Operating principle

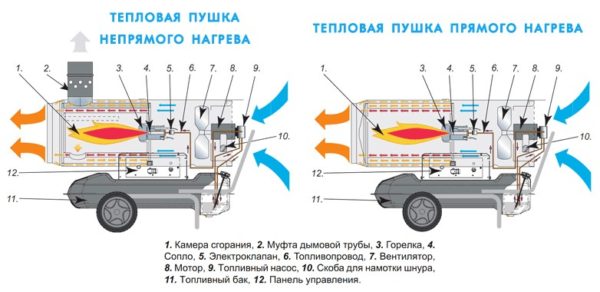

Such guns are often called fan heaters due to the similarity of the principle of operation, but they have certain differences. They work in the same way as other similar products: air flows around the combustion chamber housing with a fan and heats the room.

The principle of operation of the heat gun

The design of modern guns includes a special sensor that turns off the device when a predetermined temperature is reached, thus significant fuel savings are achieved. Garage craftsmen make guns that can run on different grades of used oil.

Factory-made or home-made, heaters have several very vulnerable spots, so they need frequent repairs. This is cleaning nozzles and filters, replacing the fan and much more. To find out all the vulnerabilities, you need to study the design of such guns.

Important advice! After using the gun and setting it for long-term storage, the remaining fuel must be drained, and the tank must be thoroughly rinsed from the remaining diesel fuel. It is unsafe to use fuels that have been stored for a long time.

Overview of faults and methods of repairing a heat gun with your own hands

Heat guns are one of the most effective types of equipment for space heating.

And this is not surprising: after all, with the help of these heating units, it is possible to heat a room in a fairly short period, even large ones.

This is achieved due to the fact that the principle of operation of the heat gun is as follows: heat is generated in the structural unit of the unit, and then, with the help of a powerful air flow, is supplied to a given place.

The uniqueness of the principle of operation of heat guns has led to the fact that recently equipment of this type has begun to be used quite often to achieve various industrial and domestic purposes. In other words, heat guns have gained extraordinary popularity due to their technical characteristics and ease of use.

But everyone probably knows that no matter how high-quality and efficient the equipment is, sooner or later failures occur in its functioning and malfunctions may occur. In such situations, the owners of heat guns, as a rule, contact specialized service centers.

However, there is another approach for identifying and eliminating defects in the operation of heating units of this type, which lies in the fact that the repair of a heat gun can be done by hand. Therefore, this article will be devoted to how to correctly find out and troubleshoot the operation of gas and diesel heat guns.

Product design

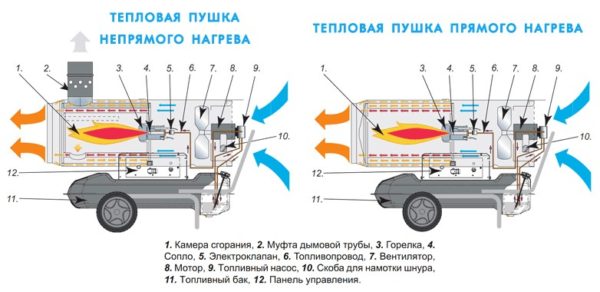

Products with an indirect method of space heating have chimneys through which all combustion products are removed, so in practice they can be used to heat living spaces. They are much safer, but they use oxygen for combustion, so ventilation or periodic ventilation is needed. Their power is lower because losses occur through the exhaust system.

Diesel heat gun device

With a direct heating product, all combustion products remain in the room, so they cannot be used where people constantly live. They are used to heat construction sites and warehouses where there is a natural flow of air, because lack of ventilation can lead to carbon monoxide poisoning.

All products are equipped with a powerful metal body: it excludes the ingress of foreign objects that can cause damage or become a source of fire.A fuse must be installed that turns off the device when the case is very hot.

For circulation, a compressor or a small pump is used, for pumping into the room - a fan, which experts consider one of the vulnerable points of these products. A burner and a fuel supply pipeline are located inside the housing.

The main elements of a diesel heat gun:

- there is an exhaust pipe to remove smoke;

- a fuel tank located at the bottom of the product;

- pump or compressor driven by an electric motor.

Repair work of old fan heaters

It is with this technique that one has to deal most often. But there is nothing to worry about, because the device of such heat guns is relatively simple, so with minimal knowledge of electrical engineering, you can cope with this work. In the simplest version, the heat gun is a metal case, inside of which there are several heating elements (heating elements), as well as a compressor for air injection. To regulate the temperature, a multi-position switch is used, less often "automatic machines". Let's talk in detail about how to repair a heat gun as a whole or any elements separately. As a rule, it makes no sense to give old products to the workshop. The cost of restoration work will be high, but their quality is highly questionable.

