Heat-reflecting screen behind the radiator: should we install it or not?

- What is a Heat Reflective Screen

- Where does the heat go

- Polyethylene foam heat-reflecting shield

- Why do you need foil

- Pros of a Heat Reflective Screen

- Disadvantages of a Heat Reflective Screen

- If the radiator is in a niche

- Installation Recommendations

- What not to do

- Installation steps

- Other types of screens

What is a Heat Reflective Screen

In a nutshell: What is a Heat Reflective Screen

The heat reflective shield increases the efficiency of the heating system.

Doesn't require complicated installation and costs a penny.

The structure becomes a barrier between the heat source and the outer wall surface.

The room temperature rises by 2-3 degrees.

At the same time, energy consumption is reduced by 5-7%.

Where does the heat go

Heating devices in buildings are installed under windows.

The goal is to warm up the air inside and create a heat curtain that prevents the penetration of cold from the street.

Heat spreads from a heated object to a cold one.

The wall temperature is lower than that of the radiator.

In the cold season, the surface behind it heats up to 35-40 ° C.

Instead of heating the air inside a warehouse or office, some of the energy is spent on heating the outer walls.

Benefits of a heat-reflecting shield behind a heatsink

- The heat-reflecting element allows heat to be redirected to the interior of the room, rather than heating the exterior walls. Due to this, you can increase the temperature in the room, while saving on heating.

- Such radiators can be decorative, that is, thanks to this, nondescript places under the batteries are emphasized.

- Radiators do not get clogged with dust due to the suitable cold air from below, they become easy to clean.

The main advantage is the supply of warm air to the room, as well as the prevention of moisture penetration.

Polyethylene foam heat-reflecting shield

Substances have different ability to conduct heat.

To prevent energy consumption, the heat-reflecting screen must have a low thermal conductivity - not higher than 0.05 W / (m * K).

Polyethylene foam heat-reflecting shield

Indoors, it is not recommended to use structures made of flammable substances with a loose structure.

For example, mineral wool emitting formaldehyde and microscopic dust is not suitable for the screen.

Although her thermal conductivity coefficient is suitable - 0, 039 W / (m * K).

Heat-reflecting screens made of insulating materials based on polyethylene foam have proven themselves best:

- penofol,

- porilex,

- isolona,

- stisol,

- tepofol.

They are hypoallergenic and safe for human health.

The thermal conductivity of different types of polyethylene foam ranges from 0.029 to 0.032 W / (m * K).

Four millimeters of this barrier will retain the same amount of heat as 10 centimeters of mineral wool.

For insulation between the wall and the heating device, a layer of 3-5 millimeters is enough.

A prerequisite: the heat-insulating screen behind the radiator must be duplicated with aluminum.

Izospan

Today, many firms and companies produce reflectors for heating batteries, which are designed to reflect different energies, in this case, heat.

Consider Izospan products, which are made of materials suitable for heating screens.

For instance:

- Izospan FD - polypropylene woven fabric, which is backed up with metallized polypropylene film;

- Izospan FS - non-woven polypropylene fabric, also duplicated with metallized polypropylene film;

- Izospan FX - foamed polyethylene on one side is backed up with metallized lavsan film, has a thickness of 2 - 5 mm.

These screens are used to improve the efficiency of heating devices such as radiators, reflectors, batteries, convectors and others.

They are located behind the battery, that is, on the side from which they want to redirect heat energy into the room. During installation, the metallized side comes into contact with the heating battery and reflects heat energy towards the room, this increases the efficiency of the heater.

Usually, any heating device is mounted under windows, compensating for the widespread air coming from the outer walls, and this leads to the fact that the radiator heats not only the room, but also the cooled wall. Therefore, more heat is consumed to heat the outer walls than to warm up the room, and by using heat reflectors behind the radiator, heat loss can be reduced.

In addition to this function, the metallized reflective screen protects the outer walls and insulation from the penetration of water vapor. If the walls are saturated with moisture, then they lose their heat-insulating qualities.

