In heating, water can reach 80-90 ° C. And if for pipes with radiators this is still normal, then for a warm floor such a temperature is too high. In order to be able to stay on the floors normally, a three-way valve is used. Although it is installed far from only for these purposes, it is indispensable in a system with almost any solid fuel boiler. Let's figure out what kind of mechanism it is, what it is for and how to choose the right three-way valve for the heating and water supply system.

The advantages of a three-way valve

The positive qualities of the device include:

- Compact size.

- High level of functionality.

- Easy to use and maintain.

- Good seal tightness.

- Long period of use.

- Low level of hydraulic resistance.

- Lack of stagnation zones.

- Easy installation.

- No daily maintenance required.

- Convenient and easy switching.

But, despite all the advantages, there are several disadvantages in his work.

Crane construction

The design of the device in its shape resembles a tee with a T-shaped direction of pipes. It is because of this feature that it is called "three-way valve" or as it is also called "tee".

The product includes several parts:

- Sealed body made of metal (cast iron, bronze, carbon steel or brass).

- Shutter with bores of different shapes.

- Three nozzles (holes):

- weekend;

- with hot water supply;

- with cold water supply.

The tee also has additional characteristics that are prescribed on its packaging. These include:

- Type of valve installed in the system (conical, cylindrical or ball).

- Fastening principle (flanged, pinned, coupling, welded or socket-butt-end).

- Mechanics (landing) in the valve (tension or stuffing box).

- Control method (manual, actuator or electronic).

- Blanking valve shape (S, T, L).

- Completion with additional sensors or devices.

