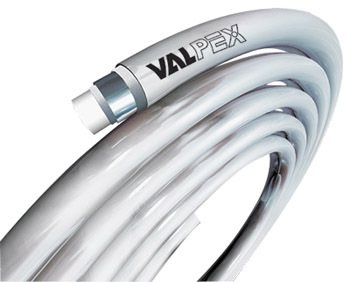

In order to conduct a hot water supply and heating system in the house, many use metal-plastic pipes. This high efficiency equipment has the necessary hydraulic and thermal characteristics for efficient operation. therefore metal-plastic pipes for heating, reviews of which are presented in this article, are so common

.

Advantages of pipes made of metal-plastic

Advantages of pipes made of metal-plastic

- they are resistant to corrosion;

- they can be easily bent, therefore, metal-plastic is often used in rooms with complex geometry;

- resistant to temperature extremes;

- pipes have a low noise level when water moves;

- metal-plastic is characterized by a small linear elongation when heated;

- pipes are easy to install, they can be laid both on the wall and on the floor;

- they have a low specific weight and large footage in bays (up to 500 m), which allows laying a pipeline in areas without the use of connections;

- the surface of the pipes is chemically inert, so the risk of mold growth is minimized;

- long service life (more than 20 years);

- acceptable price.

Disadvantages of a metal-plastic pipeline

In addition to a large number of advantages, this material also has its disadvantages:

- polymer pipes are afraid of open fire and mechanical stress;

- metal-plastic is not recommended to be kept in direct sunlight, ultraviolet light has a detrimental effect on the surface of the pipes;

- during installation, some problems with the connection may arise, the inner diameter of the thread of the fitting is smaller than that of the pipe, so the holes can overgrow over time;

- during the installation of the threaded fitting, there is a possibility of the pipe being pinched by the nut, which can lead to rupture;

- metal-plastic is afraid of kinks, crushing, chemically active substances.

The choice of diameter when installing heating

Most often, among the proposals, you can find pipes made of metal-plastic, for which the outer diameter varies from 16 to 63 millimeters. The wall thickness can be varied from 2 to 3.5 mm. Which pipes are best to use depends on the maximum pressure.

When marking, two values are often used - the outer diameter with an indication of the wall thickness or the inner diameter.

If we consider the main options for execution, then all pipelines for a private house can be divided into several groups:

- the outer diameter of 16 and 20 mm is most often used as a drain when supplying hot water to faucets in the bathroom and in the kitchen;

- a cross-section of 26 and 32 mm along the outer circumference of the pipe can be used for installing a "warm" floor system and organizing heating distribution when working with low pressure flows;

- external diameters of 40 and 50 mm are perfect for creating the basis for individual water supply and heating systems in a private house.

Features of the structure of pipes. Specifications

Water supply and heating metal-plastic pipes are composed of 5 layers:

- inner polyethylene makes the product smooth, and also prevents the growth of bacteria and the accumulation of harmful substances;

- 2 adhesive layers connect aluminum and polymer;

- aluminum foil, which gives the pipeline hydraulic resistance and oxygen impermeability;

- the outer layer of polyethylene endows the pipeline with high temperature resistance, and also protects against mechanical stress.

Reinforced-plastic pipes do not contain substances harmful to the human body, therefore, such a pipeline is used in drinking water supply systems.

In order to install heat channels in accordance with all the rules, you need to comply with technical standards and take into account the features of metal-plastic pipes. Main parameters:

- the pipeline can function effectively at a coolant temperature of no more than + 95 ° С;

- the maximum pressure value that must be created at temperatures from 0 to 25 ° C is 25 bar, at 95 ° C - 10 bar.

Compliance with these technical parameters guarantees the service life of pipes from 40-50 years.

Marking

Marking

- pipeline diameter;

- polymer type: polypropylene (PP-R); polyethylene (PE-R); heat-resistant polyethylene (PE-RT); high-strength cross-linked polyethylene (PE-X);

- nominal pressure (PN);

- type of pressure stitching (a, b, c, d);

- batch number;

- production date, etc.

Before purchasing metal-plastic pipes, each buyer has the right to request a quality certificate for the goods sold.