The most effective is a heat-reflecting screen made on the basis of polyethylene foam (Izospan FX).

Why do you need foil

Polished aluminum has a higher reflectance of thermal radiation than other metals.

This means that maximum heat will return inside the room.

It is not worth using screens with a double-sided metal backing.

The foil layer on the side of the cold wall does not carry a functional load - it simply has nothing to reflect.

Unscrupulous sellers in building markets deceive buyers by talking about new metallized coatings with fantastic characteristics.

These are fairy tales.

Any polished metal refracts heat rays, but the reflection coefficient is negligible and does not affect thermal efficiency.

The cost per square meter of a thermo-reflecting screen with aluminum foil is more expensive than with a metallized film.

The difference is small - 5-10 rubles.

Pros of a Heat Reflective Screen

Pros of a Heat Reflective Screen

The heat-reflecting shield behind the heatsink solves two issues:

- increases heat transfer - the main goal,

- reduces heat loss.

All this at minimal cost.

Areas behind the heaters get hotter than others.

As additional insulation, the screen restores their thermal conductivity along with the rest of the wall.

The idea is not new.

It has been tested many times in practice and discussed in specialized literature.

The effectiveness of heat-reflecting screens says

- Umnyakov N.P. - a reference manual "How to make a house warm" and

- German engineer Inrolf Tiator is the author of the manual "Heating Systems" (original name "Heizungsanlagen").

In their opinion, a heat-reflecting screen behind the radiator can reduce the heat loss of a 0.51 meter thick brick wall by 35%.

Cons of a Heat Reflective Screen

Disadvantages of a Heat Reflective Screen

The area behind the radiator is no more than 5% of the total area of the outer wall of the room.

The main heat loss occurs through infiltration and windows.

Against this background, the improvement of heat transfer in the area of half a meter is minuscule.

But if you add up the reduction in heat loss in the entire building, the amount of savings will be significant.

For non-insulated walls with low thermal resistance, a heat-reflecting screen is useless.

The heat loss is so large that the improvement of heat transfer on a plot of 0.5 sq. M. will not even be noticeable.

Inspection of the heating system from 15,000 rubles.

Learn more

If the radiator is in a niche

In buildings where heating devices are located in niches, heat loss is higher.

The walls behind the radiators are thinner and colder than the others.

Heat is given off not to one, but to three low-temperature surfaces at once.

Therefore, if space permits, it is worth increasing the thickness of the insulating one to 10-15 millimeters.

In addition to the material, it is important how the heat-reflecting screen is attached to the radiator.

Illiterate editing will negate the entire expected effect.

Installation of heat-reflecting screens

Advantageous characteristics

The installation of heat-reflecting screens in rooms behind radiators has a number of positive aspects.

The list of advantageous characteristics of foil-clad material includes:

- extensive areas of application;

- the ability to achieve energy savings by reducing heat loss coming from the batteries;

- ease of installation, transportation, maintenance of heat reflectors;

- light weight and excellent flexibility of the insulation;

- the ability to use different materials for fixing;

- low percentage of thermal conductivity;

- the ability to install on your own;

- no difficulties when cutting heat-shielding cloths of any size;

- providing protection from moisture;

- the possibility of insulating the inner surfaces of the walls;

- a wide range of materials for the implementation of the energy saving program;

- the possibility of complete isolation of walls from heating by heating radiators;

- reduction of heat losses up to 10%;

- ensuring reflection of heat flows up to 97%;

- affordable price for all segments of the population.

It is not difficult to buy a heat shield. It can always be purchased on the market for building thermal insulation materials, in online stores, as well as in specialized shopping centers.