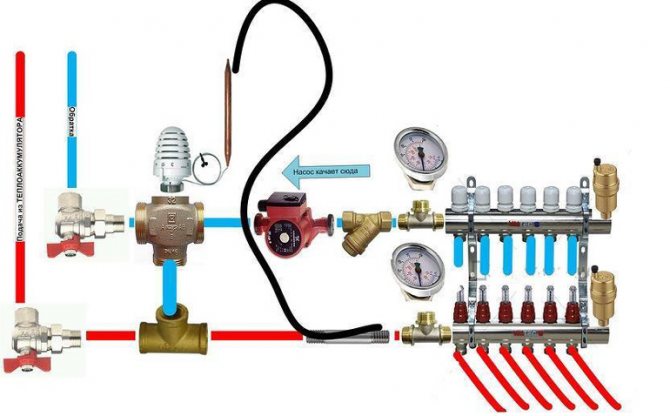

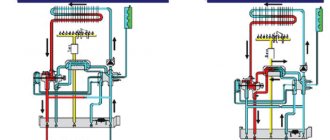

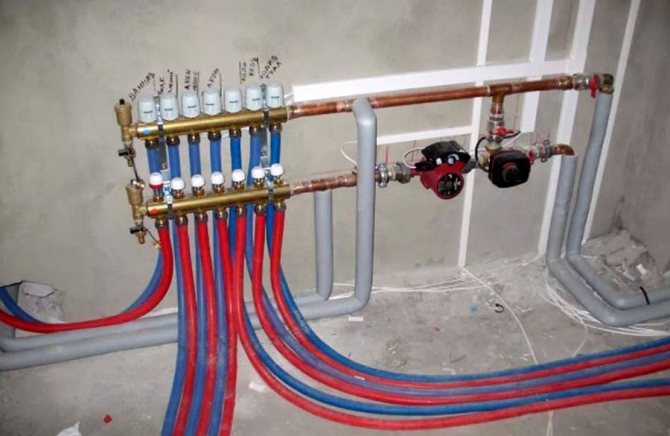

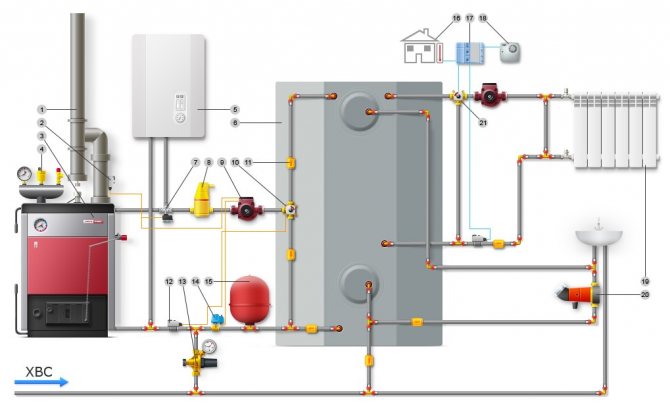

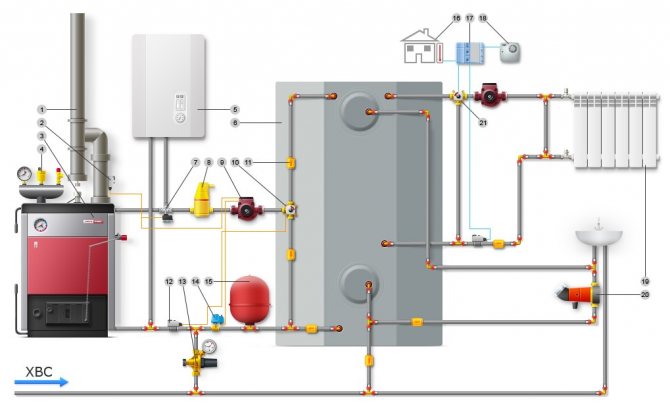

Scheme for connecting a three-way valve to the heating system

Applications

Modern valves are in great demand and are actively used in various fields of human activity. Often they are installed in modern heating mains, which require constant adjustment of the proportions when mixing different coolant flows. For such purposes, it is customary to use electromagnetic devices or models with a thermal head.

As for domestic use, in this case, it is enough to purchase a thermostatic mixing device that will allow you to regulate the temperature of the coolant. It is fed both to the underfloor heating pipeline system and to heating radiators. And if the household device is equipped with automatic control, then it will be much easier to change the temperature regime in the room.

The use of a three-way valve in the heating system is profitable and economical

It should be noted that the use of a tee in a heating system to balance possible temperature jumps is not only beneficial, but also economical. The device allows you to reduce the amount of fuel consumed by several times, while the final indicators of the efficiency of the system will noticeably increase. In some rooms, the presence of such a device is simply necessary. For example, if a warm floor is installed in the house, then the device will prevent excessive heating of the floor covering.

