During the construction of residential buildings, most people have problems that are associated with the choice of insulation materials. Understanding what is better, basalt wool or mineral wool, it should be noted that these two types of thermal insulation materials are representatives of the same class.

The solution to this issue should be approached somewhat differently, paying attention primarily to the characteristics of basalt and mineral insulation. Therefore, let's compare in order to understand which of the presented heat insulators are the most optimal for use.

The difference between basalt and mineral wool

It is important to understand that in the modern construction industry, the concept of mineral wool has a wide meaning. This material is a special type of insulation that has a characteristic fibrous structure on an artificial basis. Various mineral raw materials are used for its production: glass, blast-furnace slags, rock basalt rocks. That is, mineral wool is the general name for all types of heaters of this class, which include:

- fiberglass;

- slag fiber;

- stone (basalt) fiber.

Thus, basalt wool is one of the types of mineral wool, so the question of which one is best to use is not entirely correct. More correctly, you should choose between fiberglass, slag fiber or basalt fiber. Most often, the consumer's choice is between mineral fiberglass and mineral stone fiber, that is, between glass wool and stone wool. To figure out which of these materials is better, you need to compare their properties and characteristics.

Mineral wool assortment overview

The insulation received this name because the basis of the products is natural minerals, sometimes even some types of stones. What is their fundamental difference, and what is better to use for insulating a house or a roof, our article will answer.

- Glass wool Is the most famous and popular product of modern building insulation technologies. The prime cost of a running meter is low, and the quality indicators are very high - it retains its original properties for a long time, if all laying conditions are fully observed. Produced from quartz mineral stone by the finest splitting under special thermal conditions. In fact, this is a very economical and at the same time high-quality insulation, and the latest technologies have saved the cotton cloth from harmful glass impurities, but not all manufacturers accurately follow the process technology, therefore, there may be residual effects of poor quality mineral wool in terms of environmental indicators. But for safety reasons, it is better to wear gloves and a protective suit. It is convenient to work with it - the products are supplied in rolls of the required length, low weight indicators will allow you to easily insulate the house even alone.

- Slag, as the name implies, is produced from metal production waste, when steel is obtained by adding ore and coal, and slag waste, that is, a kind of suitable mineral for secondary raw materials. In addition to lumpy slag, dusty residues, other fine fractions, which are used as a filler, can be added to it, which affects the quality characteristics of products for thermal insulation of premises. The main threads are obtained by blowing the liquid fraction with a pore powerful jet or compressed air, during the process it is additionally saturated with silica filler.Then the fibers go through the stage of pressing and forming the finished product into large rolls. Negative points are visible in the low quality of the canvas, moreover, over time, it begins to emit acid vapors, which does not allow the use of insulation for living quarters. In the photo - slag:

- Stone cotton blocks for insulation... Immediately it is necessary to make a reservation that this is a large group of heaters, which can be conditionally divided into organic and inorganic origin: The organic type is wool of wood fiber characteristics., peat, pyroclastic, that is, they are made from natural elements with little or no preparatory processing. Since the base of the cotton wool is natural, the environmental indicators of such heaters are quite high, moreover, they are lightweight and easy to use;

- Mineral wool made from asbestos fibers is classified as inorganic. (by the way, very harmful, they can settle on the lungs and will never be removed from the body), basalt and other stone minerals, but they all have the name of inorganic origin. All such products, except for the asbestos type, are absolutely safe for human health, and they can be used to insulate any residential premises.

Now let's talk about the main differences between basalt wool and other types of mineral wool.

Basalt insulation - its main features

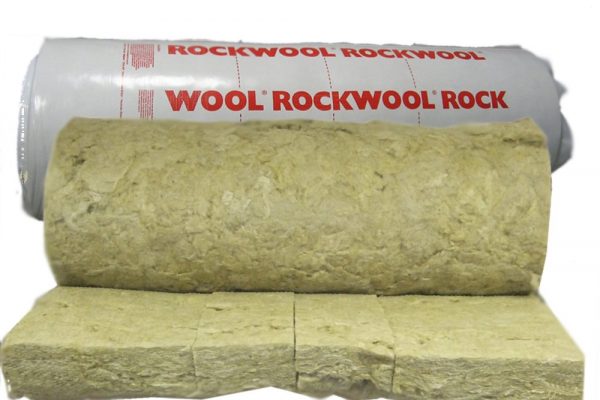

Basalt, aka stone wool, is made on the basis of fibers, which are obtained in the process of melting volcanic mountain gabbaro-basalt rocks. During production, this material is mixed with special binders, which are subsequently important for the operation of the material.