It is interesting! The heating is turned on, and the batteries are cold: practical tips for restoring the heating system

Installation Recommendations

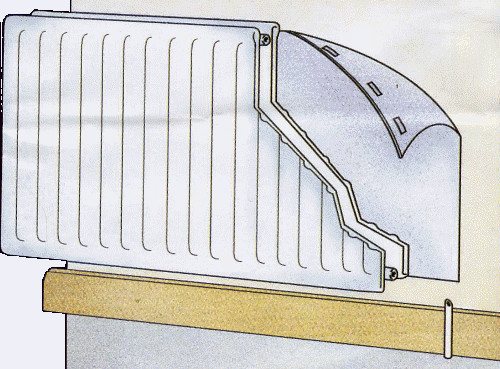

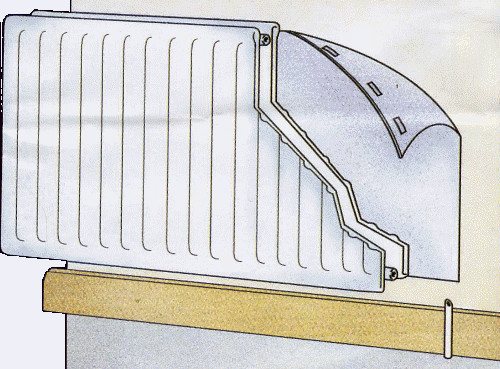

The screen is mounted on the wall behind the heater.

The reflective layer unfolds towards the heat source.

It is important not to allow contact between the radiator and the foil, so as not to impede heat transfer.

Russian manufacturers consider a gap of 1-2 centimeters between them sufficient, foreign ones - at least 4-6.

The air gap is part of the thermal insulation barrier.

The thermal conductivity of air depends on temperature and ranges from 0.0259 to 0.0915 W / (m * K).

It makes no sense to put a heat-reflecting screen behind the radiator if it is mounted close to the wall. Squeezed-in insulation will actively collect dust, but will not affect convection in any way.

Ideally, it is necessary to provide a gap between the wall and the heating system at the design stage.

Then you will have room to maneuver.

Recommendations for the installation of thermal reflective screens

Heating devices (central heating battery) are usually installed on the outer walls of the room under the windows. A working battery heats up the section of the wall directly behind it. It turns out that this area is much warmer than the rest of the wall, and can reach 40 ° C. It turns out that the battery diligently consumes heat to heat cold bricks or concrete slabs of the outer wall of the house, instead of heating the air inside the apartment.

This installation of the battery causes increased heat loss. If the battery is installed in a niche, the heat loss will be even greater, since the thin back wall of the niche protects against heat loss even worse than a whole wall.

The use of heat-reflecting screens that insulate sections of the walls located behind the heating devices will help to significantly reduce heat loss in such a situation. Materials with a low coefficient of thermal conductivity (about 0.05 W / m • ° С) are used as such screens, for example, penofol - a foamed base with one-sided foil. Conventional foil for such purposes will work ineffectively, becausethe foil is metal and it will heat up in the same way as the battery and, as a result of contact with the wall, will transfer heat to the wall. Therefore, between the foil and the wall, there must necessarily be an interlayer of material with low thermal conductivity and small thickness. It is all these properties that are combined in materials such as Porileks with foil or Penofol. Recommended insulation thickness is 3-5mm. The reflective layer must face the heat source.

When installing the heat shield, it is best to position it closer to the wall surface rather than the battery surface. You can attach it to the wall with regular double-sided tape, or with a stapler - to a wooden strip. The screen size should slightly exceed the projection of the device onto the wall section.

By reducing heat losses by installing a heat-reflecting shield, energy savings can be 2% for convectors with a casing, 3% for convectors without a casing, steel panel radiators - 4% of the heat transfer of the device.

And for such a screen you can only use !!! polished aluminum foil materials such as Porileks LF and Penofol. Materials with all kinds of metallized spraying films, of various manufacturers and brands, do not have the properties described above - and therefore the installation of such materials will be useless.

What not to do

Place the machine too low.

If the distance between the floor and the lower part of the radiator is less than 10 centimeters, the productivity of heat transfer decreases, and cleaning becomes more difficult.