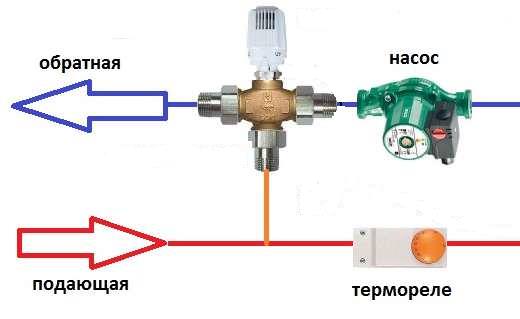

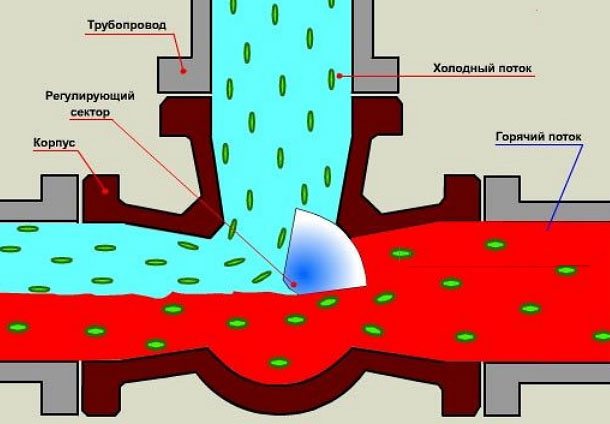

Operating principle

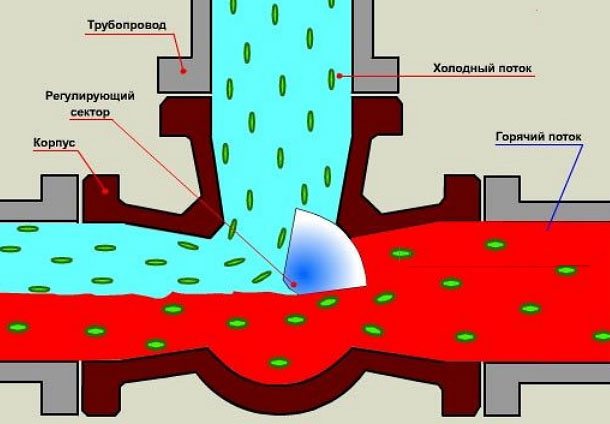

For the product to work, cold and hot streams of water must be connected to it at the same time.The installation diagram itself is presented in the form of arrows indicating the direction of flows. The hot water flow acts as a heat carrier (supply that comes from the boiler), and the cold one acts as a return flow.

A valve is installed between the nozzles of the tap, which regulates so that water is supplied to two out of three holes. According to the position of the installation and its connection, two functions are subdivided:

- mixing of streams of cold and hot water;

- division from one line to two outputs.

Depending on the position of the valve, the following situations are possible:

- the valve is half open - the outlet stream has an average water temperature;

- the valve is fully open - the hot stream comes directly from the boiler and the water has a maximum temperature;

- the valve is closed - only cold water flows into the outlet stream.

Important! The tee does not block the flows supplied to it, but only redirects water from one inlet to one of the outlets. At the same time, you can block either one of the outputs, or half of both.

Heating circuit of a three-way valve with a boiler

What is the three-way valve with a thermostat responsible for?

This valve narrows the duct water, due to which its amount decreases, and the outgoing heat is supplied in a smaller size. The device is responsible for regulation of the amount of water, to control room or floor temperature.

Device

In terms of external characteristics, a three-way valve for heating with a thermostat is very similar to ordinary tee for water separation, but in fact, all parts of this "tee" perform special functions.

- Thermal head with robust sensor. With the help of such a device, the temperature of the water entering the valves is adjusted and regulated.

- Top poppet and bottom poppet valves are necessary to start the mechanism, since they optimize the operation of the main valves, distilling water and thereby giving it the required temperature.

- One valvethrough which the three-way valve hot water gets in.

- Second valvethrough which the device enters cold water.

- Third valve, whence, with the help of the work of the upper plate and the lower plate, water is formed at a temperature that set via the thermostat.

- Pressure relief chamber... This equipment controls the water pressure in the valves, increasing their performance and relieving them by pressure.

- Stuffing box seal. The device guarantees the tightness of the entire structure. It is necessary due to the fact that the compartments and the heating circuit quickly fail due to any breakdown in the little things, since water "does not like" when it is handled negligently, and, if the opportunity arises, tries to flow out of the pipes, flooding the surrounding space.

Principle of operation

Exists two types of design:

- saddle;

- turning.

The principle of operation depends on what type of construction is on the device.

- If this saddle, then the displacement rests on the translational movement, where stock constantly, it hits the saddle, then flies out of it.

The saddle is either completely closed by the stem, or only slightly opens the mouth, releasing water. Thus, the saddle-type design drives water and regulates the amount of hot or cold liquid outlet of two valves, simultaneously mixing and transferring the resulting temperature and quantity of water into the "mixing" compartment.

- If this turning, then the regulator becomes not the stem, but a small ball or sector (part of a sphere)... A device works like a conventional ball valve: the ball turns, providing a passage of liquid either from a compartment with hot water or from a tap with cold water, as with a saddle system, only instead of a stem, a ball that works without a seat on the overlap of two valves. Of 3 valves mixed water comes out, set by temperature through the thermostat.

The temperature set through the device is stored in the gap between the two compartments with hot and cold water supply. When it changes, the gas in this place starts narrow or widen, depending on the change in the adjustment parameters.

This gas presses on the stem or ball, slightly opening one of the valves, thus the required amount of water flows out and a new temperature corresponding to the set one is formed.

Valve actuator types

Valve actuator types:

- Direct acting valves... They function as follows: when the temperature changes, the expanding gas presses on the ball, sector or rod.

