What is a Compression Fitting

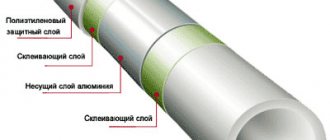

Installation of pipelines made of metal-plastic cannot be done by welding or gluing; for this, the method of mechanical crimping is used. There are two types of connections - one-piece and detachable.

For the first type, press fittings are used. Permanent connections are made mainly in closed engineering networks, mounted under the floor or in the wall. They do not require periodic maintenance. They are carried out using a special tool called press tongs.

Crimp, or compression, fittings are used for detachable connections, the most common today. Their execution does not require expensive tools, just a few wrenches.

Design features

Detachable connections are used, as a rule, for the installation of open pipelines, as well as for the connection of any working devices.

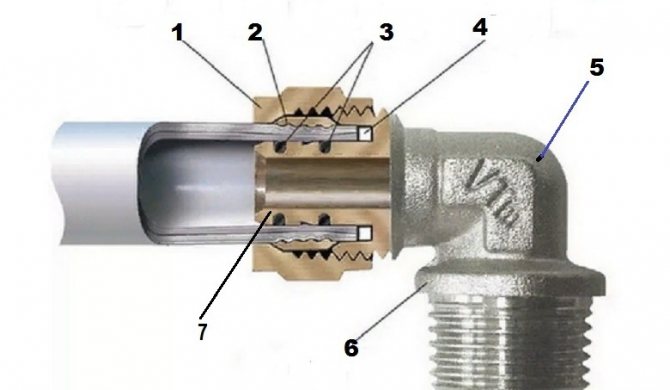

Compression fittings consist of the following parts:

- Union nut.

- Crimp ring (cracker, collet).

- O-rings made of E.P.D.M. (ethylene propylene diene rubber).

- Teflon dielectric gasket.

- Fitting body.

- Restrictive collar.

- Stock.

A suitably prepared metal-plastic pipe is put on the stock of the product. This is done all the way into the dielectric spacer, which is used to limit stray currents.

O-rings are used to enhance the tightness of the system under the influence of internal pressure. The union nut crimps the metal-plastic pipe on the rod with the help of a cracker.

The installation of crimp connectors does not require the use of expensive tools, only scissors, a calibrator, a beveller and a set of wrenches are needed. If necessary, the fittings can always be disassembled and connected to the pipes again. With proper installation and operation, compression connectors will last long enough.

The disadvantage of such parts is the need to constantly monitor their condition and periodically tighten.

Compression Fittings Prices

compression fitting

Types of press tongs, their pros and cons, technical parameters

Crimping pliers used for crimping metal-plastic pipes can be used for domestic and professional purposes:

- Household - designed for household purposes. It is a tool with a simple design and not expensive.

On a note! More often, the set, in addition to manual pressing tongs for metal-plastic pipes, contains a crimping head and replaceable nozzles of different diameters.

- Professional - used by construction companies that carry out large volumes of installation of metal-plastic products. They are driven by electric or hydraulic motors. The use of these devices increases the speed and volume of work performed. In terms of cost, they are more expensive than household ones, in this regard, purchasing them for household purposes is not profitable.

In addition, there are press pliers: manual, hydraulic and electric type.

| View | Characteristic | pros | Minuses |

| Manual | The simplest model. Powered by mechanical stress. Equipped with two handles connected to the crimp head with a gear. When they are compressed, the action is transmitted to the head and exerts pressure on the fitting sleeve. In such a device, it is possible to adjust the length of the handles. Such a model is often equipped with a universal head with a set of liners, with different diameters. | Compact, easy to operate.They are lightweight (2.5 g). and low cost. | The ability to use them only for metal-plastic products with a cross-section of up to 26 mm. Muscle strength is required. |

| Hydraulic | They have a hydraulic press connected to the head. During operation, the piston enters the cylinder, thereby creating a force, it is transmitted to the head. Recommended for metal-plastic pipes 50 - 100 mm. | There is no need to use physical force, it has been replaced by hydraulic force. Labor productivity is increasing. | The cost is high and requires constant maintenance. |

| Electrical | It is powered by the mains or battery. There are also universal ones. | A reliable device with the help of which metal-plastic products with a size of 110 mm and above are connected. In electric pressing tongs, the load is distributed evenly over the entire joint area, which increases the quality and makes the process smooth. Allows you to lay engineering communications of a significant scale. | High price and large size, the ability to use them only in large areas. |

Hand tool

Hydraulic tool

Electric tool

In addition, there are press tongs for crimping metal-plastic pipe-rolling materials. in the form of a press pistol, it looks like a drill, with a pistol grip. The device is easy to use.

