Warming is a very important step in preparing for winter. Therefore, it is important to understand how to properly insulate a house, and what you need to know in order to keep warm in your room.

As practice shows, up to about 30% of the heat is lost as a result of poor insulation of the walls.

This can lead to improper design, the use of old building materials, as well as a complete disregard for basic standards.

Insulation can be carried out both inside the house and outside. Walls, ceiling, floor, windows can be insulated. But experts say that the most effective is external insulation of the walls of the house.

Home insulation technology is very similar, and in this article we will consider the outdoor insulation method as a more effective method.

As insulation, both outside and inside, such materials are suitable as:

The most effective type of insulation is considered to be external wall insulation. This type of insulation has its undeniable advantages.

: reliably protects the entire structure from adverse environmental conditions (rain, wind, snowfall, and so on), contributes to an increase in the level of sound insulation, blocks the manifestation of fungus and mold (from inside the house).

Differences in insulation

The main property of this type of insulation is to minimize heat loss during the cold season, as well as reduce heating on hot summer days. Plus, keeping your walls warm can save you a lot on your heating bill.

You can perform this operation various materials

, which differ in the type of the raw material itself:

- organic;

- inorganic;

- mixed.

There are many varieties of materials on the building market.

, which will help to make the walls warm, and as a result, increase the energy efficiency of the whole house:

- mineral wool

- a special fibrous material that can be obtained by melting rocks, various kinds of metallurgical slags and their mixtures. A fairly common material for wall insulation, it is found in the form of a roll or slabs. There are several options for such cotton wool, which differ in their density; - glass wool

... It is a fibrous material (mineral fiber, similar in its properties to mineral wool). It can also be found in rolls or slabs. There are several material options that differ in density, thermal conductivity; - polystyrene, aka expanded polystyrene

... Gas-filled plastic that has many air bubbles. It can only be found in slabs. It differs in density and in the degree of flammability.

Types of thermal insulation

All these materials are necessary in order to insulate the house from the outside.

How to fix the material

The following types of fastening of insulation materials can be distinguished:

- fastening the selected material using various kinds of adhesive mixtures

... After their application, plastering is carried out; - a method of installing the material in which a small gap is specially made

... The wall is mounted in just one brick. For this, a special solution is used. This installation method is called -

three-layer non-ventilated wall

; - ventilated facade

... First, the wall is protected with special waterproofing, on top of which the insulation itself is already attached, and then the windscreen is mounted and, of course, the outer sheathing is installed on the frame itself. It can be clapboard or siding.

It is worth noting that each of the technologies has its own advantages and its own nuances of implementation.

External insulation methods

Before starting an operation to insulate a house, you should understand that the choice of material depends on the specific conditions of its use. Having studied the possible insulation materials, the following pros and cons of each of them can be noted:

- wadded heaters

... All of their varieties have good sound insulation properties, in contrast to foam (using foam, it is worth in addition to use contractions for sound insulation); - cotton-type materials are afraid of moisture, and this is quite logical

... Only 2% of getting wet is enough, and the properties of such a heater drop by all 50%. Be sure to store the material in places where there is no moisture; - foam is a combustible material

, and it is best to choose the one that belongs to the G1 group.

Before starting the insulation process, you should understand how the wall cake works, and what you need to know in order to insulate the walls correctly and competently.

A foam block house is a fairly popular design that has its own advantages. At the heart of such a structure is a very rigid structure of certain vertical posts with horizontal bridges. Small cells are formed, in which the insulation itself is laid (the one that was determined in advance).

Alternative

Almost any building material used for the construction of walls requires subsequent finishing, decoration of the facade. With all its advantages, the foam block and any facing material are used in combination, and in the case of using brickwork, in fact, you have to build a second wall. Is there any way to make the process easier by combining foam blocks with finishing?

There are options with a front side, on which a texture is applied that imitates plaster, brickwork, or even having a marble-like surface, artificial stone of different colors, patterns and textures.

Foam block with textured facing side

The use of this option for construction eliminates the need to use facing tiles, bricks or other facade material.

Options for foam blocks with a facing side

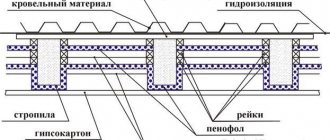

Wall cake

Despite the fact that a wall cake of this design is quite simple, it has its own nuances and must be performed in accordance with all the rules.

Such a wall consists of:

- outer layer, it is also facing;

- membrane of special design;

- the place where the insulation is installed is the crate. Mineral wool is most often used as a heater;

- sheets of vapor barrier material;

- the last layer is lining from the inside.

Wall cake

Despite the fact that a house made of foam blocks is being built so that its walls bear minimal heat loss, it should also be insulated.

Interior decoration

Decorating the walls from the inside is easier than from the outside, since the decorative and protective layer is not affected by precipitation, frost, sun and wind. Despite this, the interior decoration of a foam block house requires accuracy and strict adherence to technology.

If the wall is to be plastered, it must be pre-treated with a high-quality primer. It improves the adhesion of the finish to the smooth foam block.

Although the surface of a single foam block is even, masonry seams, chips and cut areas minimize this advantage. The putty cannot always level the foam block wall to the required condition. In this case, the lighthouse gypsum plaster will help you out.

The interior decoration of a house made of aerated concrete is practically no different from work on the protection of a foam block wall. You can do it yourself using ordinary drywall.

For fixing the sheets, a starting putty is used.It is applied to the sheet with wide and thin strokes at several points (8-10) and then pressed tightly against the wall and fixed with self-tapping screws. After the putty has dried, the sheet adheres firmly to the gas block and can be finished with wallpaper, latex or silicone paint.

A light batten frame and lining of wood are another good way of interior wall cladding made of aerated concrete. Time-consuming leveling of the surface is not required here. It is enough to accurately set the frame in two planes, after which the installation of the lining is easy and fast.