The thermal part of the three-way valve is located here, however, this equipment is not present in all devices. A probe located inside the pipeline can act as a sensor in such a device.

- Indirect valves... They work in much the same way as direct-acting valves, differing only in less, but no less important function.

Three-way thermostatic mixing valves:

- Mixing. Such a device 2 branch pipes, one of which is outlet. The first branch pipe is equipped with warm or hot water, and the second is connected to the "return" system, that is, all the cooled water remaining after the previous heating is returned to it. When both connections are opened, the water is mixed and, under the control of the thermostat, the desired outlet temperature is set. Further, the water spreads along the entire circuit.

- Isolating valve - this is a device that works back to the mixing one, not combining water into one stream through the outlet, but, on the contrary, dividing the whole mixture of water of different temperatures into hot or cold. For this view, there is one entrance and two exits. The design is used in bathrooms, if it is necessary to have hot from only one tap and cold only from another tap.

Varieties of cranes

Product classification according to various criteria:

- Depending on the valve, a distinction is made between:

- Regulatory.It is equipped with an electromechanical device that opens the required valves. It also includes a stock with manual or automatic adjustment. Important!The stem cannot be knocked out even by the strongest water pressure, since it is located inside the device.

- Shut-off. In his build there is a ball device that switches the flow of water. The peculiarity of this device is that it is installed on systems with low pressure. It is very simple in design, requires constant maintenance and wears out quickly.

- By product material:

- Brass- the most demanded material, due to a long period of operation, small dimensions and low weight.

- Carbon steel Is a great alternative to brass.

- Cast iron - used for pipes of large diameter (from 40 mm and more). It is not practical for private houses.

- Bronze - material with a long period of operation.

- Depending on the installation method:

- coupling;

- flanged;

- tsapkovy;

- for welding;

- nipple-end.

- For the heating system, such types are used as:

- With constant hydraulics- regulated in accordance with quality indicators. It is suitable for consumers with high-quality heat transfer fluids of a certain volume.

- Variable hydraulics - regulated according to the required amount of water. It is more suitable for those for whom quantity matters.

- From the variant of the flow part of the device:

- trial and drain;

- full bore.

- Built-in shutter type:

- conical;

- cylindrical;

- ball.

- By the shape of the plug valve, the following types are distinguished:

- T-shaped;

- L-shaped;

- S-shaped.

- From the mechanics of the gate element:

- Stuffing box- controls the adjustment of the water jet from the top of the armature due to the gland;

- Stretch - controls the adjustment of the water jet from the bottom of the armature by means of the nut.

- Depending on the housing heating:

- heated;

- without heating.

- Depending on the technical parameters, such valves are distinguished:

- T-shaped- the adjusting knob can be in 4 positions;

- L-shaped - the adjustment knob has two modes, including a 180 degree rotation angle.

- From the device control mechanism:

- Manual- connects water flows in approximate proportions, cheap, looks like a standard ball valve;

- Electric drive - for work, additional equipment is used, a motor or a magnetic method, there is a possibility of getting a shock from the current;

- Pneumatic actuator - the most optimal option for use. Important! With the electric drive, you can easily balance the heat so that the temperature level in the rooms farther from the boiler is the same as in the neighboring ones.

How does a three-way valve work in a heating system

The principle of operation of the valve is to mix water streams with different temperatures. Why do you need to do this? Without going into technical details, you can answer this way: to extend the service life of the heating boiler and its more economical operation.

The three-way valve mixes heated water with cooled water after passing through the heating devices and directs it back to the boiler for heating. Everyone is able to answer the question of which water to heat faster and easier - cold or hot.

Simultaneously with mixing, the valve also divides the flows. There is a natural desire to automate the control process itself. For this, the valve is equipped with a temperature sensor with a thermostat. In this case, the electric drive works best here. The quality of the functioning of the entire heating system depends on the drive device.

- Such a valve is installed in those places of the pipeline where it is necessary to split the circulation flow into two circuits:

- With constant hydraulic mode.

- With variable.

