Circulation pumps for heating and air conditioning systems

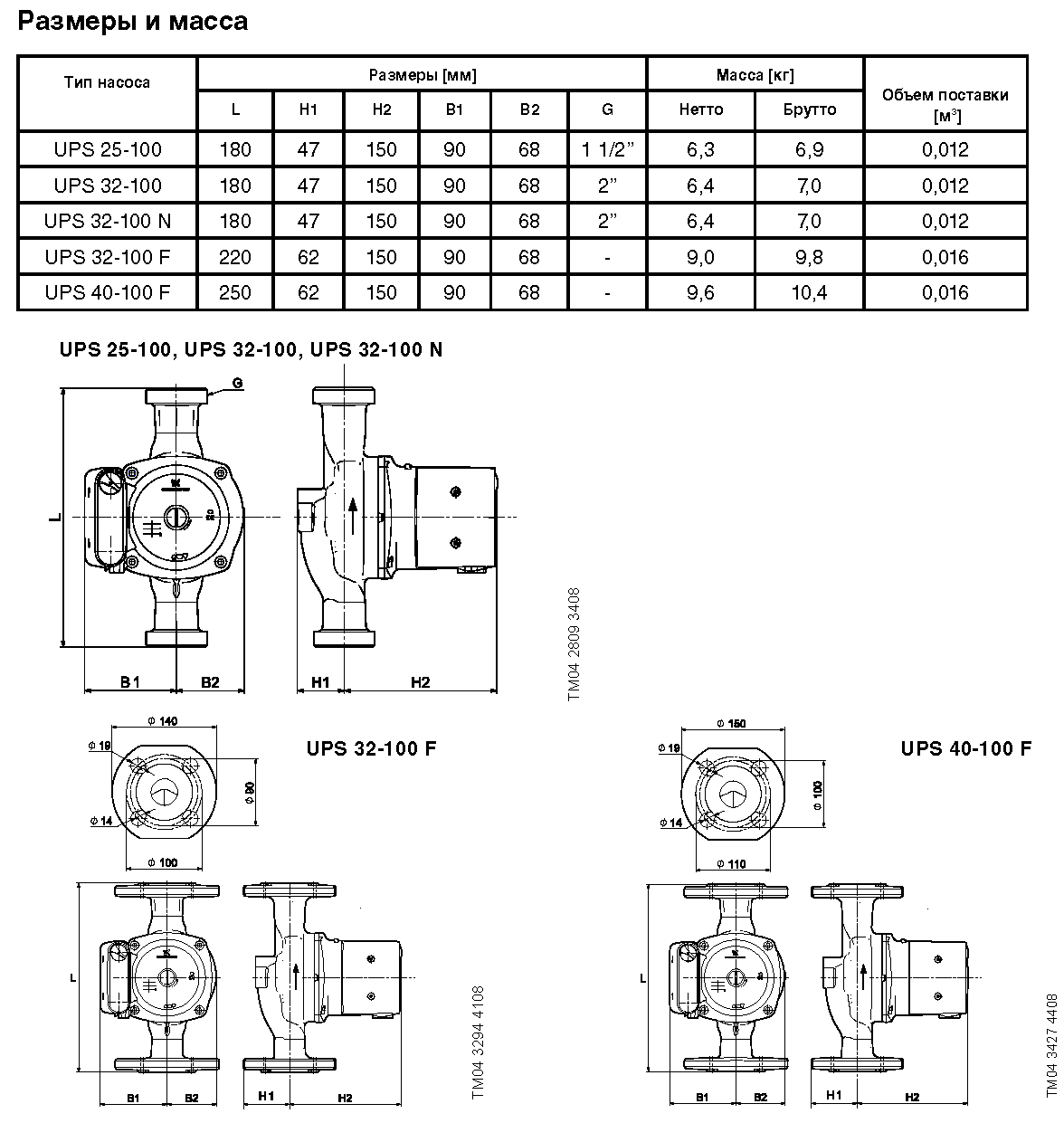

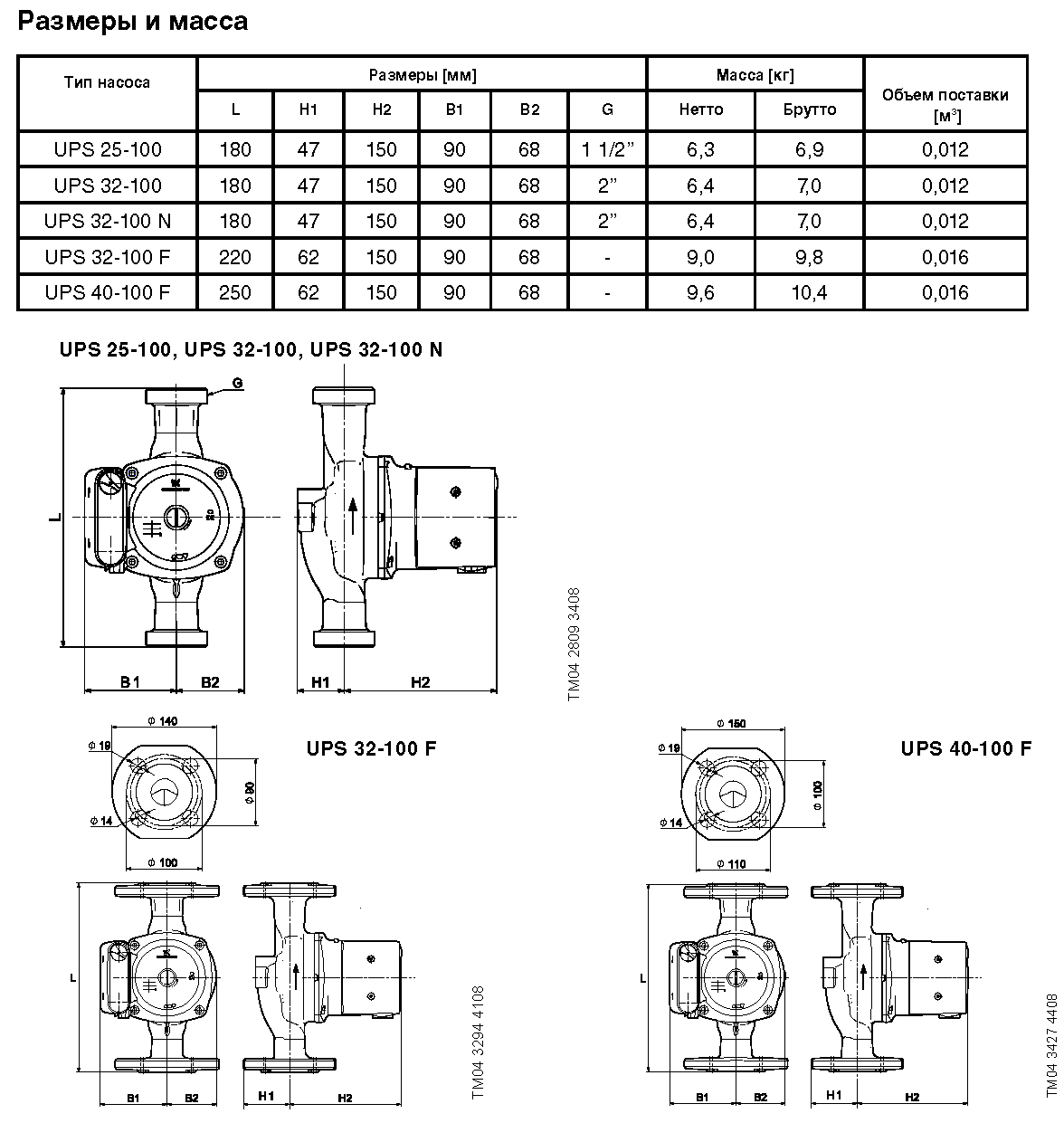

This three-speed pump is designed to operate in heating systems with stable or low-variable flow rates. Depending on the needs of the network, using a simple and convenient switch, you can set the required speed. Thus, from the many UPS Series 100 pumps, you can easily select the size that best suits your system.

SOLAR series

Grundfos Solar pumps are single-stage circulation pumps equipped with a glandless electric motor. The pump and the electric motor form a single unit. The ceramic rotor bearings are lubricated with the pumped liquid. Grundfos Solar pumps are designed to circulate the heating medium in solar heaters for hot water systems. They are also used in application, refrigeration and air conditioning systems.