Vapor barrier and waterproofing

So that the wall insulation is not in vain, it is worth remembering all the necessary steps, one of which is - installation of vapor barrier

... Such an operation is necessary in order to provide the structure with moisture protection. It is especially relevant in damp rooms.

A procedure such as vapor barrier is a kind of barrier between water vapor and insulation.

When working with such material, you must be extremely careful not to pull the coating too much so that the film does not break.

Depending on the type of walls, the vapor barrier procedure can be different:

- if the walls are processed inside the house

... It is worth remembering that the film is applied horizontally, from bottom to top. The fastening process itself is carried out using a stapler or small nails.

The film overlaps, the joint of which must be at least 15 cm.

After that, the vapor barrier layer is fixed with a wooden frame. It should be understood that the quality of the procedure performed also depends on the quality of the film. It is worth buying high quality and modern materials; - vapor barrier for siding

... If you are planning to cover the house with siding, you should not neglect the vapor barrier. It is best to use foil film. The insulation itself is made with the reflective side outward. The procedure is the same as for internal work; - for

... A feature of this type of house is the absence of a rigid base, and as a result, the vapor barrier procedure is carried out between the racks. This type of house cannot be rented out without vapor barrier.

Vapor barrier and waterproofing

NOTE!

Along with vapor barrier, there is another way to protect the structure from moisture - waterproofing

... To get 100% positive effect, apply these two methods at the same time.

During this procedure, the following materials are used:

- ruberiod

... Special cardboard, which, in turn, is impregnated with petroleum bitumen, while on both sides it is coated with refractory resin; - roofing paper

- cardboard, which is treated with a tar composition; - glassine

which is impregnated with bitumen; - waterproofing membranes are the best option

.

The wall, which will give your home warmth, protect it from moisture, should consist of the following layers: wall, vapor barrier layer, insulation (most often mineral wool), waterproofing film.

Foam block with facing: types and characteristics

A house or cottage is erected using various building materials. Each owner strives to maintain comfort in the house during his stay, for which, for the most part, the heat-saving properties of the walls are responsible. This desire is easily realized if you use a foam block with a facing - a material with excellent characteristics and is very popular. In the article, we will get acquainted with the advantages, disadvantages, types, properties and technical characteristics of the facing foam block.

What kind of material and what types are there

Foam block is a material for the production of which natural ingredients are used, which is why in some countries it is called "bioblocks". Foam concrete is an environmentally friendly building material that is safe for both humans and the environment. Initially, the material was created in order to combine the qualities of wood and mineral, while remaining artificial.It was first invented by a Swedish architect at the beginning of the 20th century, but the foam block is still in demand today, as it has excellent performance characteristics. The foam block is an inexpensive, durable, economical, biologically resistant and environmentally friendly building material, which, in comparison with natural wood, does not rot, does not burn and is more durable.

The advantage of foam concrete is that it lends itself easily to facing (upholstered with clapboard, plastered, covered with facade paints, and so on). Foam blocks will not burn and spread combustion, and upon contact with high temperatures (for example, a blowtorch), the surface will not split or explode, as is the case with heavy concrete.

Types of facade foam blocks:

- Plain. A foam block with a finished facade is widespread in the construction of summer cottages and cottages. Due to the advantage - when erecting walls, the latter does not require cladding. The outer sides of the materials are factory-coated with high-quality finishes, resulting in a neat and attractive façade. Such a cladding not only allows you to improve the appearance of the house, but also allows you to protect against external influences (an indicator of resistance to moisture);

- Angular. Compared to a conventional façade unit, the product is characterized by two adjacent decorative surfaces. With the help of such foam blocks, door, window openings and corners are faced;

- Thermoblock. The main distinguishing feature is the design. The material is "collected" from several layers. The front side of the block is a facade cladding for the sake of improving visual characteristics. Next comes a thick layer - a heat-insulating filler, which makes it possible to reduce the thermal conductivity of the material. The inner side is equipped with a supporting layer, the task of which is to make the block strong and resistant to physical influences. If you need a thermal insulating material, then a foam block with lining and insulation is one of the best options. For comparison, a 4-meter wall made of a thermoblock is identical in terms of thermal insulation characteristics to a 2.4-meter brick wall, or 4.6-meter concrete. Also, the material is used to fill the walls of structures that require thermal insulation.

Foam blocks and their technical characteristics

Consider the parameters of the material:

- Thermal conductivity - 0.14 - 0.22. Based on the coefficient, it is judged how well the material retains temperature. Foam concrete blocks confidently occupy a leading position in the building materials market;

- Strength (brand) - from B1.5. Strength is closely related to the density of the product, and the denser the block, the stronger it is;

- Density - 300 - 1200;

- Frost resistance - 15 - 100. 15 - minimum species required by GOST. The indicator indicates how many freeze-thaw cycles the material withstands;

- Shrinkage - from 0.5 mm / m2. Proceeding from this, the foam blocks shrink, therefore it is very important to carry out the construction correctly, otherwise even on the finished wall there is a possibility of a crack;

- Water absorption - 10 - 16%. Blocks will absorb moisture, but not as much as similar products. It is caused by the fact that the pores of the blocks have a closed structure. For example, gas blocks have the same indicator - 25%. Despite this, in the process of building a house or cottage, it is still recommended to use protection against moisture, since water can affect the strength and, as a result, the service life of the material;

- Environmental friendliness - 2. Products are made from natural ingredients, without the use of harmful or toxic substances;

- Fire resistance. Foam blocks are materials that do not lend themselves to combustion. In high temperature conditions, they stand for 2 hours without any problems;

- Wall thickness - 6 meters. The indicator is recommended, but it is also worth considering cold bridges and low temperatures in some regions of the country. For this reason, it is recommended to erect walls 1 meter thick.

Based on the technical characteristics, we can conclude about the material itself, but you also need to take into account that foam blocks are of several types and are used for many tasks. Only knowing the complete information, a conclusion is made about the competitiveness of the product.