Usually, a constant hydraulic flow is used by consumers for which a high-quality heat carrier of a certain volume is supplied. It is regulated depending on the quality indicators.

The variable stream is consumed by those objects for which the quality indicators are not the main ones. The quantitative coefficient is important for them. That is, for them, the flow is adjusted according to the required amount of coolant.

There are valves in the category of valves and two-way counterparts. What is the difference between these two types? The three-way valve works in a completely different way. In its design, the rod cannot shut off the flow with a constant hydraulic regime.

It is always open and set for a certain volume of heating medium. This means that consumers will receive the required volume in both quantitative and qualitative terms.

Essentially, the valve cannot shut off the flow to the constant flow circuit. But it is capable of overlapping the alternating direction, thereby making it possible to regulate the pressure and flow rate.

If you combine two two-way valves, you get a three-way design. In this case, both valves must work in reverse, that is, when the first is closed, the second must open.

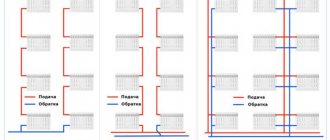

Types of three-way valves according to the principle of operation

- According to the principle of action, this type is divided into two subspecies:

- Mixing.

- Separating.

From the name alone, you can understand how each type works. The mixer has one outlet and two inlets. That is, it performs the function of mixing two streams, which is necessary to lower the temperature of the coolant. By the way, this is the ideal device to create the right temperature in underfloor heating systems.

It is quite easy to adjust the temperature of the exit ceiling.To do this, it is necessary to know the temperature of the two incoming streams and to accurately calculate the proportions of each in order to obtain the required temperature regime at the outlet. By the way, this type of device, if properly installed and adjusted, can also work according to the principle of separation of streams.

A three-way separating valve splits the main flow in two. Therefore, it has two outputs and one input. This appliance is commonly used to separate hot water in hot water systems. Often, experts install it in the piping of air heaters.

In appearance, both devices are no different from each other. But if we consider their drawing in section, then there is one difference that immediately catches the eye. The mixer has a stem with one ball valve.

It is located in the center and overlaps the saddle of the main aisle. In the dividing valve, there are two such valves on one stem, and they are installed in the outlet pipes. The principle of their operation is as follows - the first closes one passage, pressing against the saddle, and the second at this time opens another passage.

- The modern three-way valve is divided into two types according to the control method:

- Manual.

- Electric.

More often you have to deal with a manual option, which is similar to a conventional ball valve, with only three branch pipes - outlets. Electric automatic systems are most often used for heat distribution in private housing construction.

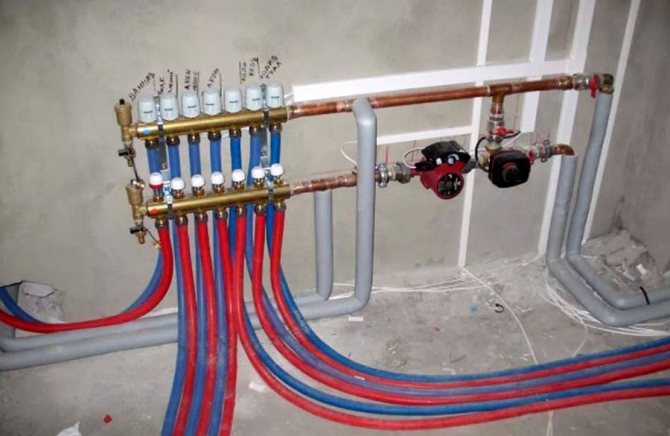

For example, you can adjust the temperature across rooms by distributing the coolant depending on the distance between the room and the heating boiler. Or provide a combination with a warm floor system. Devices of large cross-country ability are installed on heat pipes between buildings.

Like any device, a three-way valve is determined by the diameter of the supply pipe and the pressure of the coolant. Hence the GOST, which allows certification. Failure to comply with GOST is a gross violation, especially when it comes to pressure inside the pipeline.

Tap selection

To buy the right tee you should:

- Measure the diameter of the main pipe on which the device will be installed. As a rule, it is in the range of 20-40 mm. If a different size is required, purchase the appropriate adapter additionally.