It is used for pipes of their metal-plastic with a diameter of 12 to 108 mm. Operation is permissible in areas with high humidity. The use of this tool for crimping metal-plastic pipes and fittings makes the crimping process in difficult places fast and comfortable.

There are a number of press jaws equipped with a function to control the pressing. This function allows, at the end of the operation, to automatically unlock the instrument.

Fittings types

During operation, pipeline systems change the direction of movement, branch out, drown out, attach some devices or change the diameter. All these tasks are solved using assembly elements. Each such detail, depending on the purpose, has its own shape.

Fittings types:

- Taps. Change the direction of travel by 45, 90 or 120 degrees.

- Couplings. Connect two pipes of the same diameter.

- Plugs. Close the dead end.

- Tees, Crossings. Used to create branches.

- Fittings. Designed for connecting a flexible hose.

Reducing couplings are used for the installation of pipelines of different diameters. Elements connecting pipe sections with the same holes are called straight lines.

Press fitting for polyethylene.

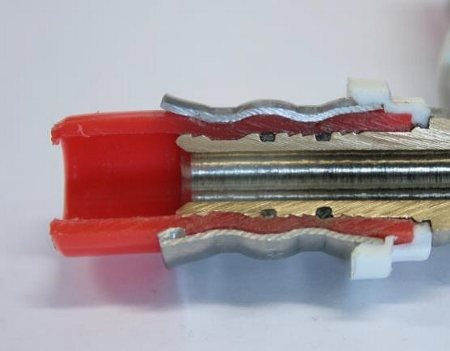

There is an opinion that press fittings are suitable exclusively for the installation of metal-plastic pipes. It's a delusion.

Press fittings are versatile. In the process of crimping the fitting, the steel outer sleeve is deformed and presses against the wall of the polyethylene pipe. In this case, the polyethylene begins to deform. Since the elastic modulus of steel is many times higher than the elastic modulus of cross-linked polyethylene, it is not the inner herringbone sleeve that undergoes deformation, but polyethylene, which enters deeper into the herringbone of the fitting and seals the connection. The inner part of the pressfitting is “biting” into the polyethylene.

Pressfitting rubber rings serve two purposes. The first ring is outside the crimp zone of the press tool. It serves to ensure tightness with small displacements of the fitting during operation or thermal expansion. The second ring is partially crimped. This ring is constantly under load from the steel sleeve. It serves to compensate for the difference in thermal expansion of polyethylene and brass.With a sharp heating or sharp cooling of the fitting, a situation may arise when a micron gap appears between the fitting and the pipe wall, which, although it will not lead to leakage, will significantly reduce the service life of the connection. In this case, this ring will fill the formed gap and ensure tightness.

When visiting one of the manufacturer's factories, we conducted an experiment: we asked to stretch the pipe on one side fixed in a fitting with a tension ring, and on the other side fixed in a regular press fitting. As a result of the application of linear stretching of the pipe with great force, the pipe itself ruptured, while both fittings remained on the pipe.

It is obvious that the correct use of the press fitting for the installation of polyethylene pipes ensures reliable and tight fixation of the pipes during the entire service life and reduces the cost of creating a heating system.

The only drawback of this fitting system, and this can be seen in the photo, is the narrowing of the flow area due to the inside of the fitting.

What materials are they made of

For the manufacture of assembly elements are used: cast iron, steel, copper, bronze, brass, plastic. It is believed that when installing utility networks, the materials of pipes and connecting elements must match each other.

To connect pipes made of carbon steel, cast iron and steel assemblies are used, copper - bronze and brass, polyethylene - plastic. Since metal-plastic pipelines are connected by mechanical crimping, the materials for the manufacture of parts must be plastic and durable.

Compression fittings for metal-plastic pipe products are made from:

- brass (an alloy of copper and zinc), plated with nickel or tin;

- of stainless steel.

Brass products have higher corrosion resistance, but they are also more expensive than stainless steel assemblies. The body and union nut of the assembly device are made of these materials. O-rings are made of synthetic rubber (EPDM). The crimp ring is made of stainless steel or Teflon.

When installing the collet, the outer layer of the pipeline sheath must not be damaged.

Preparation of reinforced-plastic pipes for connection

To carry out this work, it is necessary to prepare a flat and well-lit surface.

In addition to press tongs for assembly you need:

- scissors for metal-plastic;

- nozzles;

- scan.

Before proceeding with the assembly of the structure with press pliers, regardless of their type, preparatory measures are required.