UP series 100 FOR DHW SYSTEMS

Single-speed UP pumps with a body made of brass, bronze or stainless steel are used to circulate drinking water in hot water supply systems. A timer with day and week scales and a temperature switch are available as an option.

ALPHA + series

The characteristics of Grundfos Alpha + include those of most circulating pumps used in single-family homes. This greatly simplifies the selection of pumps. Grundfos Alpha + works in any heating system (one-pipe, two-pipe), and in the bronze version - in a hot water system.

The pump operates in any of three modes: - proportional control; - constant pressure regulation; - fixed speed.

A modern heating system maintains the required temperature in each room with the help of automatic thermostats that react to the outside temperature. It is for such systems that circulating pumps with built-in automatic regulation (Grundfos Alpha +, UPE) are needed. They change the speed depending on the needs of the system. Thus, up to 60% of electricity is saved, and hydraulic noise in pipelines is reduced.

Selection of popular manufacturers

There are many manufacturers on the market, and the products of most of them are of fairly high quality. But there are also companies that are in this area, what is called "the dog ate" and their products, if not ideal, are close to this. It will be about the companies Grundfos and Wilo.

Grundfos circulating pumps

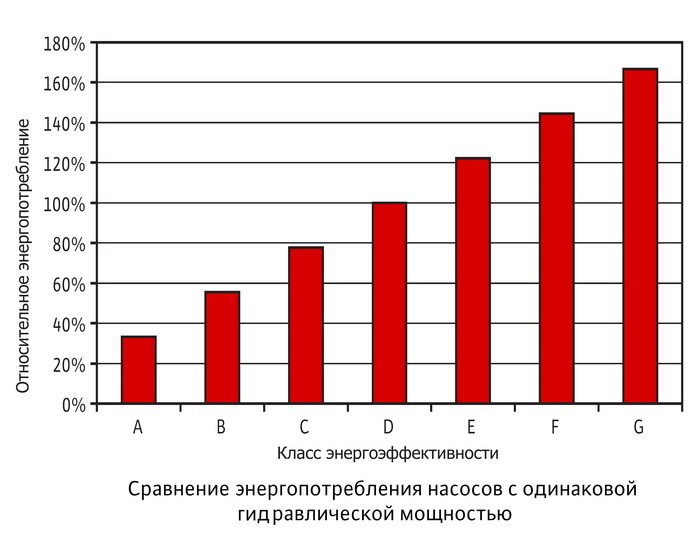

Grundfos is a Danish manufacturer, and the first Grundfos heating pump was released back in 1959 and since then the company has been improving the design of the device every year. It is also worth noting that it was this manufacturer who was the first to propose a modern classification of such devices for energy efficiency, before that no one simply thought of applying such a criterion to conventional heating circulation pumps.

Energy efficiency classification adopted by Grundfos

On the product side, the entire range can be commended for its fairly wide adjustment capabilities and excellent energy efficiency. Energy consumption is several tens of times less than that of unregulated outdated pumps.

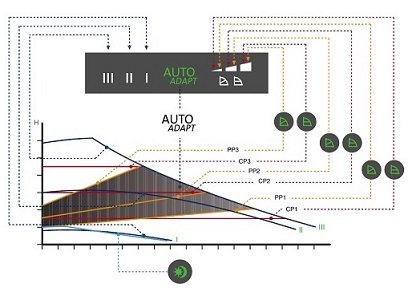

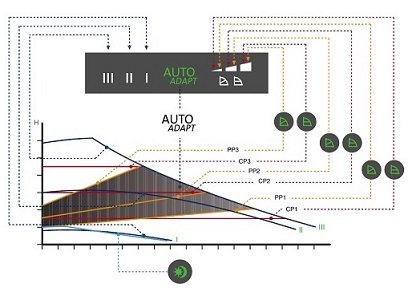

Separately, it is necessary to note the proprietary Autoadapt technology, which the models of the upper price category are equipped with. When this mode is activated, the pump itself will find the optimal ratio between the temperature in the room and the coolant current.

In order not to list all models of devices from this manufacturer, we will focus on several popular series:

- pumps for heating Grundfos 100 series - due to their quietness, they are often used in autonomous heating of private houses and apartments. The rotational speed is set manually using a regulator (a total of 3 operating speeds of the rotor);

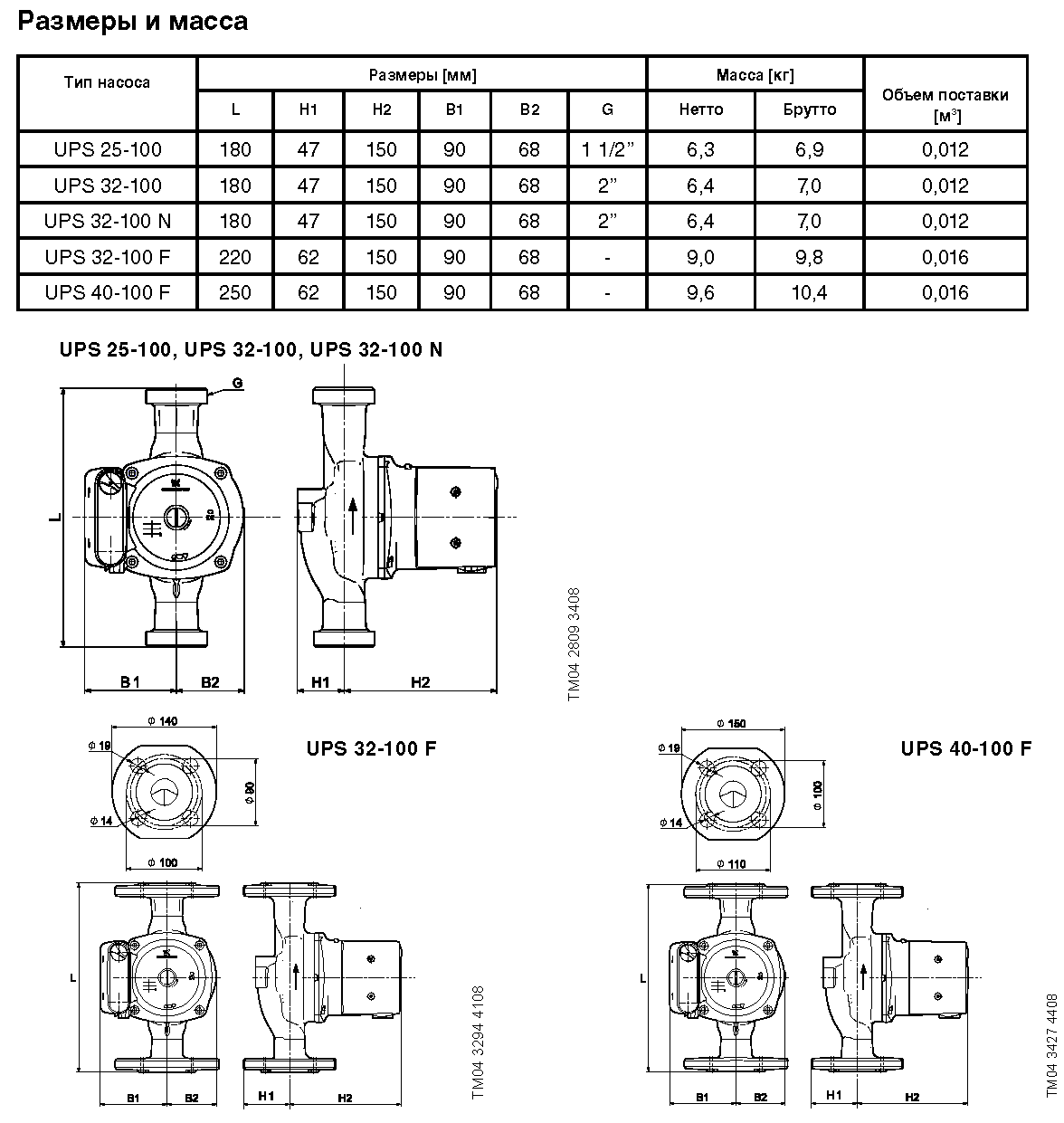

Features of some models in the 100 series

- The 200th series can be considered universal, such devices can be used not only in heating, but also in building air conditioning systems. If they are used in hot water supply systems, you will have to purchase a thermostat, which will provide protection against overheating;

200 series models

- pumps for hot water supply - it is worth noting the models UP (1 operating speed) and UPS (3 operating modes). Considering the working conditions, the body of such devices is made of steel or bronze.