- Find out the capacity of the pipeline through the heating circuits. To do this, you need to calculate how much water each pipe can pass through itself for a certain period of time.

- Find out if it is possible to connect a servo to enable the device to operate in automatic mode. This option is especially relevant for underfloor heating.

- Pay attention to other indicatorsthat were considered in the product classification.

If you cannot cope on your own, seek help from consultants.

When welding during installation, do not allow the temperature flow at the joints to be more than 100 degrees

Types of three-way valves and features of their work

First of all, three-way thermal valves are classified according to their purpose into separation and mixing:

In a mixing valve, 2 directions work to supply a heat carrier of different temperatures (hot and cold), and 1 direction outputs an already mixed fluid flow. The setting of the required temperature parameters is carried out by adjusting the temperature and proportions of the supplied flows.

At the distribution thermovalve, 1 branch pipe supplies the coolant, and the other 2 divide it among themselves and distribute it in different directions.

According to the control method, three-way thermal valves are autonomous, manual, thermostatic and electric. The last two, as a rule, work in automatic mode.

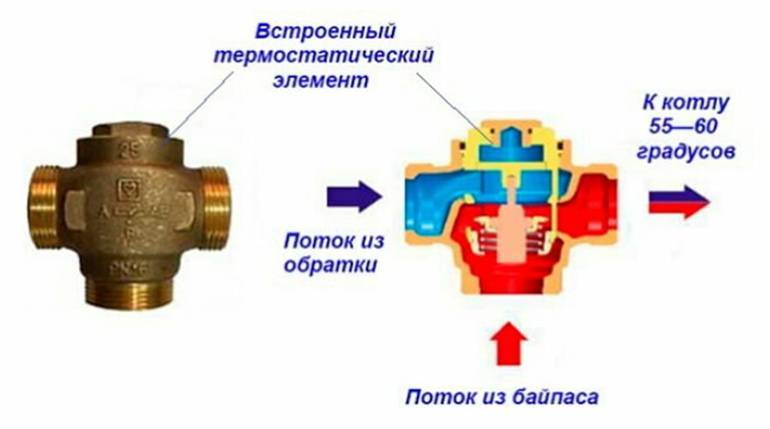

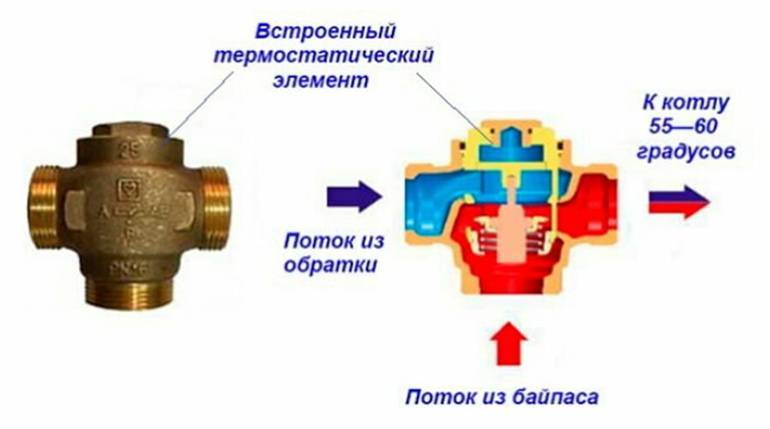

Simple stand-alone models are equipped with a thermostatic element installed inside the case with a coolant outlet temperature already set at the factory.This value remains constant throughout the entire service life.

| Self-contained mixing three-way valve | |

| pros | Minuses |

| Low price | The need to select a valve for the temperature regime of the return flow of the heat generator |

| Control of the temperature regime of the coolant | The temperature set by the manufacturer cannot be changed. |

For manual control, the stem is equipped with a valve or a rotary knob and a control panel with marks, in accordance with which the thermal regime is regulated.

| Manual mixing valve | |

| pros | Minuses |

| Relatively low price | The need for constant monitoring by a person, as a result, a protracted nature of the response to changes in environmental conditions |

| Control of the temperature regime of the coolant | |

| Possibility of changing the temperature regime during operation | Uneven heating of the heating circuit |

The three-way thermostatic valve with a thermostat is equipped with a thermostat filled with a liquid or gas medium that reacts to the slightest fluctuations in the temperature of the coolant.