Pipes and fittings

- It is necessary to measure the required size of the tubular product using a tape measure.

- Using the mark made, cut off the pipe element using scissors for cutting plastic. The trimmed edge should be straight and have a right angle to the main axis.

- It is necessary to use a guillotine press so that its lower part is parallel to the pipe, and by pressing slightly, press the cutting element into the material.

- The cut edges should be processed with a calibrator, as the pipe becomes oval after cutting. For this, the device is inserted inside the pipe, and rotational movements are carried out, thereby the end edges become round. It is better to remove the chamfer, this will simplify the process later.

- Put a coupling on the cut edge of the pipe.

Fitting

A nipple is a part that is used in assembly and is the main part of a joint. Before use, it should be checked for a number of indicators:

- Arrangement of pipe rings in specially designed grooves. Otherwise, the sleeve is removed with a screwdriver, the rings are installed in the grooves and it is put back on.

- Place the fitting inside the cut.

- Connect the parts with end edges, and insulate and seal the joint with a dielectric gasket. It will make the connection more tight and protect against corrosion.

- You can make sure that the pipe is positioned correctly in the sleeve, in the cutout on its extreme side.

After checking the fitting, you can proceed to the connection of the structure.

We make crimping

When the preparatory work is completed, you can start crimping with pliers. It is possible to pressurize with different types of devices (manual, electric or hydraulic) using a single technology. It is simple, but requires care and accuracy, since the slightest displacement cannot be allowed.

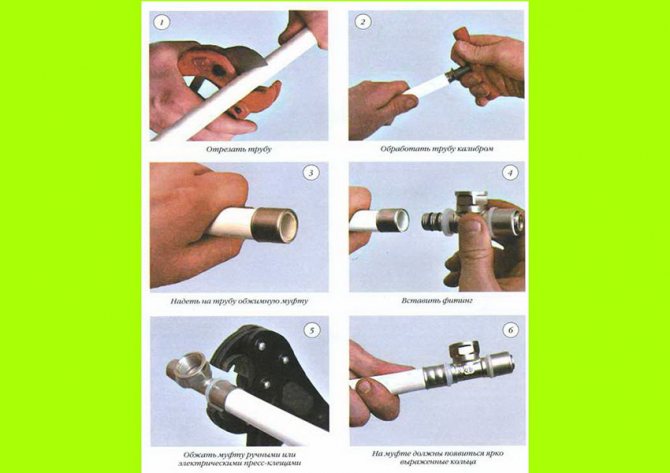

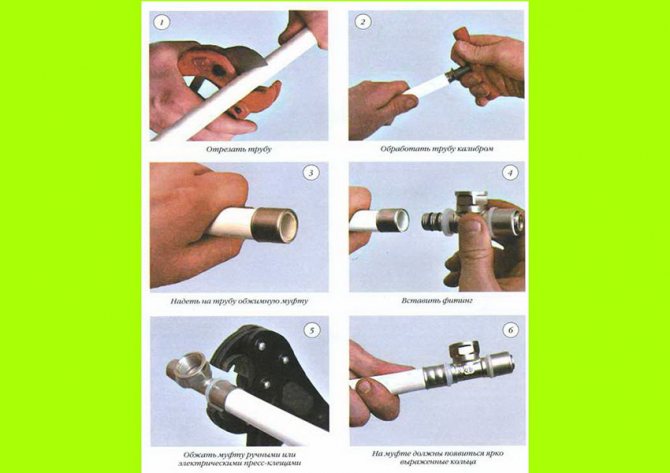

Let's analyze the installation in stages:

- On the surface, you need to put a pipe, a fitting and a press pliers, in which the handles should be moved apart on the sides by 180 degrees so that the special "jaws" are bent.

- Separate the top of the holder from the tool and insert the top of the press insert into it, it must match the size of the pipe. Place the lower part in the holder located at the bottom, then snap the device into place.

- Make a knot from the pipe and the fitting and insert it into the press pliers. Inspect the fitting sleeve carefully; it must fit inside the press insert. It is necessary that the flange stop touches the press recess.

- After that, bring the handles of the tick together, thereby compressing the pipes. At the time of crimping, there must be a right angle between the press jaws and the sleeve. To remove the press, you just need to spread the handles.

Upon completion of the actions, on the metal you will see two identical bends in an arched shape, and two clear lines in the form of a ring. The result is a well-installed fitting.

A poorly made connection will be indicated by a loose and loose nut, as well as the presence of a gap of more than 1 mm between it and the pipe.