In general, all models of this manufacturer are created in order to make the installation and operation of the device as easy as possible for a person. The installation instructions are to simply connect the pump with threaded connections on the section of the pipe that feeds the cooled coolant back to the boiler.

Pumps from Wilo

If we compare Wilo pumps for heating with the same Grundfos, then there will not be so many differences. The German manufacturer has perhaps a much more impressive development history - the company was founded in 1872, but the quality of the products is comparable.

The products of the German manufacturer are also distinguished by their durability, efficiency, high efficiency, flexible regulation and a multi-stage protection system.

Such series are quite popular:

- Star-RS - most often used in private construction, such a device is used with a house area within 200-750m2. Since pumps of this series can also be used in air conditioning, the operating temperature range is in the range -10ᵒС - + 110ᵒС;

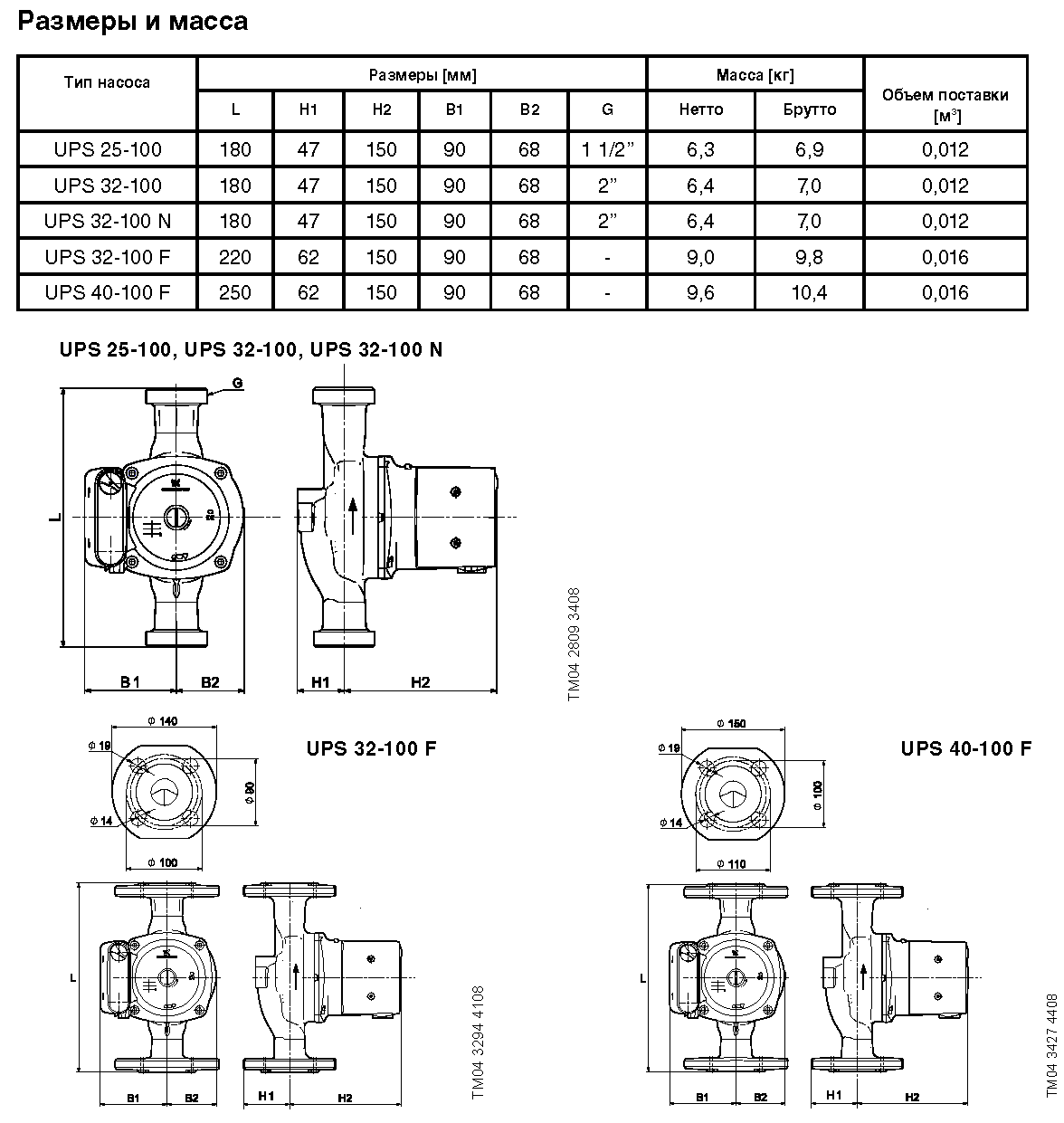

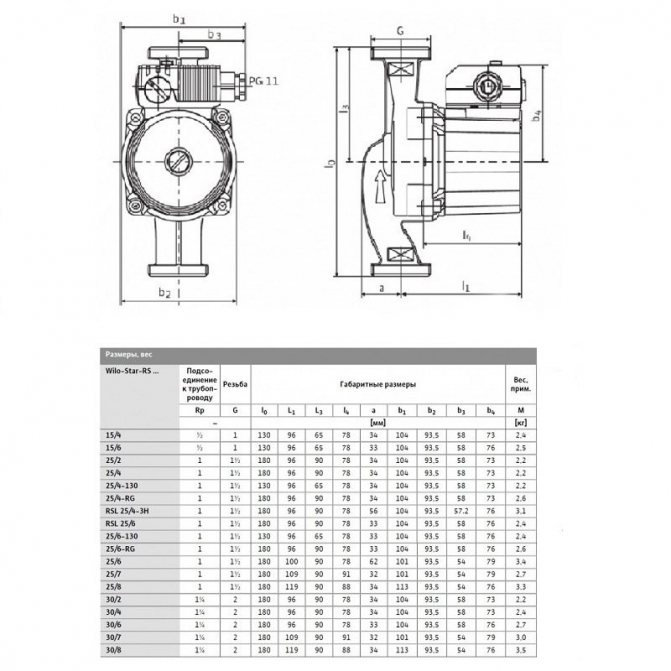

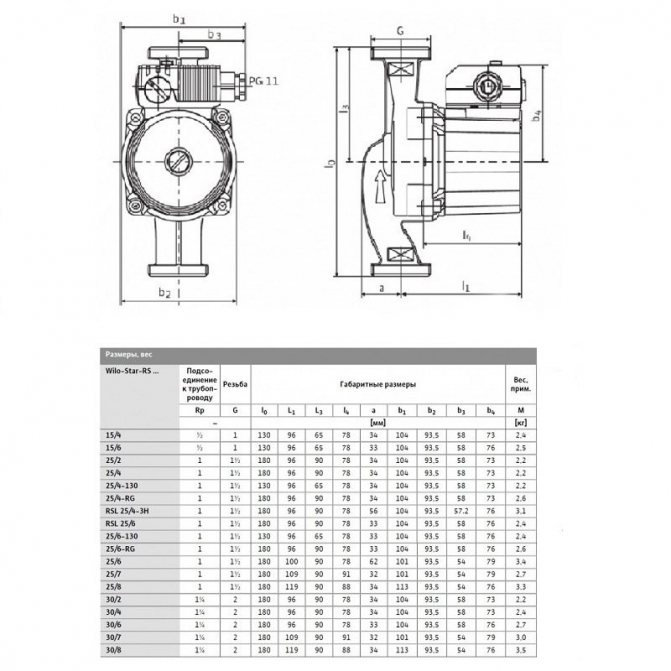

Characteristics of the Star-RS models

- The heating pump Wilo of the Top-S series is used in heating systems for heating large areas, about 1000 - 1400 m2. The operating temperature range is within -20ᵒС - + 130ᵒС, it can work in 3 modes.

Features of Top-S models

- The Stratos and Yonos series use electronically commutated motors so that the operating mode changes automatically. They can be used in heating systems of both private houses and industrial workshops.

What is important to know

The wiring diagram and methods for connecting a device such as a circulation pump to electricity can be of various designs. The choice of a specific option is determined by the characteristics of the heated object, as well as by the place where the device is located. There are two ways to connect it:

- direct connection to the 220 V power grid;

- connection to an uninterruptible power supply, which in turn is connected to a 220 V or 220/380 V network (in the case of a three-phase UPS).