As for the use of the material in construction, more and more attention has been paid to it lately. Due to the fact that foam blocks with a facing side do not require facing - this simplifies work and reduces construction time.

Advantages and disadvantages of blocks

A wide variety of building materials are now produced, the technical characteristics of which satisfy many developers. In each case, the use of a particular product is relevant. Some time ago, houses were built from logs or bricks, but now block elements are also suitable for this, which have many positive qualities.

A foam block with a facade surface is a material that has become popular and in demand, due to its affordable cost and ease of use. So, to build a house, if desired and with some knowledge, really independently, without spending money on the services of builders.

The ease of handling the material makes it cost effective. Almost every developer will afford these blocks.

Many are accustomed to comparing foam blocks with gas blocks, which is not entirely correct. Foam blocks have a poorly verified geometry, when the gas blocks are "correct", having almost perfect geometry. However, the material in question allows you to build a warmer house, which is much more significant. Also, foam blocks during the construction process will need to be slightly trimmed. If you neglect this, then the walls will turn out to be not even and neat enough. This is very important, since if such a mistake is made, there is a possibility that drafts will pass through the wall ceilings.

For a more detailed acquaintance with the material, consider the advantages and disadvantages. Let's start with the merits:

- the main plus is the weak thermal conductivity, thanks to which the housing turns out to be warm and cozy. In most cases, such houses do not require additional expensive insulation;

- frost resistance of the material is also at a height;

- light weight. This makes it easier to work with the material itself. For example, to move blocks around a construction site, you do not need to use heavy equipment, everything is done independently without unnecessary hassle;

- starting from the aforementioned advantages, one more follows - low weight favorably affects the quality of the foundation, since it does not experience excessive loads;

- the structure of foam blocks has a beneficial effect on the natural air exchange in the house. The room will have a comfortable microclimate;

- due to the soundproofing characteristics, inside the house, built from foam blocks, noise from the street will not be heard, which also contributes to a comfortable living;

- the material is used not only for the construction of country houses and cottages. If desired, smaller elements are also erected from blocks, such as flower beds, fences, gazebos, and so on;

- the foam concrete block is characterized by a large volume, so construction does not take much time;

- the material is malleable, so if the project requires it, the block is easily sawed or trimmed to the required shape;

- an environmentally friendly product that does not cause allergic reactions and does not have a negative effect on the human body. Of course, some synthetic components are involved in the production process of the material, but there are so few of them that this does not affect the quality in any way;

- a little Portland cement is required for manufacturing;

- foam blocks are characterized by a long service life, so that a house built from it will stand for a long time;

- the fire safety of the material is also not in the last place, which is a key factor for some developers. The product does not catch fire and does not intensify combustion;

- so that the blocks do not rot and dry out, additional processing is not required. Rats, mice, and insects do not favor material over wood;

- there is an opinion that only template buildings are erected with the help of this product. But it must be remembered that the blocks are easily processed, so all that is needed during construction is to show imagination;

- erected houses do not require additional finishing, especially if foam blocks with cladding were used. This not only reduces construction costs, but also saves time;

- the positive properties of the material persist for many years after the construction of the house.

Despite the list of advantages, builders recommend using the material for building houses in temperate climatic zones. In the case of harsh and long winters, you will definitely need high-quality internal insulation of the structure.

As you can see, the list of advantages is impressive, but, like any other product, foam blocks also have weaknesses. So, the disadvantages are as follows:

- foam blocks have a cellular structure, as a result of which they must be carefully handled during transportation due to their fragility;

- due to the cellular structure, special fasteners have to be used;

- shrink, in particular for blocks produced by the non-autoclave method;

- in order for the floors to be as reliable as possible, the installation of a reinforced belt is required;

- the market is overflowing with materials and some of them are handicraft counterfeits.

Conclusion

The main thing in construction is to choose the right building material so that the house is not only cozy, but also warm. An important point is adherence to the technological process, and with such a product as a foam block, work will be simple and fast.

betonov.com

Insulation of the facade from foam blocks from the outside for siding

The walls of the house can be uneven and there is nothing to worry about. But the process of warming itself should be carried out on flat surfaces, what should be done in such a situation? To do this, use a metal or wooden crate

... It is she who will help hide all kinds of flaws on the facade of the building.

The rules for establishing such material are simple:

- before you start installing the crate on the facade, you should clean it of dust, dirt (you can use sandblasting);

- in no case carry out the process of installing such a crate at temperatures below -10 degrees;

- it is imperative to leave a place for insulation (for example, for mineral wool);

- when installing the lathing no need to screw in self-tapping screws to the very end

(all the way); - the crate has its own step and it is necessary to choose it based on the dimensions of the facade panels themselves.

Siding lathing

After carrying out such a procedure, you can begin to insulate the facade. Step-by-step instructions on how to insulate the facade of foam blocks using mineral wool:

- the first thing to do is to free the entire facade of the house from dirt and dust. Also take pictures of different brackets, communications, and so on. Make the walls "bare";

- be sure to seal all cracks, cracks with a special solution;

- let it dry, then apply antifungal agents (you can buy them at a hardware store). You do not need to apply to all walls, only do it where the wall will be exposed to moisture. This is necessary so that there is no mold and mildew;

- install the crate, best of all from metal frames;

- lay a vapor barrier;

- start laying rock wool slabs.Craftsmen advise using cotton wool in slabs, since working with rolls is not convenient and will bring a lot of problems.

- after the insulation material has been laid out, it is worth applying waterproofing;

- carry out the siding process (vinyl / metal);

- on the building materials market, you can find mineral wool of different sizes, but the best option is a 10 cm thick slab.