For example, they provide water-repellent, heat-insulating, fireproof, sound-proof properties. Today, mountain minerals are used in many industries, as well as in domestic construction, for example, when laying roads, producing commemorative sculptures, stone products, etc.

Due to its loose and fibrous structure, basalt mineral stone wool maintains temperature conditions much better than mineral fiberglass. This is achieved due to the interfibrous air layers, which are formed due to the structure of the material itself. So, in winter it will always be warm in the room, since the temperature will be reliably kept inside the building, and in summer, on the contrary, it will be cool in the house, despite the hot weather. In the case of using fiberglass, this important advantage will be missing.

Which kind of wool is better: stone or mineral wool?

The installation of both watts from each other is not very different.

- Stacked on different surfaces: horizontal and vertical.

- Stone wool is less plastic, brittle, has good water repellency, good sound insulation.

- Basalt does not crumple over time and under the weight of roofing materials.

- The density of stone wool is much higher than mineral wool. The soft component flexes strongly and allows water to pass through easily. Additionally, you will have to impregnate or cover with a protective material. But when moisture penetrates, mold forms, an unpleasant odor will appear and you will have to change the coating to a more reliable one. This will be difficult due to the thinness of the fibers, they crumble strongly.

- To create good strength, acrylic is added to the glass wool.

- Also, it reacts well to physical impact, that is, it stretches and does not break, does not cause allergic reactions and does not harm the skin. Glass wool resembles cotton in structure.

- Mineral wool is harder to install in a vertical surface due to the softness of the structure.

- If insulation of the pipeline is required, then mineral wool is excellent.

- Stone insulation retains its basic characteristics longer.

Important! Stone wool is much more expensive than mineral wool and its counterparts because of the above properties. Basically, due to the durability, strength, dense structure that does not allow moisture and extraneous sounds into the home.

Both materials fully correspond to the indicators from the manufacturers. But each is better or worse for insulating certain parts of the house.

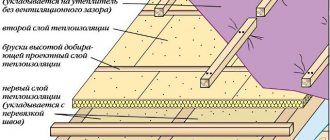

Installation of stone mineral slabs in the attic

If you need to create thermal insulation for the pipeline, then mineral wool is better suited, since it is soft, flexible and will not allow pests (mice) to get to the protected part. And for insulation of walls and floors in the house - stone wool. Because its solid structure, without the possibility of further squeezing, allows you not to change the material for many years. Also does not allow moisture and sounds that interfere with a quiet life. Ideal for living in the city and in a private house in winter.

Glass wool has become an environmentally friendly product because it does not use harmful solutions that can harm human health (cause allergic reactions, itching, damage to internal organs due to ingestion).

When building or carrying out repairs, it is often required to provide sound insulation to the house. All the same materials help to keep warm inside the room. There are many products on the market for building raw materials for housing insulation. Choosing which is better: basalt wool or mineral wool is sometimes quite difficult. A final decision can be made only after a careful comparison of the goods.

Pros and cons of basalt heat insulator

Rock-based mineral wool has a number of decent characteristics compared to other thermal insulation materials. Among the most important are:

- resistance to high temperatures;

- when heated, toxic substances are not released from the material;

- resistance to pollution;

- easily transported;

- long service life. High-quality brands of such insulation from reliable manufacturers can last up to 50 years without losing their qualities at all;

- has low sound conductivity;

- has good vibration resistance, unlike fiberglass;

- is not explosive material;

- not affected by rodents or other pests;

- with a low specific gravity, high insulation is observed;

- has good resistance to a number of mechanical influences, due to the chaotic arrangement of the fibers;

- possesses good water-repellent qualities, easily passes moisture without accumulating it.

With all the variety of advantages, mineral basalt wool also has its drawbacks:

- high cost of heat-insulating material;

- on tiled basalt insulation, the connecting sections have many seams, which subsequently cause a decrease in thermal insulation properties;

- low indicators of strength characteristics;

- Some brands of basalt wool are harmful to health, since an unsafe phenolic binder can evaporate and enter the human body with air.