Choosing the first method, the consumer runs the risk of being left without heating in the event of a prolonged power outage. This option can be considered justified only with a high degree of power supply reliability, which reduces the likelihood of a long power interruption to a minimum, as well as, if there is a backup source of electrical energy at the facility. The second method is preferable, although it requires additional costs.

Automation for pumps

Devices for controlling and regulating pumps are of two types:

- mechanical;

- electronic.

The pressure switches installed in mechanical systems and the compulsory hydraulic accumulator ensure the operation of the pump. But, the mechanical system with long-term water intake is constantly exposed to pressure drops, which has a bad effect on the technique when using instantaneous water heaters. In addition, hydropneumatic systems require constant adjustment of the automation. But such devices are quite easy to use, reliable and cheap enough.

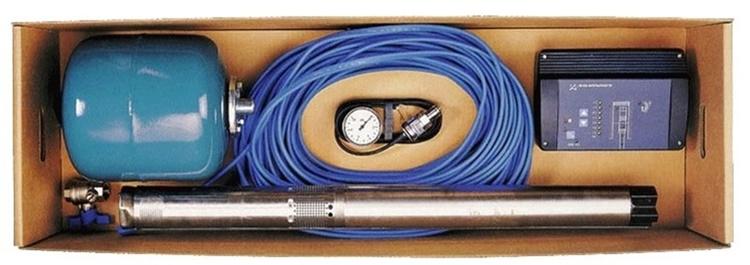

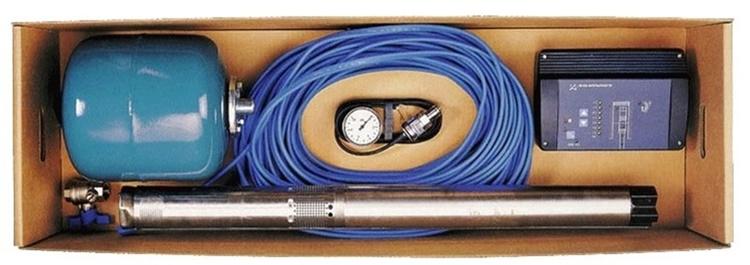

Set for automatic water supply with Grundfos automation

Hydrocontrollers, which are installed in electronic blocks, themselves track the movement of water in the pump system through flow sensors. This allows you to remove the accumulator from the electronic circuit of the device. In addition, with the help of a hydraulic controller, it is possible to increase the water pressure at times, which could not be done in devices with installed pressure switches.

Automation for pumps Grundfos

The model range of Grundfos automation (Grundfos / Grundfos) is represented by several devices:

- automatic adjustment devices;

- control cabinets;

- complex protection devices.

For example, devices for automatic pressure control (PM1 and PM2) can be produced in several modifications. The PM1 device is a model of a pressure regulation system in the basic configuration, which automatically starts up at a preset pressure of up to 2 bar. The model has a built-in dry-running protection system. By the way, RM stands for Pressure Manager.

Model Grundfos pm2 - provides the ability to adjust the pressure regulator for various types of water supply systems in the range of 1.5-5 bar. The Grundfos pm2 automation unit is equipped with:

- convenient and intuitive interface;

- voltage range selection system;

- outlet pipe (rotating);

- protective and adaptive functions (including dry running);

- built-in hydraulic tank;

- indicators of working and emergency conditions.

In addition, the Grundfos pm 2 pressure regulation system can be powered by gasoline powered generators.

Popular models and features of Grundfos pumps

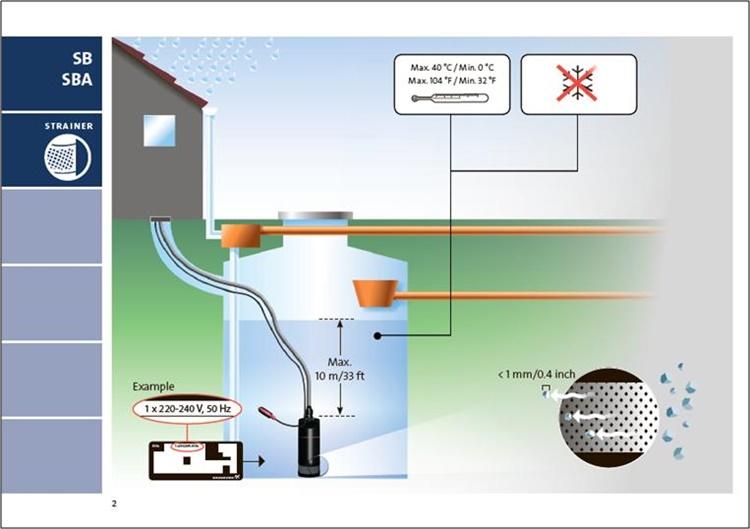

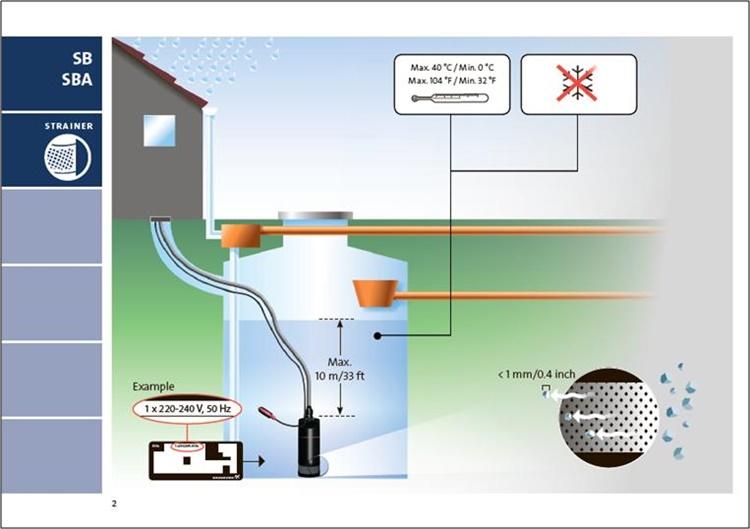

The most popular models are the SB and SBA series, as well as the SPO. The most commonly bought SBA 3 45 AW Grundfos. Their purpose is to constantly pump water from wells or containers. Most SBA models have built-in flow lock sensors and pressure switches. They have effective overheating protection: water jacket and thermal relay. Composite materials and stainless steel are used for the manufacture of units. The pumping equipment is quiet in operation.

The SBA 3 45 AW pumps are equipped with a float filter. It is a fine mesh with cells of 1 mm in diameter, which prevents the absorption of solid particles together with water. The devices are easy to install, the design is distinguished by minimalism.

The difference between SBA and SB is that the SBA series are equipped with a pressure switch, while the SB is supplied without it. All other additional equipment for adjustment, automatic control to SB can be selected separately. On the SBA, in addition to the pressure switch, a float switch, a regulation and control system are initially installed.

Characteristics of the SBA and SB series pumps. The difference is the presence of a pressure switch.

SQ Series Well Pump

The body is made of an aluminum-cast iron alloy and has an anti-corrosion coating. Other parts are made of glass fiber polyamide. There are permanent magnets in the electrical circuit, which improves the performance of the motor. The upper thrust bearing prevents the impeller from moving upward at low pressure.

SQ series well pump.

Main technical characteristics:

- motors with a capacity of 0.7-1.85 kW;

- head 36-168 m;

- productivity 1.7-9 m³ / h.

Good technical performance is complemented by other advantages:

- Smooth start protects the engine from increased loads and wear.

- The thermal sensor protects against overheating.

- Fuses protect against voltage surges.

- The dry running system turns off the device if there is insufficient water level in the source.

The lineup is represented by the SQ and SQE lines. The SQ family has 1 options for a small summer cottage, a large cottage. The pump with a power of 1.65 kW delivers 30 l / min, creating a head of 140 m. The diameter is only 74 mm, which allows the device to be lowered into a narrow well.

For the SQ 2, certain parameters are optimized.The engine power is the same, but the performance is twice as high. The head is less - 80 m versus 140 m. The SQ 1 pump filters water, and the SQ 2 pumps liquid with sand. This equipment is suitable for production and business purposes.

The SQ 3 models have collected all the positive qualities of the series. They work with dirty water, and multi-stage filtration ensures the supply of clean liquid.

The SQE 1 series is distinguished by its high performance properties. Increased productivity, head, power. Supplied complete with a membrane tank, pressure gauge, pressure sensor, control unit.