Characteristics of polypropylene pipes

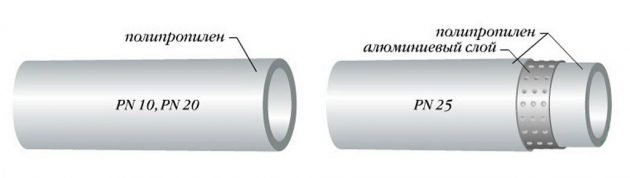

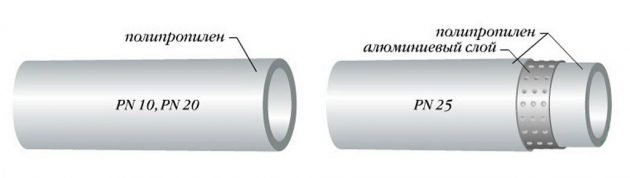

Globally, polypropylene profiles have only two types:

- Single layer. When drawing the pipe, monolithic polymer compounds are used.

- Three-layer. They are also called reinforced due to fiberglass reinforcement or polypropylene layers separated by a foil interlayer. They are often confused with metal-plastic.

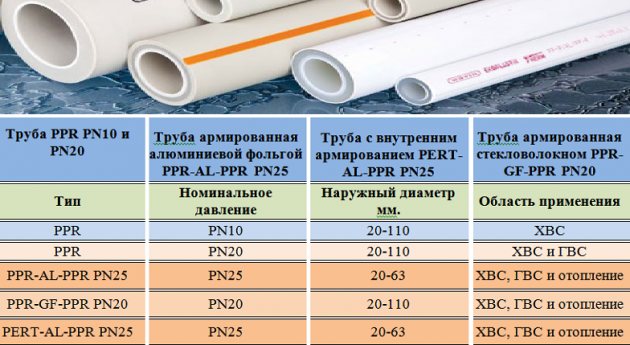

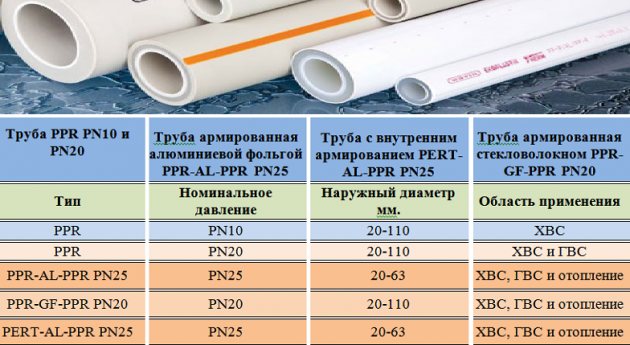

Types of polypropylene pipes

Both are classified and marked depending on the purpose and material of manufacture. PP is printed with the general index. The next letter in the marking:

- H - cold water, material of manufacture - polypropylene homopolymer.

- B - universal block copolymer-polypropylene for cold and hot water.

- R - polypropylene random copolymer - suitable for hot water and heating systems installation.

- S - fire-resistant polypropylene is the most heat-resistant variety.

All hot water pipes are suitable for summer plumbing and cold water supply.

Types of polypropylene pipes

General characteristics of polypropylene pipes:

| Property | Value, unit rev. |

| Maximum allowable pressure | Up to 2.5 MPa |

| Maximum temperature | 70 95 0C |

| Thermal conductivity of walls | 0.15W / (m * 0C) |

| Operating temperature | up to 120 0C |

| Roughness | 0,015 |

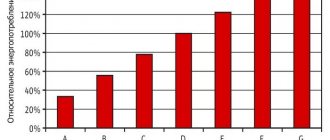

| Expansion coefficient versus temperature single layer reinforced | 0,15 0.3-0.07 (depends on the reinforcing material) |

| Life time hot cold | 50 years 100 years |

Pipeline connection methods

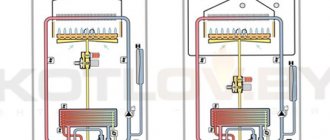

Installation of metal heating pipes involves the use of one or another installation method. To connect the pipeline, you will need a welding machine and special parts: couplings, fittings, elbows, tees, etc. There are three main connection methods: press fittings, crimp fittings and detachable elements.