Mineral wool installation scheme

Lathing with a metal profile

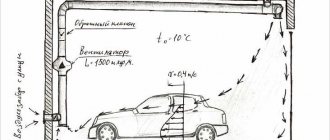

How to insulate a foam block house from the outside

What material to choose for thermal insulation? The ideal option for self-insulation of foam concrete is plate material: foam, expanded polystyrene or mineral wool mats. When using a vapor-permeable insulation (mineral wool), it should be protected with waterproofing. If the house is insulated with vapor-proof materials, then a ventilated gap must be installed, which will remove possible condensation from the wall surface.

Insulation of a foam block house with mineral wool

Mineral wool - vapor-permeable, environmentally friendly, non-flammable, prevents the spread of fire, may shrink if improperly laid. Material should be handled with personal protective equipment.

Expanded polystyrene, polystyrene - vapor-tight, has a low heat transfer coefficient and water-repellent properties, does not shrink, does not freeze. When insulating a house with polystyrene outside, it should be protected with a decorative layer from ultraviolet rays.

Another new material for warming the facades of country houses is thermal panels. The process of insulating a house with thermal panels is very simple and quick, the work is available to any non-professional builder.

Output

It is quite possible to carry out the insulation of a foam concrete house on your own. It is important to properly process the walls, before sheathing with insulation. Depending on what kind of house you have, what material it is built from, the insulation procedure may differ slightly.

Whatever material you choose for wall insulation, you need to do everything strictly according to the rules, and then your house will be warm. If you do not know which material is better to choose, mineral wool, or polystyrene, consult with the masters. But as practice shows, mineral wool / glass wool is most often used, since it has many advantages.

No, it’s wrong. Moreover, it is technically illiterate. I'm talking about builders. Your layman's delusions are understandable and excusable. Now my task is to clearly point out the mistakes and outline with you the ways to competently insulate the house. I would also add an adjective - modern insulation. Because 20-25 years ago, ideas about this process were as far from the truth as “your” builders are today. So - what does it mean to insulate a house? This phrase means to provide a comfortable temperature in the house at almost any temperature. Yes, yes, this is not only about insulation. We should rather talk about thermal insulation. The fact is that the owners of houses that have completed modern thermal insulation did not regret it even in the sultry summer of 2010. It turned out that thermal insulation saves not only from cold, but also from excessive heat. All these considerations lead us to the fact that there are insulation standards. They are designed in such a way as to provide a comfortable temperature in the house with minimal fuel consumption for heating. Each building material has its own thermal protection rate. So, "your" foam concrete also has its own, and with a thickness of 30 cm, it does not even reach half the required size. I don't want to plunge you into craft formulas, this is absolutely useless. The main thing to understand is that you need additional insulation made of special heat-insulating materials. You wrote about this, however, with a big mistake.I want to draw your attention, Polina, that thermal insulation works are performed not on the inner surfaces of the enclosing walls, but on the outer ones. So, mineral wool slabs are glued to the surface of the wall (and, I hope, you have it flat). For your southern Don region, a thickness of 10 cm will be enough. As materials, you can use ROCKWOOL, ISOVER, URSA slabs or mats. And in your region, in the neighboring Belgorod region, ISOVOL, which is not inferior to them in terms of its heat engineering qualities, is produced. Take it boldly. Plates are first glued, and then additionally fixed on the wall with plastic fungi. Next, the plates should be plastered on a special plastic mesh, and painted in any color that you determine at the family council. And cover the inner surfaces of the walls with the proposed drywall. In the accompanying photo, the existing house is insulated with expanded polystyrene plates.

How lucky Polina was! I asked about foam concrete, but I learned so many useful things. Colleagues, here I was asked a question about the demolition of the house last night. I answered briefly, little by little. You can move there. And then Polinochka's knowledge will exceed the maximum permissible. I hope that the author of the first nice letter will not be angry with me. When you make a decision, let me know. And send photos. It will be a real tracking system with negative feedback. It's my fault, it's something that jumped out of the theory of control systems. See you at the demolition.

Do not listen to the builders, you live in it and not them. But instead of drywall, of course, it is better to sheathe it with clapboard, a little more expensive, but the wallpaper will not be poured and the air will be better and more environmentally friendly.

I have an extension of 62 square meters of foam blocks to my house, so 1) definitely insulate outside, if you wish, additionally inside (I insulate the north-western wall from 2 sides) foam concrete is a very easily destructible material, so I would not do plaster on foam concrete, that's all it will allow moisture to pass through and directly transmit all external influences to the walls! I have a siding outside (it is easy to mount it myself) between it and the wall in the crate there is a high-density mineral wool for the walls and wrapped in a moisture protective film in the wind. 2) even 5 cm of insulation gives a very noticeable result, 3) 30 cm of foam block gives warmth! Yes, I spent the first winter in a bare foam concrete from 2 sides, but after warming it is much better !!! 4) inside, if the walls are even, I just glued drywall onto the other walls on the tile glue,

Master of Architecture, graduated from the Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

A foam block house is never left without decoration. This is due to the unpresentable appearance of the walls. Together with the facade cladding, thermal insulation is often performed, which should protect the building from heat losses in winter and maintain normal temperature and humidity conditions in the premises. It would be more correct to insulate the house from foam blocks, made from the outside.

Why is it better to insulate outside

Thermal insulation can be positioned on both sides, but if possible, choose the right solution for external insulation. This is justified by the following facts:

- When the thermal insulation is located from the inside, the free area of the room decreases, the insulation of the walls from the outside does not affect the internal dimensions.

- The external location of the thermal protection allows to increase the service life of the supporting structures. They are reliably protected from freezing and external adverse influences. The placement of the material from the inside does not give such an effect, protection is provided only for the room, the surface of the walls remains cold.

- The next fact follows from the previous one. If the insulation is done from the inside, the outside wall remains cold.In this case, the dew point (condensation, moisture from steam) gets inside the supporting structure and can lead to its destruction. When the heat-insulating material is located outside, moisture does not form inside the wall.