When insulating walls with basalt insulation, precautions must be taken, since crumbling dust can get into the eyes and lungs. To protect yourself from this, it is enough to wear glasses, a respirator or a gauze bandage.

Basalt wool - what you need to know about?

Insulation based on basalt wool is characterized by fiberglass, which is part of the composition, combined with special components to maintain the bond and improve the hydrophobicity of the material.

An important advantage of thermal insulation based on basalt wool is its resistance to high temperatures, which is especially noticeable when compared with mineral wool insulation. In addition, the insulator is characterized by:

- lack of the ability to release toxins when the temperature rises;

- resistance to dirt and fungi;

- high melting point;

- easy transportation and installation.

The manufacturer of basalt wool insulation claims fifty years of operational life in compliance with the basic rules of use. In addition, the characteristics of the material indicate a high level of sound absorption, which allows it to be used for insulation and noise reduction in rooms for various purposes.

Heaters made of basalt wool are much better than mineral wool and in terms of vibration resistance, they do not belong to the explosive group, they are suitable for isolating an environment with an elevated temperature and an aggressive type.

Analyzing how much better insulation based on basalt wool is really better than mineral wool, it is worth noting the special chemical composition of the material. It does not include dolomite and limestone elements, which are necessarily included in the adhesive required for the installation of mineral wool.

Basalt heaters, with all their positive qualities, weigh little and show increased resistance to mechanical damage. This is important, because at the stage of destruction, heaters pose a real danger to human health, breathing in microparticles of fibers floating in the air.

Perhaps there is no better insulation than basalt wool when it comes to the ability to cope with the effects of moisture. The material has a high level of water repellency, and when moisture gets inside, it does not allow it to accumulate.

The material also has some disadvantages. Stone wool is sold at a fairly high price, which is different from the cost of mineral wool - rather a budget option.

The peculiarities of the structure of the insulation can also be considered a minus. The material in the form of a plate, most often used for thermal insulation, has many seams in the joints, which can cause poor quality thermal insulation, especially if mistakes in installation are made.

In terms of safety, basalt wool insulation is considered more environmentally friendly than conventional mineral wool, despite minor inclusions in the composition of phenolic binders.

So, summing up the differences between basalt thermal insulation from other types of insulators based on mineral wool, it is worth noting the following important factors:

- the material is resistant to chemical and biological attacks, which distinguishes it from the same glass wool;

- the plasticity of the material in terms of indicators exceeds the same parameter for mineral insulation, including glass wool;

- the material provides a high level of thermal insulation, significantly exceeding the level of glass wool counterparts.

How much the advantages overlap the above disadvantages - everyone decides for himself after analyzing the features of alternative types of insulation, including those based on mineral wool.

The difference between stone wool compared to other mineral insulation

When considering the features and characteristics of basalt wool, its advantages become noticeable in comparison with existing similar heat-insulating materials. The most important factor of this heat insulator is its high level of biological and chemical activity. Based on this fact, stone wool has an advantageous difference compared to other insulation materials, for example, glass wool.

The types of heat insulators to which basalt is added have a unique structure consisting of short and thick fibers. Due to this, the plasticity of the material increases significantly, and the risk is reduced that when laying the insulation, it will crumble and crumble.

Features of mineral insulation (glass wool)

Compared to basalt insulation, the cost of fiberglass insulation is much lower. The difference in material prices depends on the availability and low cost of the manufacturing process. Mineral wool is produced in special packages that do not require special transport for their transportation. In comparison with basalt analogs, this is its main advantage. In addition, fiberglass is lightweight, easy to transport, and this is a very important aspect affecting the pricing of the product. The advantages of mineral fiberglass include the following qualities:

- low weight of the material;

- has a low degree of density;

- does not create large loads when used;

- has excellent chemical passivity, that is, it does not emit harmful substances;

- has high biological endurance;

- does not tend to ignite;

- due to the long fiber length it has excellent elasticity;

- does not cause corrosive processes on metal structures;

- applicable for uneven surfaces with different geometries;

- has better sound insulation than stone wool.

When choosing a mineral insulation, special attention should be paid to its thickness, the location of the fibers and its density.

What is the best choice?

Based on the considered features of the materials, it is difficult to say which of them is better - basalt insulation or fiberglass. Both materials have their own positive characteristics and disadvantages. But before making a final decision, it is worth considering the heaters presented in a more detailed comparison.