The first method assumes that the master has a hand or electric pistol, which will come in handy during installation. The press fitting is a sleeve inserted into the body. With the help of a special device, spinning is performed. These fittings look quite attractive on the outside, so pipes do not need to be laid under walls or floors. The disadvantages of this connection method is that the fittings have a high cost in comparison with their counterparts. Plus, it is impossible to dismantle the part without violating the integrity of the structure.

The essence of the installation of crimp fittings is that at the place of the pipe joint, the ring is attached and tightened with a nut. For installation in this way, you may need the following tools:

- to clean the ends of the pipes, you must use a beveller;

- to fix the fitting - wrenches;

- to change the direction of the heating channel, a pipe bender is useful;

- pipe cutter.

Compression fittings provide a detachable connection and can be reused after dismantling old pipes. And the cost of such parts is much lower than press fittings. On the negative side, it can be noted that the crimping elements need to be constantly tightened. For prevention purposes, this should be done 3-5 times a year, if the joints of the pipes are leaking more often. Another significant disadvantage is that the pipes must be constantly accessible. Therefore, it will not work to mount them in a hidden way.

The most expensive are threaded or collet fittings. Thanks to the detachable part, they can be repeatedly undocked from different parts of the pipeline and devices. Compression and detachable fittings are used for open pipe laying, used for installing a radiator system, for connecting to manifolds and when docking with valves.

The above parts are available in different metals: bronze, brass and plastic. Usually, they use cheaper options made of plastic. But they all connect the ends of the pipeline equally well.

How to choose pipes for use in a centralized heating system

Now on sale there are many brands of metal-plastic pipes intended for space heating systems. However, choosing to advise a specific brand is not always correct, you should always pay attention to the technical characteristics of the product, that is, to the declared operating parameters of pressure and temperature in the system. It goes without saying that the higher the latter, the better.

We recommend: How to install a heat meter for a house with central heating?

The next question is what pipe diameter to choose. Let's say right away that it must be larger than that of the same steel pipe that could have been installed in this place. So, pipes with a diameter of 32 or 26 millimeters are taken for risers, but 26-mm products can also be used for piping to radiators. The thing is that the marking of a steel pipe (DN) is a conditional bore, which usually corresponds to the inner diameter. While for metal-plastic pipes, the outer diameter is taken into account. This means that the useful section of the latter is reduced taking into account the thickness of the walls.

The useful section also decreases on the fittings. After all, the main element of the latter is a fitting inserted into the pipe.

Installation of metal-plastic pipes

Installation of metal-plastic pipes

- press tool;

- round file;

- pipe cutter or scissors for cutting metal;

- spanners;

- pipe bender or spring;

- calibrator.

Installation of heating from metal-plastic pipes takes place in several stages.

- First, using special scissors, the pipeline is cut into sections of a certain length. Do not use other tools, as the edges can be sharp and uneven, which can subsequently lead to leakage.

- Further, with the help of improvised means (drill, round file), a sharp edge is removed, which is located inside and outside the pipeline. If this is not done, the metal bends can damage the rubber O-ring of the fitting, leading to a leakage of the connection. To get perfectly straight pipe edge shapes, you can use a calibrator.

- A rubber band is installed on the fitting nipple, with which a seal is made. In order not to damage the rings, it is recommended to flare the pipe during calibration.

- Next, a nut and a clamping clamp are put on the pipe.

- The end of the pipeline is flared and pushed onto the nipple of the fitting.

- Next, the fitting squeegee is leveled and the clamping collar is returned.

- At the end of the installation, tighten the nut. This should not be done in full force, when the crackling sound appears, you can release the key.

After all the manipulations, it is necessary to check the heating system for leaks.

... It is necessary to fill the pipes with water and create a pressure that exceeds the operating pressure by 1.5–2 times. Air vents must be open. It is recommended to run water into the system slowly and evenly.

Recommendations for the installation of metal-plastic pipes

Installation recommendations

- you need to work with gloves, observing safety precautions;

- installation should be done only with serviceable tools;

- metal-plastic is a combustible material. Extinguishing media can include sand, foam and water spray;

- in no case should the pipes be thrown from a height and dragged;

- it is necessary to store the metal-plastic pipeline on a flat surface in a horizontal position, preferably in a closed room.

- installation can be started only after a complete inspection of the heating system and checking the components for flaws and deformations. The parts must be compatible with each other, it is advisable to study the regulatory documents and product quality certificates in advance.