It makes sense to protect the walls from the inside only under special circumstances:

- work is carried out at a high altitude (this is practically not applicable for a house made of foam concrete, since the strength characteristics of the material do not allow the construction of high walls);

- finishing of the facade is completed (without insulation), doing the work correctly (outside) will require serious financial and time costs.

If it is decided to insulate the walls from the inside, you need to especially carefully monitor the quality and safety of materials and compliance with technology (laying vapor barrier, waterproofing). It is better to give preference to more natural types of insulation, such as ecowool or insulated plaster.

You can insulate the walls from the inside with mineral wool. It is effective in terms of protection and will not block the passage of air through the building envelope.

Insulation options from the cold air side

Protection of the walls of a foam block house in the general case for all insulation options is performed in the same way. Before starting work, you need to make two decisions:

- choice of insulation;

- choice of finishing method.

If the house is located in areas that are quite favorable from a climatic point of view, you can combine these two solutions by choosing “warm” plaster. The material has two functions at the same time. To increase the strength characteristics, the layer is laid on a reinforcing mesh made of fiberglass. The work is carried out in the following order:

- cleaning the hard surface from dirt, dust and grease;

- applying a layer of primer;

- the first layer of plaster;

- fixing the reinforcing mesh;

- then you need to apply the required number of layers of plaster solution;

- The finishing layer can be paint on a silicone base.

The choice of insulation

There are several options here, which are some of the most common:

- mineral wool;

- Styrofoam;

- extruded polystyrene foam;

- ecowool;

- polyurethane foam.

It is best to choose the material that will not block the movement of air through the walls of the foam block house.

The most economical material that meets this requirement is mineral wool. Mineral wool insulation is important to carry out taking into account the characteristics of the material.

It is imperative that you do the following:

- vapor barrier from the side of warm air (the cheapest option is a polyethylene film, but it will not allow the walls to “breathe”, it is better to stay on more technologically advanced vapor barrier membranes);

- waterproofing from the cold air side (again, in this case, it is worth choosing a waterproofing or vapor diffusion membrane);

- an air-ventilated layer to remove moisture from the surface of the material is arranged between the thermal insulation and the cladding and is assumed to be at least 50 mm thick.

The choice of cladding material

At this stage, you need to choose the appearance of the house. The following materials are suitable for cladding a house from foam blocks:

- siding;

- lining;

- block house;

- brick.

Siding is the most economical and common option.

If you have sufficient funds, it is worth considering other options. The lining will allow you to finish under the timber, and the block house under the log.

In general, the installation of thermal insulation and cladding is carried out in the following order:

Scheme of cladding a house from a foam block with siding

- surface cleaning;

- fixing the vapor barrier;

- assembly of a frame from wooden bars (section depending on the thickness of the insulation) or a metal profile;

- installation of insulation with its fixing on disc dowels;

- fixing waterproofing (if the frame is made of wood, you can fix it with a construction stapler with the obligatory gluing of the joints with tape, the same is true for vapor barrier);

- plating installation, the method of fastening is selected depending on the selected material.

Another option for the exterior decoration of the house is the construction of a mile from brick. In this case, it is necessary to provide for metal or plastic ties between the two parts of the wall. Thermal insulation is installed before the erection of the brick wall and is protected by it from external influences.

A house built from foam sides is already guaranteed to retain heat, since this material itself is an excellent insulator. Most often, it is quite possible to do without additional insulation. But in some cases, such a need arises due to the design features of the walls or the small thickness of the foam blocks used.

What to use for cladding

What, how to revet the foam block? Various materials are used for finishing the facade. It can be plaster, siding, decorative stone, fiber cement slabs, corrugated board, blockhouse, tile. Often, homeowners prefer to cover the building with bricks, which can be clinker or special decorative.

The technology of facing houses from foam blocks with bricks can be somewhat more complicated than when using, for example, siding, but the result is also very high quality. You just need to remember to increase the width of the foundation in advance so that there is room on it for working with bricks.

Another important point to remember: foam blocks with any facing require a ventilation gap, with its help excess moisture will be removed, therefore it is recommended to use a "breathable" heat-insulating material, for example, mineral wool.

Brick cladding of foam blocks can be carried out in two ways:

- In parallel, literally and figuratively, with the construction of walls. As the foam blocks are laid, the decorative layer is also being erected. Labor intensity increases, but the quality of the finish is excellent.

- Consistently, that is, finishing work is carried out already on a completely built building. This technology is more widespread, as it can significantly reduce construction time.

Simultaneous erection of walls from foam blocks and brick cladding

Characteristics of a foam concrete house

When using foam concrete blocks for the construction of houses, it is envisaged to lay out single-layer walls. The idea of creating such materials, including the provision of thermal insulation of the home with little effort. They reliably retain heat in the house, but this is not the only argument in favor of choosing foam concrete for construction.

The advantages of this building material:

- The cost of a foam block is much less than a brick.

- The walls do not freeze through, due to which the life of the house is longer.

- No fungal infections or molds occur.

It must be admitted that the foam block still has a drawback, not too high strength of the building built from it. But this problem is solved with the help of reinforcement. The steel frame balances the load, which makes it possible not to worry about the integrity of the house. However, when working with a facade made of foam blocks, it is necessary to avoid excessive weighting of the structure. Important! Wall cladding with heavy materials, for example, stone, or the installation of a curtain or "wet" facade can lead to a violation of the integrity of the structure of the foam block.

Determination of the need for insulation

Foam concrete, invented in order to avoid additional work on building insulation, is really an excellent heat insulator, but this is not always enough. We are talking primarily about the regions with the lowest temperature indicators. The house, which will have to go through the severe Russian frosts, is still better to be additionally insulated.

Important! Thermal insulation works are best done outside the building. The materials used for this should be lightweight. It can be polystyrene, polystyrene foam or mineral wool.

External mounting of thermal insulation has a number of advantages.