The difference between mineral wool and stone is in the density of materials. Fiberglass is much softer, it often shrinks and is highly exposed to moisture. Water in the insulation lingers for a long time and is poorly removed, therefore, during installation, it is necessary to cover the material with a film. In addition, not all types of mineral wool can be used under screeds and plaster. Fiberglass is best used for horizontal surfaces as it will loose its shape and sag on vertical surfaces.

Speaking about transportation, it can be noted that fiberglass benefits significantly due to its low weight and small dimensions. Presumably, during transportation and unloading, glass wool can lose its original shape, but then it quickly returns to its natural position, since it has high elasticity. It is flexible, so it can be easily used for insulating all types of surfaces - pipes, crevices, attics and various irregularities.

At the same time, the service life of mineral glass wool is significantly inferior to the service life of stone. Therefore, for a long period it is more profitable to use basalt heaters. In addition, stone wool is excellent for installation in all areas of the house, it is easy to install it to the ceiling, walls, under the floor or sub-floor.

The basalt fiber heat insulator is suitable for use in any conditions, therefore it can also be used for external insulation of houses. Whereas fiberglass is several times inferior in these characteristics.

That is why most people from the private housing sector give their preference to basalt insulation. The final price of a basalt heat insulator is quite high and not every consumer can buy it, but still it is worth it. This material will allow you to perform the task of warming as efficiently as possible and get the most acceptable result, forgetting for many years about the problem of home insulation.

In general, studying the question of which insulation is better, we can conclude that everything depends on individual needs and construction work for which a heat insulator is needed. Before purchasing, it is necessary to consider in what conditions the thermal insulation material will be used.And only on this basis, make a decision on the purchase of glass or basalt fiber.

What is better basalt wool or mineral wool

To understand in more detail how basalt wool differs from mineral wool, you need to consider the characteristics of these materials. Depends on them:

- installation;

- exploitation.

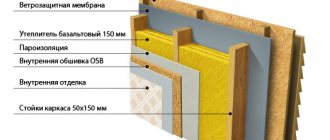

By and large, the installation of stone wool and mineral wool is no different, with the exception of minor points. Both materials can be installed on both horizontal and vertical surfaces. Stone wool is much denser, it is inelastic and brittle, practically does not absorb moisture and, even getting wet by 30%, continues to perform thermal insulation functions. This material does not shrink, all types of it can be laid under a screed or under plaster.

The first thing that distinguishes mineral wool from basalt is its density, which is much less. The material is soft, shrinks, very susceptible to moisture. Insulation strongly saturates water and removes it poorly, so it must be protected with special films (vapor barrier and diffusion membrane). Only some types of glass wool can be used for screed or plaster applications.

Installation of basalt insulation is made difficult by the fact that its fibers are short and fragile. They break, and as a result, there is a lot of dust in the air.

When it gets on the skin, it causes itching. Also, dust should not be allowed to enter the respiratory tract, since it settles in the lungs and is never removed from there. The problem of dust is also present during the operation of this thermal insulation. Small particles of basalt, which you breathe, can penetrate through the cracks in the cladding into the room. Therefore, special attention should be paid to the tightness of the casing or to make a vapor barrier layer.

In terms of exploitation, glass wool is much better. First, an acrylic-based compound is used as a binder. Secondly, the insulation is elastic, its long and soft fibers do not break, so there is no dust at all. The material does not prick, some brands, for example, Ursa PurOne, look very similar to cotton in appearance. Therefore, in terms of environmental friendliness, glass wool is much better.

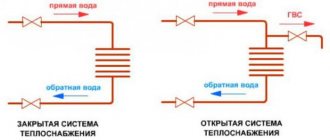

A two-pipe heating circuit with an electric boiler is no different from circuits with a gas or TT heater.

Read about the functions of a thermostat for electric heating boilers here.

Comparative table, which is better than mineral wool or stone wool:

| Basalt insulation | Glass wool | |

| Density | hard material | soft material |

| Fiber | short, brittle | long, elastic |

| Hygroscopicity | low | high |

| Thermal conductivity | 0.038-0.045 W / m * K | 0.036-0.042 W / m * K |

| Environmental friendliness | contains formaldehyde resins | acrylic based |