As soon as the coolant heats up to the set temperature, due to the expansion of the reagent, the piston system of the thermal valve is automatically activated and the branch pipe with hot flows is closed.

Three-way valves with a thermostat can be mechanical or electronic. The advantage of mechanical models is their absolute autonomy. Electronic ones require connection to the mains supply or are powered by batteries.

However, this drawback is smoothed out by the complete automation of the process, ease of setup and advanced functionality - automatic change of the temperature regime by time of day, days of the week, etc.

| Three-way mixing valve with thermostat | |

| pros | Minuses |

| Automatic control of the temperature regime of the coolant | High price |

| The ability to change the temperature regime | An extremely precise setting is required, errors in the set parameters give a small error in the operation of the system |

| Uniform heating of the heating circuit |

Three-way thermo-valves with an electric drive are controlled by an electronic control unit, which operates on a servo drive. The exit of the temperature regime of the heat carrier outside the set values is fixed by the thermostat installed in the module, which signals this to the controller. He transmits a command to the drive, regulating the flow of cold or hot coolant in the system.

In this case, none of the nozzles is, as a rule, completely closed, and only the volume of the supplied cooled and hot heat carrier is regulated.

| Three-way mixing valve with electric drive | |

| pros | Minuses |

| Automatic control of the temperature regime of the coolant | High price |

| Possibility of changing the temperature regime | Increased power consumption |

| Precise regulation of the heating medium flow temperature | Increased heat carrier consumption |

| Uniform heating of the heating circuit |

Features of installation and operation

For the correct installation of a three-way valve, you should know a few features:

- Be guided by the diagram of the arrows shown on the body. They indicate in which direction the water flow is moving.

- When welding during installation, do not allow the temperature flux at the joints to be more than 100 degrees. Make sure that dirt and scale do not get inside the device during welding.

- Choose such a place for installation, which can be easily reached if necessary.

- If the crane will work with a low-quality coolant, you will need to additionally install filters.

- You can screw the product vertically, and horizontally - this will not affect its performance.

- The valve is installed in the heating system in front of the circulation pump.

The operation of the device must be observed in accordance with the rules established in the instructions. And all parts require periodic inspection and maintenance.

Correct and correct use of the device will prolong the period of its operation and will serve properly.

Device and principle of operation

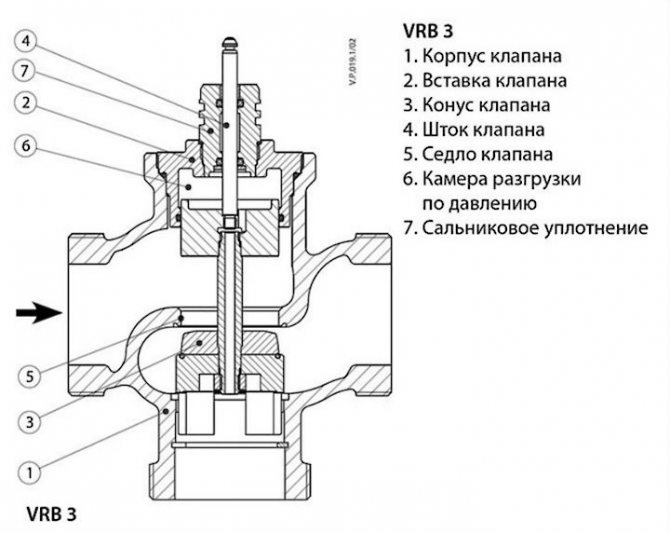

To understand what the three-way thermo-mixing valve of the most common saddle type consists of and how it works, you should study the diagram below. Inside the brass body with three nozzles, 3 chambers are arranged by casting, the passages between which are blocked by poppet valves. They are fixed on one axis - a rod coming out of the body from the fourth side.