- The service life of the facade is extended. A barrier appears that protects the wall from the outside from the harmful effects of the environment.

- Living space is not reduced. If the insulation is carried out from the inside, you will have to occupy part of the space with a heat-insulating structure.

- The "dew point" is shifted outside the walls into the insulation. Steam does not condense inside the walls of the house, there is no dampness, which increases the service life.

- Protection against freezing of walls. Internal thermal insulation, as opposed to protection from the outside, can lead to destructive effects of low temperatures on the facade.

Pros and cons of heaters

When preparing for insulation work, the choice of material should be made in favor of one of the most popular, foam or mineral wool. Both types of material are capable of high-quality insulation of your facade and have a number of advantages as a heat insulator. Explore all the options offered by the market and comparing the characteristics of these materials, you can choose which one is best for your particular home.

Benefits of Styrofoam

- The cost is low - from 200 rubles per square meter.

- Long service life.

- High thermal insulation performance.

- High quality waterproofing. Styrofoam will protect the walls from moisture from outside.

- Resistance to frost and temperature extremes.

- Additional soundproofing.

- Low susceptibility to various chemicals and biological influences.

Disadvantages of Styrofoam

- Destruction by direct sunlight and high temperatures.

- Inability to combine foam with wood. It will not work to insulate a building with wooden structures with this material.

Benefits of mineral wool

- The price is quite acceptable, albeit slightly higher than for polystyrene. From 300 rubles per square meter of material.

- Provides a high level of protection against heat loss.

- Long period of operation.

- Mineral wool provides good sound insulation.

- Reliable protection of walls from the foam block from the effects of water.

- Providing fire safety. Minvata is fireproof.

- This material is highly vapor permeable to prevent condensation.

Disadvantages of mineral wool

- Mineral wool absorbs too much moisture, which leads to a deterioration in the quality of the material.

- Requires increased care during installation. If the job is not done correctly, shrinkage can occur.

- When using this material, you must adhere to safety precautions. It is imperative to use respiratory protection, such as a respirator.

Step-by-step instructions for warming

The stages of carrying out thermal insulation work, depending on what material is used, are as follows.

Installation of foam insulation

Foam model with the best properties of protection against heat loss and steam transmission - M25. The thickness of the material of this brand is 50 mm.

Installation of mineral wool insulation

It is important to know that there are other methods to keep your home warm. You can purchase a foam block with low density values. They need to line the outside of the house and then finish it to their liking. Do not forget that not only the facade needs thermal insulation. You also need to insulate the outer part of the ceiling, the foundation and the basement.

The foam block, as an excellent building material, perfectly retains heat in the room, is characterized by a long service life, and is distinguished by the absolute harmlessness of the composition. These advantages of aerated concrete have been appreciated by many consumers. As a result, the material has become very popular in recent years. Lightweight and voluminous details of such samples allow you to build any structure in a short time.How to insulate a house from foam blocks from the outside? Many owners with a similar structure want the answer to this question. The majority of professionals believe that it is advisable to carry out such events if the wall thickness is 30 cm or less. The work does not require special skills and special skills, so anyone can do it.

Foam block houses require additional insulation.

Nowadays, the modern industry offers so many insulation materials that it is not difficult to choose a worthy one.

Attention! When erecting buildings from foam blocks, the climatic features of the area should be taken into account: relatively mild conditions allow you to create light insulation in the form of plastering the surface.

A foam block house can be finished with plaster.

How to insulate a house with plaster? For this, an ordinary cement mortar is taken, it is placed on the base in 2 layers, the thickness of each of them corresponds to 3-4 cm.Coating the outer walls with a deep-acting primer noticeably strengthens the outer layer of the walls and forms a layer on the surface that promotes good adhesion to the base.

In order for the plastering to go clearly and correctly, you should adhere to the recommendations of specialists. The quality of the prepared plastering solution affects the finish and insulation of surfaces. To properly dilute the composition, you should study the instructions on the package.

Advice! You can understand the correct dilution of the solution in this way: take a small part with a trowel and put the tool in an upright position. The composition, which lasts 20 seconds, is of good quality.

The use of suitable devices for leveling the surface, in particular, beacons. They are installed when the thickness of the plaster is 2.5 cm or more. The permissible distance between them is 15 cm.

"Pie" of house insulation from foam blocks using mineral wool

The difference is in the technology of laying the plaster layer. It is known that the mortar is applied to brick surfaces by throwing, which cannot be said about foam concrete walls. Here it is required to smear the layer with a special machine or an ordinary trowel. The height of such a layer should be less than 4 cm, after applying it, the solution should grab and dry.

The outer layer of the plastered surface is usually slightly rough to the touch.

The surface is covered with a second layer when the previous layer dries up. The beacons are removed the next day, the holes that appear on the surface are covered with the same compound using a spatula or trowel.

For the insulation of aerated concrete walls, materials such as mineral wool, expanded polystyrene, surface plastering, PVC siding, facing ceramic bricks, and waterproof paint are used.

Back to the table of contents

Foam blocks with facing side - beauty and warmth at an affordable price

Facade foam block in the construction of houses.

With all its undoubted advantages, one of the disadvantages of the foam block is its unpresentable appearance. Whatever architectural style you apply, whatever the original shape and configuration of the house, a facade with a heterogeneous gray porous surface looks cheap and sloppy.

With outdoor decoration, the picture changes dramatically, and if you have not yet decided how to sheathe the house from the outside, experts recommend paying attention to foam blocks with a facing side. They can be used both for basic masonry and as a decorative coating.

In the article we will talk about the types, technical characteristics, advantages and disadvantages of facade foam blocks, as well as about brick, and the technology of facing foam blocks with it.

Facade foam block - what is it

Decorative foam blocks are available in two types:

Cast foam block with textured side Foam block, consisting of two parts

Finished decorative finishing of the facade, significant savings on the facing of foam blocks. In the first case, the texture is applied immediately during molding, in the second, the main block is connected to the front part into a single whole by means of plastic connecting elements and forms a single monolith.