Manual pliers for metal-plastic pipes are used for crimping operations if the volumes are small and there is no power supply. You can also use a cordless tool.

For your information! It should be noted that the process of working on an electrical device lasts 2 minutes, and the rest should be 8 minutes.

Crimping pipes with any model of pressing tongs is done only once, and if the assembly is not performed correctly, it is not possible to disassemble the connection. You will have to replace all the parts and repeat the process.

Installation safety

There is nothing difficult in using this device, the main thing is to strictly follow the instructions below:

- press tongs are forbidden to use in rooms with high humidity, because moisture has a negative effect;

- when repairing, clothes should be comfortable, and construction gloves made of dense fabric should be worn on hands;

- to avoid injury, clothing should not be allowed to fall into the device.

In addition, in order for the device to serve for a long time and efficiently, it requires care. After use - cleaning the metal head with a special compound, and then lubricating the screw and crimping elements. The storage space should be dry and the press should be in a case.

Electric and hydraulic tools require careful professional care. Instructions for the equipment are set out in the passport.

Observing these simple rules, you will be able to independently make repairs for crimping metal-plastic pipes, using this device without harming yourself or the tool.

Criteria for Selection of Compression Fittings

In order to buy compression fittings for metal-plastic pipes, you should go to a specialized store. When purchasing such parts, you must definitely pay attention to the presence of a quality certificate.

This document should reflect the following parameters:

- Manufacturer's warranty obligations.

- The maximum pressure and temperature for which the connectors are designed.

- Material and weight of the product.

The device markings must be clearly visible. The product should be checked for weight. If the part is too light, then another alloy was used instead of brass or steel, mainly based on aluminum.

Be sure to check online product reviews. Very often, manufacturers use cheaper raw materials, thereby reducing the cost of products, but at the same time the quality of products deteriorates. To obtain a reliable pipeline, you do not need to strive for excessive savings and always remember that high quality products cannot have a low cost.

In practice, it has long been verified that metal-plastic pipe products and assembly elements must be from the same manufacturer. There are good reasons for this. Pipes and fittings from different manufacturers can differ in size literally by a millimeter. This is enough to reduce the reliability of the connection.

There is no common standard for all manufacturers on the shape and size of assembly elements. Each company has its own parameters for tubular products and assembly devices.

Watch a video on how to select a fitting.

Tool selection

Crimping pliers for metal-plastic pipes differ in that they can crimp communications of a certain diameter. This indicator is recorded in the instructions attached to the tool.

Advice: before purchasing press jaws, find out the maximum diameter of the pipes of the planned water supply. If the system contains engineering structures of a smaller diameter, use the special tabs that come with the tool kit to crimp them.

Optimizing the workflow and monitoring the quality of connections will allow the presence of:

- swivel mounts that allow you to rotate the tool 270˚ and work with it in hard-to-reach places;

- telescopic attachments - only hand-held models have this device. It allows you to lengthen the handles of the tool, making it easy to work with when crimping pipes of various diameters;

- a safety lock that prevents accidental opening of the tool;

- an emergency switch that allows you to immediately interrupt the crimping process;

- a comfortable handle that provides proportional distribution of the load during operation.

Professional models of press tongs are equipped with the following systems:

- OPS, which optimizes physical effort when working with the tool;

- APS, which distributes the applied forces evenly, taking into account the size / diameter of the clamped fitting;

- APC, which controls the fitting crimping automatically - the pliers will not open until the crimping process is complete;

- CFT for 10,000 cycle reliability.

Advice: when buying electromechanical press tongs, check the motor power, because this is the key to their reliable, long-term service.

Step-by-step instructions for connecting a pipe to a fitting

The installation of compression assembly elements can be carried out by any untrained person, subject to careful observance of the technology. To get the job done with tools, you need a pipe cutter, a calibrator, and two wrenches. Before starting the installation, it will be necessary to straighten the metal-plastic pipe.

The main stages of the work:

- Measure a section of the pipeline of the required size and cut it off with a pipe cutter or a hacksaw with fine teeth.

- Clean the cut area with a beveler or file.

- Use a calibrator to restore the ovality of the hole.

- First put the union nut on the pipe, and then the compression ring.

- Lubricate the fitting stem with silicone.

- Push the end of the pipe tightly against the dielectric ring until it stops on the stem of the connecting element.

- First screw on the union nut by hand, and then fix it by pressing with two keys.

Excessive force should be avoided when tightening the nut so as not to deform the threads or crush the O-rings.After the system is assembled, it is imperative to carry out testing by filling it with working fluid. In the event of a leak, re-tighten.