In a 3-way mixing valve, the outlet pipe (where the mixed water comes from) is always open, the other 2 connections are sequentially closed with a thermal head

The principle of operation is as follows: when the rod is pressed, the passage for one stream will begin to open and gradually close for another, as a result of which water of the required temperature will be obtained in the mixing chamber of the valve. It leaves the brass body of the element through a third pipe. Adjustment of the force of pressing the rod is carried out by a thermal head with an external temperature sensor installed in accordance with the diagram.

The whole process should be explained in more detail:

- Imagine that an insufficiently heated heat carrier enters from the hot water side. Then the mechanism passes it further, and the third pipe is closed. The remote sensor is filled with a temperature-sensitive liquid and is connected by means of a capillary tube to a reservoir (bellows) inside the thermal head.

- When the sensor heats up, this liquid expands, its volume in the tube and the bellows increases, as a result, the latter begins to press on the stem of the three-way valve. The moment of pressing is determined by the adjustment on the scale of the thermostatic head, set to the required temperature.

- After that, cold water from the third pipe is added to the flow of heated water and the temperature of the water at the outlet from the thermal valve remains unchanged, although the heating of the coolant at the inlet continues.

- If the incoming water continues to heat up above normal, the thermostatic valve can completely close the inlet and open the side flow to maintain the set outlet temperature. In this case, the stem is lowered to the lowest position.

- As soon as the sensor marks the cooling of the coolant, the head will slightly release the stem, the valve seat on the hot side will open and the heated water will begin to mix.

The method of adjusting a three-way valve with a thermostatic head with a sensor is the most popular, since it is quite accurate and simple, and does not require electricity.

If we are talking about a separating valve, the principle of its operation is practically the same, only when the stem is pressed, one flow begins to be divided into two. But in the switching element, the direction of movement is changed by the electric drive, which is described in detail in the video:

Blitz Tips

- Before starting the heating system, you need to check the serviceability and the condition of the three-way valve and the entire heating system.

- Do not install a faucet for pipes with a diameter of more than 40 mm.

- Open the tap very carefully in a hot environment.to avoid hydraulic valve failure.

- It is important that the stem together with the adjusting device or with a turning handle they went out towards free access to them.

- Better to buy a faucet made of brass. It will last a little longer than other materials.

- The most optimal option - crane with pneumatic control of work.

- To avoid mistakes, consult a specialist in advance.

Views

Three-way valves are classified according to the principle of operation. There are dividing and mixing valves.In floor heating systems (and in radiators), mixing devices are used that regulate the temperature of the leaving heat carrier by mixing cold and hot water.

According to the method of actuation, three-way devices are:

- Manual. They are very rare and inexpensive. Convenient if heated floors are installed in 1-2 rooms - for example, a bathroom and a nursery.

- Automatic.

In the manual position of the stem and regulation of the leaving water temperature is manually adjusted by the handle. In automatic, the movement of the stem is controlled either by a thermal head or by an electric drive controlled by an automation with temperature sensors.

Automatic valves are:

- The simplest type is with a thermostatic head. They are triggered when the temperature rises (they react to an increase in pressure). Such devices are used for radiators. The fluid in the actuator expands as temperature rises and drives the stem.

- With thermostatic head and remote sensor.

- Electrically operated. The rod is driven by an electric motor. The engine is controlled by a controller, which receives signals from temperature sensors. The actuator can control the valve using a solenoid (magnet) or mechanical transmission (servo).

- In production, in systems with high pressures and diameters, pneumatic or hydraulic drives are used.

The types of valves are shown in the photo:

Valve markings

Three-way valves are labeled with letters and numbers:

- Company name.

- Series and model number (e.g. VTA 321).

- Nominal diameter in mm (DN 20).

- Temperature range, for example 20-45 ° C - mode from 20 to 45 ° C.

- Throughput in m³ - KVS 1.6 - 1.6 m³ / hour.

An example of ESBE valve marking is as follows:

ESBE VTA 321 DN 20 20-45C, kvs 1,6

Sizes: ½ ", ¾", 1 ", 1¼" and so on, or in mm - 15, 20, 25 mm, etc.