Possible problems

As a result of continuous and prolonged operation, the equipment can have a number of problems. Most often this is not due to the wear of some individual parts, but to mediocre service. Let's analyze common malfunctions of diesel heat guns.

Intermittent fuel supply

The problem may arise due to accumulated dirt in the hoses of the system: development from fuel, oil, foreign objects, etc. This also includes a dirty tank. The malfunction is eliminated quite simply: we drain the fuel, disconnect the hoses and thoroughly rinse all the elements responsible for the fuel supply.

Fuel is non-flammable

First of all, it is worth checking the spark plugs: replace faulty ones, and dry them filled with fuel. It will also be useful to correct the gap between the electrodes if it has increased or, conversely, decreased.

The gun stalls periodically

The air filter is most likely clogged. Considering the type of fuel, it is useless to clean it. It is much more efficient to buy a new one.

Diesel Cannon Air Filter

Sometimes it's all about the quality of fuel: diesel fuel is different. Therefore, it makes sense to try to fill in fuel purchased at a gas station of another brand.

Too low temperature in the heat exchanger

If the flame in the combustion chamber does not burn intensively enough, the cannon starts to idle. We have to set the maximum level of fuel supply, whereas previously there was enough heat at average or even minimum values.

Most likely, the nozzle is clogged. The element is easily cleaned mechanically. Purge by means of a compressor is ideal.

The gun is overheating

The thermostat is to blame for half of the cases. We remove the part, process it from dirt and clean the contacts. In more advanced models, it cannot be repaired due to additional awnings - only replacement.

Heat gun maintenance

Diesel cannon of indirect heating

All preventive work on the equipment is reduced to setting up and processing the air intake system, compressor and fuel pump. The procedure for each individual heat gun is roughly the same. Let's look at the details of maintenance using the example of a classic model with indirect heating and automatic flame control.

The design of a diesel heat gun cannot be called complex. The fuel is supplied by the pump to the nozzle, after which it is produced in the combustion chamber. The burner is ignited using a pair of electrodes. The fan expels the flow through the chamber during operation. Indirect heating assumes the presence of an independent circuit, as a result of which the combustion products practically do not come into contact with the heated air.

Equipment preventive maintenance:

- Remove the cover and clean the fan from dirt.

- Disconnect the high-voltage wires from the combustion chamber and remove the fuel hose. We blow out the last one.

- We loosen the fasteners on the camera and remove the block. We clean it from soot.

- We unscrew the nuts at the end of the chamber and get access to the nozzle. We blow it out.

- Putting it all in the reverse order.

Safety measures when using guns

To ensure fire safety measures, a container with a fuel supply for the product must be located at a distance of 8 meters from heating devices or any sources of open flame.

Remember! Instead of diesel fuel, you cannot use gasoline of any brand: the probability of an explosion increases many times over, because it is more volatile.

Safety measures when using guns are quite simple - you must immediately leave the room if you feel:

- sudden and severe dryness in the mouth;

- pain in the throat, nose, or eye area;

- sudden attacks of headache;

- desires of nausea.

Many people react very painfully to carbon monoxide indoors: for example, people with lung diseases or cardiac patients with anemia, pregnant women. They are contraindicated to be located where a diesel heat gun with direct heating is used.

Frequently Asked Questions About Diesel Heat Gun Repair

How much does diesel heat gun diagnostics cost?

Diagnostics of a diesel heat gun costs 2,500 rubles, this amount is included in the cost of repairs.

Is there a specialist visit to the facility and how much does it cost?

There is a specialist departure - up to 30 km, the cost is 3500 rubles. Diagnostics at the customer's site is 2500 rubles, also included in the cost of repair.

Is it possible to make a diagnosis of a diesel heat gun in my presence?

Yes, we can make diagnostics in your presence.

Can you come to the site and pick up the diesel heat gun at the service center?

There is such a service in Moscow - the cost is 1400 rubles, in the Moscow region - up to 30 km 2400 rubles.

Do you work with legal entities and by bank transfer?

Yes, we work with organizations and by bank transfer with VAT.

How long will the repair take?

The repair can be performed from 3 to 30 days, depending on the complexity and availability of spare parts in the warehouse of the service center.

Do you repair a diesel heat gun if you bought it from another company?

Yes, we repair a diesel heat gun of any model, no matter where it was purchased.

If our diesel heat gun is not repairable according to the conclusion of the diagnostics of the service center?

We can offer the new diesel heat gun one year warranty from our service center.

Are there any discounts for regular customers?

For regular customers, there are always favorable conditions for working with our organization.

You can get more detailed information from our specialists by phone.

Why us?

Because only our company has highly qualified specialists will answer you to all your questions about any equipment 24 hours a day, 7 days a week, 365 days a year.