Both one and the other options have the following advantages over a simple foam block:

- Excellent thermal insulation that does not require additional insulation. A wall made of a decorative foam block of 400 mm corresponds to a wall made of bricks with a thickness of 1200 mm.

- Relatively light weight, allowing you to build walls with your own hands.

- Reduced construction time due to the finished facade.

- The decorative part contains special additives that give it improved moisture-repellent, frost-resistant, strength characteristics. In other words, there is no need to do external waterproofing of the blocks, since they practically do not absorb moisture, and the service life increases significantly.

- Facade maintenance is simplified, the blocks are self-cleaning from dust and dirt with rains.

Important! Despite all these unique properties, experts recommend using a facing foam block in areas with a temperate climate. Where there is a harsh, long winter, internal insulation of the building is necessary.

Heat Blocks

For cold regions, a technology has been developed, according to which the facing foam block is immediately produced with a layer of expanded polystyrene. It is also called "heat block", it has all the positive properties of facade blocks, but has a significantly lower thermal conductivity.

Foam block with cladding and insulation Production of heat blocks

The connection of the three parts of the structure is made with plastic ties, and, as you know, it does not conduct heat well, so that the thermal insulation properties of the decorative block remain at the highest level. Modern production technology makes it possible to produce material with high strength characteristics and a long service life.

Variety of textures and colors

Manufacturers offer a wide palette of colors to decorate the facade; the finishing part of the foam block has a surface that imitates the texture of various natural materials. Coloring methods allow the material to retain its original color for a long time.

You can choose a finish that matches any architectural solution of the building, reflecting different styles.

A variety of colors of the facing foam block.

Decorative foam blocks are produced not only with one finishing side. It is possible to purchase corner façade elements with decorative coating on two adjacent sides. Some manufacturers produce foam blocks with artificial stone cladding. Such a facade does not absorb moisture at all and reliably protects foam concrete from its penetration.

We offer a small selection of successful combinations and combinations of facade foam blocks in the construction of residential buildings:

House with contrasting finishing of corners Finishing of the house to match Light colors of colors Asymmetric finishing House with a balcony House in gray tones

Facing foam blocks with bricks

It is good if the construction of the walls of a residential building is carried out immediately from a decorative foam block, then, as already mentioned, external finishing is not needed. But what if the house is already built from simple blocks, and the facade needs to be protected and improved? How to veneer the foam block so that it is reliable and beautiful?

Now on the market there is a huge variety of finishing materials, but we advise you to pay attention to the "old", reliable brick, proven over centuries. Moreover, progress does not stand still, this material has also undergone many changes for the better. Therefore, even now there are many adherents of brick, and houses lined with this material have looked stylish and attractive for decades.

Advantages of brick cladding

Not only a house can be faced with decorative bricks, but also a fence can be built in the same style.

Shelter of foam blocks with bricks has the following advantages:

- Reducing heat loss.

- Low moisture absorption.

- Frost resistance.

- UV resistant.

- Aesthetic appearance.

- The durability of the masonry.

Let's talk in detail about facing foam blocks with bricks. This method is somewhat complicated, but if you have ever done masonry, then the technology of facing foam blocks with bricks differs little from ordinary stone work on the construction of walls.

We will not describe the technology in detail, if you have chosen this option, then you are not a beginner in this business. Let's consider the key points of the constructive device.

Brick types

Several types of bricks are offered for wall cladding:

Ceramic hollow brick Sand-lime brick Hyper-pressed (concrete) brick Clinker brick The bricks have a rich color range of colors An incredible variety of figured elements for facade decoration

If you are interested in the price of the material, then ceramic and silicate bricks will cost less, if you need special strength, then choose from clinker and hyper-pressed. The technology of brick cladding of foam blocks is the same for any type of material.

Each of them can be full-bodied or hollow, the second option is more popular, since its weight is less, and its heat-saving properties are higher.

Important! Brick wall cladding is laid at the stage of foundation construction, the width of which should be increased by 10-15 cm, and the masonry will rest on this shelf. But if this did not happen on time, then, as an option, you can take a 16U or 18U channel and fix it vertically on the existing foundation with anchor bolts with a pitch of 50 cm. It will serve as a support shelf for the cladding.

Distinctive nuances of brick cladding

Facade cladding, like ordinary masonry, should be started from the corner, raising it by 5-7 rows, clearly adjusting the right angle and vertical.

| We start work from the corner of the building. | |

| To avoid the formation of condensation under the cladding, a gap of 20-50 mm is made between it and the main wall with insulation. Also, gaps are left at the bottom, between the bricks of the first row. It is possible to insert plastic tubing between the seams in several places throughout the row. If you are facing an unheated room with a brick (a shed, a garage and other outbuildings), then an option is possible without insulation and an air gap. | Ventilated facade masonry. |

| The cladding can be carried out in parallel with the construction of the walls, then the fastening anchors are laid in both constructs at the same time. If this did not work out, then the flexible connection or mesh must be securely attached to the main wall of the building. It is necessary to reinforce every 4–5 rows of masonry. | Reinforcement of brick cladding. |

| On the front side, different thickness of the seams, mortar overflows, gaps, gaps in the mortar, sloppy, shaggy seam are unacceptable. To shape the seam, use special joints made of metal and having a concave or convex shape. For perfect verticality and horizontality, each row is laid out according to the sowing and checked with a level. | Joining of seams. |

| Particular attention should be paid to its quality, it should not be too hard, since the water will quickly evaporate from it, and the seam will begin to crumble. But high plasticity is also harmful, since the solution will be easily squeezed out from under the brick. This means that it will be difficult to maintain the same thickness. Excess mortar on the masonry on the front side must be removed immediately, after drying it will leave ugly stains on the brick. | The solution must be sufficiently flexible. |

Perhaps this is all that the technology of facing a foam block with a brick differs from ordinary ordinary masonry. Everything else corresponds to the stone work of the brick walls.There is an instruction that clearly stipulates this technological process, in it you can find answers to all questions.