Instructions for installing metal-plastic piping indoors

- Read the product labeling carefully before purchasing. The pipes must operate at a coolant temperature of no more than 95 ° C and a pressure of no less than 6.6 atm.

- Fasteners must be installed at a distance of 0.5 m from each other, otherwise the pipes may sag, which will lead to a violation of the circulation of the coolant.

- The reinforced-plastic pipeline is not recommended to be installed outside the premises. When the heating system defrosts, pipes can burst. Accordingly, the pipeline will have to be changed completely, which is very costly.

- The air temperature in the room should not be less than + 10 ° C. If the pipes were in frost, then before installation, the bay should stay at room temperature for at least a day.

- Open laying of metal-plastic is possible only in those places that are protected from direct exposure to ultraviolet rays, and the pipeline must also run away from open flames.

- Finishing work near the installation of the reinforced-plastic pipeline must be completed prior to installation.

- The rest of the fittings must be fastened separately without placing any stress on the pipes.

- In no case should you use sharp objects when marking.

- A broken pipe can be repaired with a wooden or rubber mallet.

- Twisting of the pipeline, deformations and lateral stresses must be avoided.

- In the longitudinal direction, the pipes require freedom, in the rest - fixation.

- The crossing of building objects is possible when using sleeves, the gap must be treated with a non-combustible material.

- It is important to ensure open access to screw connections and fittings.

Compliance with the above rules will ensure the efficiency of the heating system, and most importantly - safety.

Special properties

Lamination of a reinforced-plastic pipe

Before considering the disadvantages of heating from metal-plastic pipes, you need to objectively assess their negative sides. They are also a consequence of the use of polymeric materials and aluminum foil as a rigid base. Although they do not corrode, some types of pipes use a polymer that degrades when exposed to direct sunlight.

In addition, it is necessary to take into account the difference in thermal expansion of polymers and aluminum shells. When heated abruptly, the polyethylene layer will expand much faster than the foil. This will lead to delamination of the structure. Given this factor, the question arises - is it possible to use metal-plastic pipes for heating? Yes, but subject to the following operating conditions:

- Minimizing the manifestation of water hammer and sudden temperature jumps in heating;

- Concealed installation in those parts of the room where there is a high probability of sunlight hitting the highway;

- No surface tension, use of expansion loops to reduce the likelihood of rupture in the system.

Technical properties of metal-plastic pipes

To make a final decision, it is recommended that you familiarize yourself with the technical characteristics of metal-plastic heating pipes. To do this, you need to study the data in the table.

Despite the fact that during the installation of heating from metal-plastic pipes they can be bent, repeated deformation can lead to cracks or chips on the surface. This also needs to be taken into account during the execution of work.

As well as steel, metal-plastic pipes can collapse when exposed to negative temperatures due to the expansion of the liquid in them. In this case, it is necessary to insulate the line, as well as the installation of a heating cable.

Applications of metal-plastic pipes

Most often, this pipeline is used in the private sector for laying a heating system. In addition, it is used:

- in air conditioning installations;

- in engineering systems inside buildings under construction;

- when transporting liquid and gaseous media in industry and agriculture;

- in compressed air supply systems;

- to protect and shield other cables;

- when replacing old pipelines in buildings that are undergoing reconstruction.

Manufacturers of reinforced plastic pipes

Manufacturers of reinforced plastic pipes

The Henco product line includes not only heating ducts, but also the necessary connecting elements. The company has established itself as a reliable manufacturer; it has been on the market for over 10 years. Designers develop their own technologies for the production of pipes and fittings. The manufacturer produces the Henco RIX and Henco Standart pipelines. The main difference between them is the thickness of the aluminum foil in the structure. For a home heating system, the Henco RIX is suitable. The pipes will do a great job with the pressure, plus they are inexpensive.

The German brand Oventrop is considered the most reliable sanitary fittings of all. Despite the rather high cost, most homeowners choose it. Oventrop's main competitor is the REHAU pipe. The high-quality execution of the pipeline in conjunction with durable connecting fittings puts this manufacturer in the first place.

The cost of metal-plastic pipes is different, it depends on the size of the coil and the structure. Prices range from 30 to 300 rubles per running meter.