SQE 2 pumps are universal, used for water supply and household needs. They have 2 working positions - vertical and horizontal. High resistance to low temperature, maintenance-free. With a 1.85 kW engine, the capacity is 50 l / min, the head is 150 m. The latest modifications have a capacity of 113 l / min.

Universal pump SQE 2, used in 2 working positions - vertical and horizontal.

Features of the KR series

Multifunctional pump Grundfos of the KP series.

The equipment is multifunctional. With its help, the land is watered, water is pumped, basements, lowlands are drained, drains are pumped out. The devices have a maximum capacity of 14 m³ / h and a head of 9 m.

The A1 index in the designation indicates a float switch in the design, AV1 - that it is vertical. If index M is present, there is no float.

The devices are made of chromium-nickel alloy. This allows you to work in an aggressive environment with alkali and acids. There is a dry run protection. It is possible to clean the base from dirt, small particles in order to maintain the working condition of the device. Grundfos KP pumps can pump, in addition to clean water, dirty and waste water. The maximum size of solid particles is 10 mm.

Peculiarities of using Grundfos SRO

SPO series equipment is installed on wells and boreholes. Among the well models are submersible and surface. The latter are mounted on the base plate. This modification is convenient to use to raise the pressure in the system. Submersible pumps have a filter located on the suction hose. This additionally purifies the water before it is fed into the water supply system, and allows the intake of liquid from the lowest level.

The device for a well of the SPO series.

Design features:

- the body is made of stainless steel;

- the presence of a starting capacitor for single-phase motors;

- horizontal and vertical working position (at any angle).

Maximum performance indicators:

- productivity - 6.4 m³ / h;

- head - 75 m;

- power - 0.75-1.2 kW.

Devices for a well with automatic equipment are protected from voltage surges and overheating.

Grundfos Upa pressure boosting systems and their design

Their common parameters will be the following mandatory characteristics:

- wet rotor;

- their cast iron body with an anti-corrosion compound;

- ceramic bearings.

The rest of the models may differ slightly.

Pump for increasing the pressure in the water supply system

Grundfos Upa 120

There is a dual-mode control switch here: manual and automatic. This is necessary in order to ensure the operation of the equipment regardless of the presence and serviceability of the pressure / fluid flow sensor. If there is no sensor, the manual (forced) mode is set for the device. If there is a sensor in the pipe, the pump will turn on in automatic mode only when the water flow exceeds 90 liters per hour.

This model does not come with a flow sensor. You will need to buy it separately. But this installation can be used to connect to the water supply system directly and for open water systems.

The noiselessness of the device is achieved due to the internal cooling of the rotor, and, therefore, the absence of a fan. Therefore, it can be installed in apartments and houses without worrying about additional sound insulation.

With its relatively low power of 235 W, the device is capable of generating a head up to 13 meters. And the protection of the cable against short-circuits reliably protects the operation of the electric motor.

Uninterrupted operation is guaranteed at air humidity up to 95% and air temperatures from +2 to 40 ° С, in the range of water heating from 2 to 60 ° С and at a minimum pressure of 0.5 bar on the branch pipe. Water consumption during normal operation is up to 2.8 cubic meters per hour.

Grundfos UPA 15-90

The model 15-90 grundfos pressure boosting pump can be used for direct piping installation due to its in-line design. Built-in protection against running without water (dry running) automatically turns off the pump in case of interruptions in the water supply.

Three-position terminal box: full shutdown (OFF), automatic turn-on with installed water flow sensor (AUTO) and manual control of the system (MANUAL), which puts the unit in forced operation mode.

In this model, unlike the 120th, there is a built-in sensor, which is also called a flow switch. The noise level peaks at 35 decibels. The pump is designed without the use of oil seals. The rotor type is wet. The installation type of the device is vertical.

The power of the device is 118 W and the head is 8 meters with a throughput of up to 1.5 cubic meters per hour. The maximum water temperature is 60 ° C. The system is equipped with protection against voltage surges and overheating due to an increase in water temperature, and automatically monitors the water level in the device.

Rules for installing a pump to increase pressure

What you need to remember when connecting any pump:

- be sure to ground the connector;

- squeeze out excess air;

- turn on for the first time in auto mode.

Recommendations for installing a submersible pump

The following recommendations are very important for the correct installation of the borehole pump. HDPE pipe must withstand 16 ATM and have a wall thickness of at least 3.2 mm. The market offers customers products that can withstand 8 or 10 atmospheres and with a wall thickness of 1.8 to 2.4 mm. Suppose we have a column of working fluid 10 meters high, which, according to the laws of physics, creates a pressure of one atmosphere. When the pump is not running, the pressure in the pipe remains at the level of 10 ATM. But as soon as the apparatus starts to work, it will create additional pressure in the system of the order of 3-4 ATM. A HDPE pipe designed for 10 ATM will not withstand excess pressure and will swell. As a result, the pump will burn out, which will be impossible to get out of the well. We'll have to drill a new well. They wanted to save money, but got additional costs.

We talked about how to repair submersible pumps in an article on this issue.

The image shows examples of a substandard product and a high atmospheric clutch that were purchased from the market.

If you do not understand all the intricacies of installing a borehole pump, use the services of specialists. They will competently and quickly prepare the well, select high-quality equipment, taking into account your requirements and wishes.

Control cabinets

They are installed to control groups of pumps operating in heating complexes and complex water supply systems. Controller for the pump, which in the drawings will be designated as a module of different series (cu 100, cu212, cu 300, cu 301, cu 352).

For example, the Cu 100 model control cabinets in a plastic casing, which provide an IP 54 protection level, are suitable for single-phase (up to 9 A) and three-phase (up to 5 A) pumps. Cu 100 for three-phase motor are supplied with a float switch as standard.

The electronic equipment of the Grundfos Cu 212 is equipped with liquid level indicators and can be operated alternately with two pumps.The emergency warning system is triggered by an audible signal. The device can work in automatic and manual mode.

Grundfos Cu301

The device provides complete control and management of the entire pump system. It makes it possible to control devices remotely using the remote control and monitor possible emergency situations that may arise due to overheating or overvoltage. This system is designed for well pumping equipment.

Automation Grundfos Cu301 in the water supply system

Comprehensive protection devices are designed to monitor voltage surges, monitor overloads and overheating. The automation unit is designed for two versions of pumps (one and three-phase) with a voltage range of 3-120 A (if an external transformer is connected). The devices can operate flawlessly at temperatures ranging from -20 to + 40 ° C.

Automation for heating systems

Alpha 2 grundfos are specially designed for use in hot water and heating systems. The pump casings are made of stainless steel and equipped with frontal control panels.

They work in "auto" mode in order to independently adjust the level of productivity depending on the needs of consumption at different times of the day.

Grundfos submersible pump automation

Grundfos submersible well pumps can be fully realized with automation. The main device is a pressure switch. With its help, the operation of pumping equipment is regulated: turning on and off the electric motor when a given pressure is reached. Settings are made manually or automatically.

An important function of automation is protection against equipment operation in the absence of water. This will cause the engine to overheat and fail.

A critical drop in the liquid level occurs:

- in sources with a low flow rate;

- in tanks with limited volume;

- with high pump performance.

To protect equipment from dry running, various types of automation are used:

- Float switch. The sensor is connected to the gap in the phase of the motor power supply. When the water level drops, the contacts open, the pump turns off.

- Pressure sensor in conjunction with a hydraulic tank. If the critical point of 0.5 bar is reached, the power is cut off. Restarting is only possible manually.

- Flow switch. A sensor is connected to it, which reacts to the flow of water. If it does not pass, the pump turns off.

Turning on the pump after dry running or draining water may cause water hammer. Liquid hits the impeller, possibly damaging it. There is comprehensive protection against water hammer, which includes a check valve, a hydraulic accumulator with a pressure switch.

Submersible pump automation - pressure switch.

Most of the breakdowns are related to the electrical circuit. A strong drop or a large voltage surge can cause an interturn short circuit in the winding. Electric motors have built-in protection. When the indicators go beyond the normal range, the system turns off. If there are frequent power surges, it is recommended to install a softstarter.

For Grundfos pumps, the third generation automation has been developed and produced.