See how the pipeline is installed using collet fittings.

Installation

Threaded fittings are installed according to the marking. All elements of the connecting structure are put on the pipe and tightened with a nut. Tighten the nut until it becomes difficult to do this, but avoid over-tightening. Otherwise, the connection can be easily damaged, as they say, you can strip the thread. If the threaded connectors are not tightened sufficiently, the system will not be sealed. To check the quality of the connection, it is imperative to check the system for integrity and the appearance of leaks.

The appearance of a small leak when checking only indicates that the fitting is not tightened enough. It is very simple to fix this problem - the threaded connections are slowly tightened with a wrench. Tightening is carried out with the system running until the leak stops.

However, it happens that even with repeated tightening, the leak is not eliminated. In this case, FUM tape or flax fiber is used. These materials are wound onto the threaded connection, after which the nut should be tightened. As a rule, when the thread is in good condition, the leak stops. Compression fittings are installed in much the same way.

To ensure a monolithic non-separable structure of metal-plastic pipes, press fittings are installed. To install them, you will need a crimping tool - a press machine. The device can be manual or hydraulic.

For solving everyday tasks, the use of a hand crimping tool is quite enough. The result is a reliable, completely sealed connection with virtually invisible joints.

The cost of compression fittings from different manufacturers

The prices of compression fitting connectors depend on the type of material and weight, technical conditions, and also on the manufacturer. Today, the market offers products from both domestic and foreign manufacturers who offer various prices for their products. The cost can also fluctuate depending on the seller and the region.

In order to choose quality products at an affordable price, you need to carefully study their parameters. The characteristics of the connecting elements and information about their cost should be looked for in the catalogs of manufacturers and sellers of sanitary products.

For comparison: parameters and prices of compression fittings for metal-plastic pipes from various manufacturers.

| Manufacturing firm | Options | |||||

| Material | Diameter, mm | Maximum pressure, bar | Maximum temperature, ° C | Manufacturer's warranty, years | price, rub. | |

| Valtec, Russia-Italy | Brass, stainless steel | 16–32 | 25 | 115 | 10 | from 93 |

| ProAqua, Germany | Brass, Teflon | 16–32 | 10 | 95 | 10 | from 61 |

| Uponor, Finland | Brass, polyamide | 16–25 | 10 | 95 | 10 | from 66 |

| Ape, Italy | Brass | 16–32 | 10 | 95 | 10 | from 106 |

| Rehau, Germany | Brass, stainless steel | 16–40 | 10 | 80 | 1 | from 312 |

Crimp Fitting Varieties

There are two types of fittings for multilayer and PEX pipes that use a crimp connection: a crimp fitting with an integrated nipple and a threaded end adapter.

- Compression fittings with integrated union

This is the most common type of compression fitting where the union and body of the fitting are integral.

You can often find compression fittings in which the union extends 4-5mm beyond the union nut. This is done in order to reduce the risk of pipe kinking in the crimp connection.

There are slight differences in the design of compression fittings for reinforced plastic and cross-linked polyethylene (PEX) pipes, which will be discussed below.

The body material of the compression fittings is standard or corrosion-resistant brass.

Fittings can be either uncoated or nickel plated.

The sizes of these fittings differ in shape (straight connector, tee, elbow, water outlet, etc.) and in the dimensions of the pipes to be connected (pipe diameter and wall thickness).

- Threaded crimp adapters

A threaded ferrule adapter is a type of ferrule that consists of a push-in nipple, a ferrule nut, and a collet (split brass ring or split sleeve).

These fittings are used as end connectors for connecting pipes to the outlets of collectors, radiators, pipeline fittings.

The sizes of the threaded adapters differ:

- The type of pipes to be connected. Like all compression fittings, adapters for multilayer pipes have slight design differences compared to fittings for PEX pipes, which will be discussed below.

- The size of the connected pipes (diameter and wall thickness)

- Compression nut size and type (imperial or metric)

- The type of seal of the connected branch pipe: conical or flat.

A threaded adapter with a cone seal is used to connect to an outlet pipe with an external thread and an internally machined reverse cone. The conical threaded adapter allows you to hermetically connect a polyethylene or multilayer pipe because the adapter cone with additional O-rings fits securely into the return cone of the nozzle.

The most popular is the EK (Eurocone) cone seal connection. The Eurocone is characterized by the size of the outlet connecting pipe 3/4 "HP (male thread), and accordingly the adapter crimp nut has a size of 3/4" HP.

There are also 1/2 "crimp taper adapters, but this is not a Euro taper.