners are used. The peculiarity of these fuel-burning devices is that they are capable of operating under conditions of variable gas supply within a wide range. At the same time, the final thermal power of the unit practically does not change due to the presence of a plate heat exchanger. Such equipment is installed in low-temperature individual heating systems.

The power range of Vilant gas boilers from 12 to 112 kW makes it possible to install equipment in houses and apartments with different values of the heated area.

Advantages and disadvantages

Like any other household equipment, products from the Vaillant trademark differ in certain design features.

- Built-in security management systems. Protection systems are implemented against a sudden decrease in the gas supply to the burner, against sudden overheating of water when its flow is blocked, from sudden extinguishing of the burner flame, from disconnecting the power supply (for turbocharged versions), from disturbances in the circulation of the coolant, from its possible freezing when the boiler is turned off.

- Built-in fault testing system. When triggered, it displays an error code on the display screen, according to which you can perform an initial diagnosis of the malfunction.

- Plate heat exchanger, which has high operational resistance and cost-effectiveness; therefore, the warranty period of the Vilant boilers is up to 15 years.

- A sufficiently large storage tank capacity - up to 150 liters of water, which is quite acceptable for domestic needs.

- Easy to install and reliable flue gas evacuation system, which ensures high operational reliability and does not pollute the environment.

Disadvantages of Vilant double-circuit boilers, which can lead to malfunctions:

- Incomplete equipment of the basic version: in particular, the absence of an expansion tank does not make it possible to maintain the required flow rate of the coolant. Thus, boilers from the Vaillant trademark will function reliably only with a stable inlet pressure of cold water.

- In open-type units, the absence of a fan causes an insufficient level of traction.

- In the presence of automation systems, Vilant boilers are turned off during power outages, therefore, when the power supply is restored, they have to be started manually. At the same time, the gas consumption increases, and therefore the efficiency of these units is somewhat lower in comparison with similar products of competing firms (up to 90%).

- Use only purified water, no antifreeze additives.

Comparative characteristics of the main parameters of the most popular brands from this company are given in the table.

| Model | power, kWt | Heated area, m2 | Exe- nie | Hot water capacity, l / min | Furnace type |

| atmoTEC + VUW200-5 | 20 | up to 150 | wall | 9,6 | open |

| turboTEC + VUW TNT 242-5 | 24 | up to 200 | 11,4 | closed |

What the instruction requires

The initial start-up of this system assumes that it will be performed by a specialist of the specialized service center, which sets the following order of switching on (hereinafter, the instruction for the Vilant gas turbine wall boiler is meant):

- Preliminary water treatment (the company does not guarantee the operation of Vilant boilers for hard water).

- Removing air from the heating system of an apartment or house.

- Preliminary check of all settings of the gas heating circuit, in particular gas pressure and heat load on the unit.

- Boiler test run: includes functional check, check in heating and water heating modes

- Checking the functioning of automation and control systems.

Typical malfunctions

When reviewing this section, materials were used not so much for operating instructions for the Vilant gas boiler, as materials for user reviews. Of the most common malfunctions, the following are noted.

- The necessity of installing softening filters, since plate heat exchangers become clogged with scale relatively quickly.

- Increased noise level (according to experts, this is due to the sub-optimal design of the fan).

- Insecure sealing system of the pump, as a result of which water often gets into it.

- A voltage regulator is required, otherwise the electronics will become unstable.

Naturally, not so much as a malfunction, but as a disadvantage, many users highlight the high cost of the unit itself and spare parts for it, as well as some service restrictions, since not all cities have service centers.

Top Summarizing the above, it should be noted that Vilant gas boilers are periodically subject to malfunctions. But this does not remove their undoubted advantages - quality and reliability.

Source: KotelStroi.com