It is designed to perform the following tasks:

- maintaining a given water level;

- protection of the electric motor from dry running and critical voltage changes;

- shutdown of equipment in extreme situations;

- start-up after restoration of normal conditions;

- smooth start and stop of the engine;

- blocking of switching on when closing.

Connection methods

Electrical connection with plug and socket. This method involves installing an electrical outlet in close proximity to the place where the circulation pump is installed. Sometimes they can come with a connected cable and plug included, as in the photo:

In this case, you can simply plug the device into the mains using an outlet located within the reach of the cable. You just need to make sure that there is a third, grounding contact in the outlet.

In the absence of a cord with a plug, they must be purchased in addition, or removed from an unused electrical appliance

Pay attention to the cross-section of the conductors of the cord. It should be between 1.5 mm2 and 2.5 mm2

The wires should be copper stranded to resist multiple bends. A cord with a plug for connecting electrical appliances to the network is shown in the photo below:

Before connecting the circulation pump, it is necessary to find out which of the three wires of the cord is connected to the grounding pin of the plug. This can be done with an ohmmeter, while checking the integrity of the remaining wires.

Open the terminal box cover. There are three terminals inside the box, designed to connect the device to the network, with the designation as in the picture:

We unscrew the clamp of the cable box (in the first photo it is a plastic nut into which the cable is inserted), put it on our cord, put the cord into the box. If there is a cable clamp inside the box, thread the cord through it. We connect the ends of the wires of the cord pre-stripped from insulation with the terminals.

You need to connect the wires connected to the plugs to the L and N terminals (do not be afraid to mix them up, this is not critical), to the PE terminal you should connect the wire of the grounding contact of the plug (but you cannot be mistaken here). The instructions supplied with the product prohibit using it without protective grounding. Next, tighten the clamp (if available), tighten the cable gland clamp tightly, and close the terminal box cover. The pump is ready to be connected to the mains.

Fixed connection. The diagram for connecting the circulation pump to the mains with grounding is provided below:

The requirements for the cross-section of the wires are the same as in the previous version. With this installation, the cable can be used both flexible and inflexible, copper, VVG, or aluminum, AVVG. If the cable is not flexible, the installation must ensure its stability. For this, the cable is secured with clamps along the entire route.

In this version, a residual current device (differential circuit breaker) is used. Instead, you can use a conventional single-pole circuit breaker, passing only the phase wire through it. If the machine is installed in a panel where there is a PE bus, then the cable from the pump to the machine must be three-core. In the absence of such a bus, the PE terminal should be connected to the grounding device. This connection can be made with a separate wire.

Separately, I would like to consider such an installation option as connecting a pump to a UPS. It is the most preferred and ensures the independence of the heating system from power outages. The connection diagram of the circulation pump to the uninterruptible power supply is provided below:

The power rating of the UPS should be selected based on the power of the pump motor. The capacity of the storage battery is determined by the estimated autonomous power supply time of the circulation pump, that is, the time when the power grid is disconnected. We talked about how to choose a UPS for a boiler in a separate article. Requirements for cable cross-section, as well as for the presence of protective earth, apply to all connection options.

Finally, we recommend watching video instructions for connecting various pump models to the electrical network:

Grundfos

Wilo Stratos-PICO

Connection diagram of the circulation pump to the thermostat

So we examined how to correctly connect the circulation pump to the mains. The diagram and video examples helped to consolidate the material and clearly see the nuances of the installation!

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but on the supply or return pipeline - it doesn't matter.Modern units are made of materials that can tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more "comfortable" temperature are untenable, but if you feel calmer, put it in the return line.

Can be installed in the return or direct pipe after / before the boiler before the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter at all whether there is a pump in the supply or return line. What matters is the correct installation, in terms of strapping, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If the heating system has two separate branches - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule remains on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each part of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first, and much less heat is required there. In the presence of two pumps in the branch that goes up, the speed of movement of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. Nevertheless, less heat is still much better than its complete absence, because in areas where electricity is often cut off, the system is designed as a hydraulic system (with natural circulation), and then a pump is cut into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with underfloor heating are compulsory - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since the forced circulation heating system is inoperative without a pump, it is installed directly in the break in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer-sump must be installed in front of the unit.

Installation of a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is placed on the bypass, which is closed, all the time while the pumping is running. In this mode, the system works as a forced one.

Installation diagram of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the crane on the lintel is opened, the crane leading to the pump is closed, the system works like a gravity system.

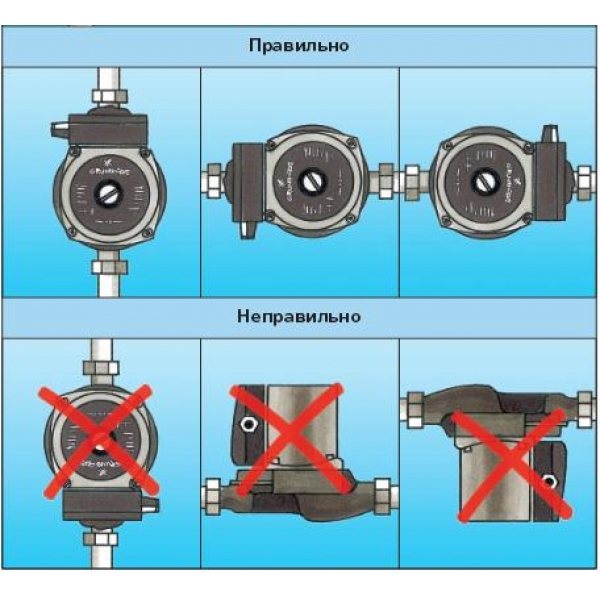

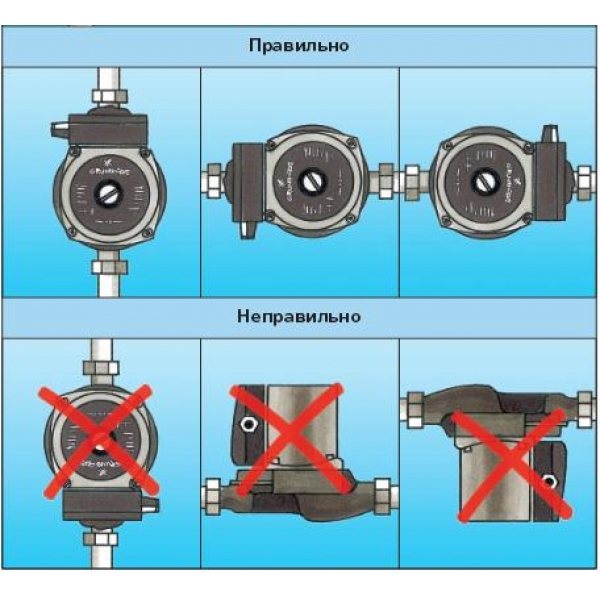

Installation features

There is one important point without which the installation of a circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow.There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Circulation pump Grundfos Alpha 2, as a reserve for increasing the efficiency of the heating system

- the main

- Articles

- Circulation pump Grundfos Alpha 2, as a reserve for increasing the efficiency of the heating system

12.01 2016

On this site, we regularly publish articles about the main elements of modern heating systems: heating boilers, radiators, pipes, expansion tanks. Now we will talk about circulation pumps and what requirements are imposed on them.

As already mentioned several times, the main disadvantage of a natural circulation heating system is the low circulating head of the coolant and, as a result, the increased diameter of the pipes. It is enough to make a slight mistake with the choice of the pipe diameter and the coolant will be "clamped" and will not be able to overcome the hydraulic resistance. It is possible to "unclench" the system without any significant alterations: turn on the circulation pump in it and move the expansion tank from the supply to the return, although the transfer of the expander to the return is not always necessary. With the correct reconstruction, the tank is replaced from open to closed.

What power should the circulation pump be and how and where to install it?

Circulation pumps for domestic heating systems have a fairly low energy consumption of about 60-100 W., and modern pumps of class "A" (for example, Grundfos Alfa 2) consume from 5 to 45 W. In general, circulating pumps do not raise the water pressure, but only help it overcome local resistances in the pipes. These pumps can be compared to a propulsion device (propeller) of a ship: the propeller pushes the water and ensures the advancement of the ship, but at the same time the water in the ocean does not increase or decrease, i.e. the overall water balance remains the same. The heating system is a closed loop and the amount of water in it remains constant.