Having picked up an original type of masonry, a contrasting or tonal combination of brick colors, you can get a successful interesting design of the building.

Various types of masonry.

Important! It must be remembered that with decorative brick cladding, it is necessary to strictly observe the vertical and horizontal rows, as well as the thickness of the seams, because the flaws can no longer be hidden behind the finish.

Offers to see photos of interesting combinations of different colors and textures of facing bricks.

House in the Gothic style Combination of different textures of bricks Finishing with brick in the same tone Solid color house with contrasting finishing of the basement House in brown tones Contrasting the masonry seams

Conclusion

We offer you to watch the video in this article, it more fully and clearly discloses all the questions on this topic.

The choice of material for the construction or cladding of a building is a very serious event, it depends on it whether your home will be dry and warm. And it doesn't matter if you are building from facade blocks, or the facing of foam blocks is made of bricks, the main thing is that the technological process is followed. Then your home will delight all households with coziness and comfort for many years.

kladka-info.ru

Styrofoam is a great option

You can insulate a house from aerated concrete with expanded polystyrene. It is also actively used to decorate walls made of bricks and concrete.

Advice! When choosing a suitable material for home insulation, you should take a closer look at options such as expanded polystyrene or special-value foam. These samples will perfectly protect the outer walls from frost and create coziness in the house.

The material in question is afraid of adverse weather effects, so it needs appropriate protection. The outer surface is covered with a layer of facade putty.

Styrofoam sheets are easy to install, so they can be installed even at a height. They differ in a democratic price.

Such layers are fixed to the surface with special dowels or glue.

The installation of such material involves going through the following stages:

- The surface of the outer walls is primed.

- Fixation of expanded polystyrene sheets. You can choose the method of fastening yourself: this is an adhesive solution or special self-tapping screws that look like fungi. When choosing fasteners, it is best to use plastic samples, because metal ones are not so practical and can corrode.

- Placing a reinforcing mesh on the surface allows you to hold the finishing materials well in the form of plaster. The insulation is covered with a special glue, and this retaining component is fixed on it. The mesh looks like a roll, it is applied in such a way that the next layer is found on the previous one with a distance of 10 cm. Then the surface is dried.

- Treatment of the base with plaster or putty. Such actions are as simple as possible, so anyone familiar with the styling technology can organize them.

The foam block is a rather fragile raw material, so you should make holes in it and hammer nails very carefully. Bonding of boards should be carried out in dry weather at an air temperature above + 5 ° С.

The height of the expanded polystyrene sheet for walls made of such blocks should correspond to 5 cm.

Back to the table of contents

What is a foam block

A foam block is a material in the form of building blocks made of foam concrete. Foam concrete is formed by adding a foaming agent to the solution due to the hardening of the resulting mixture.

Today, three technologies for the production of this material are distinguished:

- Classic

... An ordinary cement-sand mortar is being prepared, into which foam is added by means of a foam generator. After that, the solution is thoroughly mixed with the foam, and the finished mixture is poured into molds.As a result of hardening, foam concrete is formed. This production technology is considered the most reliable and is used by most manufacturers. - Dry mineralization

... The dry mixture of components is mixed with low expansion foam, continuously supplied by the foam generator. As a result, we obtain a stable foam concrete mixture with a small volume of free water. - Barotechnology

... The baro mixer is filled with foaming agent and water, after which all the remaining components are added. Further, pressure is created by forcing air with a compressor, after which the concrete mixture is transported under pressure to the place where it will be distributed over the forms.

The foam block belongs to materials made of aerated concrete, that is, it is characterized by a porous structure with closed cells.

Characteristics of foam blocks

Benefits

- Low price. Even in comparison with aerated concrete, which also belongs to aerated concrete, the cost of this material is on average 20% cheaper.

- Ease of installation. If you are familiar with the features of brickwork, then you can easily build walls made of foam concrete with your own hands, which have several working nuances, which we will talk about below.

- Refractoriness.

- Relatively light weight, which makes it possible to use such structures (for example, columnar) for cocking. The low weight also makes the installation process much easier.

- The material is resistant to various chemical influences, as well as biological factors (decay, damage by rodents, etc.).

- Moisture resistance.

- Ease of processing. The material is perfectly cut and sanded, which is another advantage over the gas block.

The following instruction will help you in implementation:

- First, we clean the blocks from dust, dirt, snow, etc.

- All types of bases are suitable for this material due to its low weight. The only requirement for the foundation is that it must be strong and even.

Advice! The columnar foundation is suitable for relatively small and foam block structures with a maximum of two floors.

- start from any angle. The optimal wall thickness is 2 blocks + a facing layer of half a brick.

- The first row is placed on the waterproofing layer. In this case, you can use sheets of roofing material, laying them in two layers.

- Laying can be carried out on a cement-sand composition. The ratio of cement and sand is 1: 3. The seam thickness should not exceed 30 mm.

- All subsequent rows are laid on a light mortar with a seam thickness of about 15 mm.

- If you work in hot and dry weather, wet the blocks with water just before laying.

- After laying the first row, it is necessary to check its levelness with a level. This is the starting point for all subsequent work, therefore, if even minor irregularities are found, they should be removed using a grinding tool.

- Control the voids in the seams. It is necessary to fill horizontal, vertical and inter-row joints with cement mortar so that no cavities remain. Remains of the mortar should be removed during the laying process.

- Blocks can be set with light blows with a rubber mallet.

- To achieve greater strength, the walls are reinforced with metal mesh or reinforcing bars, laid in each row or through a row.

- For partitions, formwork is mounted above windows and doors, into which a reinforced frame is laid and concrete is poured.