Do not raise the device too high.

When the gap between the floor and the battery is more than 15 centimeters, the air temperature gradient increases relative to the height of the room, especially in the lower part.

Do not install the device close to a wall.

The distance between the top of the radiator and the window sill is at least 15 centimeters. Less degrades heat flow.

Installation steps

The most reasonable thing is to provide for the installation of a heat-reflecting screen during the construction phase - after the rough finish, before the installation of heating.

If the repair is complete and the radiator is in place, you will have to remove it.

The size of the screen must correspond to the working surface of the heater.

Then it will be invisible and will not spoil the interior.

In production areas where aesthetics are not important, it is worth increasing the area by 10 percent to ensure maximum reflective effect.

The wall under the window is cleaned of dirt and crumbling plaster, defects are putty, irregularities are removed with sandpaper.

You can start installing.

The heat-reflecting screen behind the radiator is attached with wallpaper glue, liquid nails or furniture nails.

If there is enough space, a more reliable option is a lattice base made of thin wooden planks.

Additionally, we get an air layer between the wall and the thermal insulation sheet.

It will have a positive effect on heat transfer.

The radiator returns to its place.

It is important to adjust the position of the device so that a distance of one and a half centimeters (minimum) remains between the foil cover and the back side.

If possible, make the gap larger.

The heat-reflecting screen does not need special care.

Sometimes it is enough to wipe the dust on it.

If the aluminum layer is scratched or torn, metallized tape will help remove the damage.

The functionality will not be affected by this.

Installation features

The niche for the radiator is covered with foil material

To maintain a comfortable temperature in the house, a heat reflector is placed behind the radiator and pipes. It saves about 10% of heat. When choosing a material for installation, it must be borne in mind that the dimensions of the sheets must be larger than the heating battery. The type of connection of the radiator is also taken into account.

The heat-reflecting shield can be attached to a construction stapler.You can install it yourself according to the instructions from the manufacturer.

Basic tips from experts in installing the screen for the battery:

- Better not to buy a matte metallized material. Polished foil is more suitable as a heat reflector.

- For installation behind the radiator, a one-sided heat-shielding foil is sufficient. Double sided is used for other purposes. Its cost is higher, and the efficiency will not change.

- A fence of 1-2 cm should be left on both sides of the insulator. Due to the presence of the distance, the optimal thermal resistance of the reflector will be obtained, the screen will be able to effectively reflect all the heat into the room.

Characteristics of Heat Reflective Screen Materials

Rules for installing a reflector behind a radiator:

- It is necessary to ensure the tightness of the screen. To do this, all joints are sealed with metallized tape.

- Effectiveness is achieved only when using metallized aluminum foil. In the case of using a material with a metal spraying or produced by a thermal method, the desired effect will not be achieved. This is due to the small thickness of the metallic reflective layer.

- If it is impossible to put a professional reflective screen, you can make an independent reflector. To do this, take plywood and cover it with foil or use galvanized sheet metal.

- The effectiveness of the screen is directly related to the distance between the reflector and the battery.

- The insulation thickness must be at least 5 mm.

- The reflective surface must point towards the radiator.

Installation is done with a stapler, liquid nails, or other adhesive recommended by the manufacturer.

Before installing the screen, it is better to remove the radiator

Procedure:

- Measurements of wall sections and radiator.

- Purchase of materials. You need to add a stock to the resulting size.

- Checking the presence of a distance between the heater and the place of installation of the film. If there is no free space, the battery suspension needs to be adjusted.

- Removing the radiator.

- Marks the wall where the brackets will be installed. Removing the fasteners on which the battery hangs.

- Inspection of the integrity of the masonry wall surface. Cracks, crevices and other defects should be repaired if necessary. Aligning the walls.

- Bonding the screen.

- Installing the hangers and radiator in place.

We suggest that you familiarize yourself with How much one section of a cast-iron battery weighs