The inclusion of a circulation pump in the heating system makes it possible to significantly increase the range of the heating system, reduce the diameter of pipes, introduce full-fledged automation, which saves fuel and creates comfortable conditions for a person. A pump installed in the heating system sucks in water on one side and pumps it into the pipeline on the other due to the centrifugal force that occurs when the impeller rotates - a vacuum occurs in the inlet pipe, and compression occurs on the outlet pipe.

To ensure the silent operation of a forced circulation heating system, it is necessary to carefully match the water flow rate and the diameter of the pipelines.

| Consumption l / min | 5,7 | 15 | 30 | 53 | 83 | 170 | 320 |

| Diameter inches | ½ | ¾ | 1 | 1¼ | 1½ | 2 | 2½ |

To ensure the noiselessness of the system and the delivery by it of the required volume of the coolant, it is necessary to make a small calculation.

The optimal flow rate of water passing through the boiler, recommended by many firms - manufacturers of boiler equipment, is calculated using a simple empirical formula Q = P, where Q is the flow rate of the heat carrier through the boiler, l / min, P is the power of the boiler, kW. That is, for a 30 kW boiler, this will be 30 l / min, which means that the diameter of the pipe suitable for the boiler will be 1 inch, according to the "noiselessness" table that we give. Similar calculations are valid for radiators.

We determine the power of the circulation pump by the water consumption. For every 10 meters of circulating ring length, 0.6 meters of pump head is required. For example, if the total length of the pipe ring is 90 meters, the head should be 5.4 meters.This is the reason for looking for such a pump in catalogs or go directly to the store, where the sales consultant will pick it up for you. If pipes of smaller diameters than recommended are used, then the pump power must be increased. Since the thinner the pipes, the greater their hydraulic resistance. And accordingly, when using pipes of a larger diameter, the pump power can be reduced.

In order to ensure constant circulation of water in heating systems, it is advisable to install at least two circulation pumps - one of which is working, the other (on the bypass) is backup. Or one pump is installed, and the other should always be at hand, in case of replacement if the first breaks down.

It should be noted that the calculation of the heating system given here is extremely primitive and does not take into account many factors and features of the individual heating system. Most likely, this calculation is given for understanding the physics of processes in the heating system, taking into account the circulation pump in the heating circuit. In real life, heating engineers are involved in calculating the heating system.

The circulation pump in the heating system is filled with water and experiences equal (if the water is not heated) hydrostatic pressure from both sides - from the inlet (suction) and outlet (discharge) nozzles connected to the heat pipes. Modern circulating pumps made with water-lubricated bearings can be placed both on the supply and return pipelines, but most often they are placed on the return line. Initially, this was due to a purely technical reason: when placed in colder water, the service life of the rotor bearings and the stuffing box through which the pump shaft passes increases. And now they are put on the return line rather out of habit, since from the point of view of creating artificial water circulation in a closed loop, the location of the circulation pump is indifferent.

So, for the correct selection of the pump, a number of parameters must be taken into account:

- Maximum head (m) - the maximum height to which the coolant must be raised. The head is responsible for supplying the coolant to the top point of the heating circuit and overcoming the hydraulic resistance.

- Maximum flow (m3 / hour) - the maximum possible volume of the coolant that needs to be pumped per unit of time at full load of the system.

- Passage diameter of the pipe, DN (mm) to select the diameter of the pipes for installation.

- The chemical composition of the coolant is water, antifreeze liquid or a mixture of these. If the pump is used to pump a fluid that is more viscous than water, the performance of the hydraulic system is reduced. Therefore, the correct selection of the pump must be done taking into account the viscosity of the pumped liquid.

Consider an example of a pump operating with an anti-freeze liquid - ethylene glycol, which has a 2-4 times higher viscosity than water. The pump, all other things being equal, will require a more powerful one. It was empirically found that the headroom should be increased by 50-69% and by 10-15% in productivity. Here we omit, and the fact that the power of the radiators must also be increased due to the fact that the heat capacity of ethylene glycol is inferior to water. In addition, there is a risk of depressurization of the system due to the high fluidity of ethylene glycol, etc. Of course, the owner of the heating system does not fill the system with an anti-freeze, not from a good life. He is afraid that in the event of a prolonged power outage, his system will defrost. Modern trends in heating technology imply the presence of an uninterruptible power supply (UPS) in the configuration of the heating network. In this case, the lack of electricity will be compensated for by the energy stored in the UPS batteries.

Selection of the pump for the maximum head

The pump specifications usually indicate the maximum head.Some are guided precisely by this figure, although this is not entirely correct. If you look at the graph reflecting the pressure-flow characteristic (on this graph, the operating point of the pump is selected), you can see that at the maximum head, the flow is zero. The duty point is calculated based on the lift height and the required flow rate. The pressure that the pump should create is determined as the sum of the resistances of the pipeline, radiators, valves throughout the heating system at a given flow rate of the coolant.

It will not be possible to choose the circulation pump you need 100% - each heating system has its own characteristics, and the pumps are a serially produced product with average parameters. If you have a pump with excess power than necessary, you will get noise in the pipes. Modern pumps have several operating modes (3-position speed switch). Empirically, you can choose a mode when the pump starts to work efficiently, but there is a class of electronic circulation pumps that adapt to the operation of the heating system themselves, and this will be discussed below.

Modern smart pumps

The term “smart home”, which is widespread today, implies the use of a new generation of technology that has additional functions and capabilities that are classified as “intelligent”. For example, the new AUTOADAPT automatic adaptation technology allows the Grundfos Alpha 2 pump to recognize the requirements of the heating system and precisely select the required setting for operation. And the "night mode" function automatically reduces the engine speed to a minimum, when at night the heating boiler transfers the heating system to an economical mode with a decrease in the temperature of the coolant. Also, the homeowner at any time can find out about the amount of energy consumption and the state of the heating system thanks to the LED indicator that this pump is equipped with.

As an example, consider: a heating system with a conventional Grundfos circulation pump, model UPS 25-40, which has a 3-position mechanical speed switch.

In a ready-assembled system, this pump is correctly selected according to its pressure-flow characteristics, at the selected speed level it will work correctly throughout the entire heating period, which includes both frost and thaw. But the load on the heating system throughout the year is uneven and uneven, and work at full capacity is required only during the coldest days of the year, and the rest of the time, resource consumption can be limited. In addition, radiators with thermostats, underfloor heating that change the hydraulic resistance, which is compensated by the pressure, contribute to the variable flow rate of the coolant. It would be most reasonable to replace the existing circulation pump with an electronically controlled pump. Theoretically, of course, you can try to switch the pump speed steps yourself, based on the changing situation as the load on the heating system changes, but:

- It is difficult to guess the optimal step for a particular moment in time.

- There are only three steps and the tuning will not be very precise.

- The switching process will be fairly frequent.

In contrast to the traditional circulation pump with mechanical speed changeover, the energy efficient electronic circulation pump Alfa 2 automatically adapts to each specific heating system and selects the optimal operating mode. This analysis is performed regularly, regardless of the season, the most appropriate settings are selected. When the boiler switches the heating system to economy mode and lowers the temperature of the heating medium, the pump "night mode" function automatically reduces the engine speed to a minimum.

In Grundfos Alpha2 and Alpha2L variable speed pumps, by controlling the speed, the head can be changed proportionally or kept at a constant level and reduce the head in response to a decrease in heat consumption. When the heat demand decreases, the thermostatic valves close and this leads to a decrease in the flow rate and an increase in the pump head.

If, for example, an unregulated pump is installed in the system (standard three-speed, operating at a constant speed regardless of the heating demand), then when the thermostatic valve is closed, the pressure drop across it increases due to the increase in the pump head in the area of low performance. This increased pressure drop across the valve leads to a local increase in the water velocity, which in turn causes an unpleasant cavitation noise. And if a variable pump is installed in the system, for example, the Grundfos Alpha 2 model, then with a decrease in the pump flow, the pressure in front of the valve will drop and thus there will be no cavitation noise, and the coolant supply will correspond to the real demand of the system. Accordingly, by reducing the head, variable pumps reduce energy consumption.

Grundfos Alpha2 circulating pumps

Since October 2020, Grundfos LLC has begun supplying updated ALPHA2 circulation pumps with extended functionality, and at the same cost!

The updated ALPHA2 have the following advantages over the previous version:

- Built-in dry-running protection with automatic restart extending pump life.

- Summer mode function that automatically protects the pump and check valves from souring during the summer season.

- Improved starting performance capable of starting the rotor even if the pump is blocked after a long period of inactivity.

Purpose The GRUNDFOS ALPHA2 pump is suitable for:

- Fixed or variable flow systems;

- One-pipe systems;

- Two-pipe systems;

- Underfloor heating systems;

- Recirculation of water in hot water supply systems;

- Systems in which it is necessary to reduce performance during the night;

- Energy consumption and consumption indication;

- Improved hydraulics;

- Compact dimensions;

- Instant network connection with ALPHA plug.

Specifications

Flow rate (Q): up to 3 m3 / h Head (N): up to 6 m Pumped liquid temperature: from 2 ° C to 110 ° C

The main difference between Alpha2 L and Alpha2 circulation pumps is the number of intelligent operating modes. The Alpha2 L models, in this sense, are simplified versions of the Alpha 2 series. Alpha2 pumps, in contrast to Alpha2L, have some more advantages - cataphoresis coating of the flow path, which makes this part of the pump more corrosion-resistant and improves hydraulic characteristics. includes a heat-insulating casing.

With the new ALPHA2, you don't have to worry about complicated pump settings. It is enough to install the pump and leave the factory settings using the AUTOADAPT mode. In this case, the pump automatically adjusts its characteristic in the set performance range, while the following occurs:

- adjustment of the pump characteristics according to the size of the system;

- adjustment of the pump characteristics in accordance with load fluctuations over time. In AUTOADAPT, the pump is set for proportional control.

The updated ALPHA2 will automatically analyze the heating system, find the optimal operating point and, as the needs of the system change, will continue to adjust its work.

On the operating characteristic (Q / H) the following are highlighted:

Red - regulation curves with low, medium and high head values (CP1-CP3).

In yellow, proportional control curves from low head to high (PP1-PP3).

Blue color - fixed speed (I - III)

Night mode function

automatically reduces the pump pressure when the heating boiler switches to an economical mode of operation. When a temperature drop of 10-15 ° is registered in the discharge pipeline, within approximately 2 hours, the Alpha2 pump automatically switches to night mode (and the rate of temperature decrease must be at least 0.1 ° C / min.) When the temperature (in pressure pipeline) will rise by about 10 ° C, the pump will return to normal operation. It is important to note that the pump must be installed in the flow line!

The Alpha2 pump display has eight light fields (2) indicating pump settings.

The Alpha2 has a separate power consumption indicator light (1) that shows in real time the current power consumption (in watts). There is also a separate indicator light on the display indicating the state of the night mode (3) and a button for activating the night mode function (4). The Alpha2 pump has a built-in flow sensor and the current flow is also shown on the pump control panel (display). All operating modes are controlled by pressing one key (5), the button for selecting pump settings.

To the list of articles

Other articles

16.05 Energy efficient water heaters HAJDU

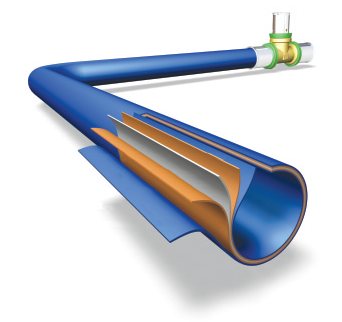

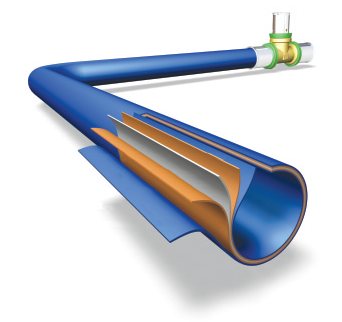

28.12 "Superpipe" in the service of the people. Pipes made of cross-linked polyethylene produced by METZERPLAS (Israel)

21.11 Cast-iron radiators RETRO are always in demand The solution of modern heating in the style of antiquity and sophistication can be a cast-iron radiator, artistic casting of which was created according to drawings and drawings of the turn of the century.

25.10 Overview of Bosch instantaneous gas water heaters

Basic rules for installing the pump

When installing an electric pump for heating, one must remember to observe a number of important rules:

- ball valves must be fixed on the sides of the pump. If it is necessary to dismantle the pump, using ball valves, the likelihood of the coolant leaving the system will be excluded;

- a filter cuts in front of the pumping device. This is necessary to protect the device from various particles that are present in the coolant;

- there must be an air valve at the top of the bypass. It will remove the air accumulated in the system. You can choose automatic or manual valve type;

- threaded connections must be made with gaskets and sealant. This is necessary to avoid leaks;

- there is an arrow on the pumping device that shows the direction of movement of the coolant. This direction must be observed during the installation process;

- to make the process of using the pumping device completely safe, connect the device only to a grounded outlet. Therefore, before installing the pump, a number of steps are required to ensure grounding.

An electric pump is connected to heat the house according to the following algorithm:

- choice of location. The connected pump needs periodic maintenance. You also need to ensure that there is access to the mains. Therefore, the location must be chosen taking into account these factors. Of course, proximity to the mains is not a requirement: you can extend the mains power cable to the required installation location. But this will create additional inconvenience. It is best to install the pumps at the entry point to the expansion tank. Thus, it is possible to achieve the highest possible temperature indicators in a given place;

- if the pump is installed in an existing network, the coolant must first be drained. If the heating system has been in operation for a long time, it must be thoroughly cleaned of accumulated dirt inside. To do this, fill it with water several times and then empty it;

- the installation of the pump and the functional chain of fittings is carried out in accordance with the rules described above;

- when the installation process is completed, the heating system must be filled with coolant again;

- now you need to check the system for performance.For example, if the heating pump does not turn on, there may be some problem with the power supply. It is necessary to check the fuses and phases. If everything is normal, the drive winding is probably burned out. All errors at this stage should be corrected;

- after that you need to open the central screw. It is located on the case cover. This procedure is necessary in order for the excess air to escape from the pump. When the water comes out, then everything is in order: the air is completely removed. It should be noted that the manual pump should be vented every time before turning on the device.

Knowing how to put an additional pump in the heating system, you can easily do this procedure yourself. Positive changes in the use of a heating system with an embedded pump are noticeable in the first days of operation.

It is better to buy a pump for an automatic heating boiler. In this way, you can protect the device against misuse. When connecting equipment to the network, it is better to use an automatic fuse with a flag, which will perform two functions: a fuse and a switch. Install the fuse at a distance of more than 50 cm from the boiler.

It is possible to install the pump in a heating system where there is already one pump. But here we must take into account some of the nuances. The pumping device turns on when the thermal relay is activated.

In order for both devices to work synchronously, the second device must also be connected to a relay.

An additional pump can be connected to the main one by means of a parallel connection. Knowing how to connect the heating pump to the mains, this will not be particularly difficult.

Most often, pumping equipment operates from 220 volts. But there are units operating from 380 volts. Today on sale you can also find a 12 volt heating pump with a smooth speed variator. Such units are irreplaceable if there is no possibility of connecting to a 220 volt power grid. Thanks to the electronic speed variator, the pump turns on smoothly, it is possible to set the exact parameters of the device. But still, a 12 volt heating pump is used extremely rarely.

Distinctive features of circulation pumps

Each modern model has its own special technical characteristics of the Grundfos circulation pump. Thanks to the timely acquaintance with the properties and parameters of a particular model, you will save your time, which could be spent on searching and checking similar equipment purchased in the store. Grundfos is a famous Danish company that manufactures pumps.

The most attractive thing about Grundfos models is their small size and relatively low weight. These parameters of the Grundfos pump will simplify installation and placement in any room size.

Installing a circulation pump in the heating system near living rooms will not create any inconvenience. The consumption during operation of a small power of electric current determines the efficiency of heating. In addition, the developers offer some pump models that do not require special installation. Self-installation of pumps from the Grundfos company will not be difficult. Since, especially for such cases, on the Internet, you can easily find detailed video instructions with step-by-step installation of the pump

Overview of technical specifications

You can get an idea of the technical characteristics of the device using the example of one of the manufacturer's models, which can be pump Grundfos UPS 25-40CTThis device is in high demand among the owners of country houses.

If you analyze the numbers present in the marking, then you can understand that the model is equipped with nozzles with a diameter of 25 mm, with a pressure of 4 m. This product is able to ensure the efficient operation of the heating systems of a one-story house.

In the event that the heating is presented in the form of a one-pipe system, then such a grundfos circulation pump will be able to successfully perform its functions in a two-story house.